Connecting structure for paper pipes and paper frame using same

A connection structure and paper tube technology, applied in the connection of rods, connection components, furniture connections, etc., can solve the problems of complex connection structure, loose connection, troublesome assembly and disassembly, etc., to achieve firm connection, simple installation and disassembly, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

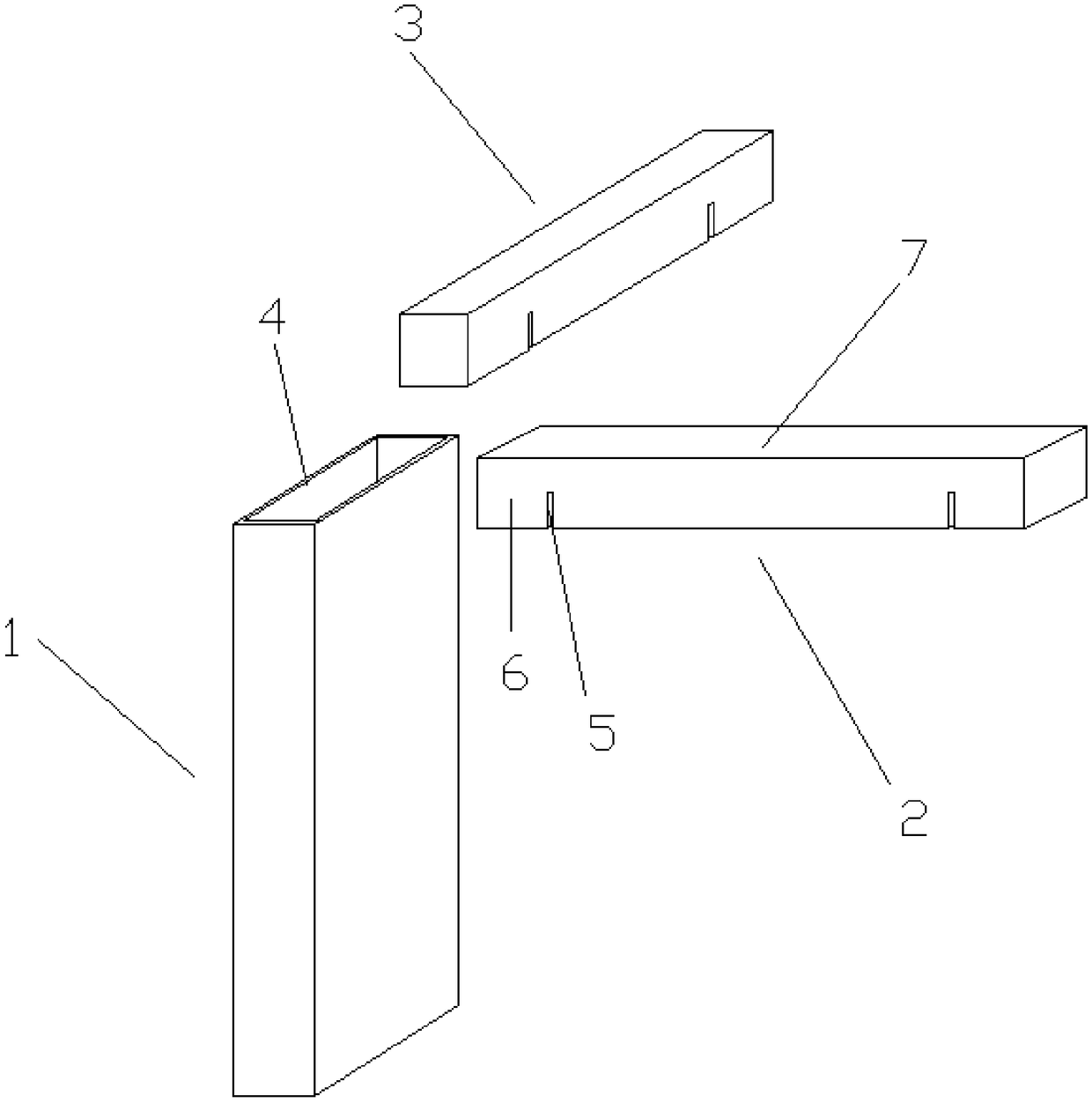

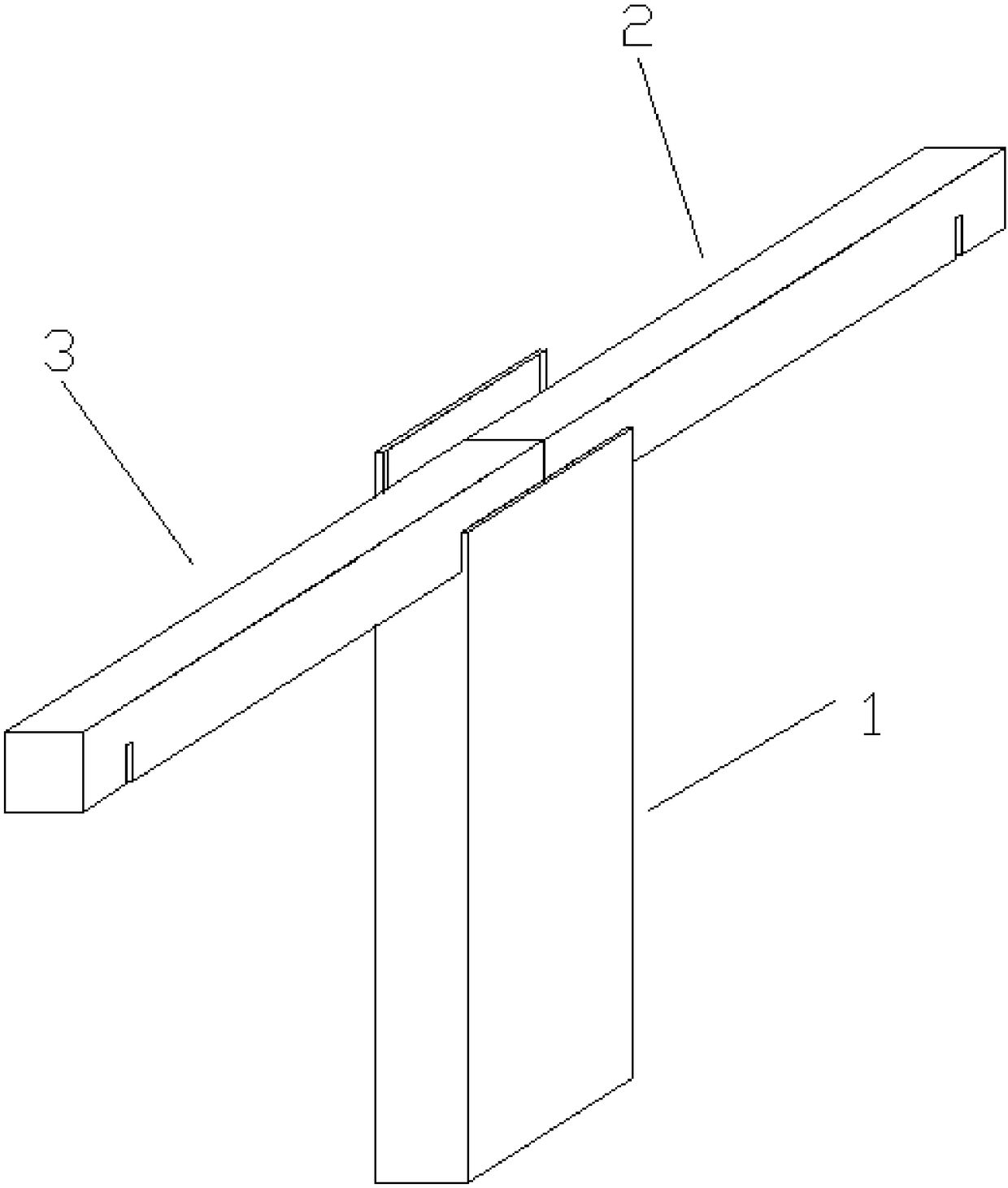

[0032] like figure 1 and figure 2 , a connection structure of paper tubes, comprising connecting paper tube one 1, supporting paper tube one 2 and supporting paper tube two 3, the connecting paper tube one 1, supporting paper tube one 2 and supporting paper tube two 3 are all rectangular tubes , the end connecting the paper tube one 1 is the connecting end one 4, the supporting paper tube one 2 and the supporting paper tube two 3 are provided with a card slot 5 parallel to the end face at a position close to the end face, and the card slot 5 will support the paper tube One 2 and supporting paper tube two 3 are divided into a snap-in part 6 and a supporting part 7; supporting paper tube one 2 and supporting paper tube two 3 are respectively clamped on the front wall and the right wall of the connecting end part one 4, and the front wall and the right The part on the wall that is clamped with the supporting paper tube is called the clamping part. The left wall and the rear wal...

Embodiment 2

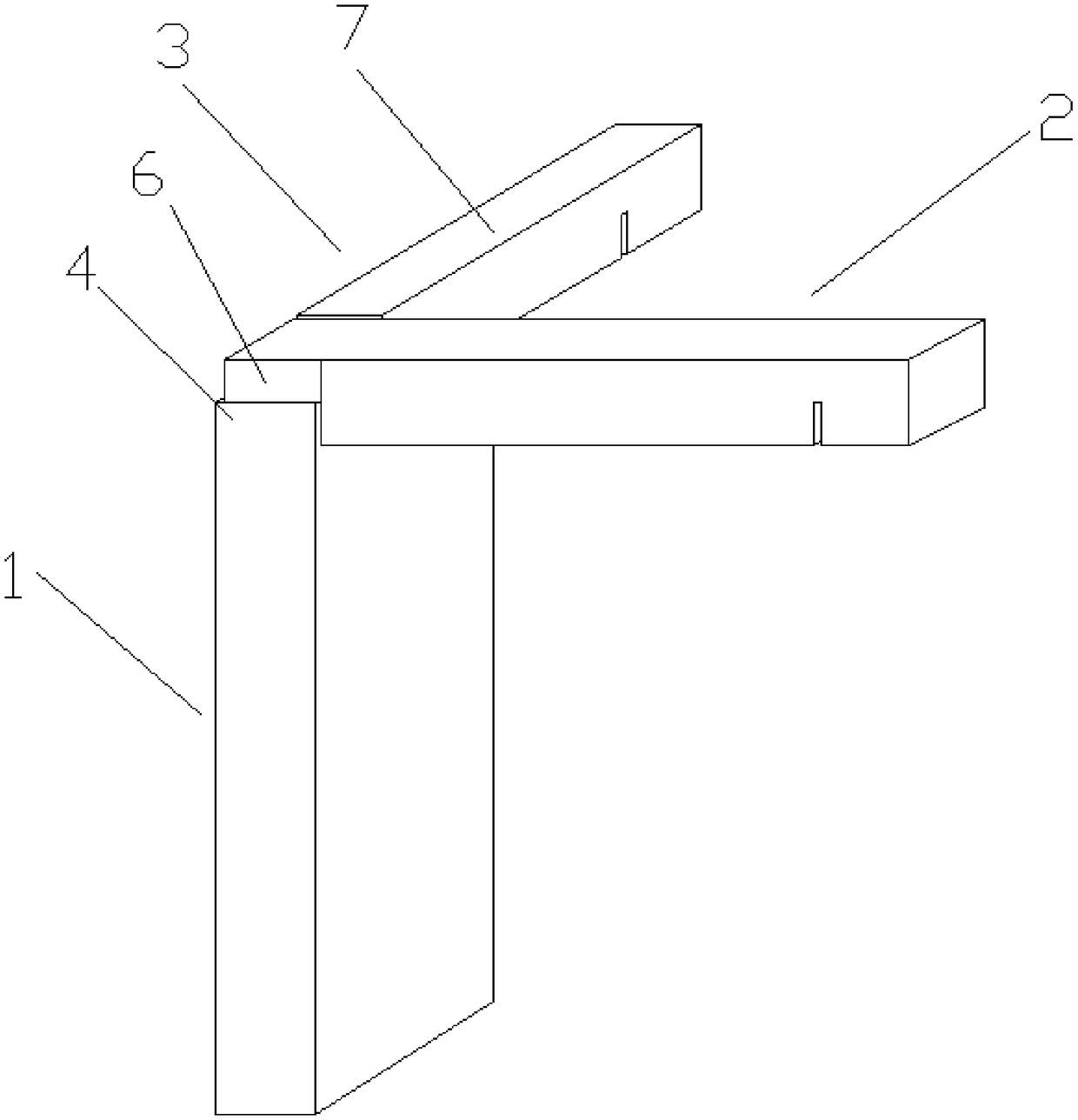

[0035] like Figure 4 , on the basis of Embodiment 1, the first abutting portion on the connecting end part 4 extends outwards with a first baffle 8, and the height of the first baffle 8 is greater than or equal to the supporting paper tube 2 higher than the first baffle. The first baffle plate 8 can completely cover the front and left sides of the supporting paper tube one 2 and the right side of the supporting paper tube two 3 at the height of the abutting portion. Since the rear wall and the left wall of the connecting end part-4 are respectively in contact with the front and left sides of the supporting paper tube-2 to form an abutment effect, after the first baffle plate 8 is added, the supporting paper tube-2 and their The abutting effect is more firm, and when the height of the first baffle plate 8 is higher than the height of the supporting paper tube 12 above the first abutting part, it is convenient to install other structures on the connection structure, and the fun...

Embodiment 3

[0037] like Figure 5 , on the basis of Embodiment 2, the second abutting portion on the connecting end-4 extends outwards with a second baffle 9, the height of the second baffle 9 is less than or equal to the support paper tube-2 and the support paper tube The second 3 is higher than the height of the second abutting part, increasing the second baffle plate 9 on the one hand can strengthen the abutment effect of the supporting paper tube 2 3 and the connecting end 4, and also stabilize the supporting paper tube 1 2 and the supporting connection The clamping effect of part one 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com