Uniform-distribution screening device for copper-based powder

A screening device and copper-based powder technology, which is applied in the field of uniformly distributed copper-based powder screening devices, can solve the problems of not being able to make full use of the effective screening area of the screen, low screening efficiency, and less edge powder. , to achieve the effect of increasing the usable area, improving the screening efficiency and changing the discharge port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

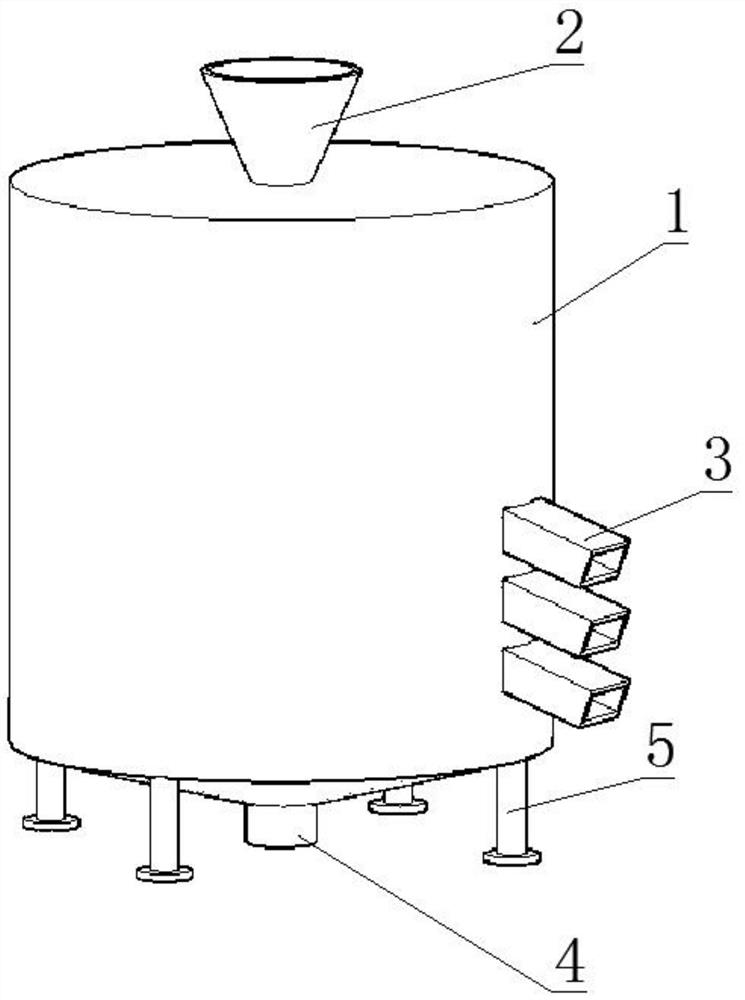

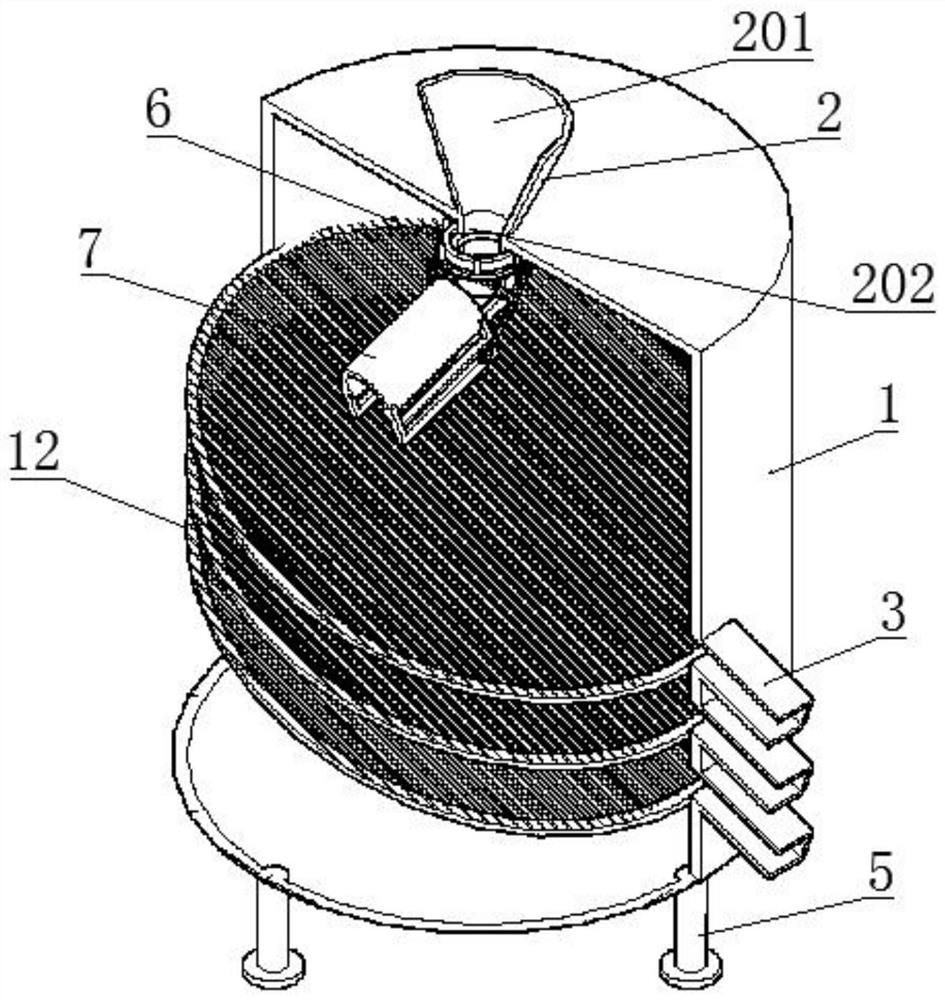

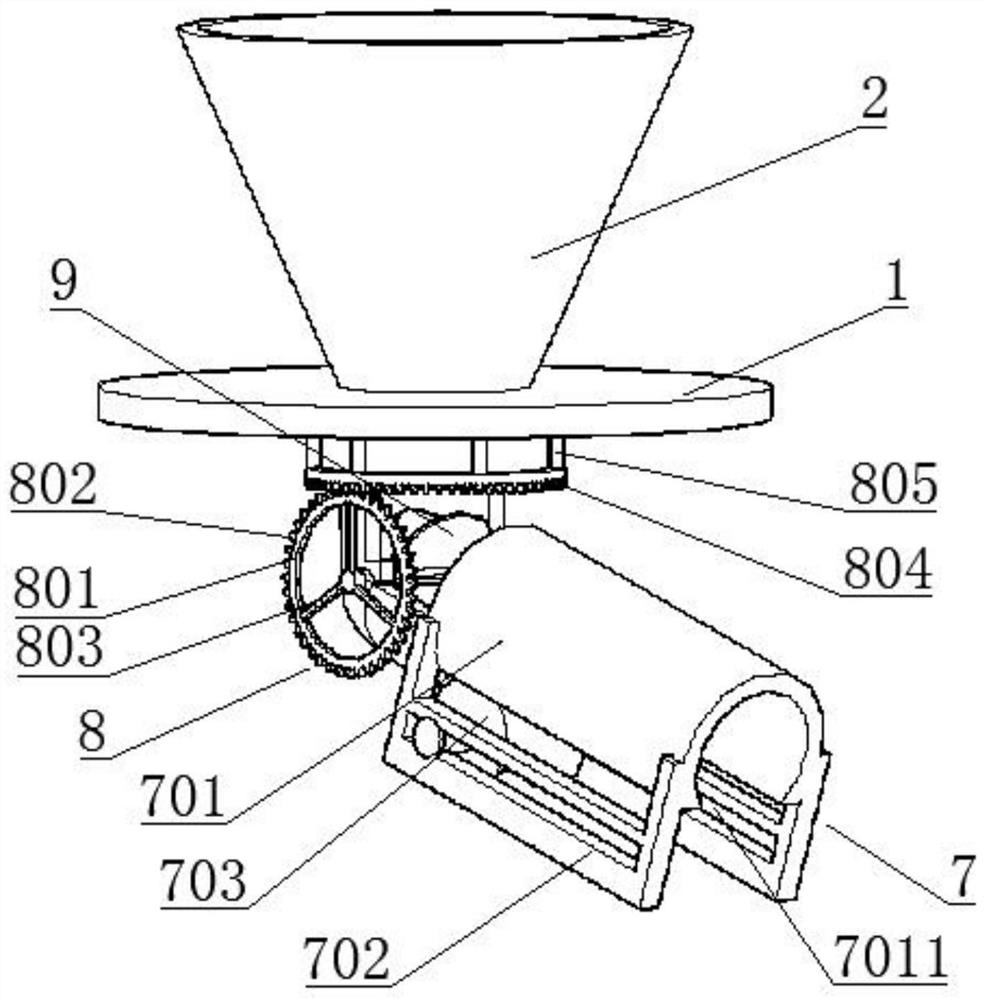

[0041] Such as Figure 1-6 As shown, a copper-based powder evenly distributed screening device includes a screening cylinder 1, a feeding cylinder 2 is arranged on the top of the screening cylinder 1, and a feeding device 6 is rotatably connected to the bottom of the feeding cylinder 2. The device 6 includes a power mechanism 9, the power mechanism 9 is connected to the screening cylinder 1 through the first transmission mechanism 8, and the power mechanism 9 is connected to the distribution mechanism 7 through the second transmission mechanism 10. The distributing pipe 701, the bottom side of the distributing pipe 701 is provided with a cross cut 7011 parallel to the axis of the cloth pipe 701, and a roller 703 rollingly connected with the cloth pipe 701 is arranged below the cross cut 7011, and a guide belt 704 is wound on the roller 703. The end of the guide belt 704 is fixedly connected to the end of the feed pipe, a screen fixedly connected to the screening cylinder 1 is ...

Embodiment 2

[0044] Such as Figure 1-7 As shown, a copper-based powder evenly distributed screening device, including a screening cylinder 1, is characterized in that: the top of the screening cylinder 1 is provided with a feeding cylinder 2, and the bottom of the feeding cylinder 2 is rotatably connected with a feeding device 6. The feeding device 6 includes a power mechanism 9. The power mechanism 9 is connected to the screening cylinder 1 through the first transmission mechanism 8. The power mechanism 9 is connected to the material distribution mechanism 7 through the second transmission mechanism 10. The distributing pipe 701 connected to the barrel 2, the bottom side of the distributing pipe 701 is provided with a cross cut 7011 parallel to the axis of the cloth pipe 701, and a roller 703 rollingly connected with the cloth pipe 701 is arranged below the cross cut 7011, and a guide is wound on the roller 703. The material belt 704, the end of the material guide belt 704 is fixedly con...

Embodiment 3

[0047] Such as Figure 1-8 As shown, a copper-based powder evenly distributed screening device includes a screening cylinder 1, a feeding cylinder 2 is arranged on the top of the screening cylinder 1, and a feeding device 6 is rotatably connected to the bottom of the feeding cylinder 2. The device 6 includes a power mechanism 9, the power mechanism 9 is connected to the screening cylinder 1 through the first transmission mechanism 8, and the power mechanism 9 is connected to the distribution mechanism 7 through the second transmission mechanism 10. The distributing pipe 701, the bottom side of the distributing pipe 701 is provided with a cross cut 7011 parallel to the axis of the cloth pipe 701, and a roller 703 rollingly connected with the cloth pipe 701 is arranged below the cross cut 7011, and a guide belt 704 is wound on the roller 703. The end of the material guide belt 704 is fixedly connected to the end of the feeding pipe, and a screen mesh fixedly connected to the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com