Texturing machine

A texturing, crimping technology, used in textiles and papermaking, etc., that solves problems of operation, impossible to handle silk threads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

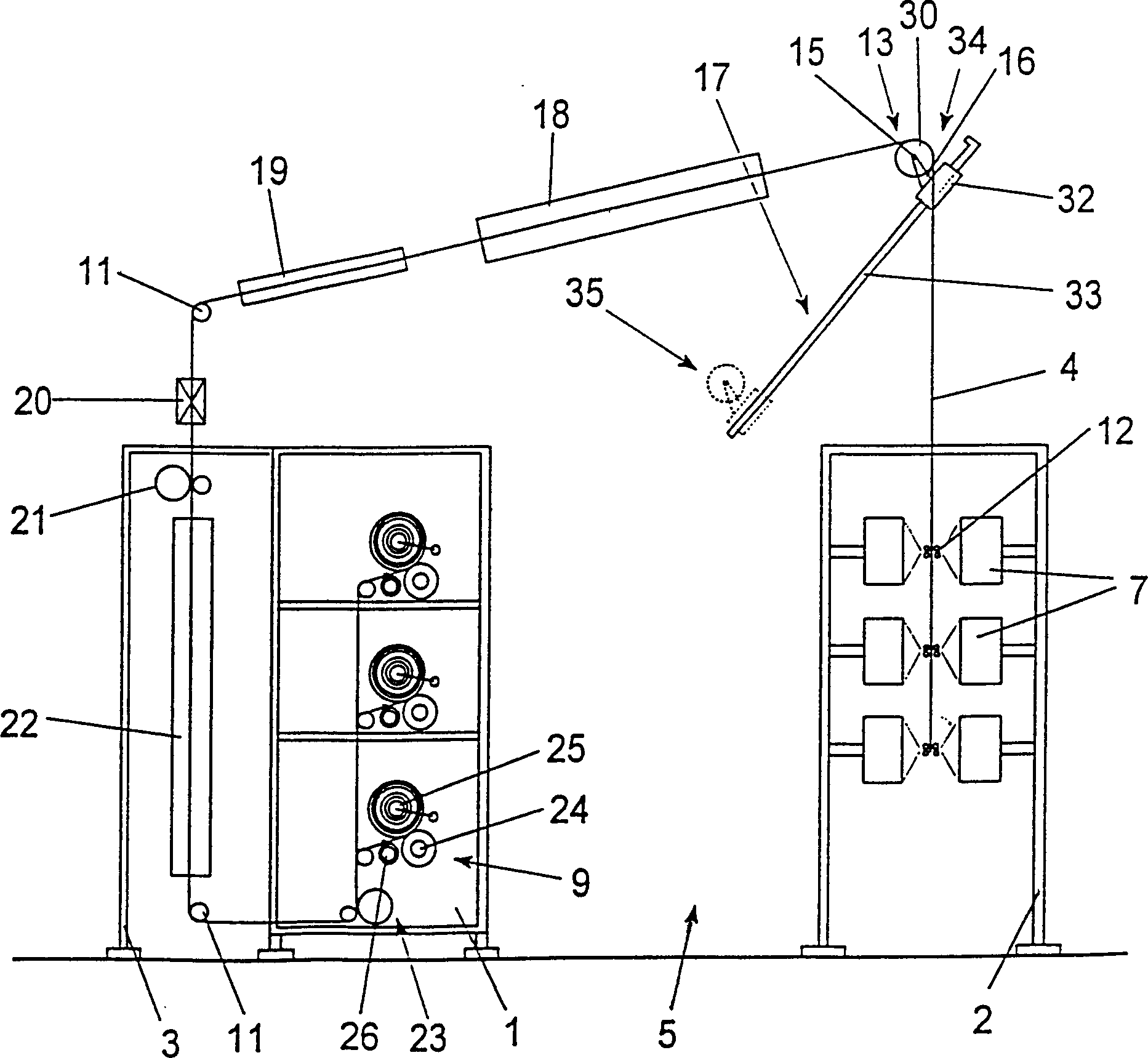

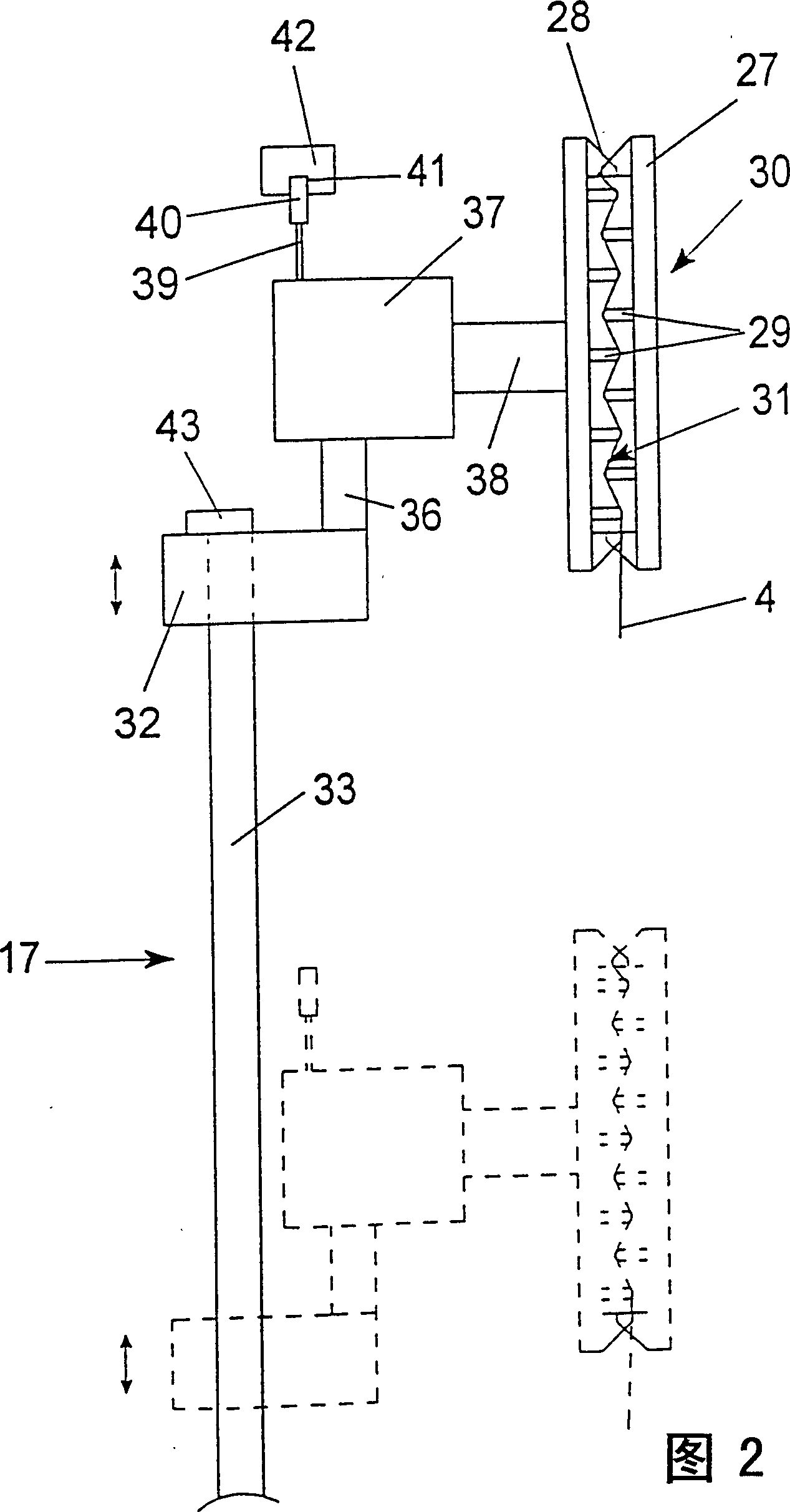

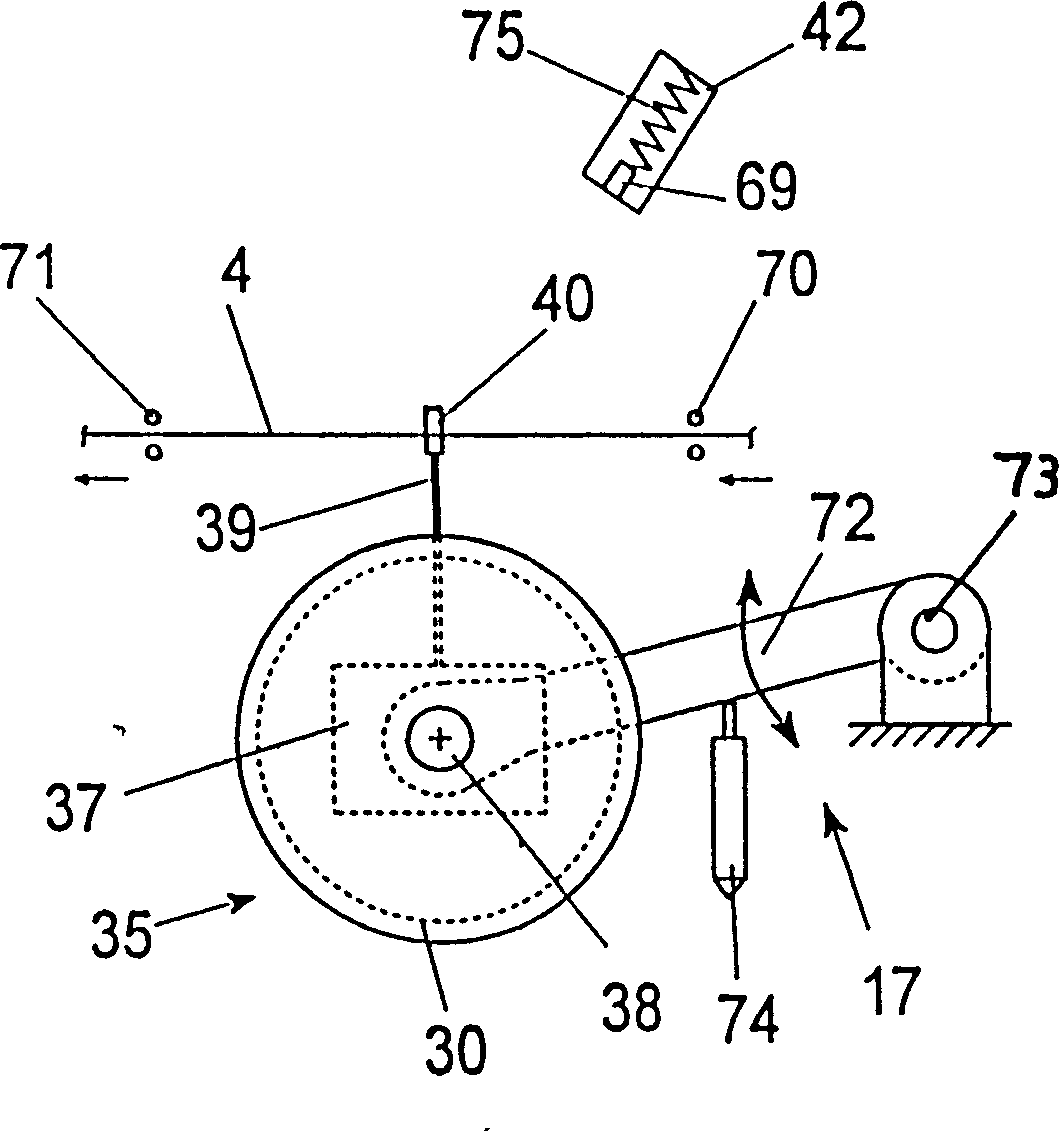

[0037] figure 1 An embodiment of a texturing machine according to the invention is shown in . Here is a half-machine of a semi-automatic false-twist texturing machine. Because the two half machines are set up mirror-symmetrically to each other. exist figure 1 Only half of the double machine is shown and described in the .

[0038] The machine has a creel stand 2 and a winding stand 1 . A processing stand 3 for mounting a second heater 22 is provided beside the winding stand 1 . In the creel frame 2, a number of feed bobbins 7 are arranged in layers on top of each other. An operating / doffing channel 5 is formed between the creel stand 2 and the winding stand 1 . A first conveying device 13 , a heating device 18 and a cooling device 19 are arranged in the same plane above the machine base. The false twisting device 20 and the second conveying device are supported on the processing stand 3 . The processing stand 3 is arranged on the opposite side of the winding stand 1 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com