Lifting mechanism in vacuum cavity

A technology of vacuum chamber and lifting mechanism, applied in crystal growth, discharge tube, electrical components, etc., can solve the problems of insufficient sealing performance, occupying chamber space, corrosion, etc., and achieve the effect of good synchronization and good dynamic sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

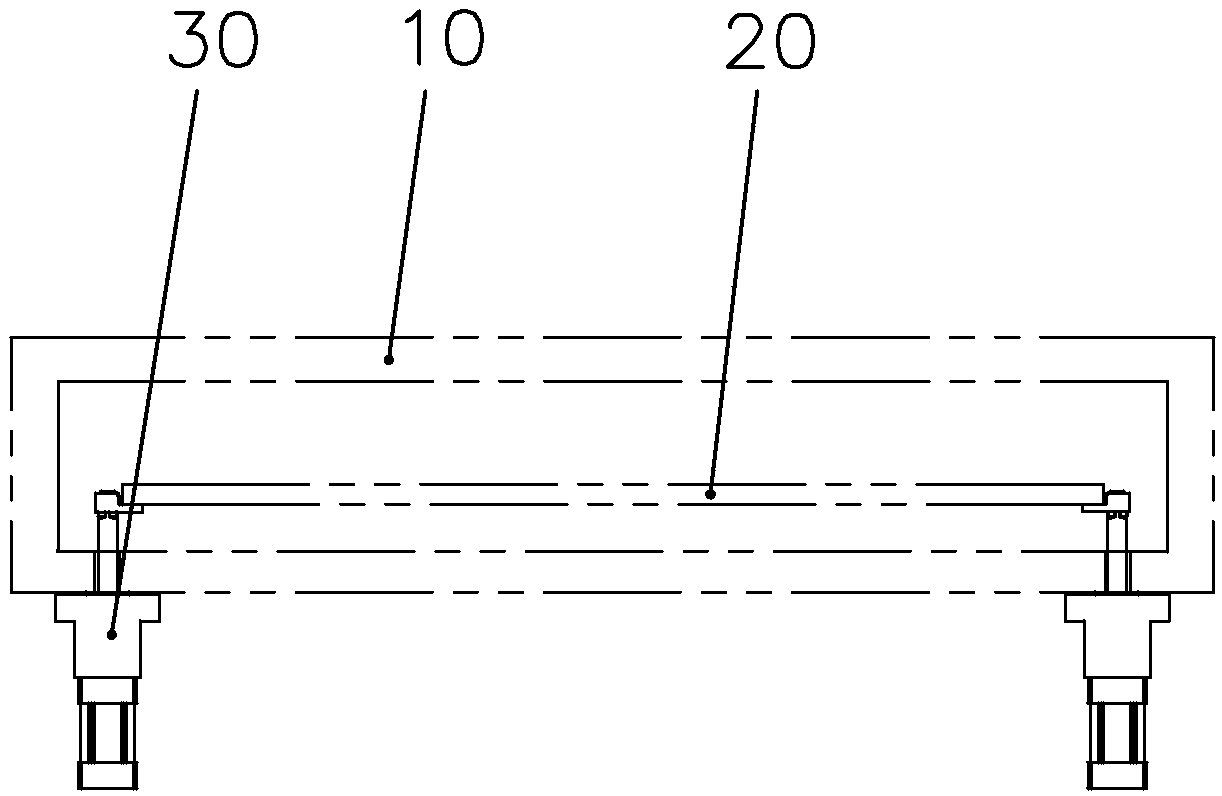

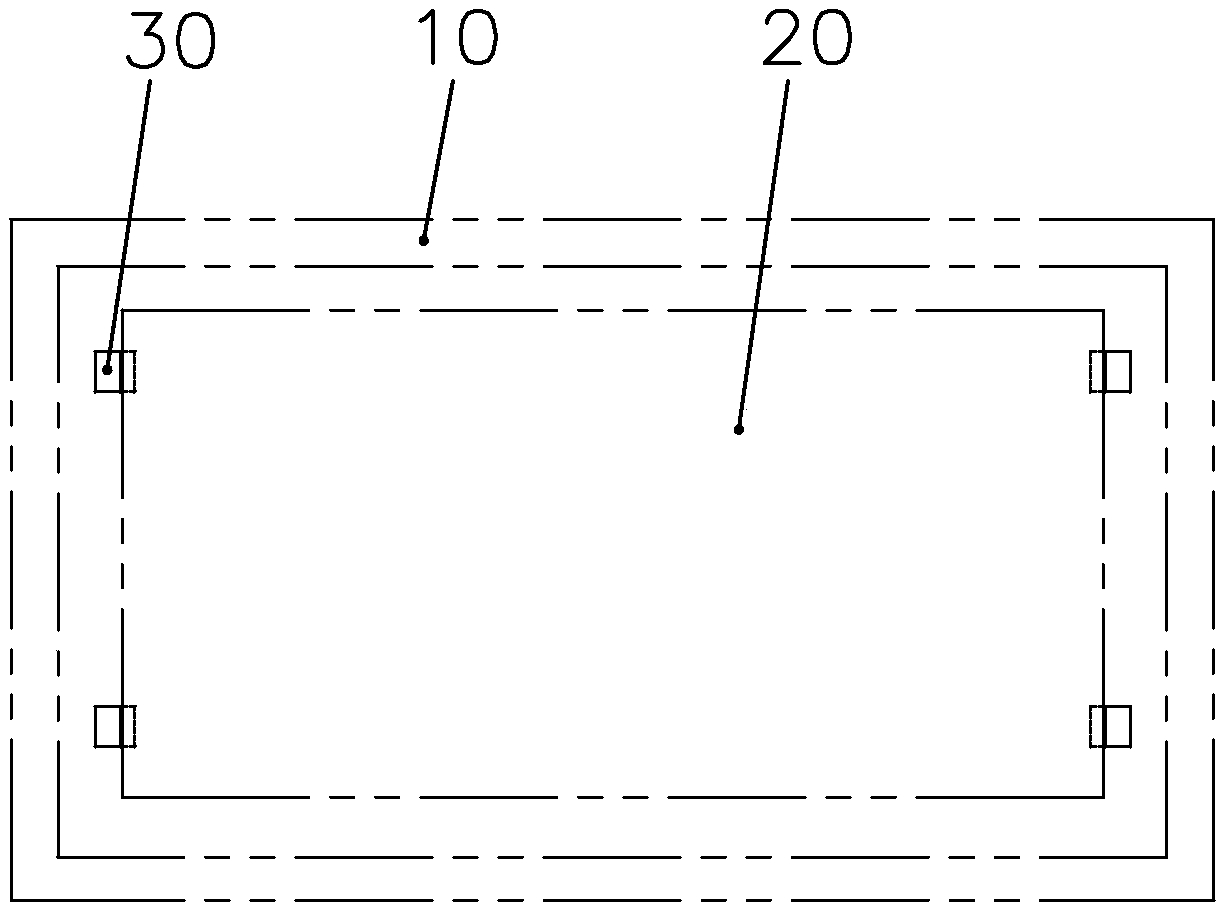

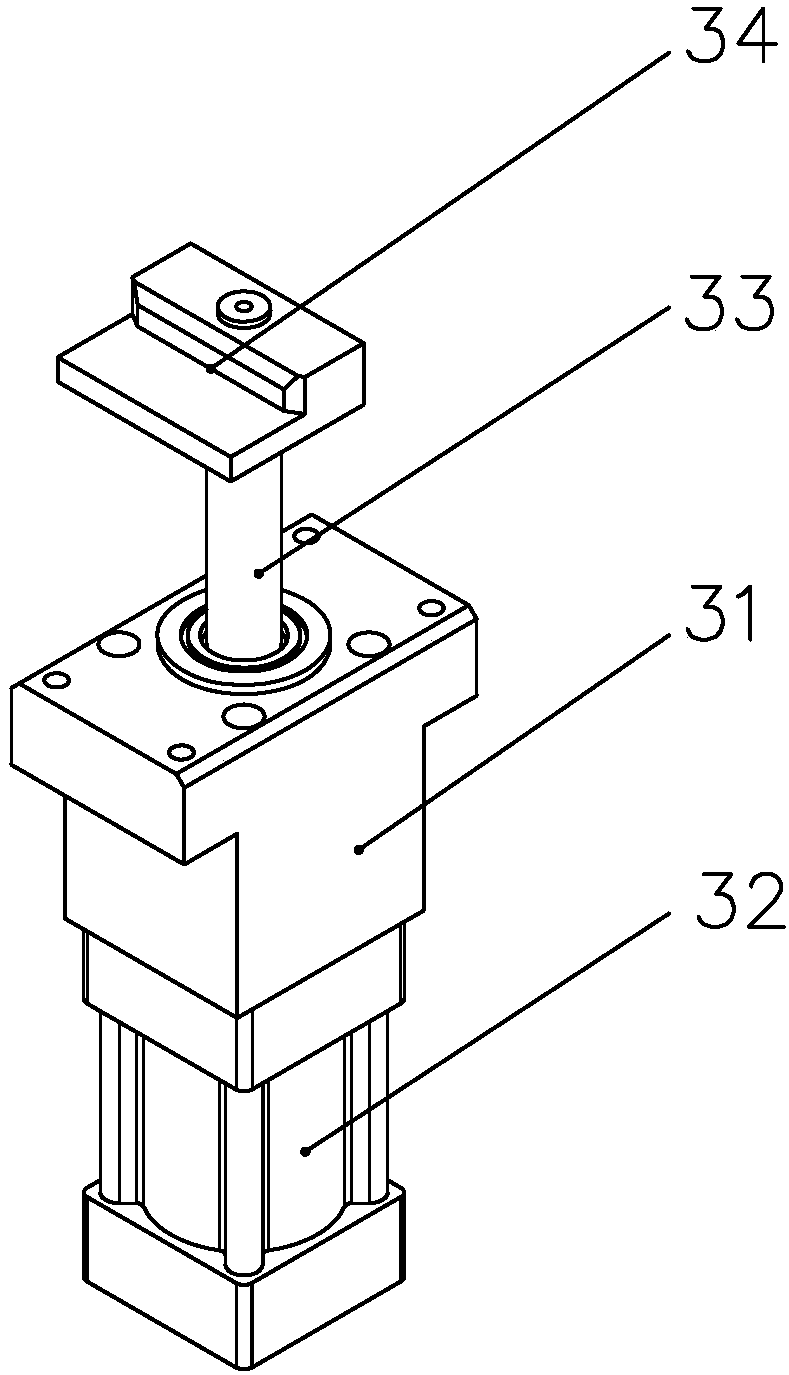

[0024] refer to Figure 1-4 , the cavity lifting mechanism 30 provided by the present invention is installed symmetrically at the four corners of the bottom of the vacuum chamber 10. The lifting mechanism 30 includes a fixed base 31 installed on the outside of the chamber bottom plate 11 of the vacuum chamber 10. The fixed base 31 is equipped with Cylinder 32, cylinder 32 drives lifting shaft 33, and one end of lifting shaft 33 stretches into vacuum chamber 10 inside through chamber bottom plate 11 and end is provided with the top plate 34 corresponding carrier plate 20; Teflon, and the outer ring of the lifting shaft 33 is processed as a high-precision sealing surface, which ensures good dynamic sealing and corrosion resistance; the inside of the fixed base 31 is provided wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap