A plate spraying device

A technology for plates and limit plates, applied in the field of plate processing, can solve the problems of paint waste, affecting the painting quality of irregular plates, spraying to paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

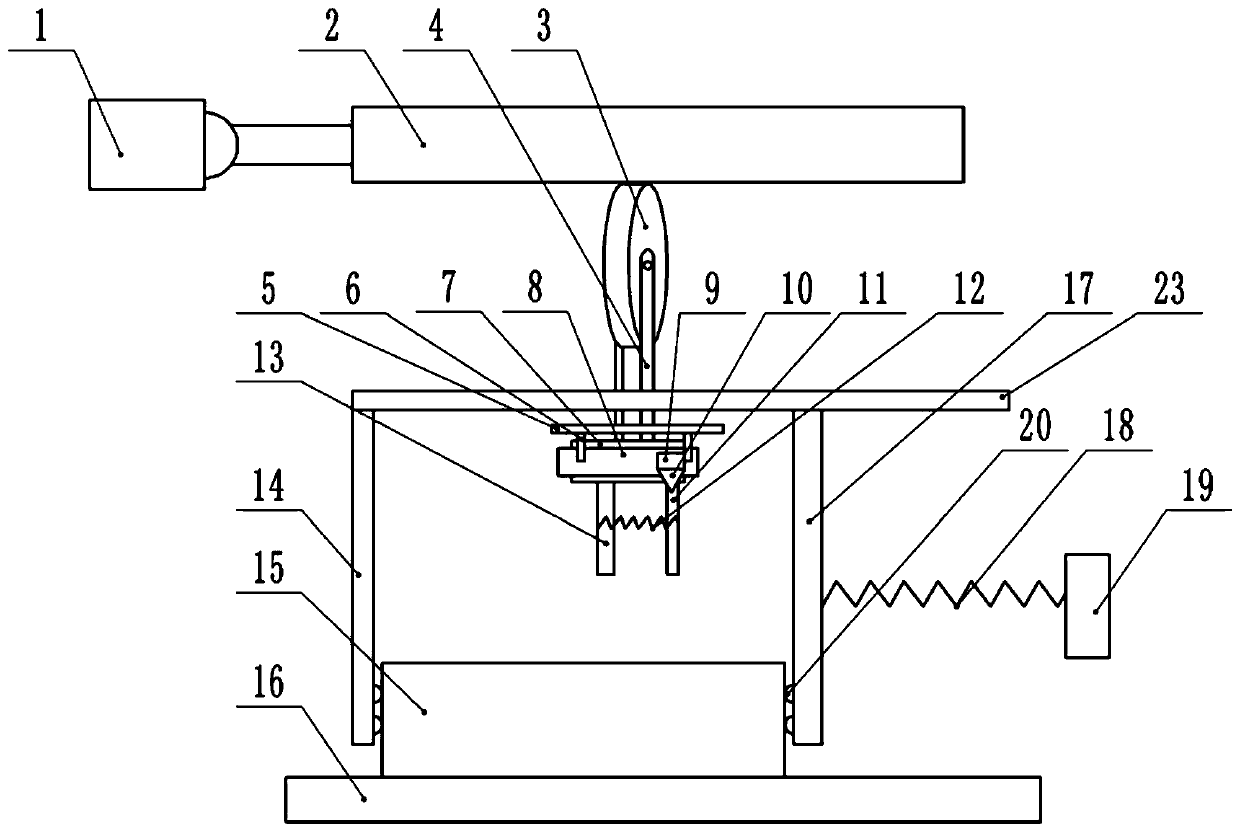

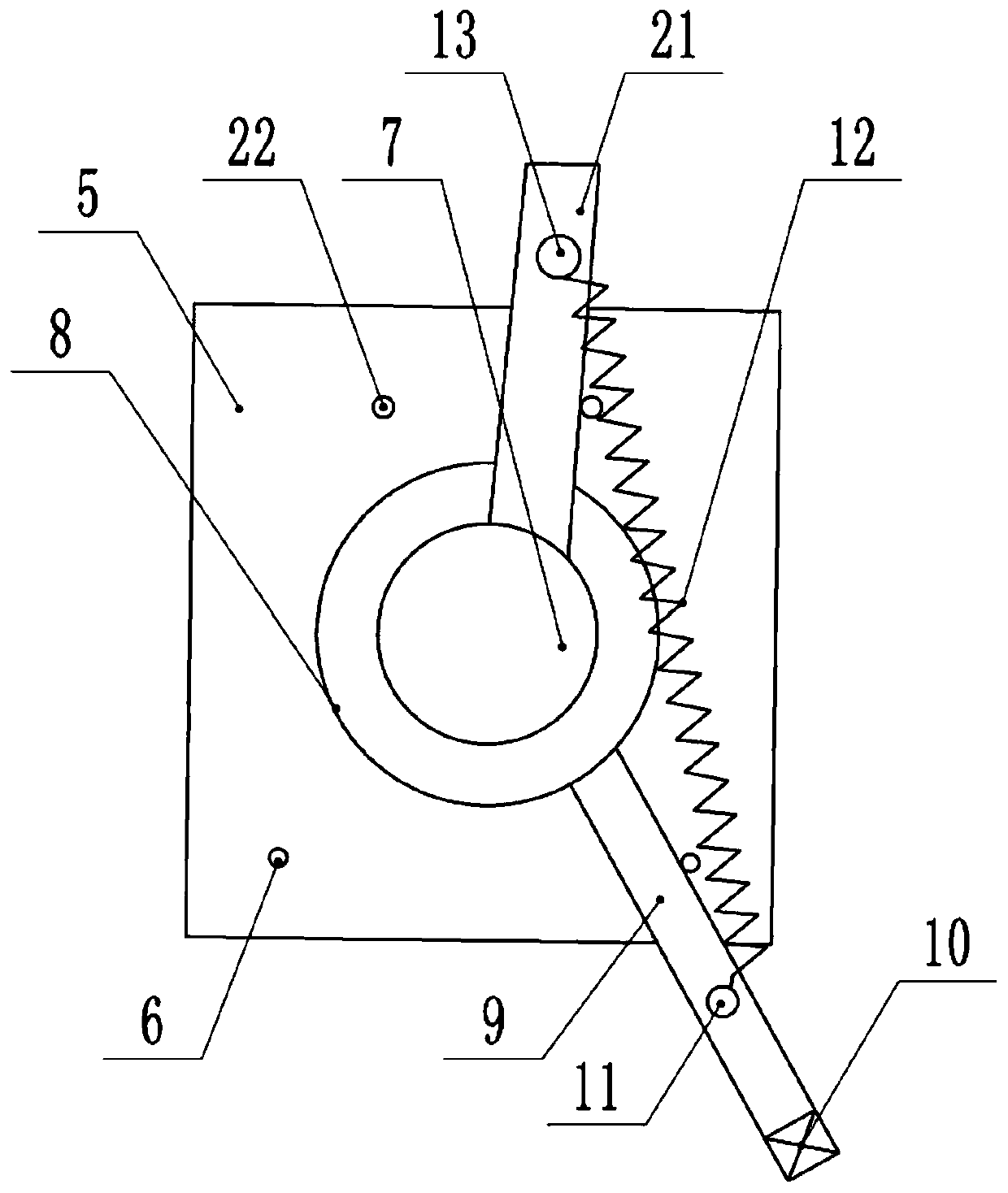

[0014] The following is further described in detail through specific implementation methods:

[0015] The reference signs in the accompanying drawings of the specification include: motor 1, driving roller 2, roller 3, bracket 4, fixed plate 5, front limit post 6, rotating disc 7, rotating ring 8, active rod 9, nozzle 10, first Vertical rod 11, tension spring 12, second vertical rod 13, fixed limit plate 14, plate 15, placement mechanism 16, sliding limit plate 17, spring 18, fixed block 19, ball 20, driven rod 21, rear limit Position column 22, slide rail 23.

[0016] The embodiment is basically as attached Figure 1-Figure 2 Shown: a plate painting device, including a frame, the frame is provided with a placement mechanism 16, the placement mechanism 16 includes a placement frame and a number of transmission rollers, and the two ends of the transmission rollers are respectively rotatably connected to the placement frame, and the placement mechanism 16 A plate 15 is placed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com