Tool wear control method and control device based on wireless communication

A tool wear and control method technology, applied in the field of mechanical processing, can solve the problems of no monitoring technology to effectively prevent tool wear, and the inability to adjust the cutting speed of the tool in real time, so as to avoid abnormal wear, increase service life, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

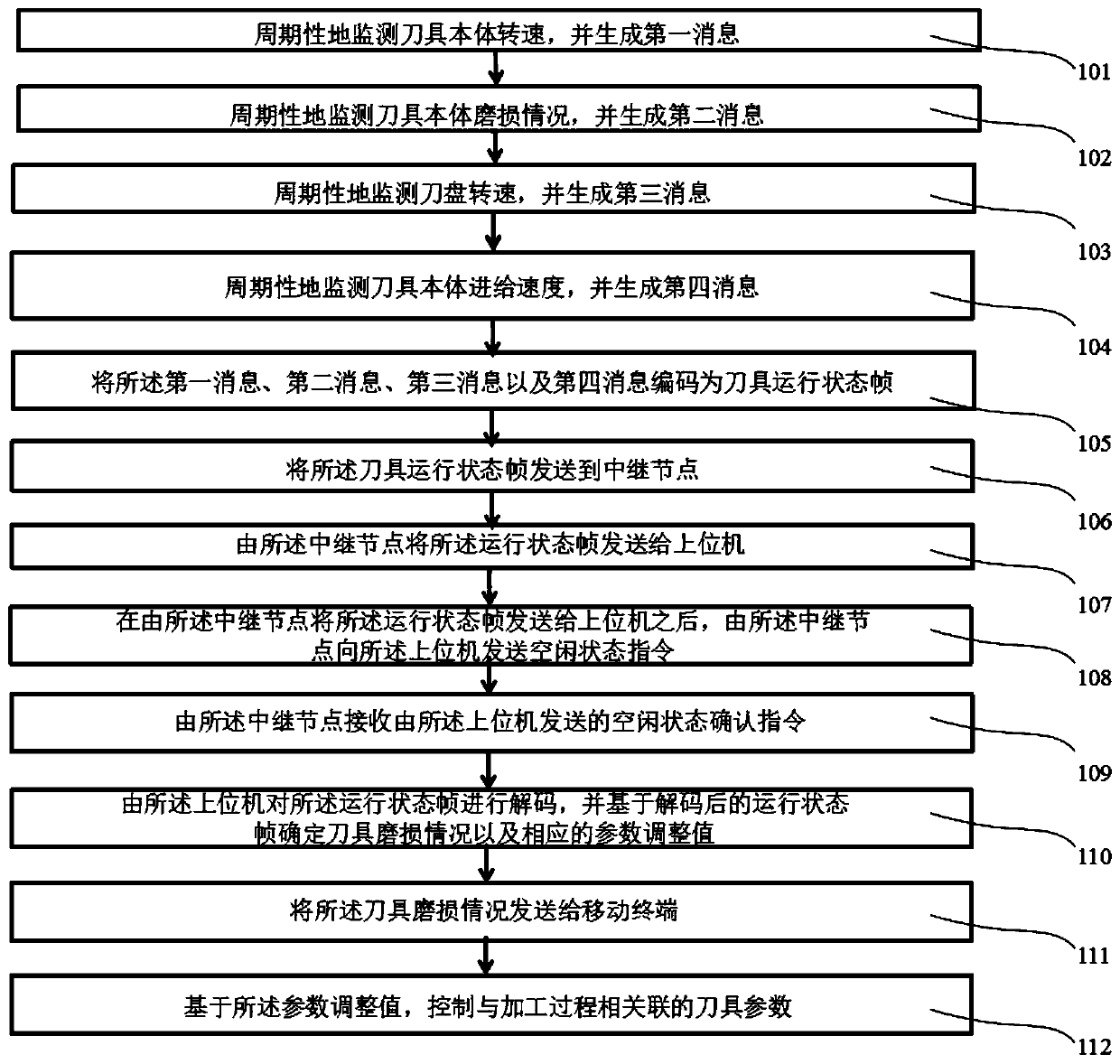

[0019] figure 1 It is a method flowchart of a method for controlling tool wear based on wireless communication according to an embodiment of the present invention. Such as figure 1 As shown, the method of the present invention includes the following steps: Step 101: Periodically monitor the rotation speed of the tool body, and generate a first message; Step 102: Periodically monitor the wear condition of the tool body, and generate a second message; Step 103: Periodically Periodically monitor the rotation speed of the cutter head, and generate a third message; Step 104: Periodically monitor the feed speed of the tool body, and generate a fourth message; Step 105: Combine the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com