A device for vacuum creep aging forming of complex curvature aluminum alloy components

A technology for creep aging forming and aluminum alloy components, which is applied in storage devices, feeding devices, positioning devices, etc., can solve the problems of no creep aging forming devices or methods for aluminum alloy components, and reduce time and labor costs. The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

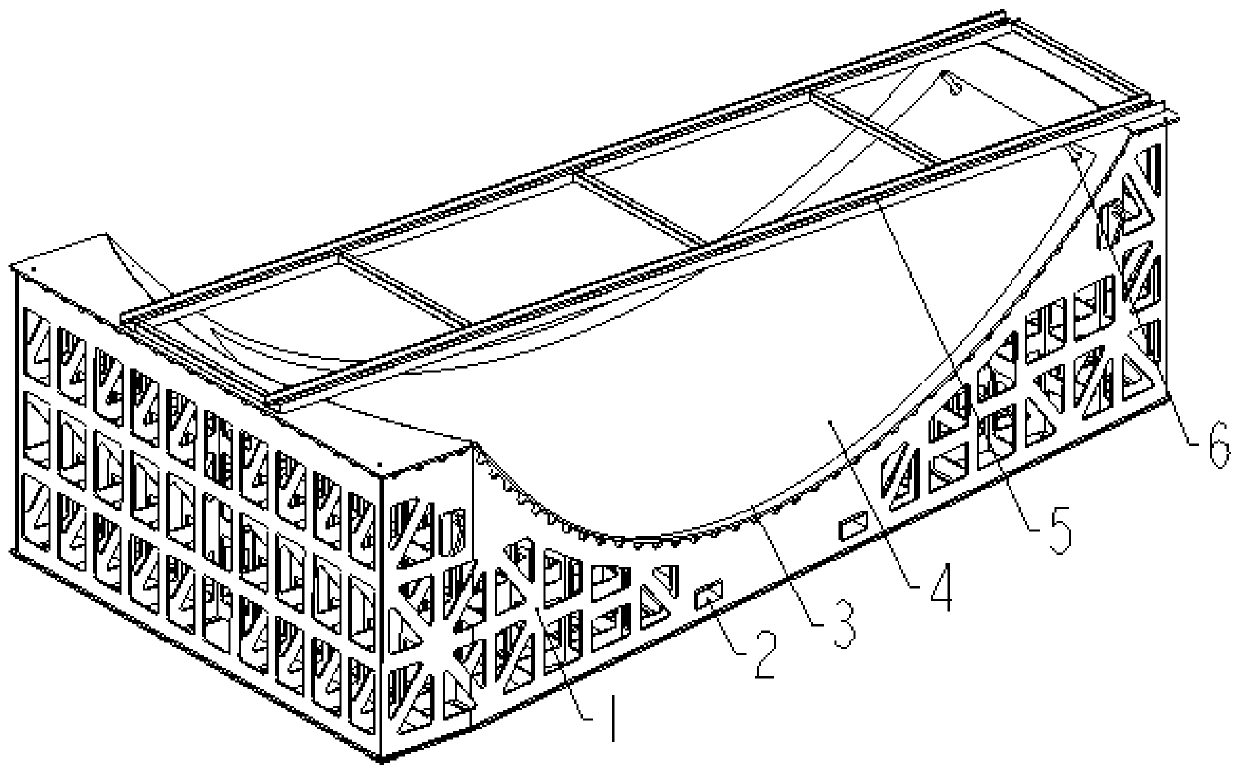

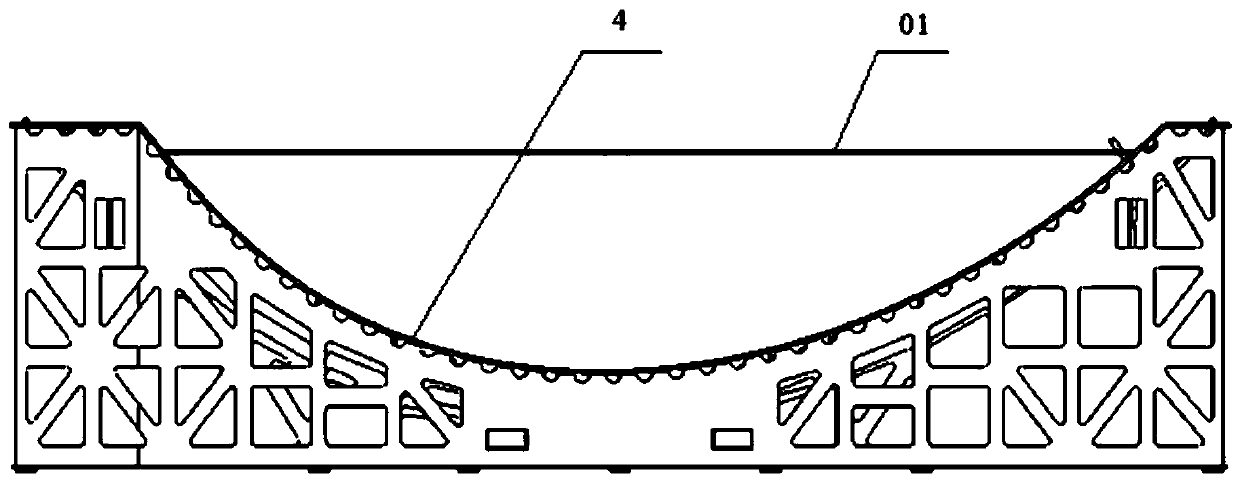

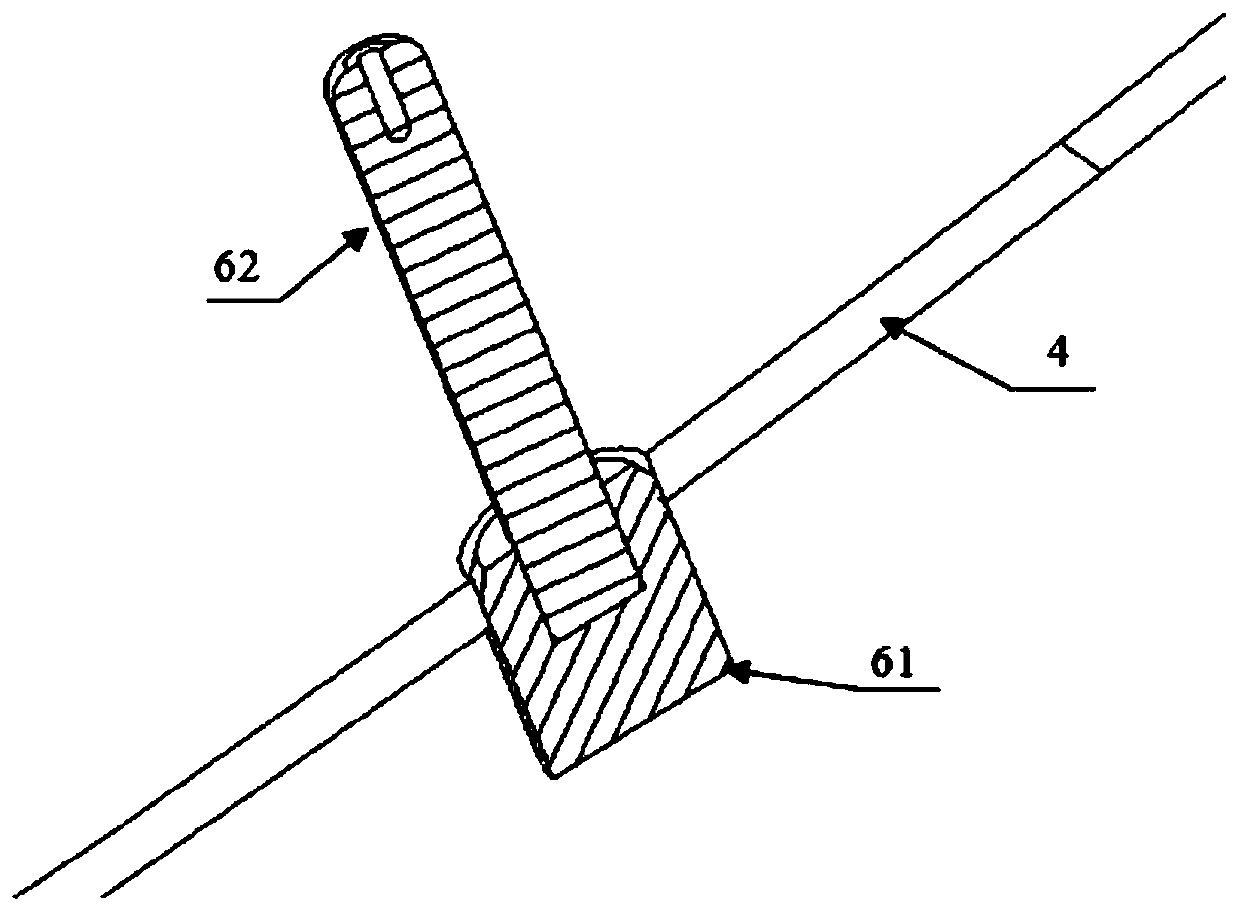

[0027] A creep aging forming tool for large complex curvature components, such as figure 1 As shown, it mainly includes mold surface 4, positioning structure 6, reinforcement structure 5, clamping plate 1 and auxiliary structure. The mold surface consists of a complex curvature forming surface in the middle and platforms at both ends. The complex curvature forming surface is 15-20mm thick, which is the forming surface for the final bending and bonding of components, and the two ends of the platform are used to stick vacuum bags. The positioning structure includes a positioning column and a fixing block, and preferably also includes a positioning line drawn on the surface of the mold, so that the component is bent downward and finally fits the mold and is located in the target area. The reinforcement structure 5 is welded by two longitudinal U-shaped steels, and its main function is to increase the strength and rigidity of the mold during lifting and transportation. Clamp 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com