Tires with improved wear and rolling resistance properties

A technology for tires and treads, applied in the direction of rolling resistance optimization, heavy-duty tires, tire parts, etc., can solve problems such as performance degradation and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

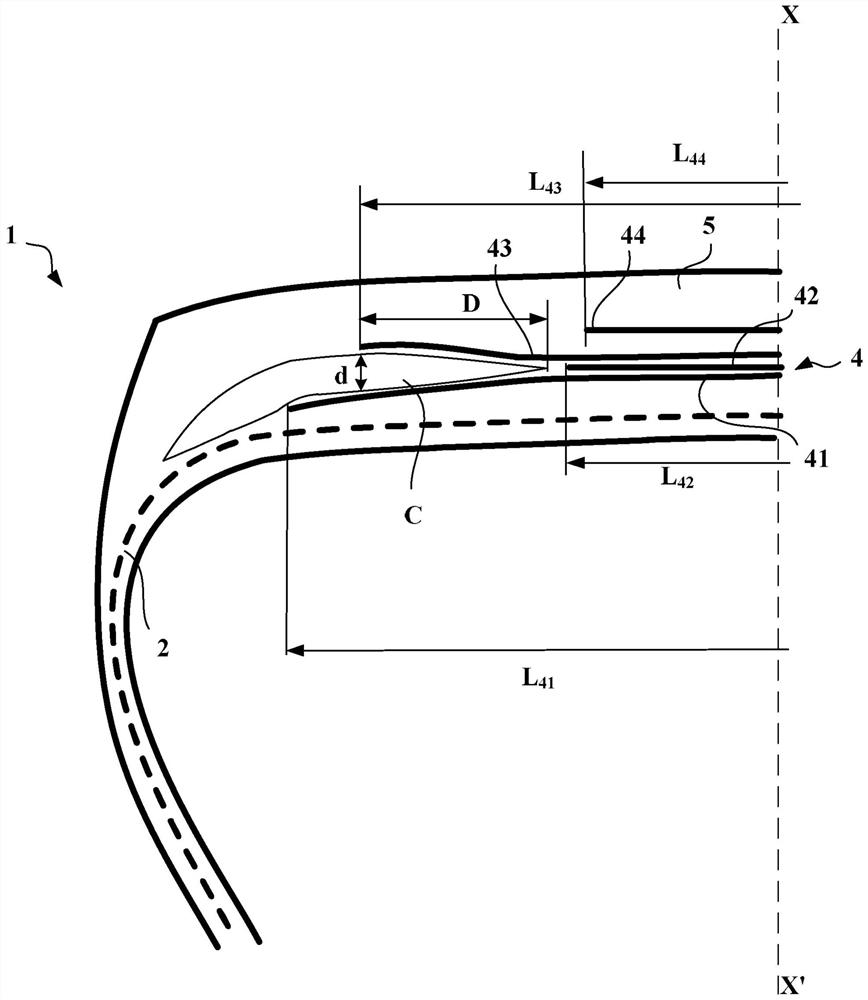

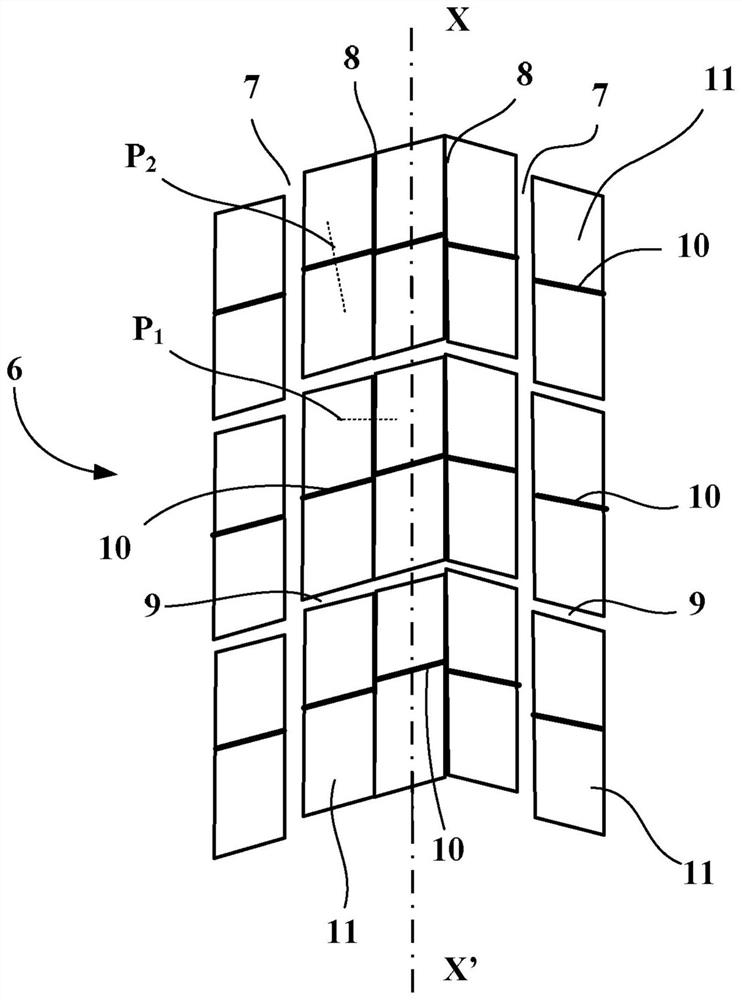

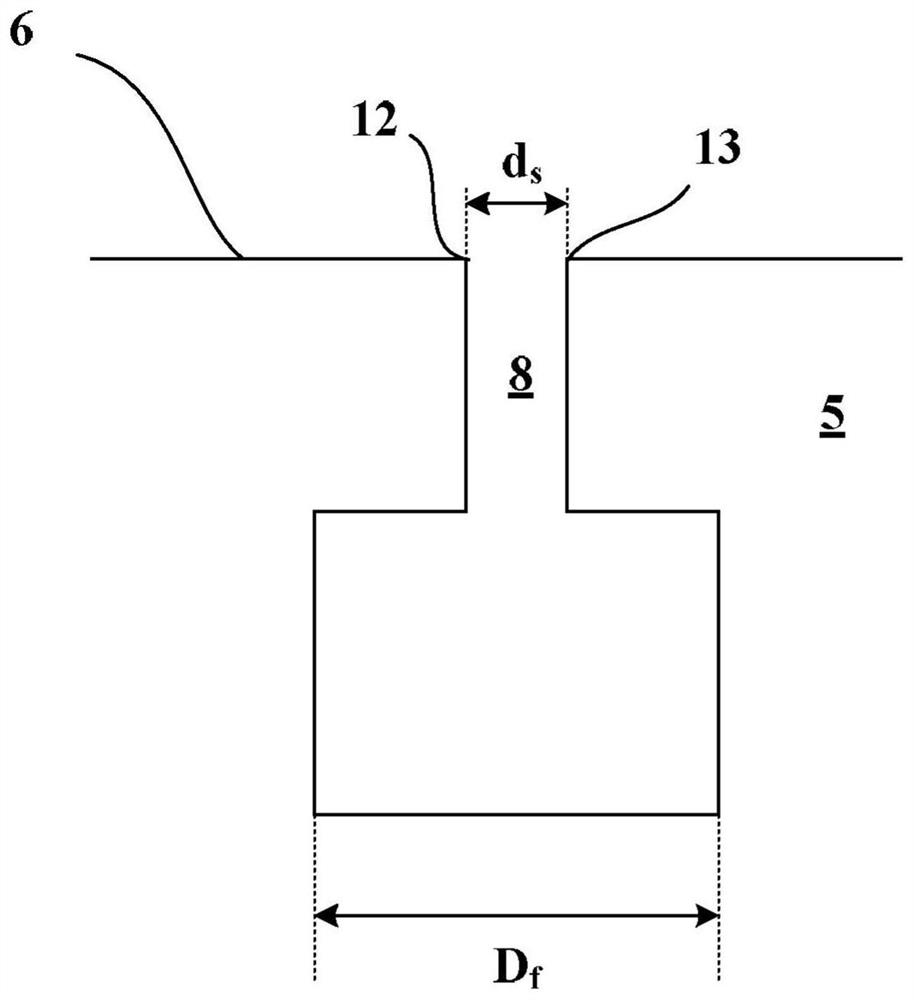

[0154] exist figure 1 In , a tire 1 of size 315 / 70R 22.5 has an aspect ratio H / S equal to 0.70, where H is the height of the tire 1 on its mounted rim and S is its maximum axial width. Said tire 1 comprises a radial carcass reinforcement 2 anchored in two beads (not shown in the figures). The carcass reinforcement is formed from a single layer of metal cords. Said carcass reinforcement 2 is hooped by a crown reinforcement 4 formed radially from the inside to the outside by:

[0155] - a first working layer 41 formed of unwrapped 9.28 non-extensible metal cords continuous over the entire width of the ply and oriented at an angle of 24°,

[0156] - a layer 42 of circumferential reinforcing elements formed of 21x23 steel metal cords of the "dual modulus" type,

[0157] - a second working layer 43 formed of unwrapped 9.28 non-extensible metal cords continuous over the entire width of the ply and oriented at an angle equal to 24° and crossing the metal cords of layer 41,

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com