Expansion fixing connection structure for home hardware

A technology of expansion fixing and connecting structure, applied in the direction of connecting members, thin plate connections, furniture parts, etc., can solve the problems of complicated opening of threaded holes, easy deformation, loose and falling off of screw teeth, etc., to achieve a simple and reliable overall structure, increase contact Area, to avoid the effect of loosening and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

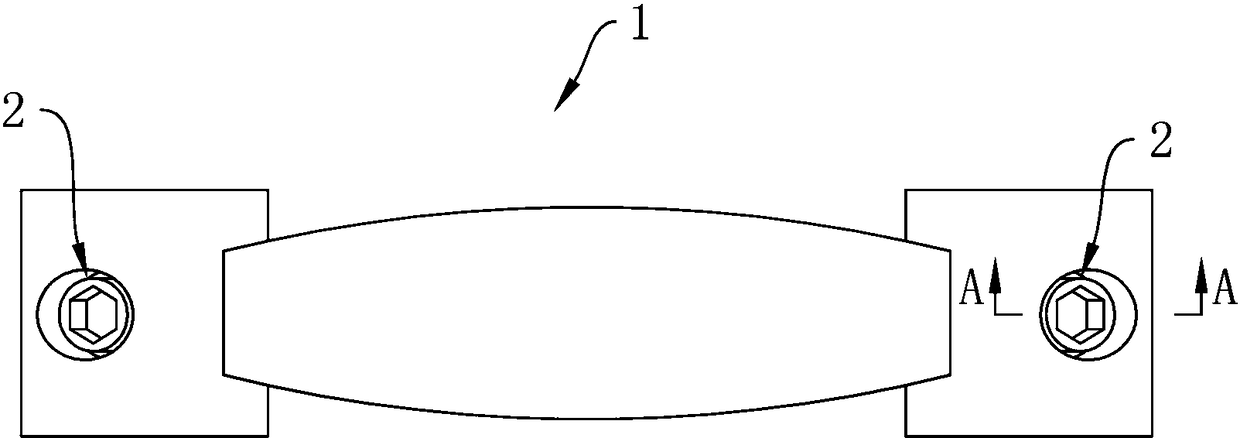

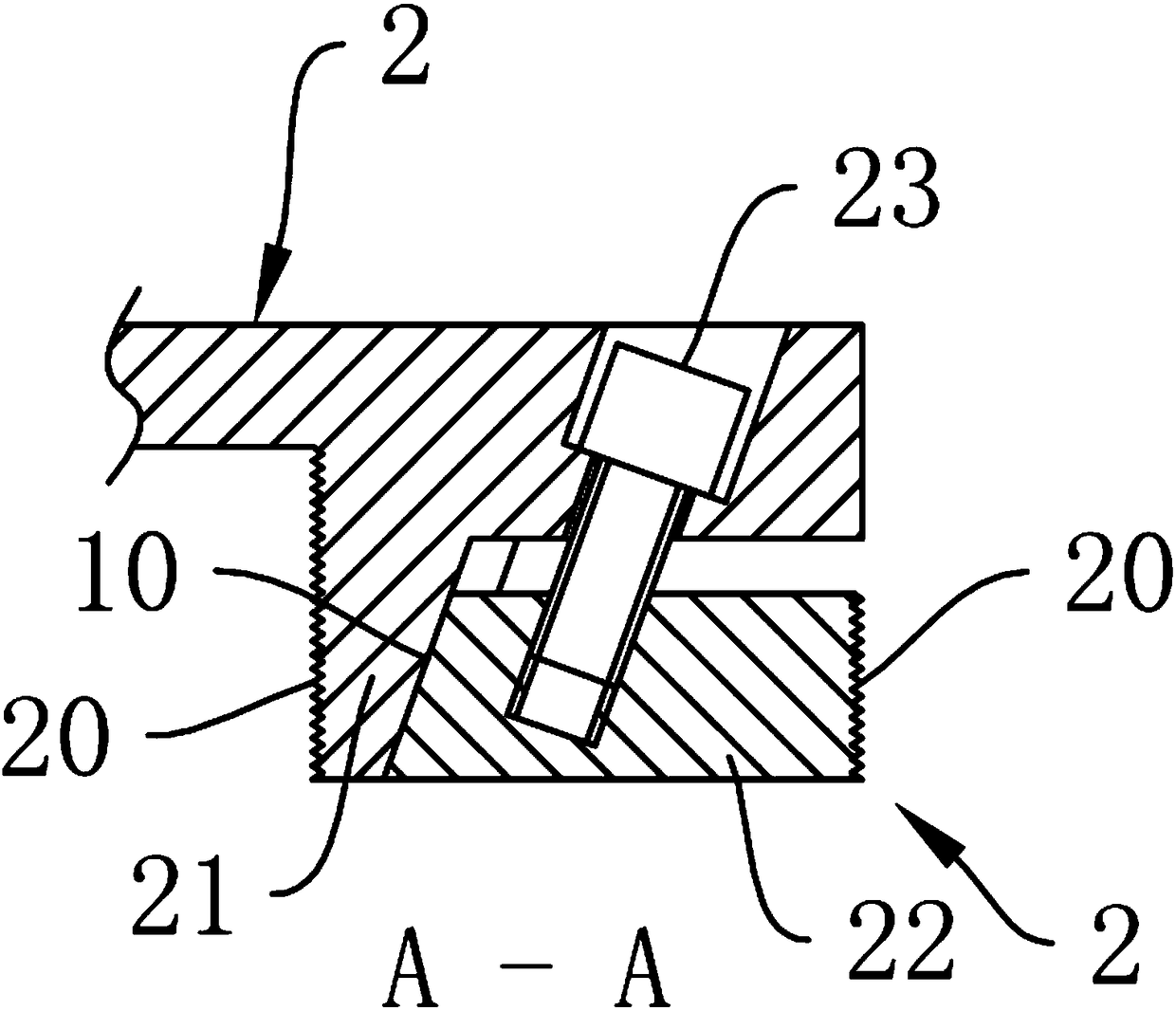

[0038] like figure 1 and figure 2 As shown, an expansion and fixing connection structure of household hardware according to the present invention includes a handle body 1 and an expansion and fixing assembly 2, wherein the expansion and fixing assembly 2 includes a fixing seat 21, a tightening block 22, and an adjusting screw 23. The fixing seat 21 is integrated with the handle body 1 or fixed on the handle body 1, the side wall of the fixing seat 21 is provided with a guide slope 10, and the end surface of the tightening block 22 is provided with anti-slip concave-convex lines 20, and the tightening block The other end of 22 is close to the guide slope 10, and the adjusting screw 23 is rotatably inserted in the fixed base 21 or the handle body 1 or simultaneously inserted in the handle body 1 and the fixed base 21 and screwed to the tightening block 22, so that when the adjusting screw 23 is turned, the tightening block 22 slides along the inclined direction of the guide sl...

Embodiment 2

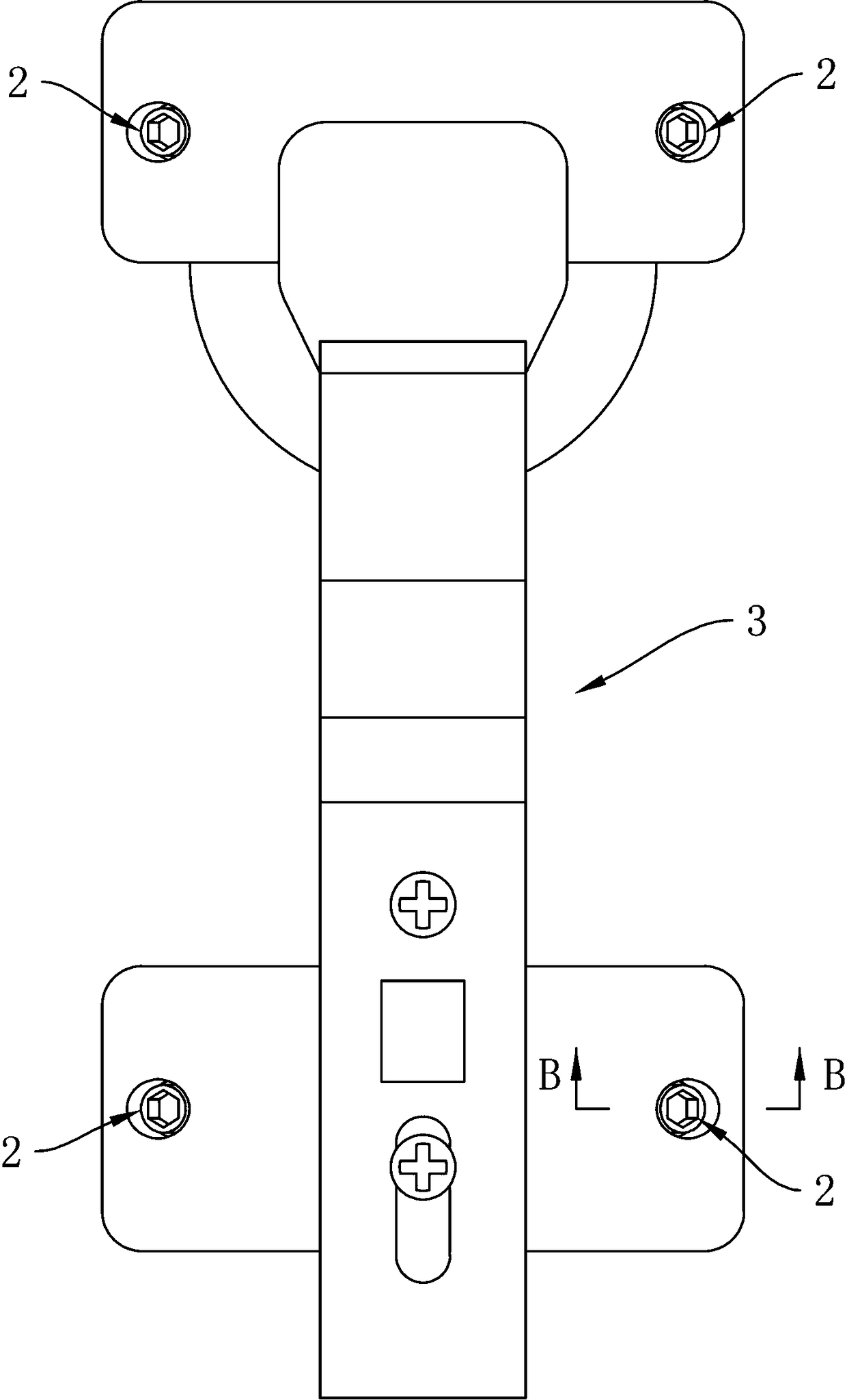

[0042] like image 3 and Figure 4 As shown, an expansion and fixing connection structure of household hardware includes a hinge body 3. In order to realize the purpose of the new invention, the two ends of the hinge body 3 are respectively provided with expansion and fixing components 2, and the expansion and fixing components 2 include Fixing seat 21, tightening block 22, adjusting screw 23, described fixing seat 21 and hinge body 3 are integrated structure or are fixed on the hinge body 3, and described fixing seat 21 sidewalls are provided with guiding slope 10, and described tight One end of the fixed block 22 is provided with an anti-slip concave-convex pattern 20, the other end of the fixed block 22 is close to the guide slope 10, and the adjusting screw 23 is rotatably inserted in the fixed seat 21 or the hinge body 3 or at the same time It is threaded on the hinge body 3 and the fixing seat 21 and screwed on the tightening block 22 so that when the adjusting screw 23...

Embodiment 3

[0046] like Figure 5 to Figure 8 As shown, an expansion and fixed connection structure of household hardware includes a hinge body 4, and the hinge body 4 includes two hinge blocks 41 that are hinged together. In order to achieve the purpose of the present invention, the hinge blocks 41 There is an expansion fixing assembly 2 on it, and the expansion fixing assembly 2 includes a fixing seat 21, a tightening block 22, and an adjusting screw 23, and the hinge block 41 is integrally structured or fixedly connected with the fixing seat 21 on it. A guide slope 10 is provided on the side wall of the fixing seat 21, and an anti-slip concave-convex pattern 20 is provided on the end surface of one end of the fastening block 22, and the other end of the fastening block 22 is closely attached to the guide slope 10, and the adjusting screw 23 can be Rotately put on the fixed seat 21 or the hinge block 41 or at the same time on the hinge block 41, the fixed seat 21 and screwed on the tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com