Land leveler, tray type working device thereof and traction frame and rotary frame connecting device

A technology of connecting device and working device, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of difficulty in adjusting the radial clearance and axial clearance of the slewing frame, the blade and the traction frame, and achieve simple structure, clearance Simple, low-cost effects to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

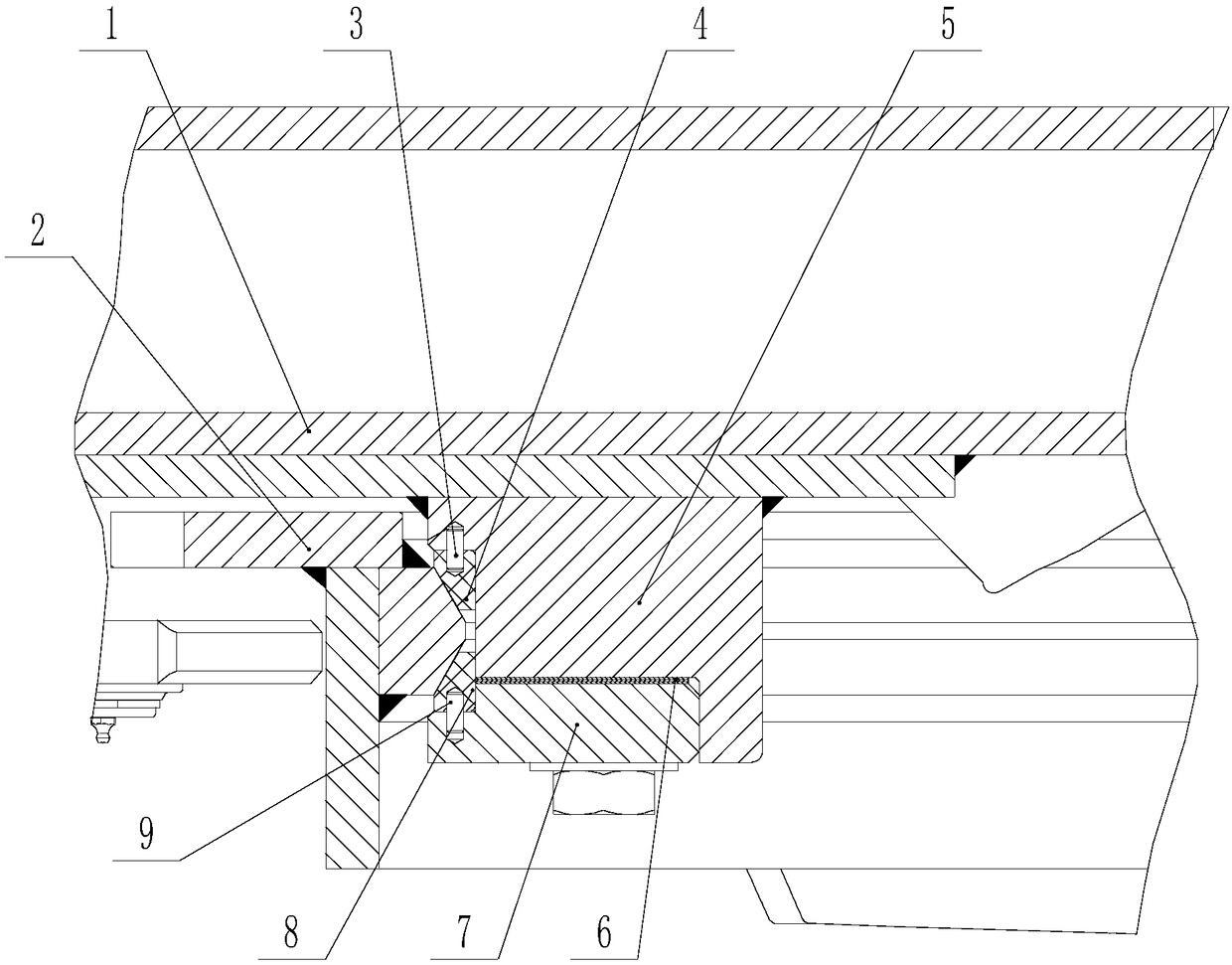

[0028] Such as Figure 1-3 As shown, a connection device between the traction frame and the slewing frame includes an upper guide plate 5, a lower guide plate 7, an upper wear plate 4 and a lower wear plate 8, the upper wear plate 4 is connected with the upper guide plate 5, The lower guide plate 7 is connected with the lower wear plate 8, the upper guide plate 5 is connected with the lower guide plate 7 and an adjusting gasket 6 is arranged between the upper guide plate 5 and the lower guide plate 7; the upper wear plate 4 The upper guide plate 5 is connected with the positioning pin I3 and the screw I11, and the lower wear plate 8 is connected with the lower guide plate 7 through the positioning pin II9 and the screw II12.

Embodiment 2

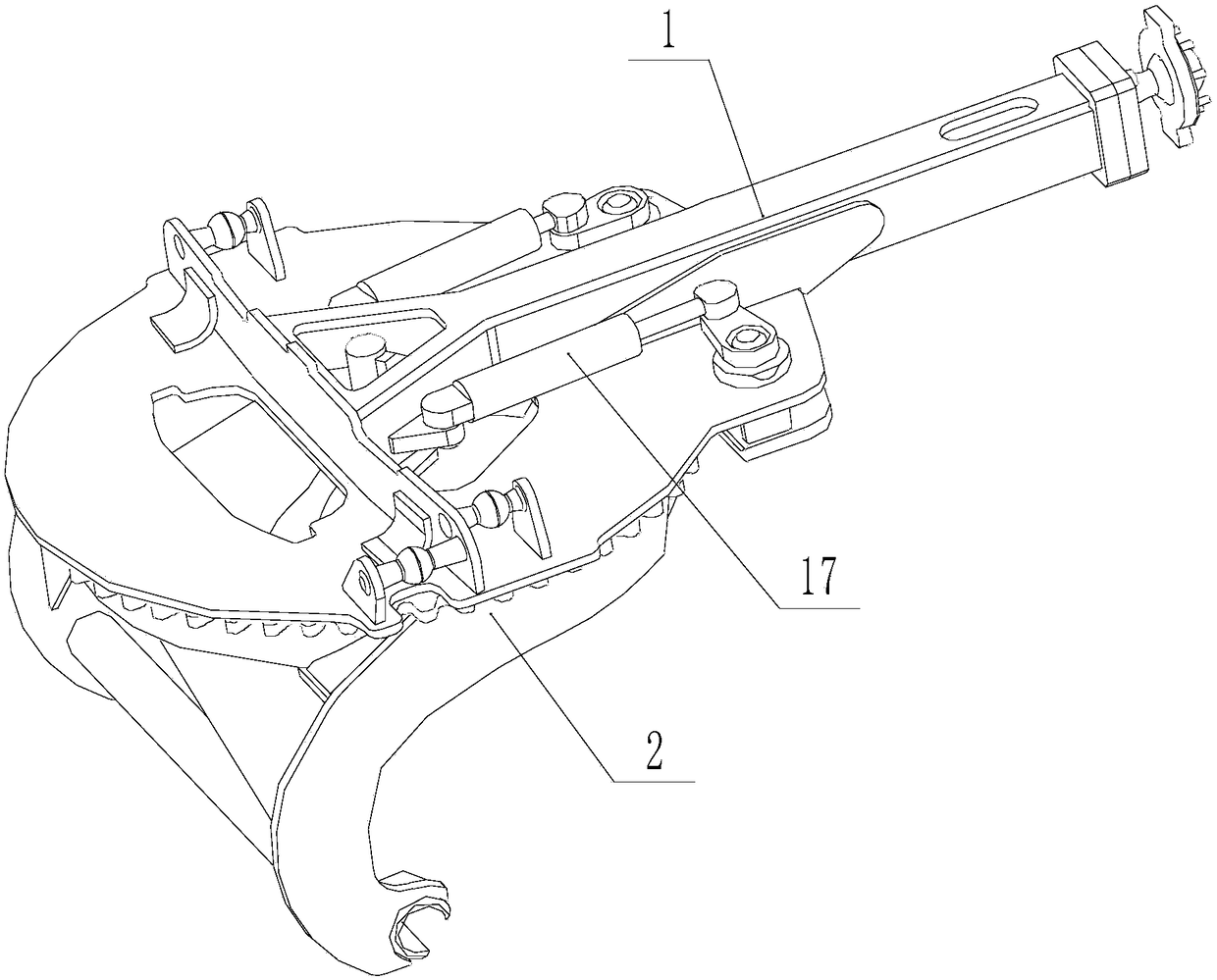

[0030] A pallet-type working device, comprising a traction frame 1, a rotary frame 2 and a rotary drive mechanism 17, the above-mentioned traction frame and rotary frame connecting device is arranged between the traction frame 1 and the rotary frame 2; the rotary frame 2 is arranged on the traction Between the frame 1 and the lower guide plate 7, the upper wear-resistant plate 4 and the lower wear-resistant plate 8 are arranged between the rotary frame 2 and the upper guide plate 5 and the lower guide plate 7; the rotary drive mechanism 17 drives the rotary frame 2 to realize the The relative rotary motion of the traction frame 1.

Embodiment 3

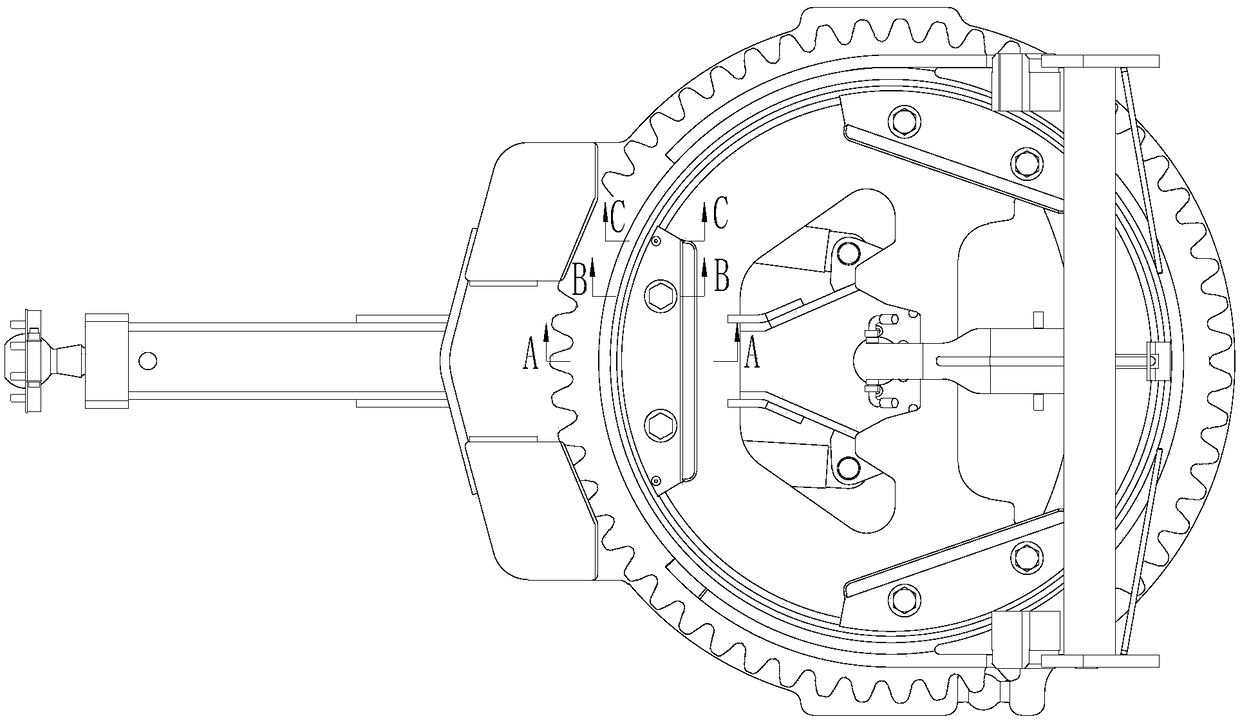

[0032] Such as Figure 3-5 As shown, a pallet-type working device, the upper guide plate 5 is welded on the traction frame 1, and the lower guide plate 7 is assembled and connected with the upper guide plate 5 through the bolt I10 and the adjusting gasket 6. Other parts are identical with embodiment 2.

[0033] Such as Figure 6 As shown, the traction frame 1 is provided with three or more upper guide plates 5, and the lower guide plate 7 is processed with several pin holes 20 for positioning, screw holes 21 for positioning and bolt holes 19 for fixed connection with the upper guide plate 5. .

[0034] In this embodiment, when installing, the lower guide plate 7 passes through the upper guide plate 5 to assemble the bolt I10. When in use, according to the requirements of the working conditions, the rotary drive mechanism 17 drives the upper and lower sliding surfaces of the inner ring of the rotary frame 2 and the upper wear plate 4 and The lower wear plate 8 relatively sli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap