A storage device and its working method

A working method and material storage technology, which is applied in the direction of thin material processing, transportation and packaging, winding strips, etc., can solve the problems of hot stamping effect, inaccurate control of feeding speed, waste of anodized aluminum, etc., to save hot stamping Material, control stability, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

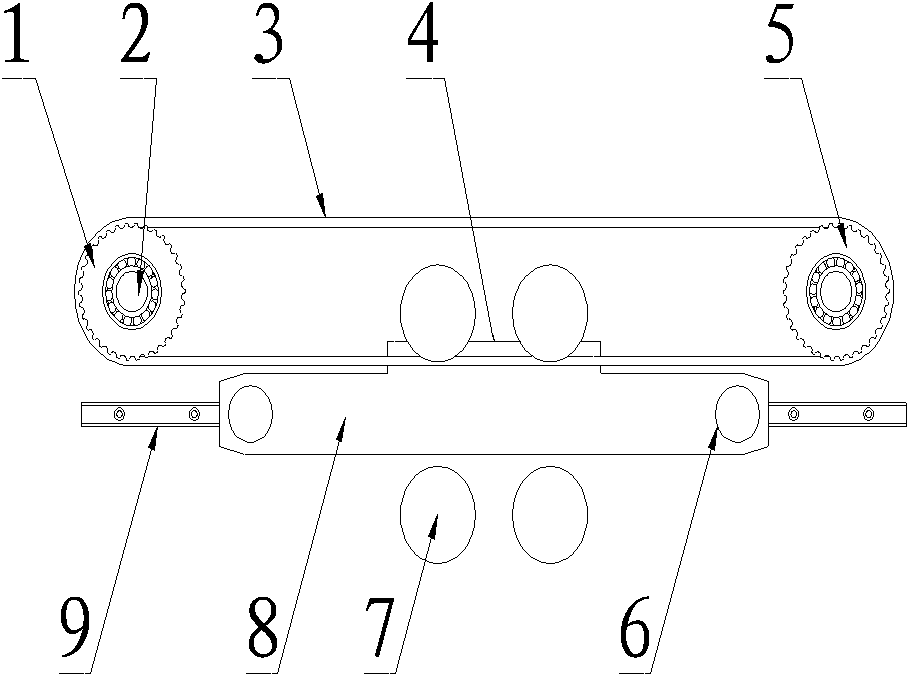

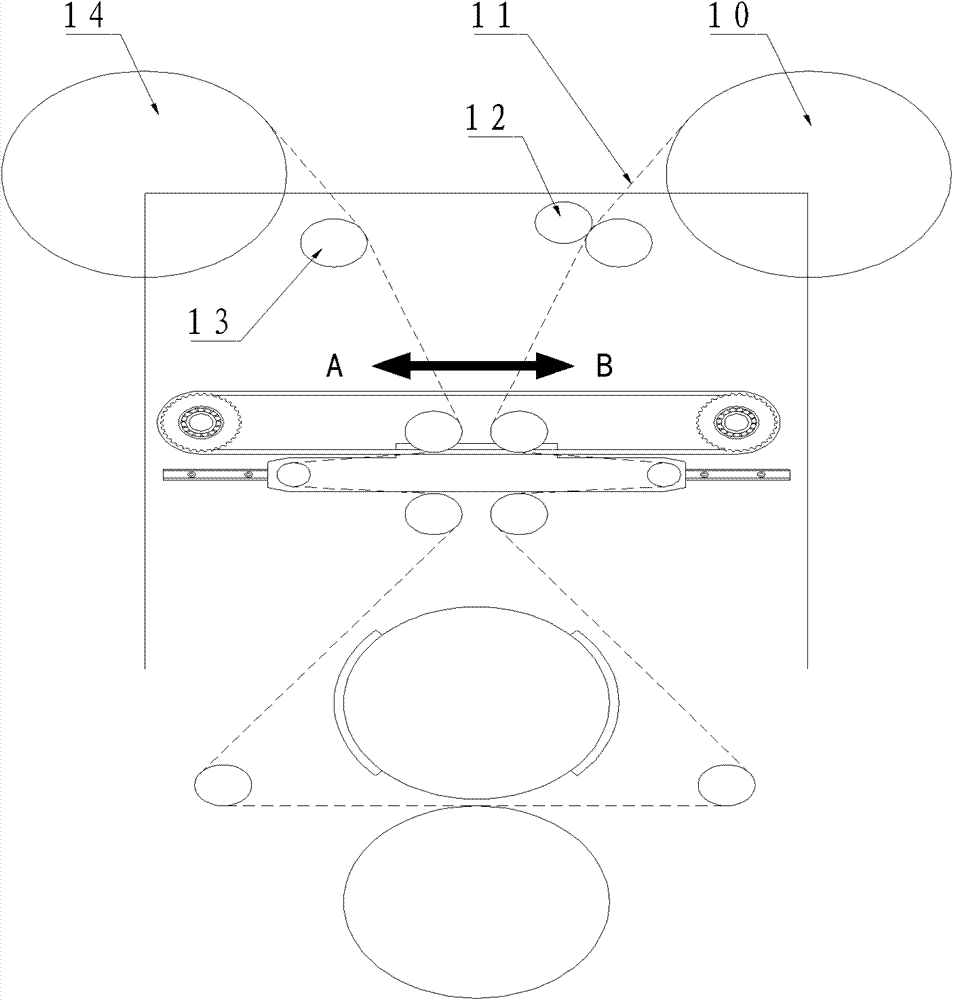

[0025] Embodiment: a kind of storage device (see figure 1 ), which is characterized in that it includes a synchronous transmission device, a storage roller 6, a fixed material passing roller 7, a connecting plate 8 and a linear guide strip 9; the synchronous transmission device is connected with the connecting plate 8; the connecting plate 8 passes through the guide groove It is in a gap fit with the linear guide strip 9; the storage roller 6 is installed on the connecting plate 8; the fixed feeding roller 7 is installed below the connecting plate 8; the fixed feeding roller 7 and the linear guide strip 9 are fixed on the wall panels.

[0026] The synchronous transmission device includes a driving wheel 1, a synchronous belt 3 and a driven wheel 5; the synchronous belt 3 fits on the driving wheel 1 and the driven wheel 5, and is connected with the connecting plate 8; the driving wheel 1 passes through the transmission shaft 2 is connected to the drive unit. (See figure 1 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com