A production line for wood processing

A production line and wood board technology, applied in metal processing equipment, machine tools suitable for grinding workpiece planes, manufacturing tools, etc., can solve the problems of low efficiency and labor consumption, and achieve the effect of ensuring quality, improving efficiency and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

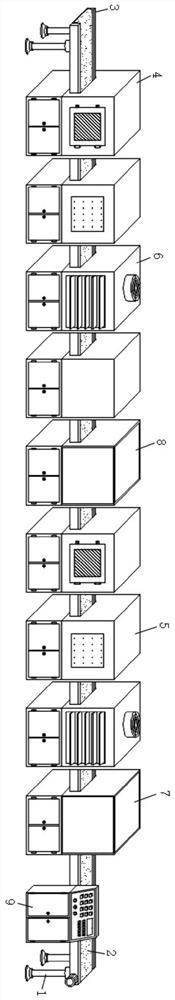

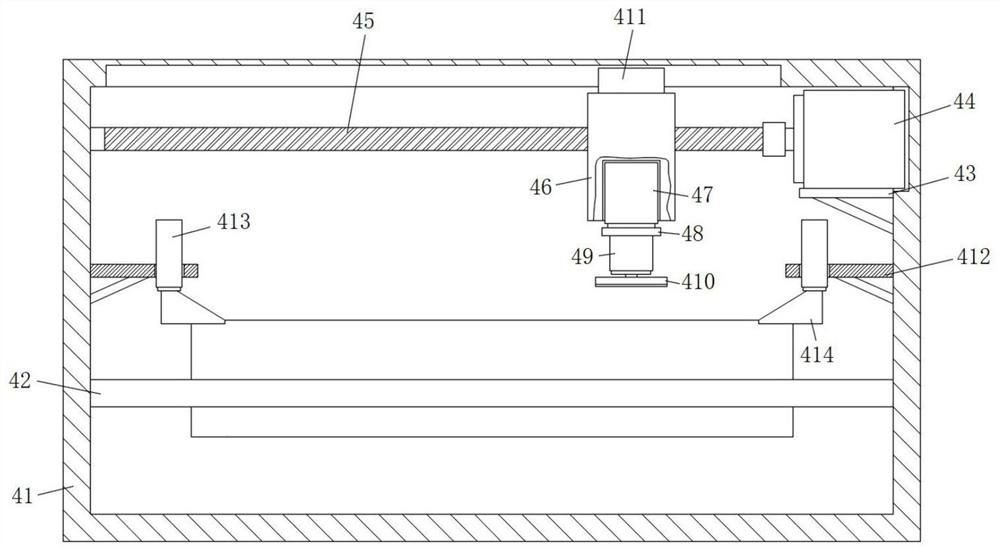

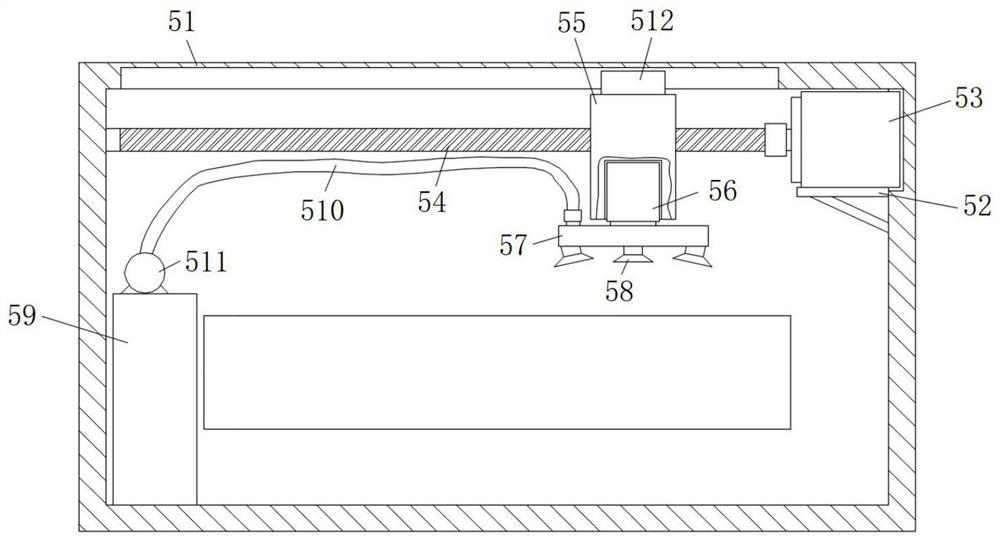

[0031] refer to Figure 1-7, a production line for wood board processing, including support bases 1, four support bases 1 are arranged and fixed on the working surface in a rectangular shape, conveyor belts 2 are installed on the upper ends of the four support bases 1, and the front and rear sides of the conveyor belts 2 are provided with There are baffles 3, and the two sides of the conveyor belt 2 are respectively provided with wood processing devices. The wood processing devices include a polishing mechanism 4, a painting mechanism 5, an air drying mechanism 6 and a detection mechanism 7. The polishing mechanism 4 includes a polishing box 41, and the front and rear of the polishing box 41 The side inner wall is fixedly connected with abutment plate 42, and the upper part of the front side wall of the polishing box body 41 is also fixedly connected with mounting frame 1 43, and the top surface of mounting frame 1 43 is fixedly connected with servo motor 1 44 by screws, and th...

Embodiment 2

[0034] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, both sides of the baffle plate 3 are fixed at the top of the support base 1 .

[0035] The top surface of the butt plate 42 is attached to the underside of the upper belt surface of the conveyor belt 2 .

[0036] In this embodiment, the top surface of the abutment plate 42 is attached to the lower side of the upper surface of the conveyor belt 2, so that the plate is more stable during grinding, and provides a certain guarantee for the high-quality production of the plate.

Embodiment 3

[0038] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are three spray heads 58 and they are evenly installed on the bottom surface of the hollow dish 57, and the spray heads 58 on both sides are all inclined from the outside of the hollow dish 57 to the inside of the hollow dish 57. .

[0039] In this embodiment, the spray heads 58 on both sides are arranged inclined from the outer side of the hollow dish 57 to the inner side of the hollow dish 57, so as to realize the spraying on the side of the plate, thereby ensuring the quality of the spraying on the plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com