Carbon-supported nickel catalyst doped mg (bh 4 ) 2 Based hydrogen storage material and preparation method thereof

A technology of nickel catalysts and hydrogen storage materials, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor reversibility, slow hydrogen release kinetics, The thermodynamic properties are too stable, etc., to achieve the effects of improved reversible properties, regular material morphology, and fast hydrogen release kinetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

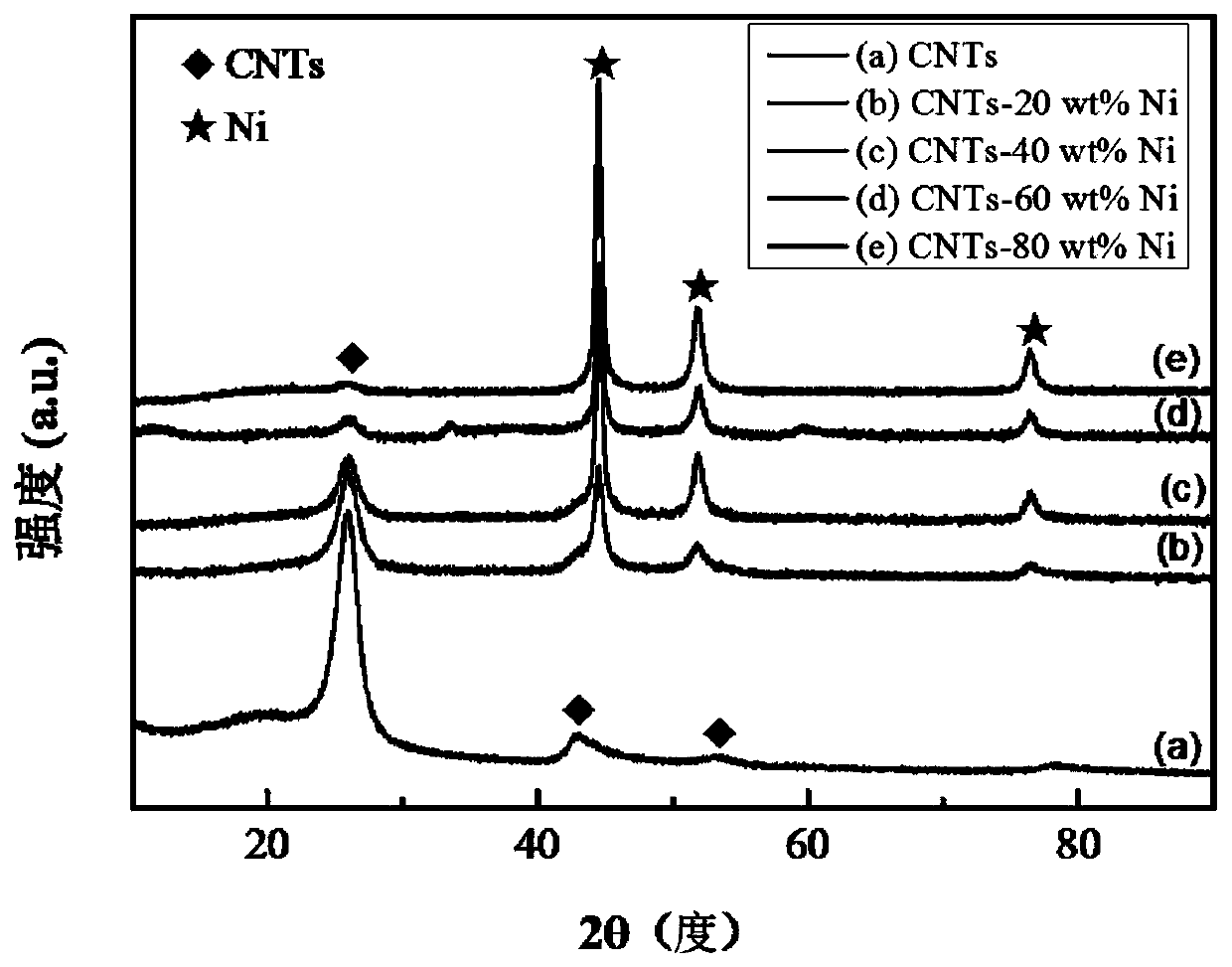

[0037] In this embodiment, five kinds of carbon-supported nickel catalysts are prepared by solution chemical reduction, and the specific preparation methods are as follows:

[0038] First, as shown in Table 1, a certain mass of functionalized CNTs was mixed with 40ml of ethylene glycol solution and ultrasonically vibrated for 2 hours, so that the CNTs were fully dispersed in the ethylene glycol solution to obtain solution a; Nickel nitrate hydrate (according to the proportioning in Table 1, ensuring that the mass fraction of Ni is 20wt%, 40wt%, 60wt% and 80wt%) was mixed with 10ml deionized water, and magnetically stirred for 2h at 40°C to prepare a solution b; Then, mix the two solutions of a and b and then add 10ml of hydrazine hydrate solution, stir magnetically at 80°C for 2h, then add NaOH (2.5mol / L) solution to adjust the pH value to slightly greater than 10, and then mix the The solution was kept at 110°C (in an oil bath) for 2 hours to ensure that Ni was completely red...

Embodiment 2

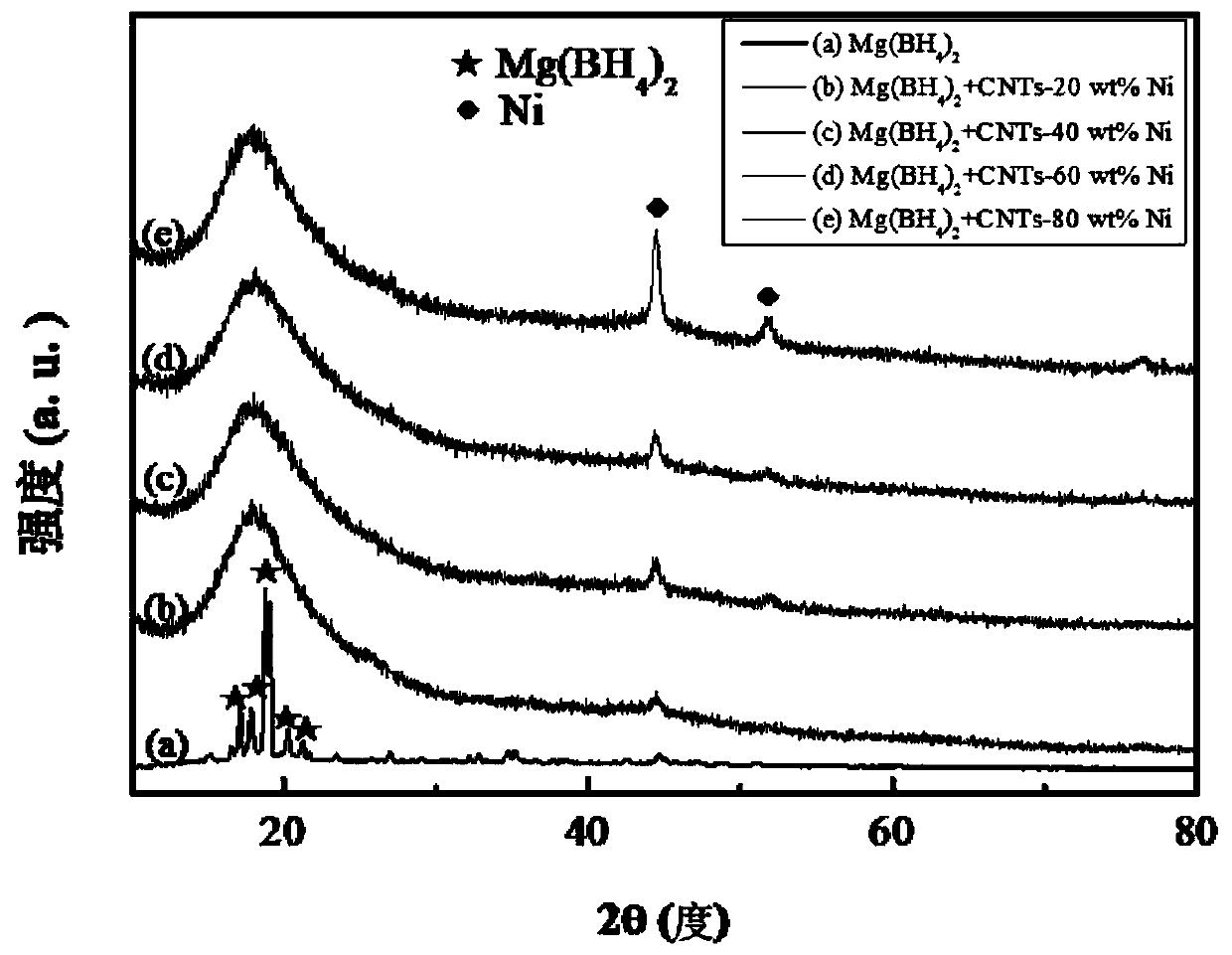

[0043] This embodiment includes the preparation of five hydrogen storage materials, and the specific preparation methods are as follows:

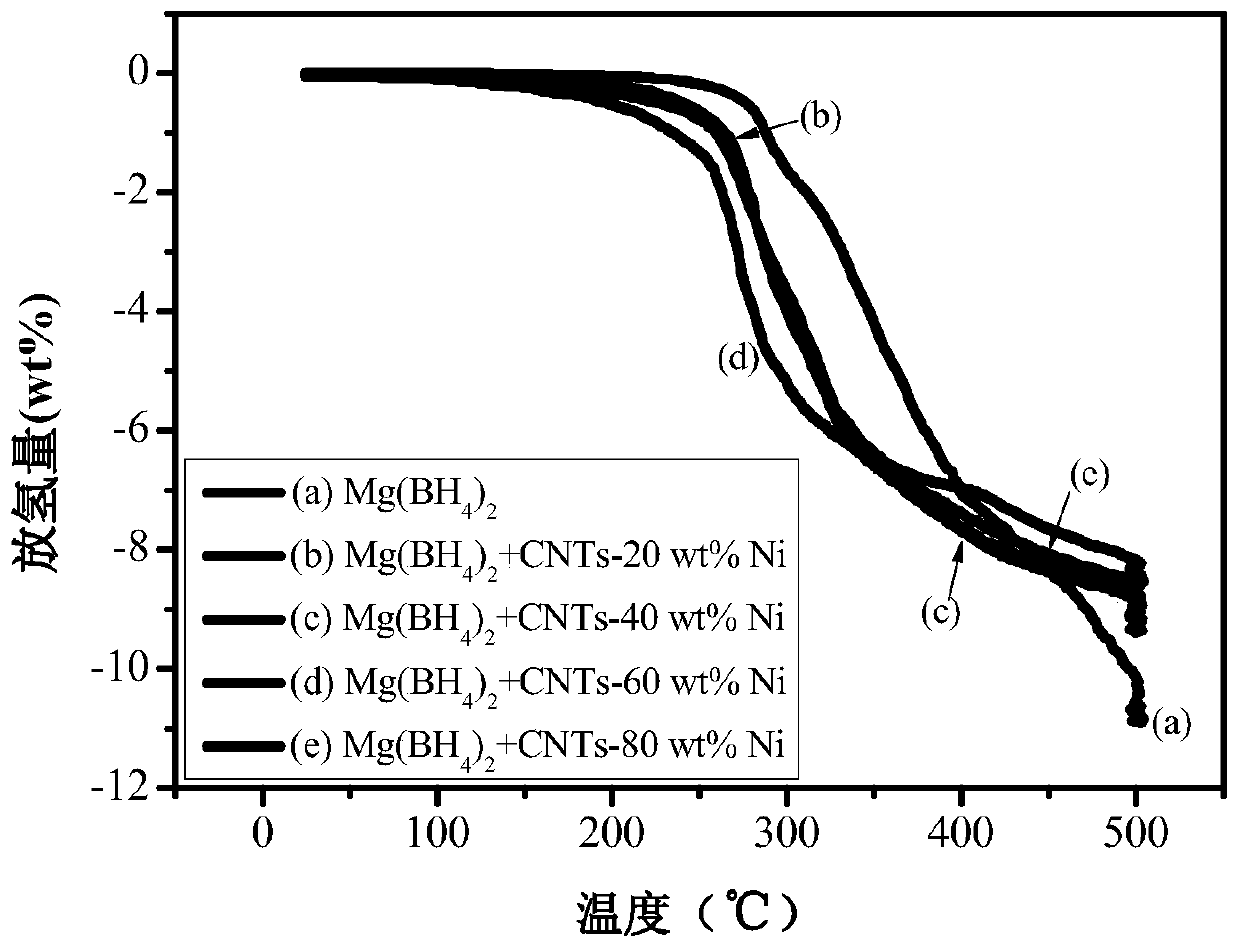

[0044] According to Table 2, weigh Mg (BH 4 ) 2 The powder and the additive CNTs-xNi (x=20-80wt%) prepared in Example 1 were used to prepare the mixed raw materials used in Example 2-II to Example 2-V respectively, wherein the additive was added as Mg(BH 4 ) 2 In the powder (that is, the amount of additive is additive and Mg(BH 4 ) 2 5wt% of the total mass of the powder), then five parts of mixed raw materials were put into 50ml ball mill jars and carried out mechanical ball milling, wherein the weight ratio of balls and mixed raw materials was 40:1, and the hydrogen gas (H 2 ) for protection, the ball milling speed is 350rpm, the ball milling time is 10 h, and during the ball milling process, every 6 minutes of ball milling is rested for 6 minutes, so as to prevent the ball milling tank from overheating the sample Mg(BH 4 ) 2 Decompo...

Embodiment 3

[0052] The additive CNTs-60wt% Ni was added to the raw material Mg (BH 4 ) 2 After mixing, the hydrogen storage material Mg(BH 4 ) 2 +CNTs-60wt%Ni, the whole ball milling process was filled with 3bar hydrogen (H 2 ) for protection, and rest for 6 minutes every 6 minutes during the ball milling process, the ball milling product is Mg(BH 4 ) 2 +CNTs-60wt% Ni hydrogen storage material.

[0053] The hydrogen storage materials prepared by different ball milling processes were tested by DSC at different heating rates, the temperature and heating rate in the test results were further sorted out, and the Kissinger equation was used for fitting to calculate the apparent activation energy of hydrogen desorption of the samples. The results are shown in Table 3 and Figure 6 . From Figure 6 It can be seen from the figure that the apparent activation energy of hydrogen desorption of the hydrogen storage material prepared in Example 3-II is reduced to 119.58kJ / mol, which is differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com