Milling, planing and laying integrated milling-planing machine

A milling machine and milling technology, applied to roads, road repairs, roads, etc., can solve the problems of cumbersome procedures, waste of manpower and material resources, etc., and achieve the effect of improving maintenance efficiency and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

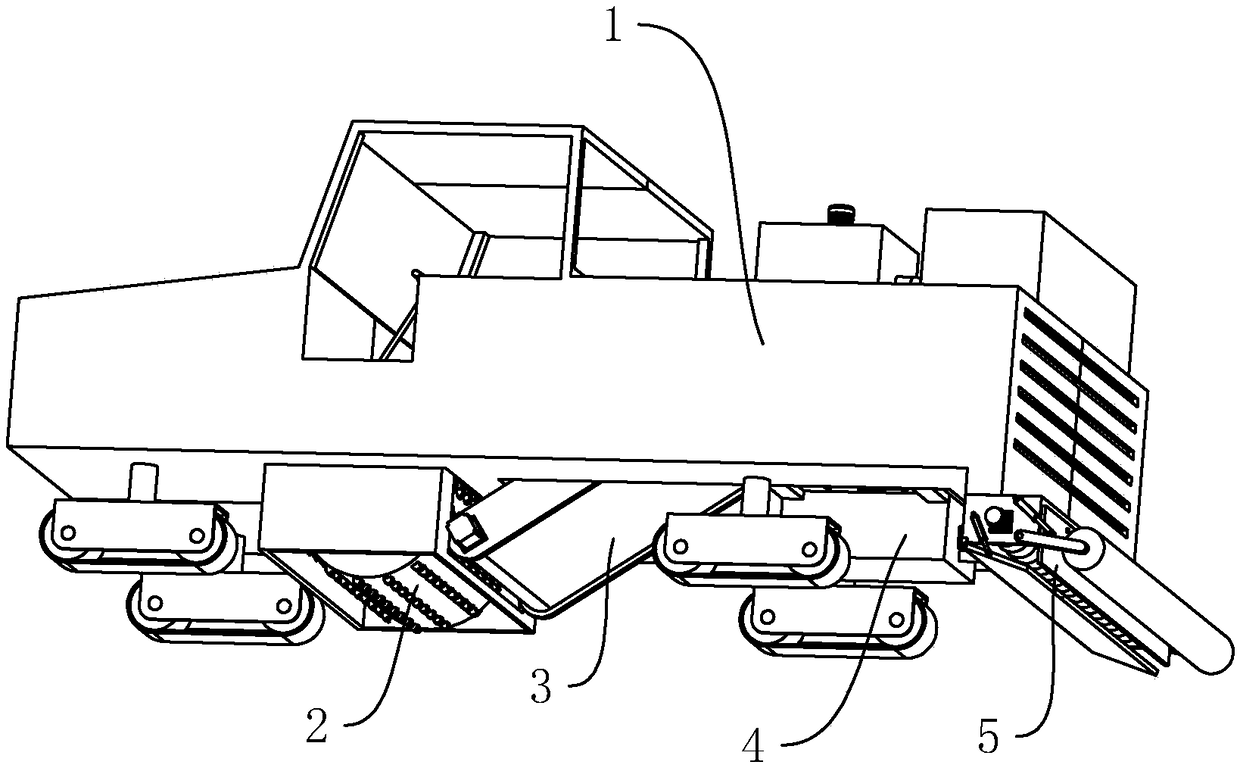

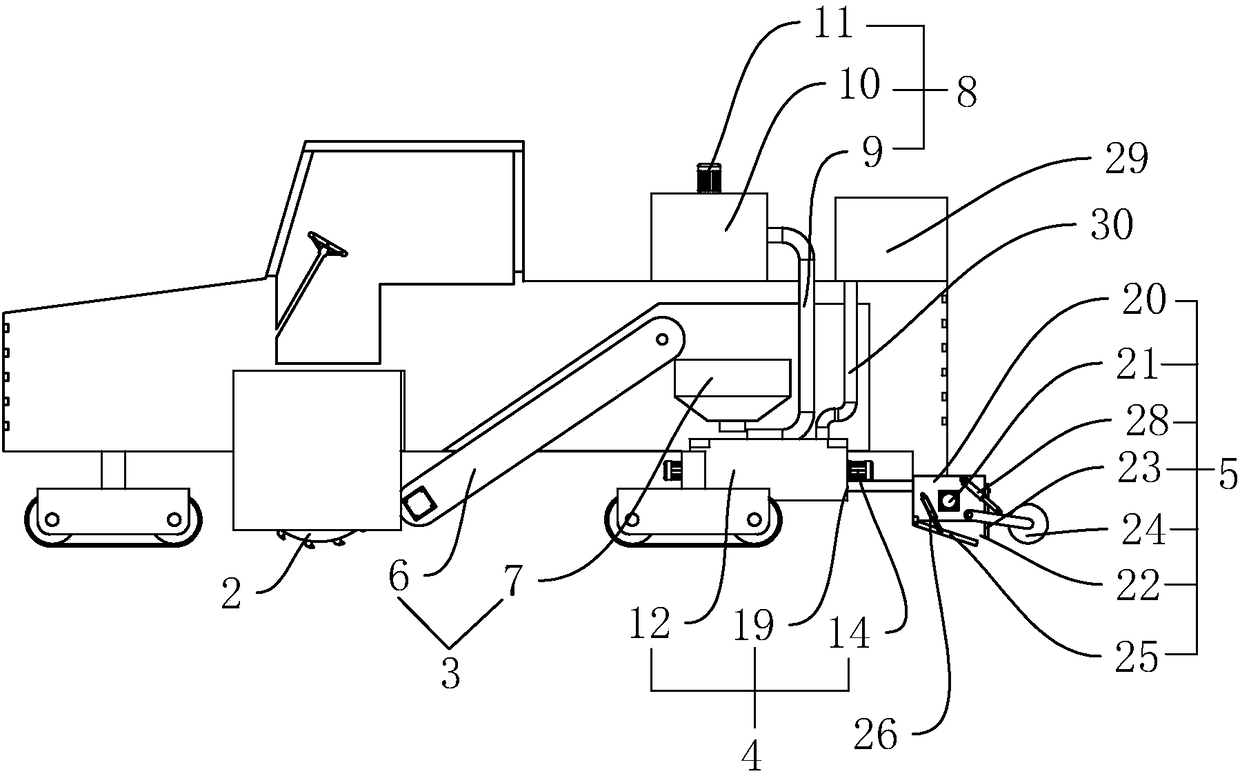

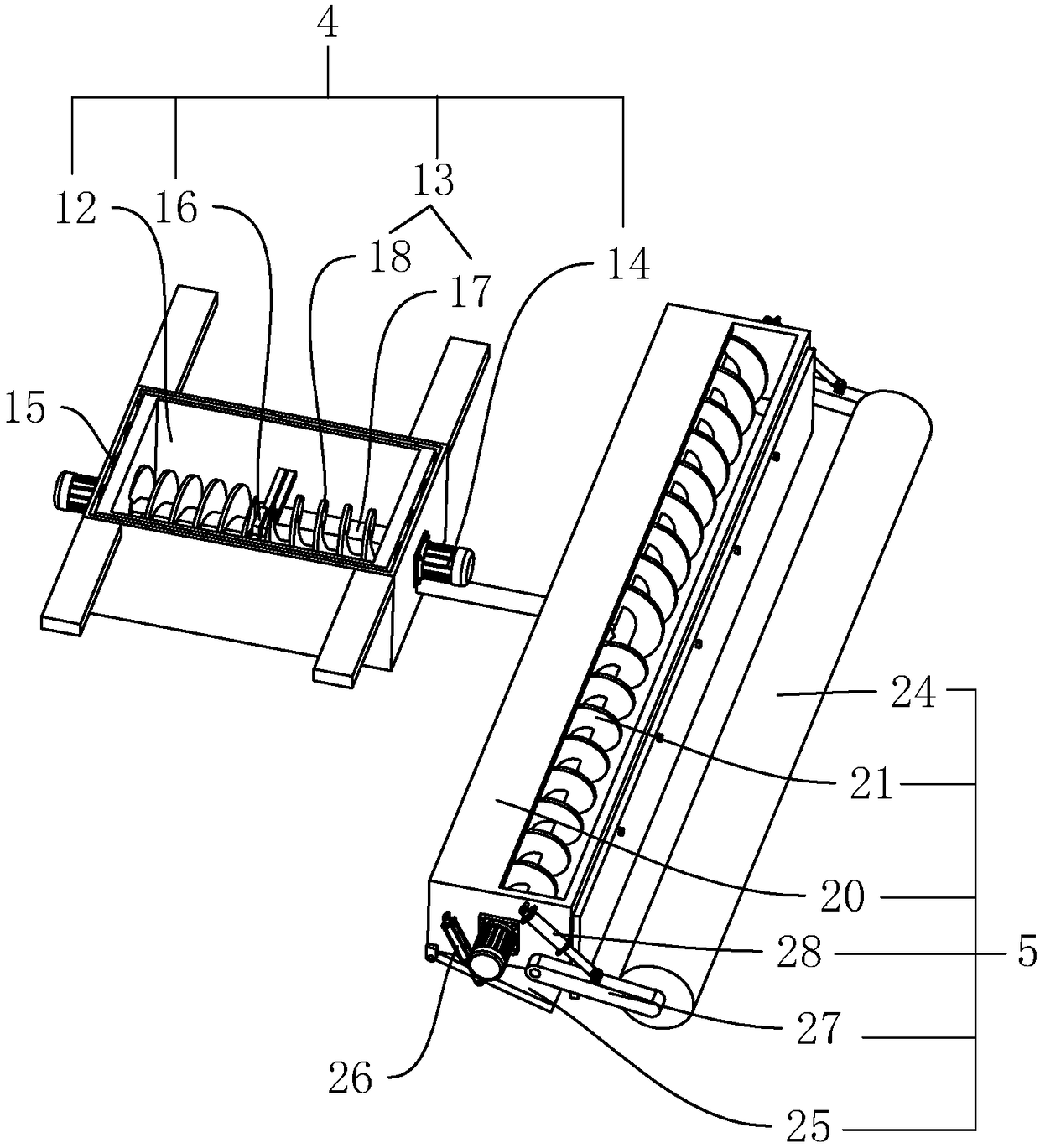

[0036] A milling machine integrated with milling, planing and laying, such as figure 1 and figure 2 As shown, it includes a body 1 and a milling roller 2 arranged under the body 1. The milling roller 2 is connected to the bottom of the body 1 through a rotating shaft 17 and is driven by a motor to complete the milling action. After the planing roller 2 and used for collecting the milled asphalt collection assembly 3, the mixing mechanism 4 arranged behind the collection assembly 3, and the paving mechanism 5 arranged behind the collection assembly 3, one end of the paving mechanism 5 is connected to the mixing mechanism 4. The other end extends to the ground; the milling roller 2 is driven by the motor to rotate, and the surface of the milling roller 2 is provided with several blades, and the damaged asphalt pavement can be broken by the rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com