Lifting-free unloading vibrating type semitrailer bucket

A vibrating, semi-trailer technology, applied in motor vehicles, loading and unloading vehicles, vehicles used for freight, etc., can solve the problems of increased transportation consumption, large energy consumption, and increased overall weight of the semi-trailer, reducing the The effect of transportation consumption, reducing energy consumption, and facilitating uniform unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

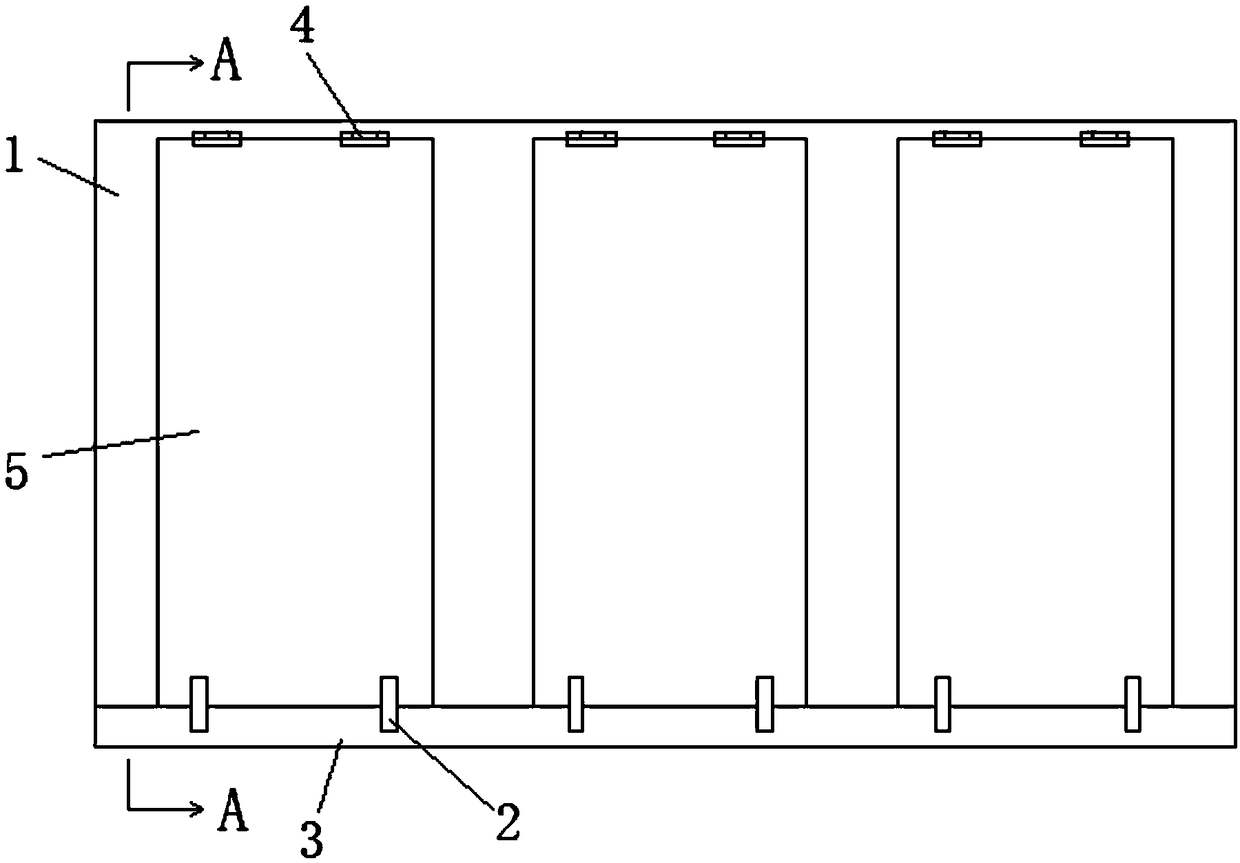

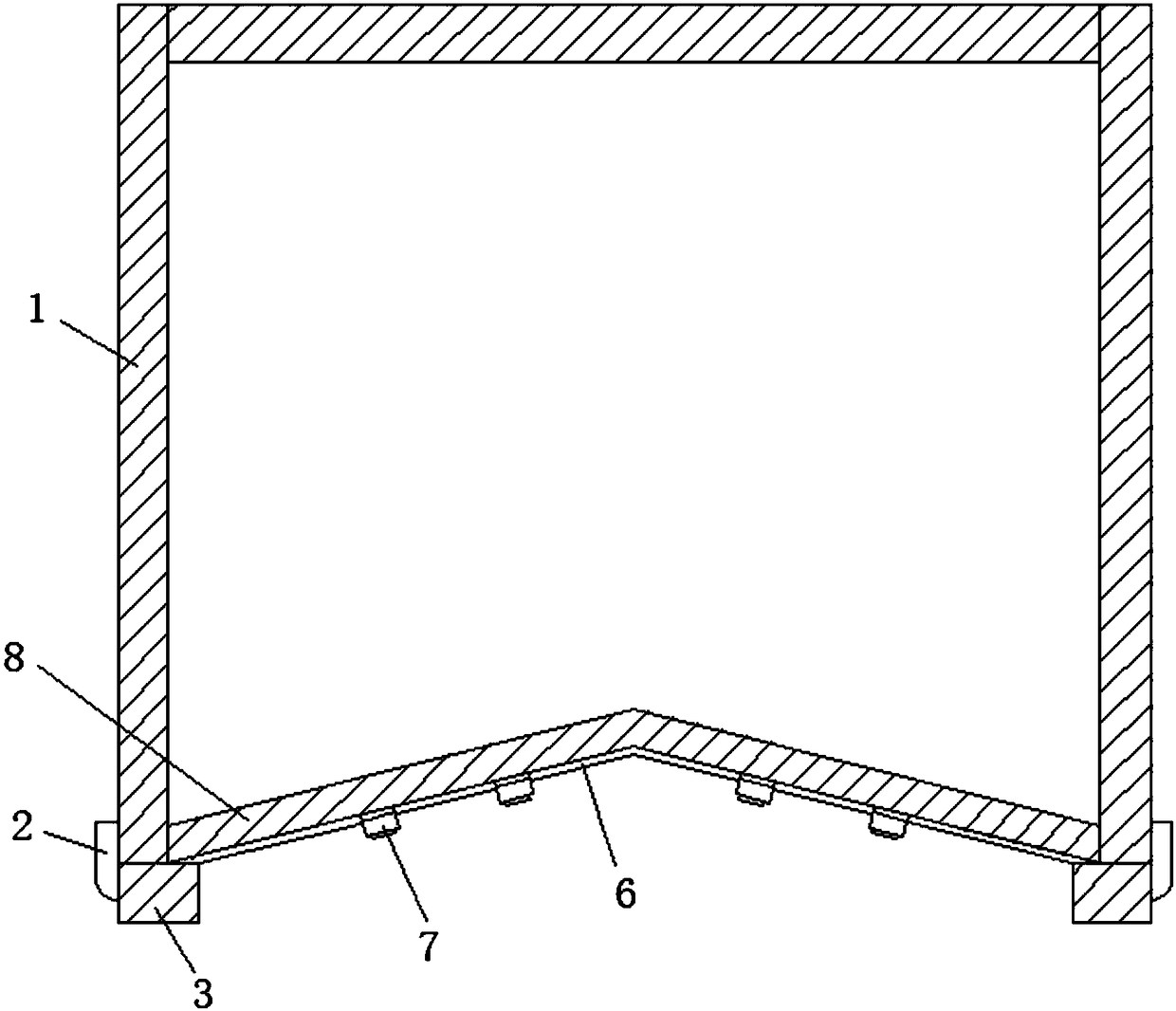

[0031] Such as figure 1 with figure 2 As shown, a vibration-type semi-trailer body without lifting and unloading, including a body frame 3 and a body frame 1 fixedly installed on both side beams of the body frame 3, the lower part of the body frame 1 is provided with a middle The material receiving plate 8 facing upwards and having a triangular cross-section, the length direction of the material receiving plate 8 extends along the length direction of the bucket frame 1, and the two sides in the length direction are respectively fixedly connected with the two side beams of the bucket underframe 3, and the material receiving plate 8 A plurality of vibrators 7 are installed on the bottom of the plate 8, and at least one side door 5 for unloading is respectively installed on both sides of the bucket frame 1, and the opening and closing of the side door 5 is controllable.

[0032] In this embodiment, the upper end of the side door 5 is hinged to the upper part of the bucket frame...

Embodiment 2

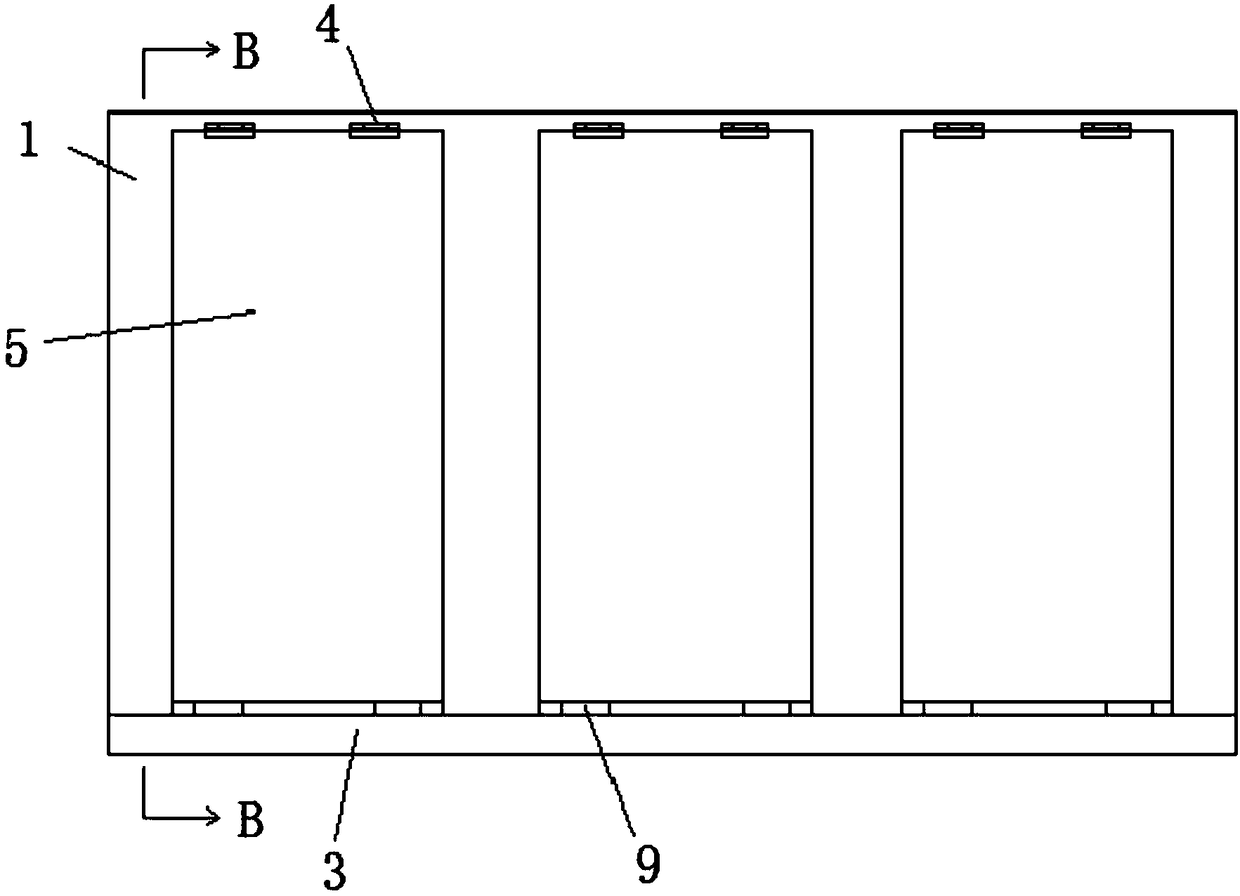

[0035] Such as image 3 with Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the locking mechanism includes at least one electromagnetic lock 9, the electromagnetic lock 9 is fixed on the lower end surface of the side door 5, and the electromagnetic lock 9 is energized to absorb the vehicle body chassis 3 and the vehicle body. For the connection of the side beams corresponding to the underframe 3, the electromagnetic lock 9 is deenergized to release the connection between the adsorption bucket underframe 3 and the side beams corresponding to the bucket underframe 3.

[0036] Working mode: when unloading, control the power-off of the electromagnetic lock 9 to release the connection between the adsorption vehicle bottom frame 3 and the side beam corresponding to the vehicle bottom frame 3, start the vibrator 7, and the side door 5 is opened by the gravity of the material, and the material is loaded along the The two slopes of the plate 8 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com