Water system used for rail fault detection car

A flaw detection vehicle and rail technology, applied in the water system field of rail flaw detection vehicles, can solve the problems of easy freezing of connecting hoses, rearward center of gravity, poor quality, etc., and achieve the effect of beautiful and generous layout, improved operation efficiency, and convenient later maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

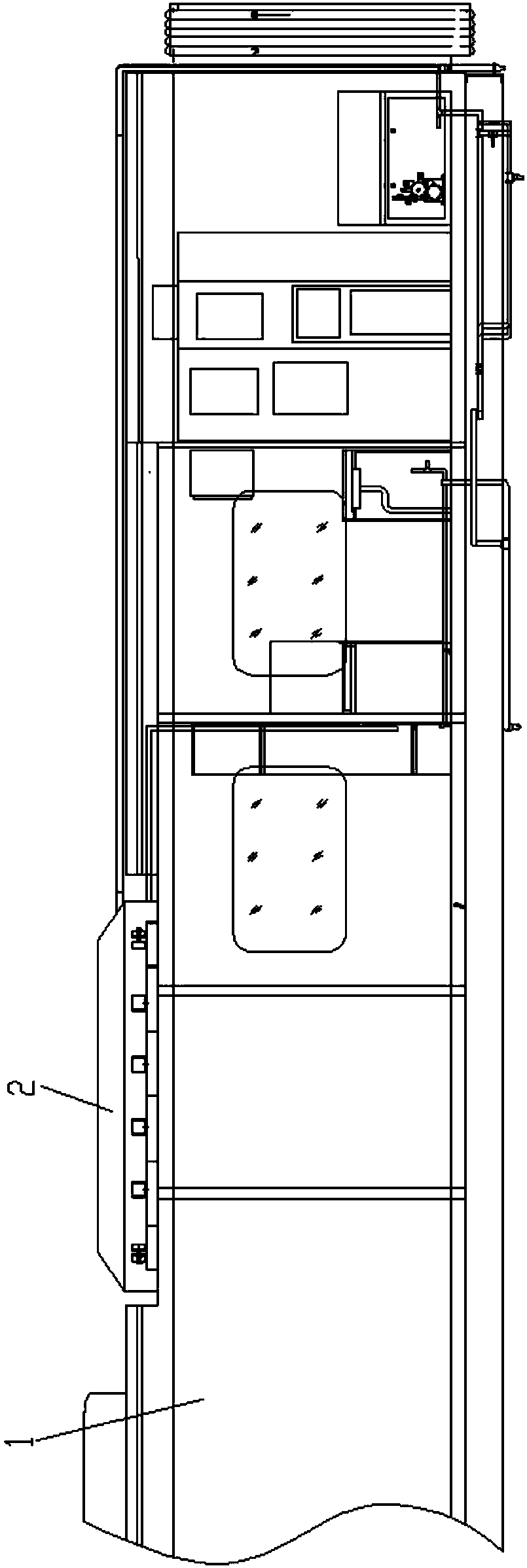

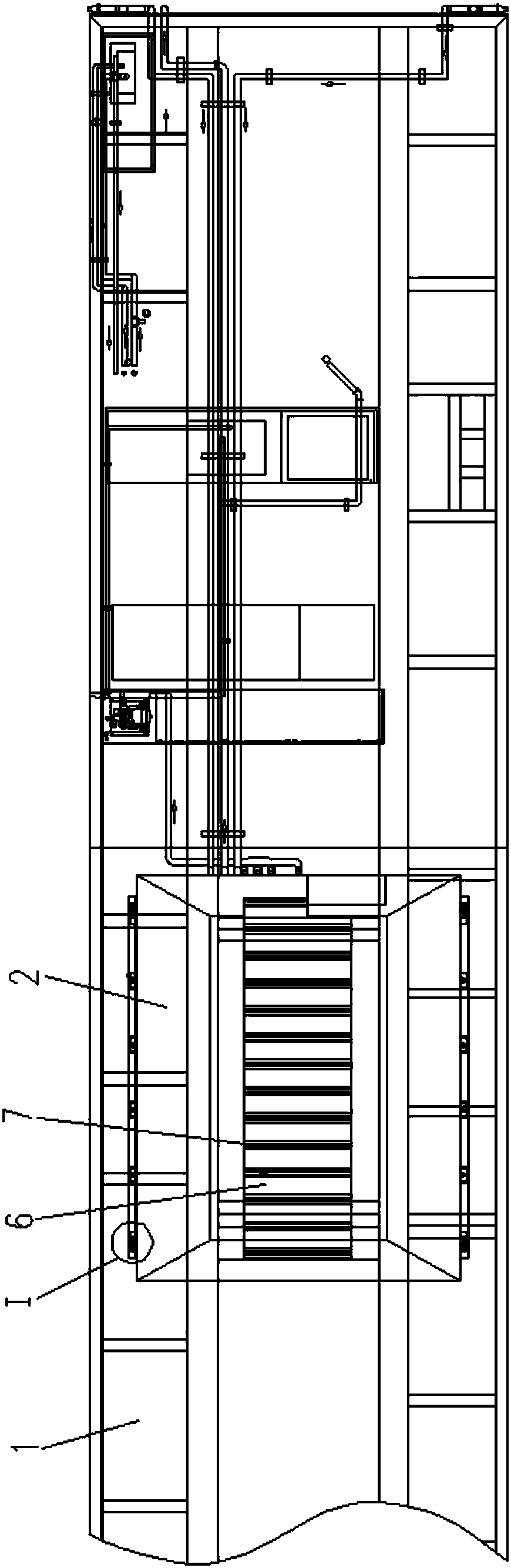

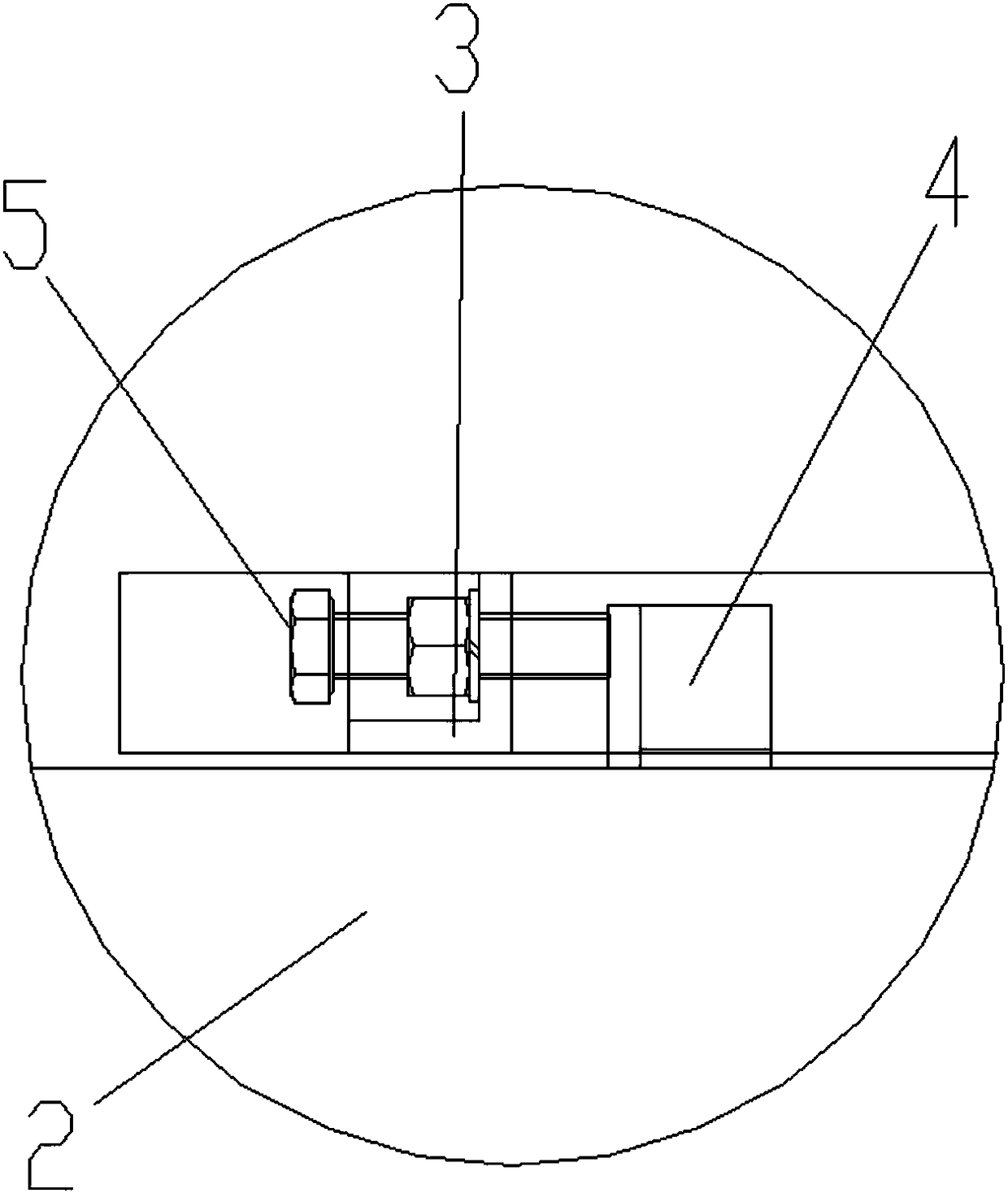

[0022] In order to solve the problem that the existing living and working water system of the existing flaw detection vehicle has a small capacity that cannot fully meet the needs of personnel and operations, the integrated shape of the water tank is not ideal, the hose connected between the tractor and the inspection vehicle is easy to freeze, and the operation water system of the inspection vehicle The parts are arranged dispersedly and the overall effect is not good, the position of the water tank causes the vehicle body to tilt and the center of gravity is shifted, and the working water temperature cannot meet the working requirements in the severe cold winter.

[0023] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are part of the embodiments of the present invention, rather than all of them. Based on the embodiments of the present invention, al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com