Plate painting device

A plate and limit plate technology, which is applied in the field of plate processing, can solve the problems of spraying paint, affecting the quality of spraying paint on irregular plates, and wasting paint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is further described in detail by specific embodiments:

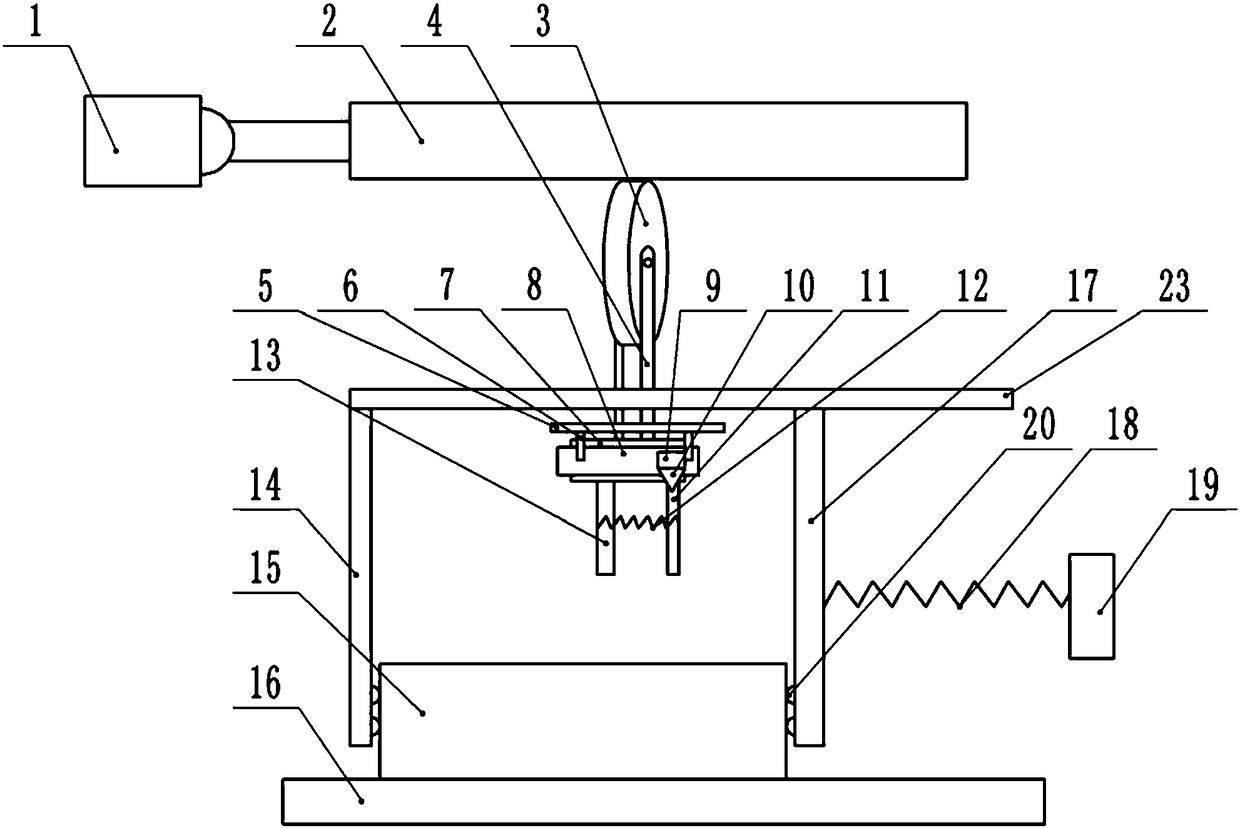

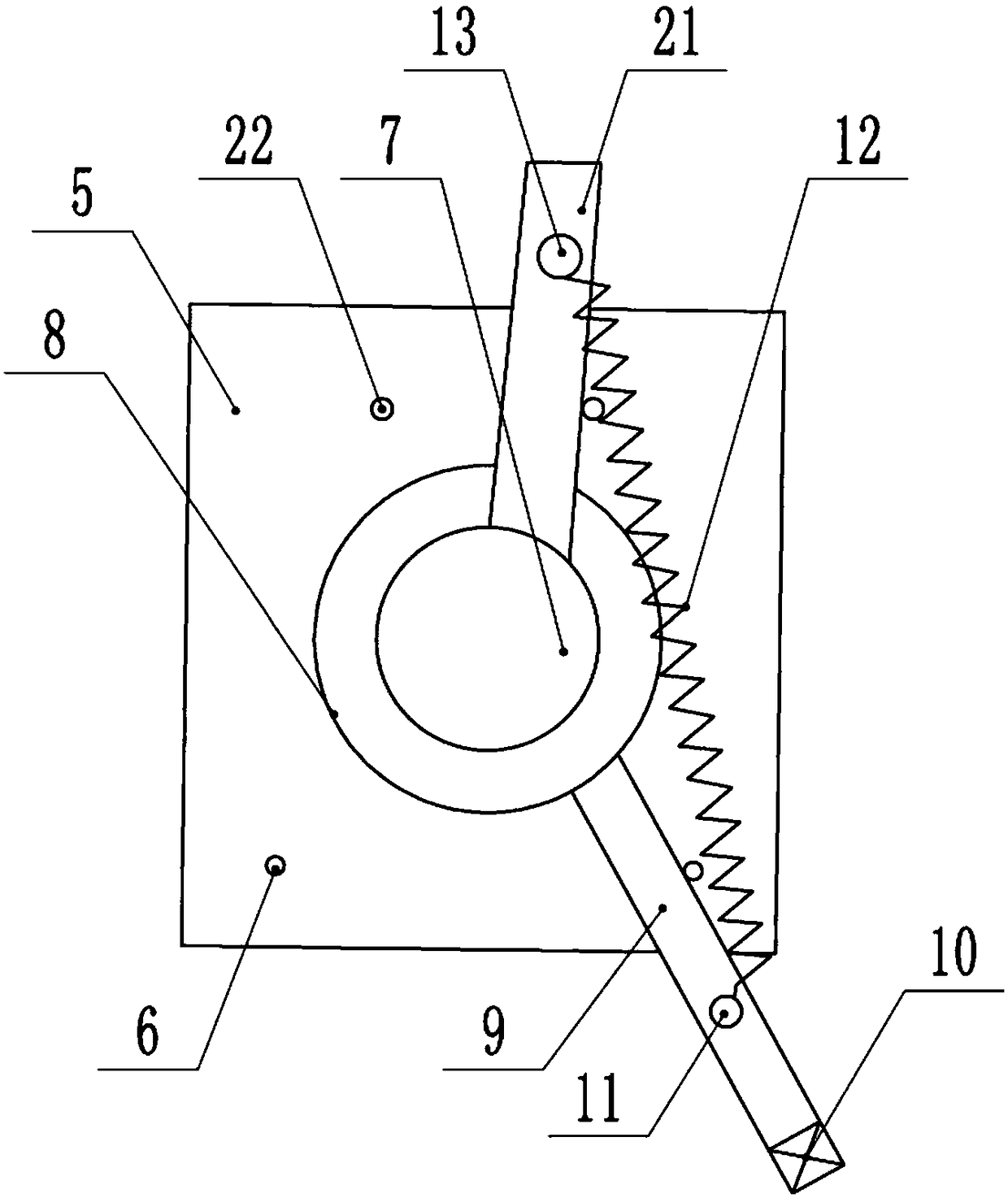

[0015] Reference numerals in the accompanying drawings include: motor 1, driving roller 2, roller 3, bracket 4, fixing plate 5, front limit post 6, rotating disk 7, rotating ring 8, active rod 9, spray head 10, first Vertical rod 11, tension spring 12, second vertical rod 13, fixed limit plate 14, plate 15, placement mechanism 16, sliding limit plate 17, spring 18, fixed block 19, ball 20, driven rod 21, rear limit Position post 22 and slide rail 23 .

[0016] The example is basically as attached Figure 1-Figure 2 Shown: a sheet painting device, including a frame, a placement mechanism 16 is arranged on the frame, the placement mechanism 16 includes a placement rack and a number of conveying rollers, the two ends of the conveying rollers are respectively connected to the placement rack, and the placement mechanism 16 A plate 15 is placed thereon. A slide rail 23 is provided above the placement m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com