A Digital Sampling Manufacturing Method for Catheters Based on Actual Assembly Space on Arrows

A technology of actual assembly and manufacturing methods, applied in the direction of manufacturing tools, assembly machines, auxiliary devices, etc., can solve the problem that the waiting time of final assembly affects the efficiency of model final assembly, does not adapt to the development trend of digital manufacturing of launch vehicles, and cannot meet the requirements of the development of new models of heavy-duty vehicles. Demand and other issues, to achieve the effect of eliminating the waiting time for final assembly, improving the efficiency of final assembly, and efficient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further elaborated below in conjunction with embodiment.

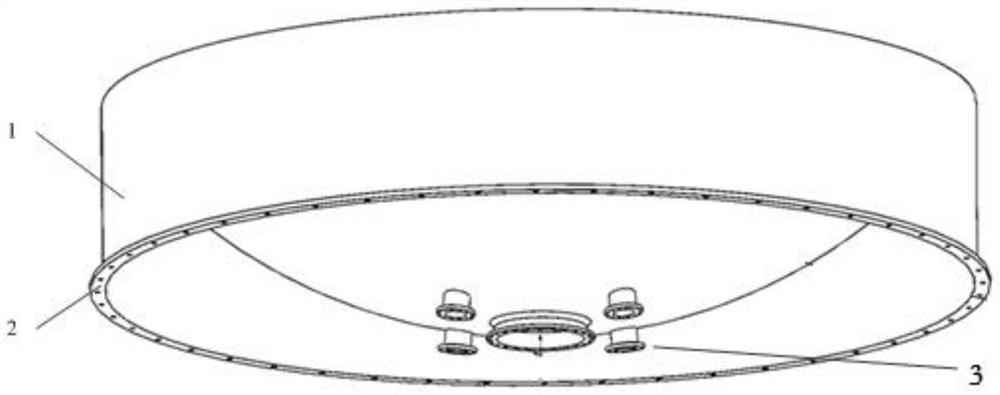

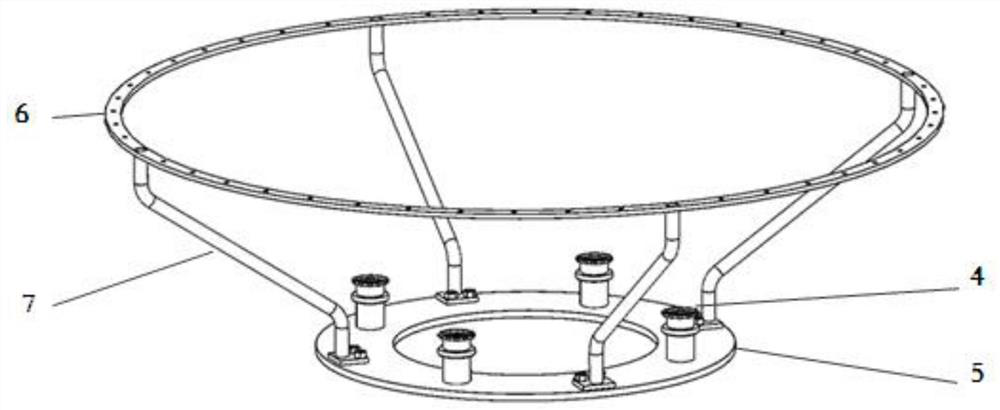

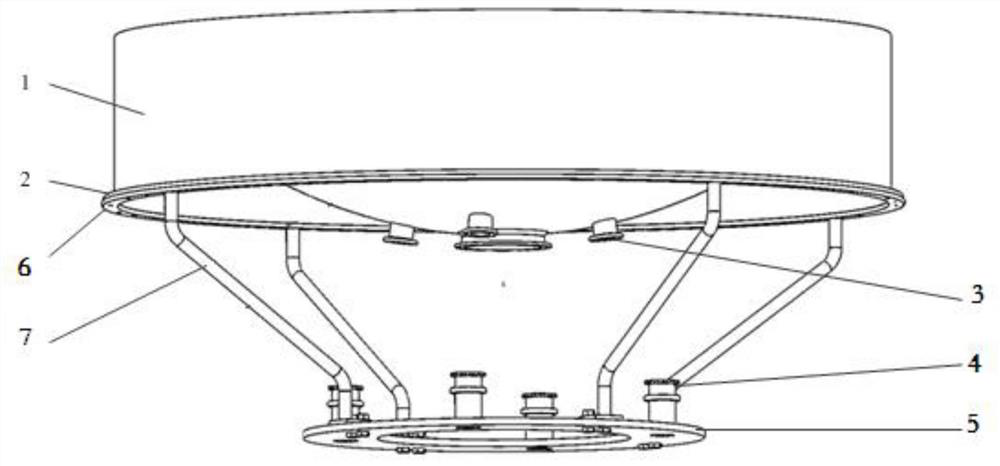

[0043] In the separate state where the engine and the fuel tank 1 have not yet been docked, the spatial position of the tank flange is measured; first, the model of the fuel tank 1 must be established, such as figure 1 , the fuel tank 1 is a cylindrical structure placed vertically in the axial direction; four fuel tank conduit installation flanges 3 are installed around the center of the bottom of the fuel tank 1; the bottom outer ring of the fuel tank 1 is provided with a fuel tank installation docking ring 2; Then build the model of the engine mounting plate and the engine mounting docking ring, such as figure 2 , the engine mounting plate 5 is an annular plate structure; the engine mounting plate 5 is placed horizontally; the engine mounting docking ring 6 is also a ring structure; the frame 7 is a plurality of rod-shaped structures; the frame 7 is arranged on the engine mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com