Concrete tubular pile system suitable for soft soil foundation and construction method thereof

A technology for concrete pipe piles and soft soil foundations is applied in soil protection, infrastructure engineering, sheet pile walls, etc. It can solve the problems of secondary settlement of soil and achieve the effect of facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

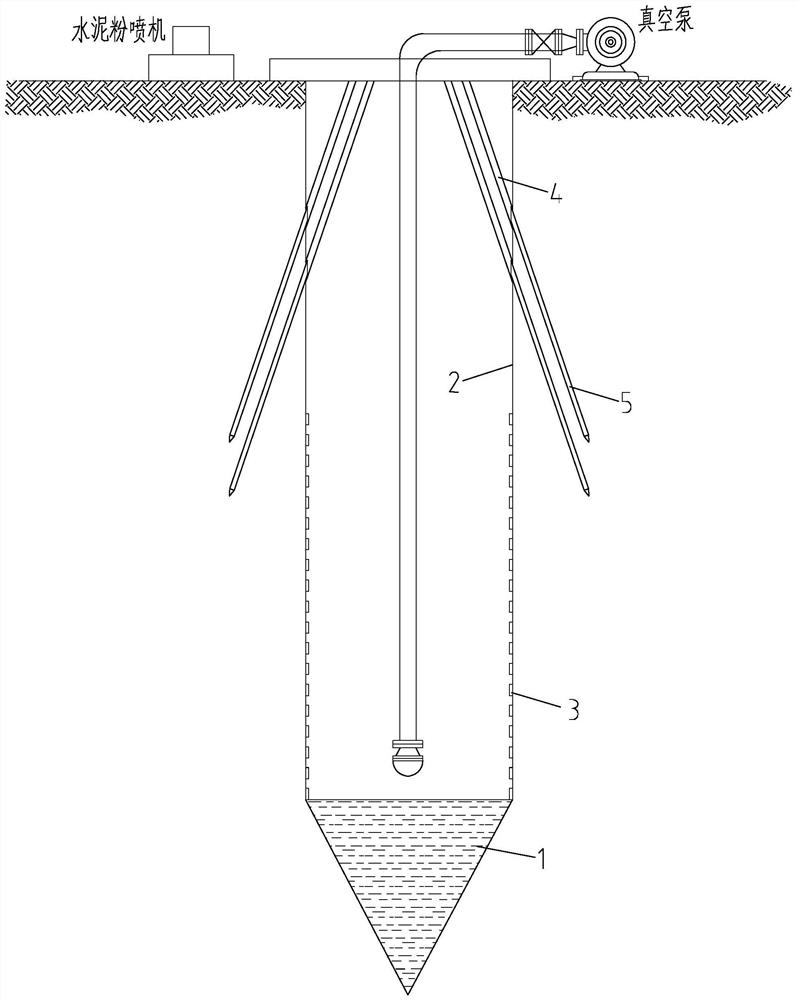

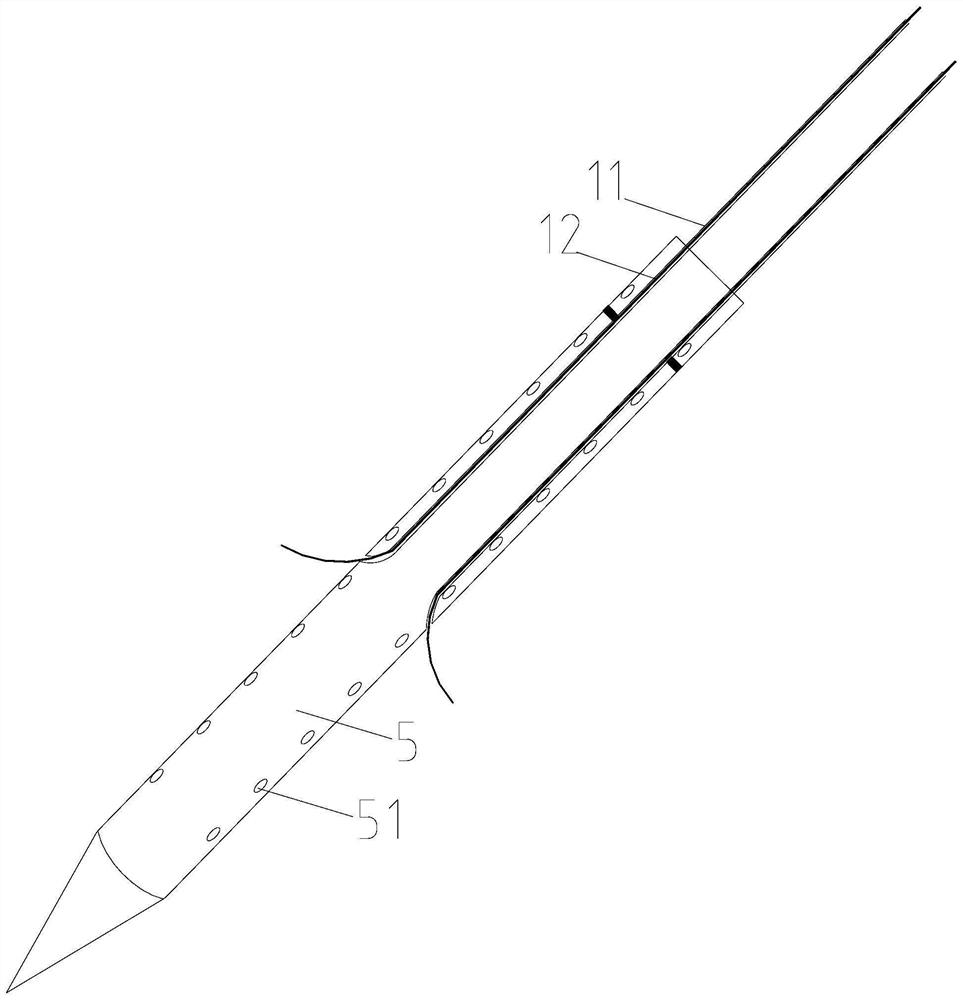

[0030] Such as figure 1 As shown, the concrete pipe pile system according to the present invention is arranged in the soil foundation, and includes a pile point 1, a pipe body 2, a hollow conduit 4 and a soil fixing pipe 5, and the pile point 1 is arranged at the bottom of the pipe body 2 The hollow conduit 4 is arranged obliquely downwards in the tube body 2 at a first angle with the vertical direction, its two ends are open, and its lower end communicates with the side wall of the tube body 2 and is fixed to the tube body 2 The outer diameter of the soil fixing pipe 5 matches the inner diameter of the hollow conduit 4, and the soil fixing pipe 5 passes through the hollow conduit 4 and extends to the outside of the pipe body 2, so that the soil fixing pipe 5 Fixed with soil foundation.

[0031] By setting the hollow conduit 4 and the soil body fixing pipe 5, the present invention can pass the soil body fixing pipe 5 through the hollow conduit 4 and then fix it with the soil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com