Linear transport system with minimal transport spacing

A technology for transmission systems and transmission components, applied in the direction of propulsion systems, conveyors, non-mechanical conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In the drawings described below, the same reference numerals designate the same elements. For greater clarity, identical elements will only be described the first time they appear. However, it is clear that variants and embodiments of elements described with reference to one of the figures can also be applied to corresponding elements in the remaining figures.

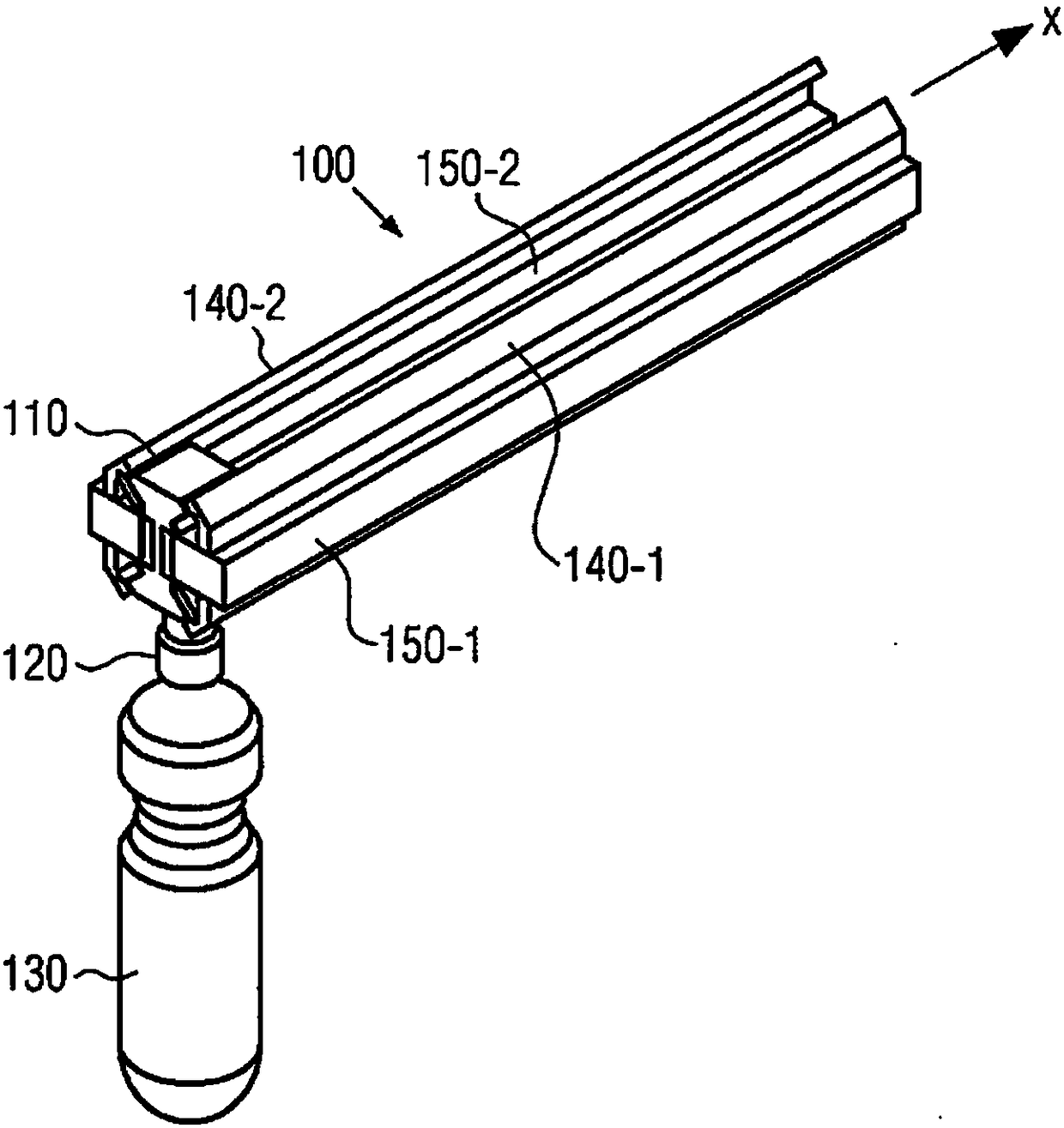

[0069] figure 1 A three-dimensional view of a linear conveyor system known from the prior art and described, for example, in DE 10 2013 218 389 A1 is shown. The illustrated linear conveyor system 100 includes a conveyor track having a first rail 140-1, a second rail 140-2, a first long stator 150-1, and a second long stator 150-2. The conveying system shown thus forms a double-rail system with linear motors on both sides.

[0070] Between the two rails, the transfer element 110 is systematically moved by means of magnetic interaction with the long stators 150-1 and 150-2. This conveying direction is indicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com