Automatic feeding and discharging device for six-corner-rod numerical control lathe

A technology of automatic loading and unloading, CNC lathe, applied in the direction of automatic in/out of workpieces, metal processing mechanical parts, metal processing, etc., can solve problems such as low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

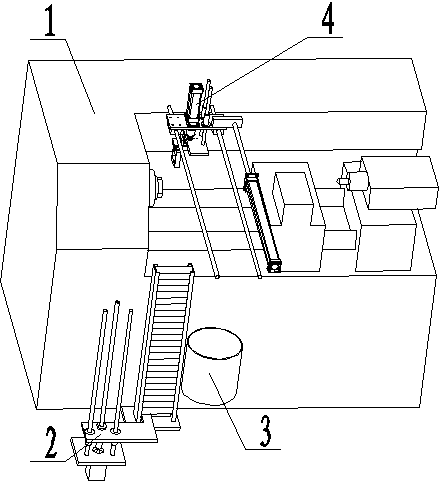

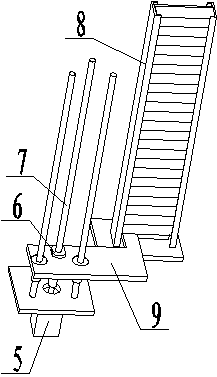

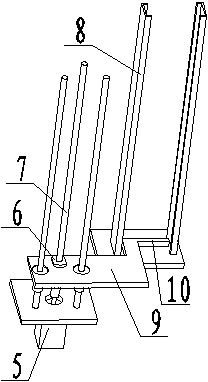

[0014] Figure 1 to Figure 7 It is a structural schematic diagram of an automatic loading and unloading device for a hexagonal bar CNC lathe of the present invention. It is known from the figure that the automatic loading and unloading device of a hexagonal bar CNC lathe includes a device 2 and a manipulator device 4; Figure 2 to Figure 4 Known, described one-out device 2 comprises motor one-5, ball screw pair one, limit plate 8, moving plate one-9 and out-one device frame; Described motor-one-5 is fixedly connected on out-one device frame On, the shaft of the motor one 5 is fixedly connected with the ball screw one 7 in the ball screw pair one; the ball screw one 7 in the ball screw pair one is hinged on the frame of a device, and the ball screw The screw nut one 6 in the pair one is fixedly connected with the moving plate one 9; the moving plate one 9 is arranged on the frame of the first device, and forms a moving pair with the frame of the device one, on the one nine of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com