Automatic pit-digging soil-discharging apparatus for forest trees

An automatic, tree-pit technology, applied in the field of forestry, can solve the problems of soil digging obstruction, time-consuming and labor-consuming, cumbersome operation, etc., and achieve the effect of easy shoveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

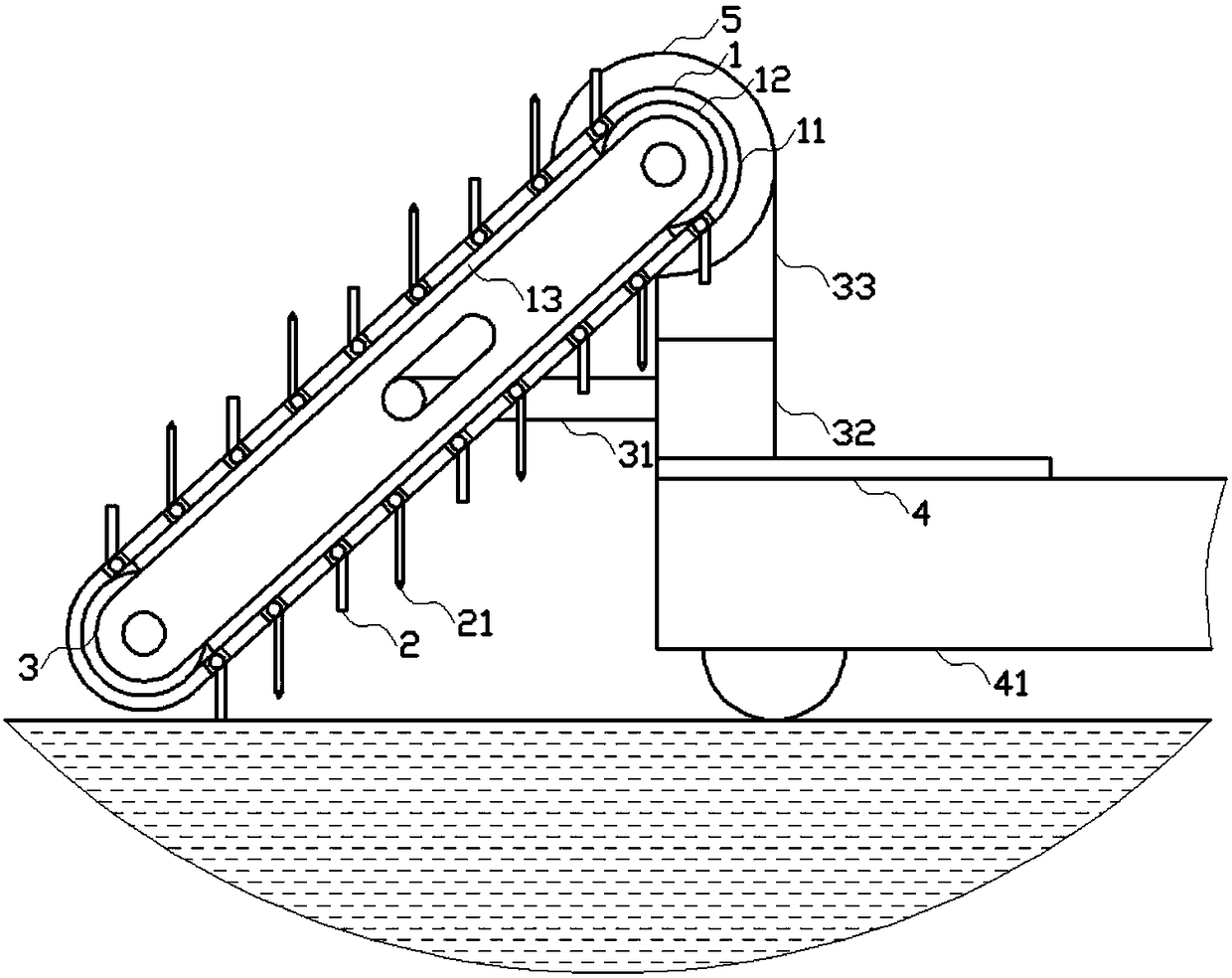

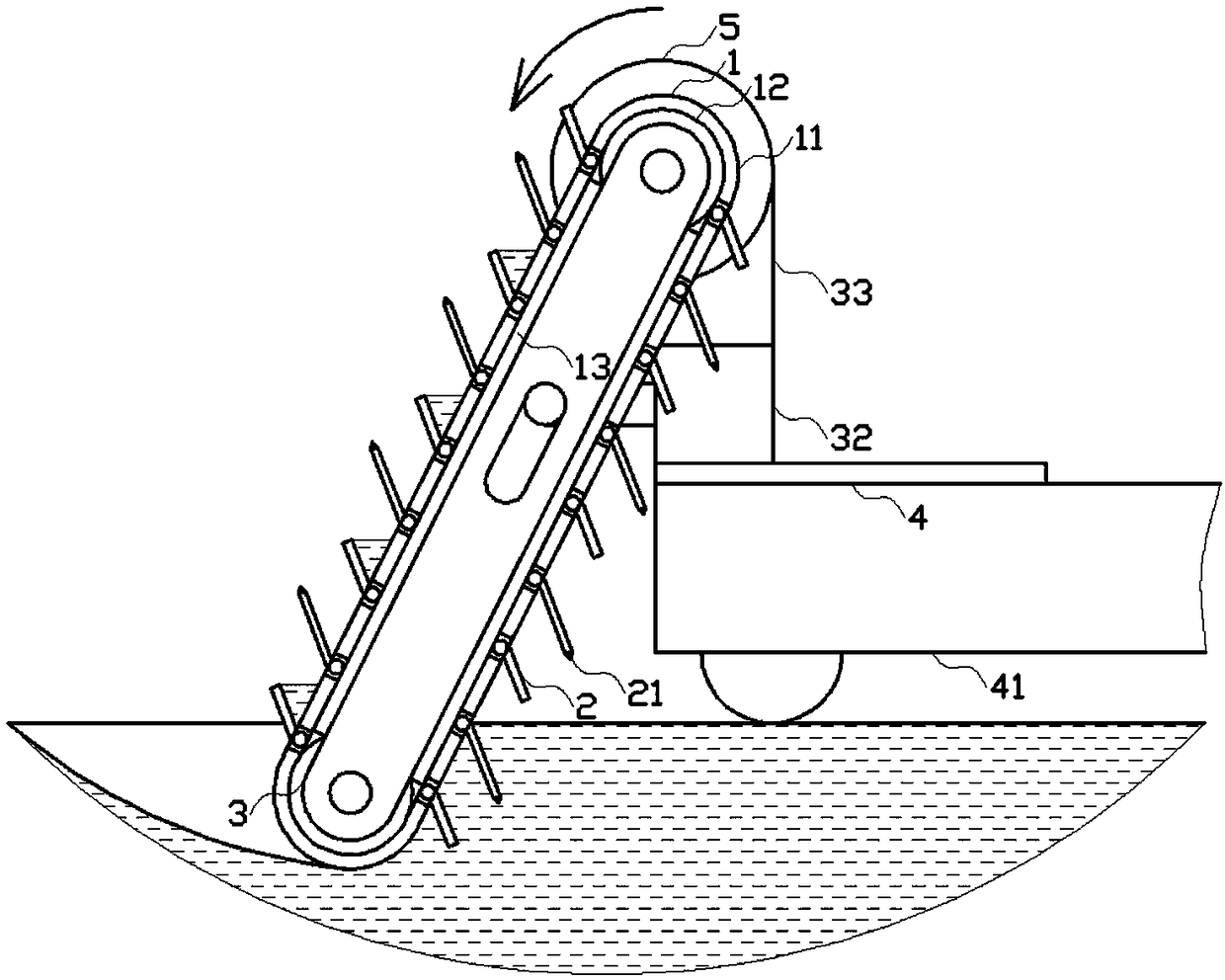

[0012] Such as figure 1 , figure 2 As shown in the embodiment, the automatic tree pit excavation device for forest trees is a kind of soil that can be loosened and scooped up by installing a shovel plate and a planer bar on the chain plate, and the scooped up soil can be scooped up under the movement of the chain plate. It is transported to the collection module, and at the same time, the angle of the chain plate can be controlled by the telescopic rod, so as to adjust the depth and width of the excavated tree pit, so as to achieve the effect of digging the tree pit. It includes a transmission module 1, an excavation module 2, a rotating module 3, collection module 4 and motor 5; the transmission module 1 includes a chain plate 11, a sprocket 12 and a support plate 13; On the wheel 12, the fixed angle between the chain plate 11 and the horizontal plane is an ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com