Detection ruler for perpendicularity, flatness and levelness of wall columns and detection method thereof

A verticality and detection ruler technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of affecting the measurement results, large deviation, and inability to adjust, so as to achieve the effect of accurate measurement data, fast judgment method, and easy folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

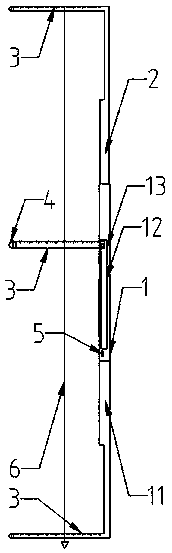

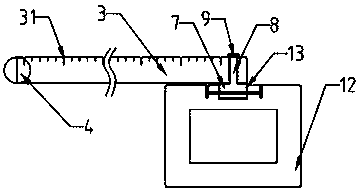

[0038] Such as figure 1 , figure 2 As shown, the female ruler 1 in this embodiment is a cuboid, and there are two female rulers 11 and 12 respectively, and the wide sides of the first female ruler 11 and the second female ruler 12 pass through The rotating shaft is connected, and the first female ruler 11 and the second female ruler 12 can be rotated and folded along the rotating shaft; the sub-ruler 2 is provided with one, and the sub-ruler 2 is placed in the first female ruler 11 or the second female ruler 12, And it can slide and position along the length direction of the first female ruler 11 or the second female ruler 12 .

[0039] Specifically, both the female ruler 1 and the sub-ruler 2 are of cuboid structure, the sub-ruler 2 is installed in the second female ruler 12, and a chute for the sub-ruler 2 to slide is arranged in the second female ruler 12, and the chute is rectangular. , and the length is greater than or equal to the length of the sub-ruler 2; there is a...

Embodiment 2

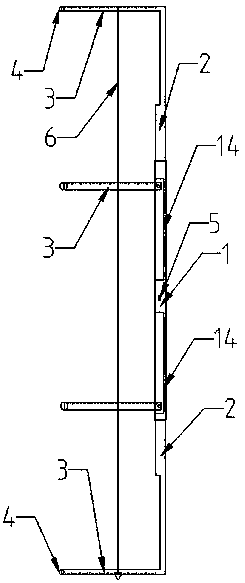

[0042] Such as image 3 As shown, the female ruler 1 in this embodiment is provided with one, and a sub-ruler 2 is rotatably installed at the upper and lower ends of the female ruler 1 respectively, and the sub-ruler 2 can be folded along the rotating end, and is connected with the female ruler 1 The sides are close to each other; the lengths of the two sub-rulers 2 are consistent with the length of the female ruler 1, and the rotating ends of the two sub-rulers 2 are respectively located at two opposite sides of the female ruler 1. There is a rectangular notch at the upper end and the lower end of the two sub-rulers 2 up and down, and the rectangular notch is located on the same side; the measuring scale 3 is provided with four, two of which are rotatably installed on the female ruler 1 respectively, and the other two One is rotatably installed at the rectangular notch of the sub-ruler 2, and its rotating ends are respectively located at the upper end of the upper terminal ru...

Embodiment 3

[0044] Such as Figure 4 As shown, there are two female rulers 1 and two sub-rulers 2 in this embodiment; the two female rulers 1 are connected by a rotating shaft, and can be rotated along the rotating shaft and folded; the two sub-rulers 2 are respectively placed Inside the two female rulers 1, and can slide and position along the length direction of the female rulers 1. There is a rectangular notch at the upper end and the lower end of the two sub-rulers 2 up and down, and the rectangular notch is located on the same side; the measuring scale 3 is provided with four, two of which are rotatably installed on the female ruler 1 respectively, and the other two One is rotatably installed at the rectangular notch of the sub-ruler 2, and its rotating ends are respectively located at the upper end of the upper terminal ruler 2 and the lower end of the lower terminal ruler 2, and the measuring scale 3 can be folded in the rectangular notch, and the measuring scale 3 is in the After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com