Lapped installation thread-off-proof release buckle and release buckle box

A buckle box and anti-off technology, applied in the direction of fasteners, belt buckles, clothing, etc., can solve the problem of inconvenient plugging and unplugging methods, and achieve the effect of reducing the probability of tripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

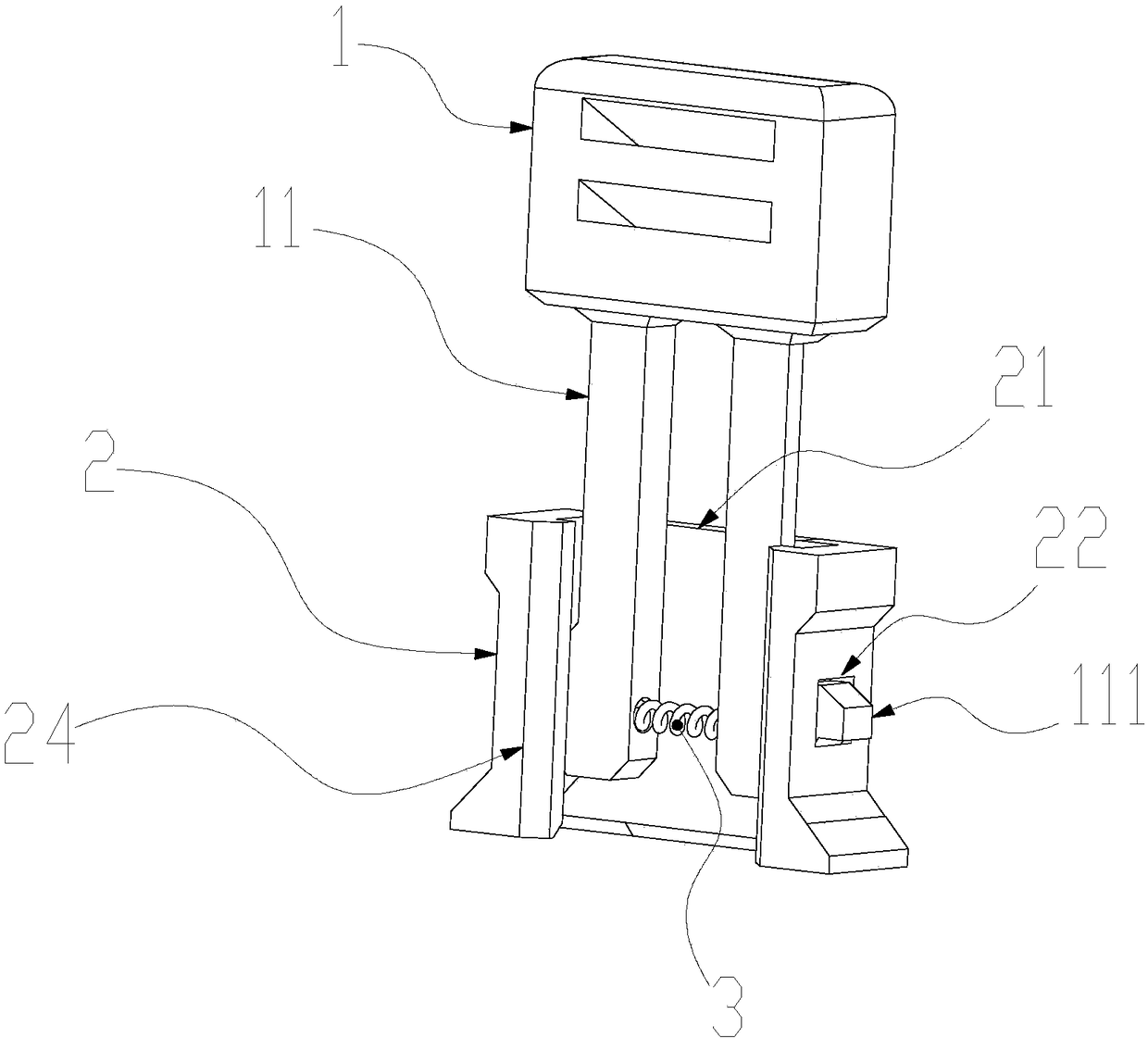

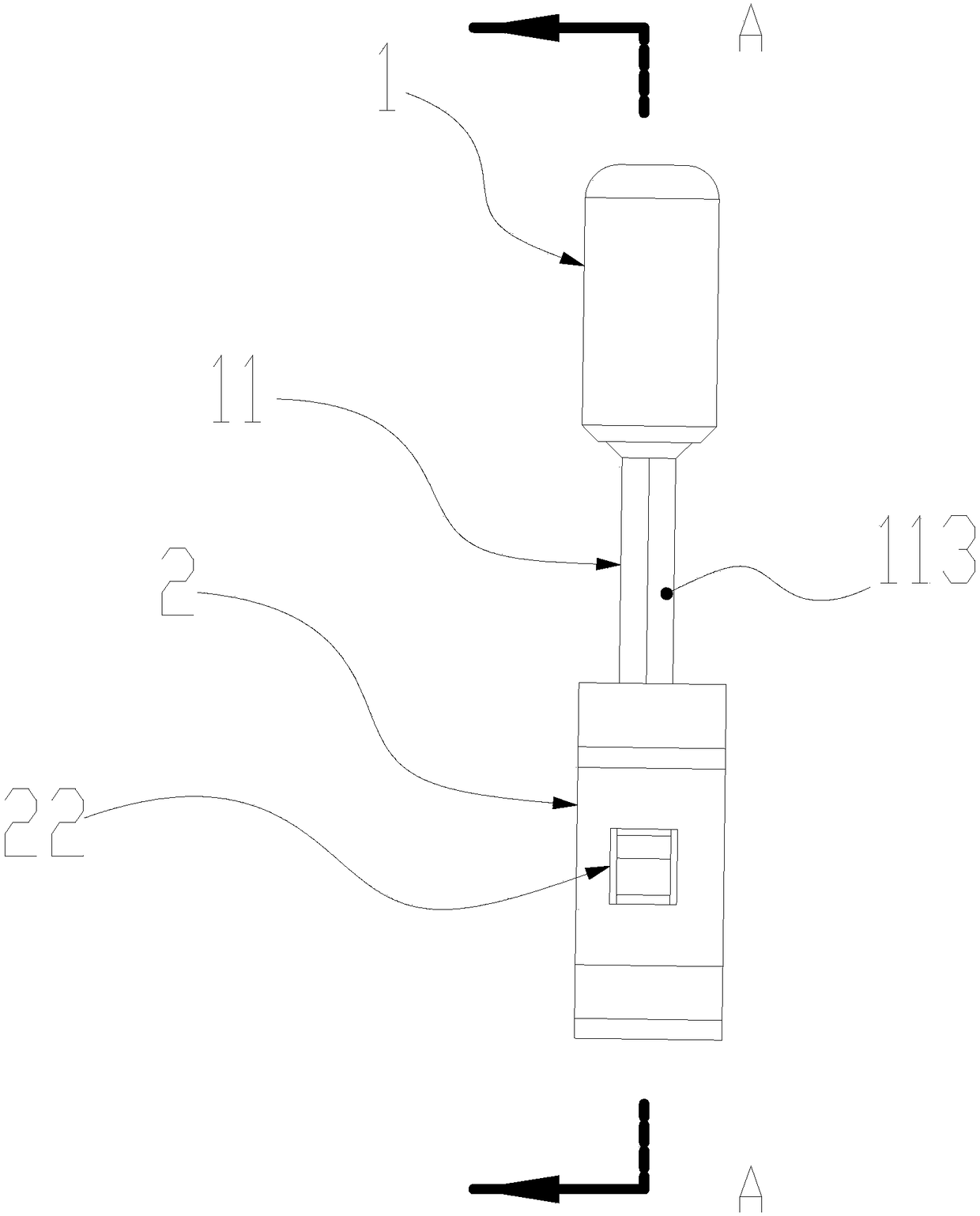

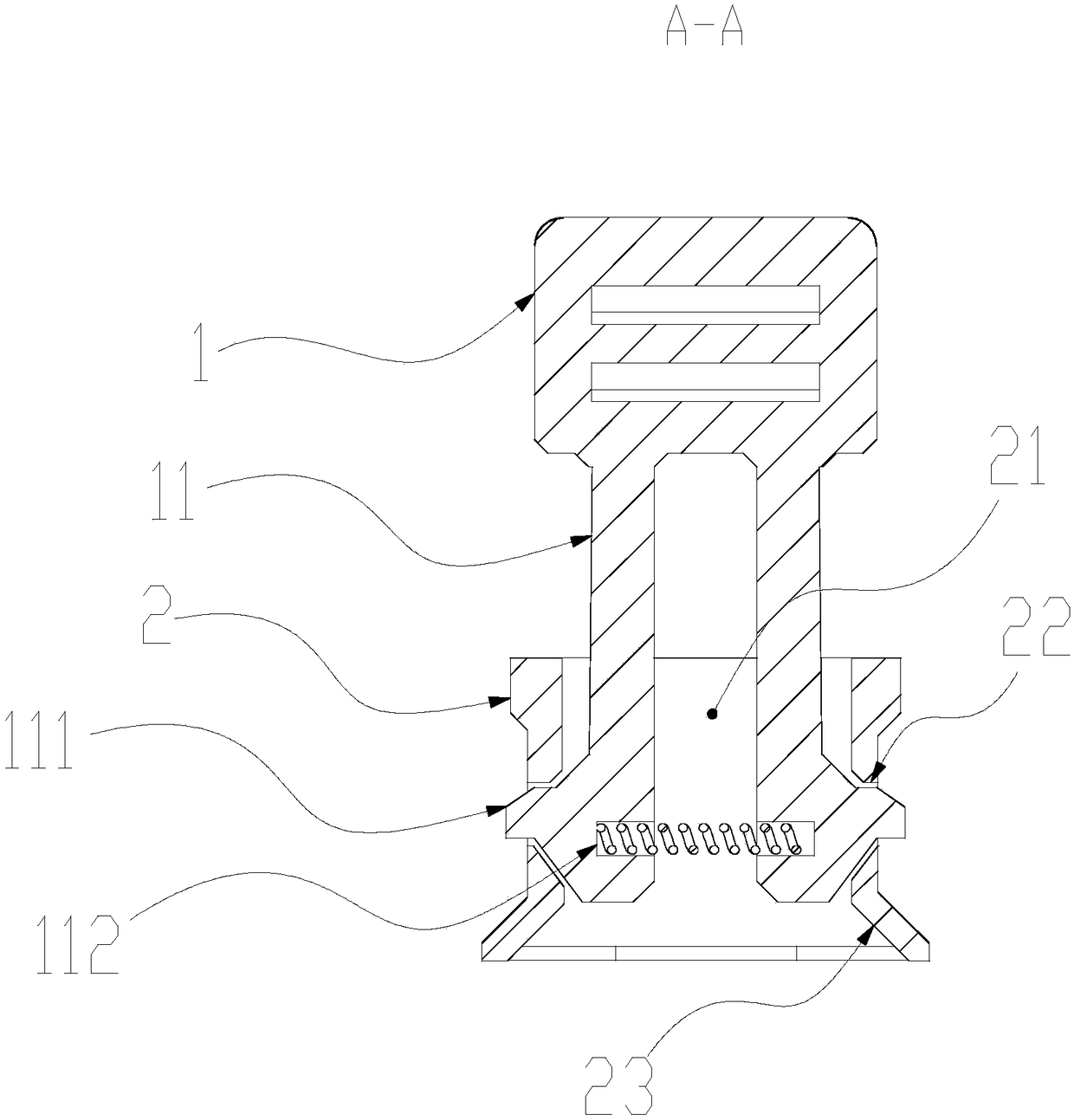

[0020] Such as Figure 1~3 The shown one is a buckle and a buckle box for leaning installation, including a buckle 1 and a buckle box 2 . The buckle 1 is provided with two extending connecting bars 11 . An outer side of the connecting bar 11 is provided with a mating boss 111 extending outward. A sliding installation chamber 21 is provided inside the buckle box 2 , and an installation through hole 22 is provided on the side and bottom of the sliding installation chamber 21 facing outward. The above-mentioned matching boss 111 is fixed in the installation through hole 22 , and one side of the above-mentioned buckle box 2 is provided with an opening 24 for quickly leaning against it.

[0021] In order to further realize the mutual fixing of the buckle and the buckle box, a spring installation groove 112 is also provided on the inner side of the above-mentioned connecting bar 51 .

[0022] In order to increase the speed of installation and improve the cooperation with the mati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com