Automatic tooling for assembling buckle with fabric

A fabric, automatic technology, applied in fasteners, clothing, applications, etc., can solve the problems of low efficiency, high labor intensity, increase production costs, etc., to prevent shaking and ensure continuous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

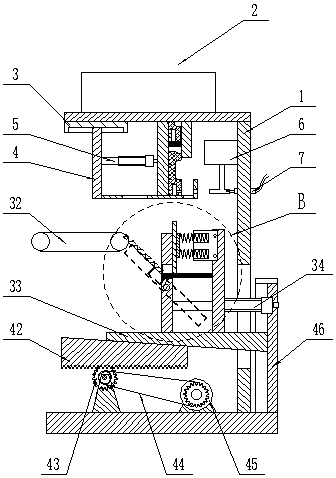

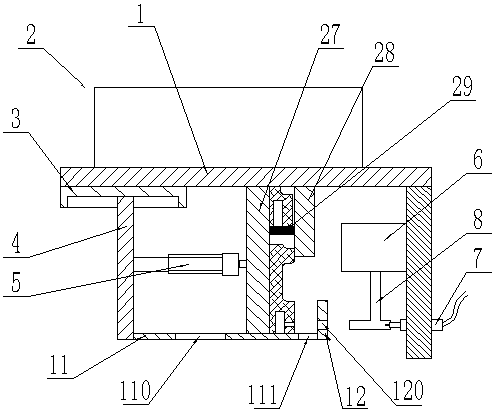

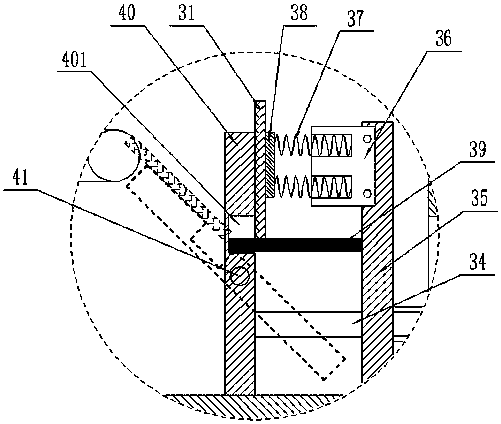

[0032] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

[0033] like Figure 1-Figure 8 As shown, the specific structure of the present invention is as follows: it is used to assemble the buckle and the cloth into a notebook connecting fastener; it includes an assembly machine 1, and the top plate of the assembly machine 1 is provided with a single material feeding tray 2 for the buckle, An inner baffle 28 and an outer baffle 27 for unloading the buckle main body 30 are provided at the opening 19 of the single-material feeding tray 2 for the buckle, and the height of the outer baffle 27 is greater than that of the inner baffle 28; The lower end surface of the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com