Automatic paint spraying equipment for door handle

An automatic painting and door handle technology, applied in the direction of spraying devices, etc., can solve the problems of low painting efficiency, complicated operation, limited height adjustment of automatic painting mechanism, etc., and achieve the effect of high painting efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

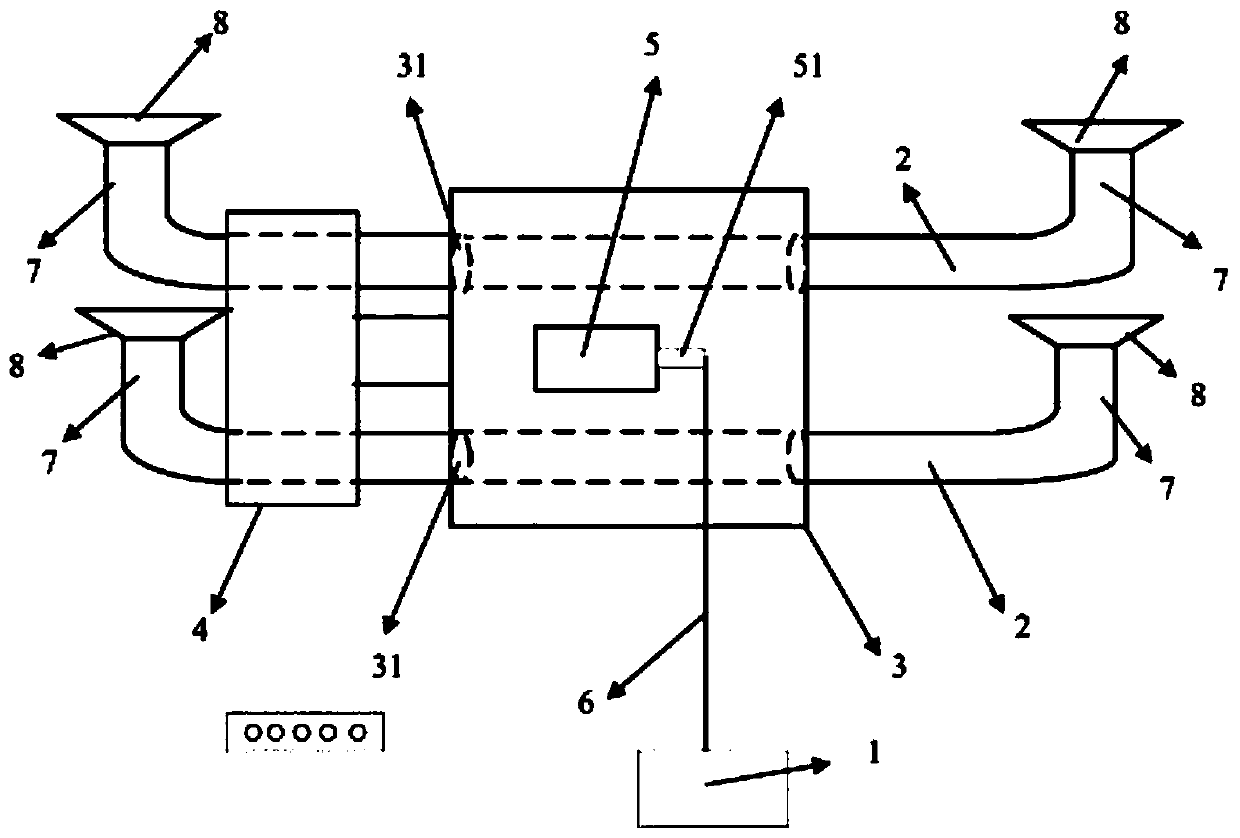

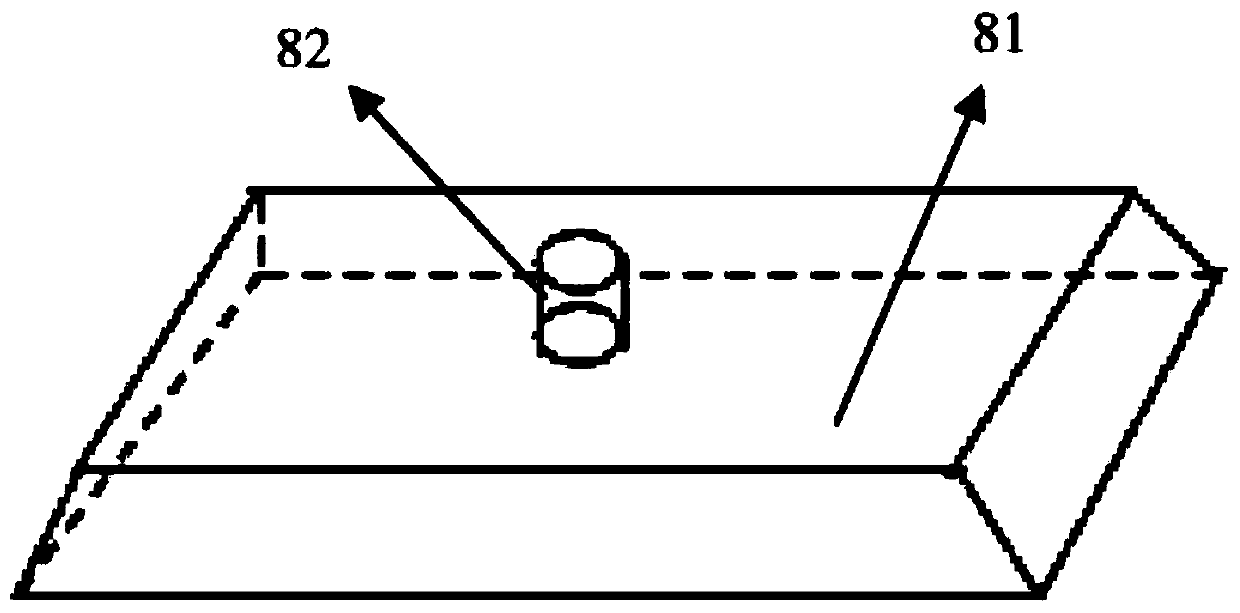

[0014] Embodiment: A kind of automatic painting equipment for door handles, including automatic painting mechanism 1, automatic painting device also includes at least one retractable installation rod 2, sliding seat 3 arranged on at least one installation rod 2, for driving sliding The seat 3 moves linearly along at least one mounting rod 2 and the motor 5 installed on the sliding seat 3. The linear driving mechanism 4 is installed on the left end or the right end of at least one mounting rod 2. The rotating shaft 51 of the motor 5 A metal wire 6 is fixedly arranged on the top, and the automatic painting mechanism 1 is hoisted on the metal wire 6. A connection seat 7 perpendicular to the installation rod 2 is respectively provided at both ends of the installation rod 2, and a vacuum adsorption mechanism 8 is provided on the connection seat 7.

[0015] In this embodiment, the number of installation rods 2 is two, and the two installation rods 2 are arranged in parallel and space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com