Dismounting method, mounting method and dismounting and mounting device for hydroelectric gate wheel shaft sleeves

A technology of disassembly device and installation method, which is applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems that the installation quality cannot meet the requirements of technical standards, the service life of the shaft sleeve is affected, and the quality of disassembly and assembly is difficult to control, and the structure is simple. , The effect of low production cost and strong on-site practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the technical solutions of the present invention will be described in further non-limiting detail below in conjunction with the accompanying drawings and specific embodiments.

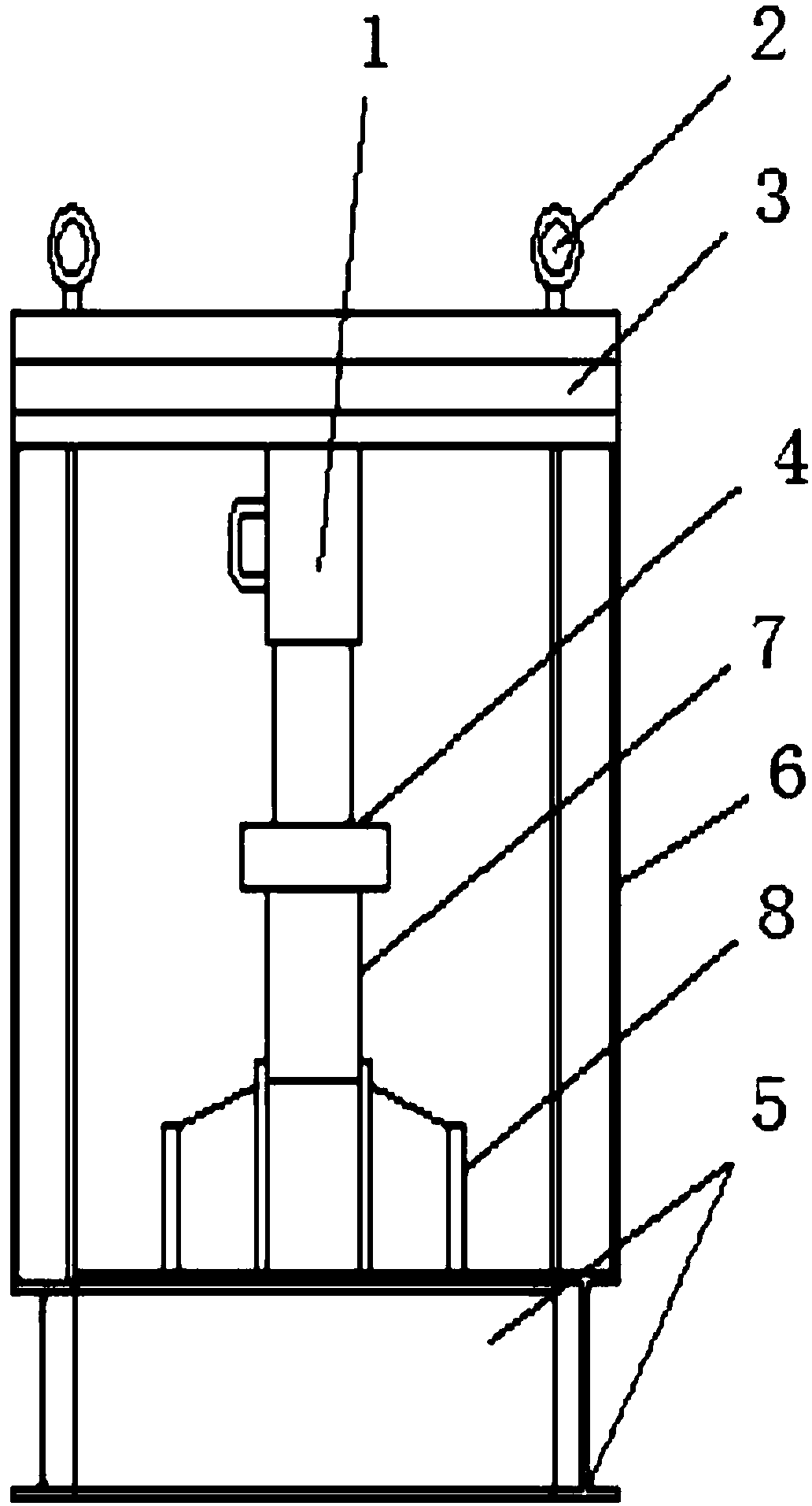

[0017] See figure 1 , the dismounting device mainly includes a support base 5, and two support rods 6 fixedly arranged on the support base 5, and a crossbeam 3 fixedly arranged above the two support rods 6, and fixedly installed on the upper end of the crossbeam 3 respectively. The two lifting lugs 2 of the part, and the jack 1, and several backing plates 4, and the top cylinder 7. Need to use top tube 7 when dismounting, needn't use top tube 7 when installing.

[0018] In this embodiment, the support seat 5 is a horizontal rectangular frame formed by tailor-welding of four I-beams of the same type and specification. The rectangular frame has a through hole (hollowed-out inner fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com