Forming tooling and forming method of large-size composite material T-shaped stringer

A composite material and molding method technology, applied in the field of composite material molding, can solve the problems of easy movement of segmented molding mandrel, inability to guarantee the straightness of long stringers, and influence on product manufacturing progress, so as to achieve easy transfer and configuration, and improve molding Quality and precision, and the effect of improving demoulding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

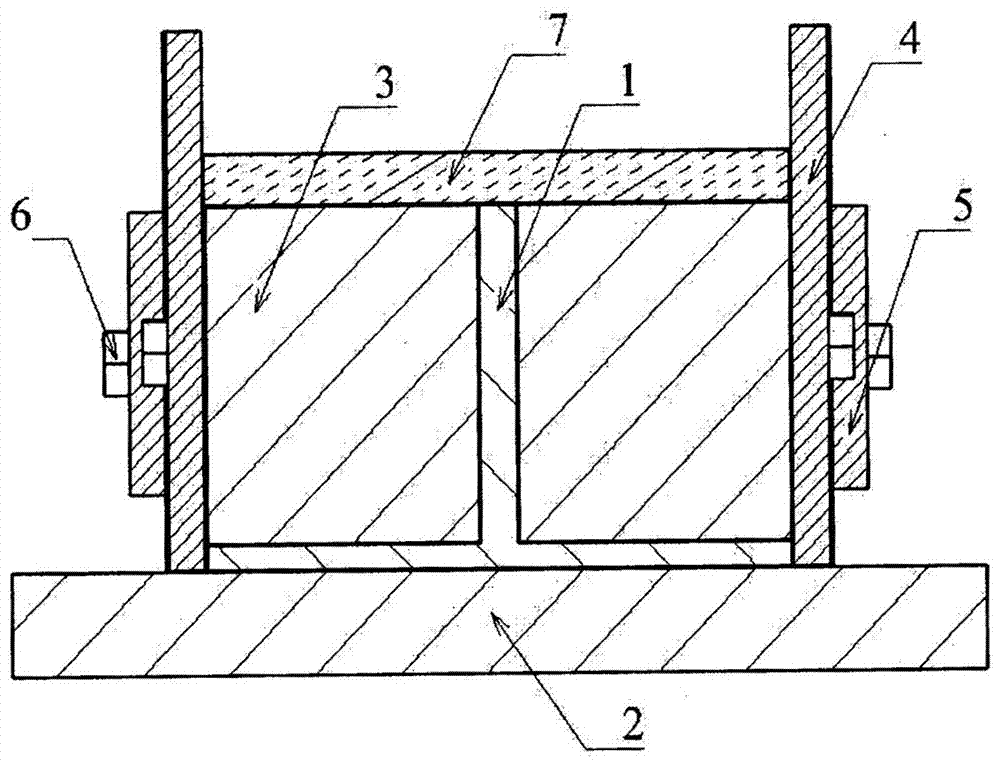

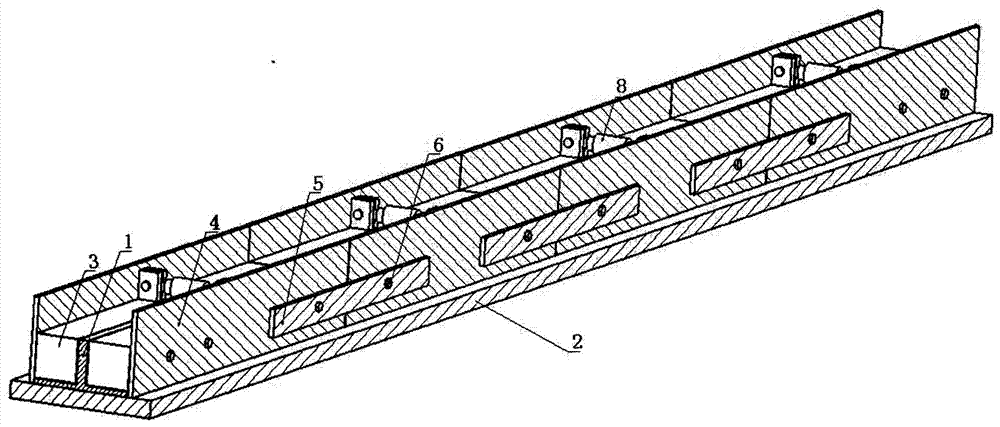

[0016] Such as figure 1 and figure 2 The forming tooling of a large-size composite T-shaped stringer shown includes a main tooling 2 and a segmented forming mandrel 3, wherein the T-shaped stringer 1 is placed upside down on the table of the main tooling 2, and the segmented forming mandrel 3 Form two rows symmetrically distributed on the left and right sides of the web of the T-shaped long stringer 1, and the segmented forming mandrel 3 is flush with the profiles of the T-shaped stringer 1 (that is, the upper surface of the forming mandrel 3 is in line with the corresponding The top surface of the web plate of the T-shaped long stringer 1 is flat, and the lower surface profile of the forming mandrel 3 is consistent with the upper surface of the lower edge of the corresponding T-shaped long stringer 1), and the segmented forming mandrel 3 and T-shaped The left and right sides of the girder 1 are provided with segmented side baffles 4, and the two adjacent sections of side ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com