A kind of embossing device for multi-process structure forming

A multi-process, slider technology, applied in the field of auto parts manufacturing, can solve problems such as general production efficiency, high collision damage rate, and differences in dot positions, and achieve the effects of reducing processes, ensuring consistency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

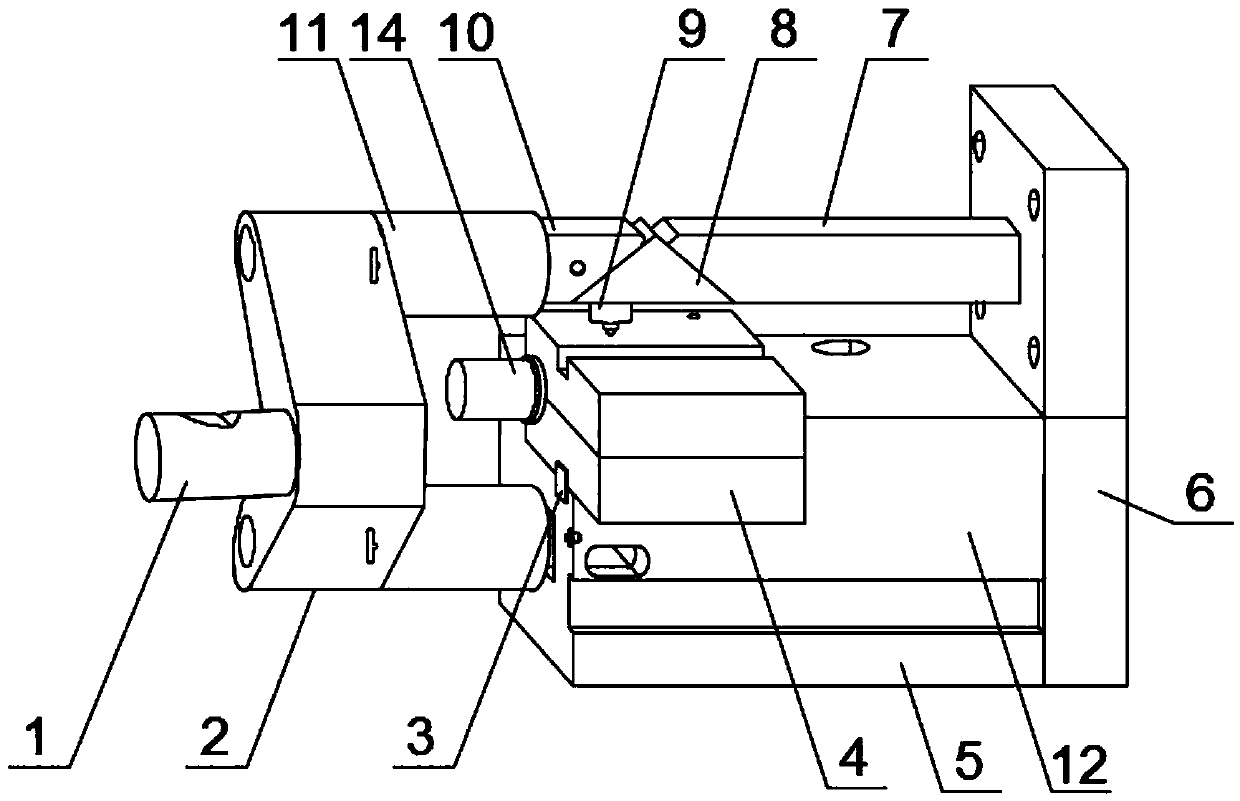

[0024] refer to figure 1 , a kind of embossing device for multi-process structure forming, including die handle 1, punching plate 2, positioning pin 3, forming clamping die 4, forming clamping die base 5, riser 6, first slider 7, second Slider 8, punching pin 9, third slider 10, dotting punch 11, mold bed 12 and pipe fitting 14, one end of forming clamping mold base 5 is provided with riser 6, forming clamping die base 5 and riser 6 They are perpendicular to each other, and a mold bed 12 is arranged on the forming clamp mold base 5, and the forming clamp 4 is installed on the upper left end of the mold bed 12, and the mold bed 12 and the forming clamp 4 are fixedly connected by the positioning pin 3, and the positioning pin 3 is a clamping pin. Buckle connection structure, easy to operate, stable and reliable, the die handle 1 is installed on one end of the punching plate 2, the punching plate 2 is symmetrically arranged with the die handle 1 to form an included angle of 45°, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com