Integrated bristle production equipment

A technology for production equipment and bristles, which is applied in the field of integrated production equipment for bristles, can solve problems such as low efficiency and manpower consumption, and achieve the effects of ensuring efficiency, high work efficiency, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

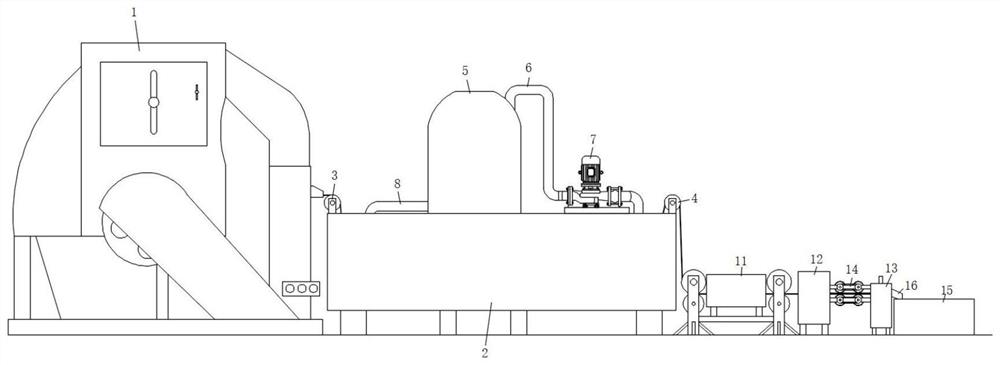

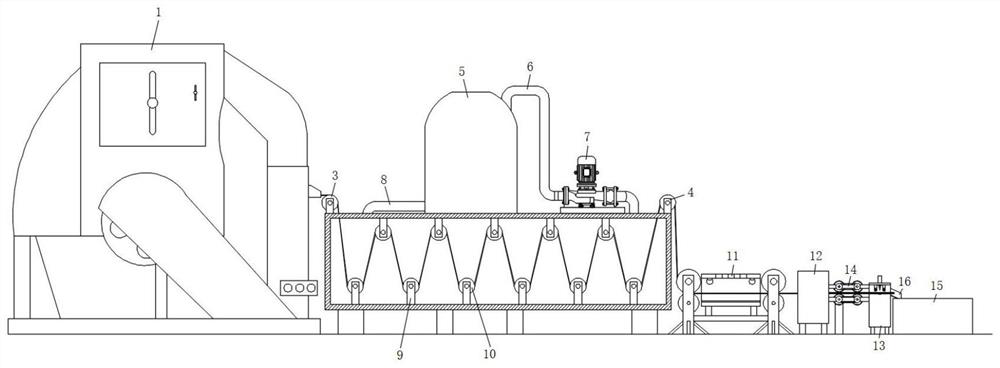

[0033] refer to Figure 1-6, an integrated production equipment for brush hairs, comprising a wire drawing machine 1 and a condensing box body 2, mounting seats-3 are fixed on both sides of the top surface of the condensing box body 2, and two mounting seats-3 on the same side are rotatably connected The reversing roller 4, a liquid condenser 5 is also arranged on the rear side of the condensation box 2, the input end of the liquid condenser 5 is connected with the top side of the condensation box 2, and a suction pipe 6 is connected, and a water pump 7 is also installed on the suction pipe 6 , the top side of the condensing box 2 is also connected with the water inlet pipe 8 on the other side of the top surface of the condensing box 2, and the inner bottom surface and the top surface of the condensing box 2 are also fixed with a mounting seat 2 9, two mounting seats 9 in the same group There are guide rollers 10 connected in rotation between them, and the bristles are wound b...

Embodiment 2

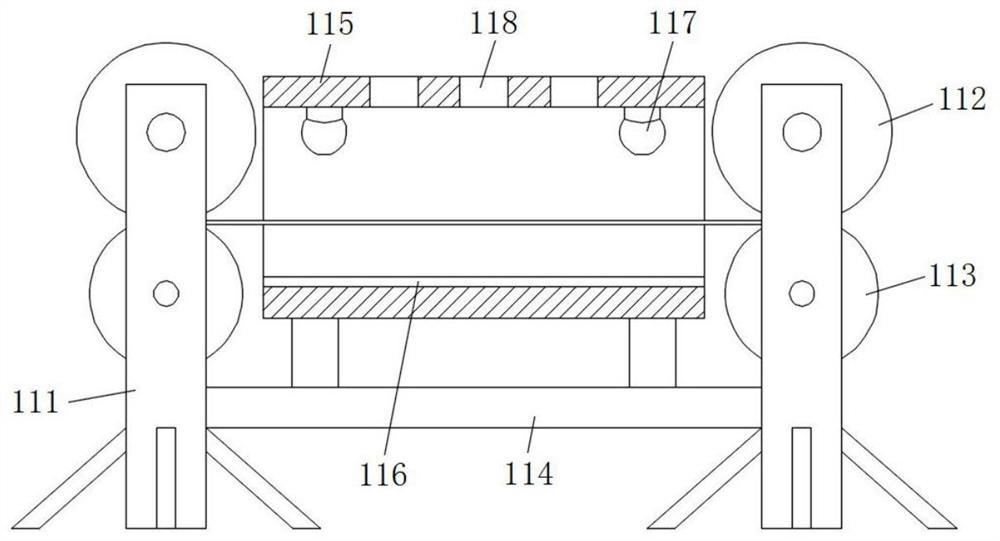

[0035] Such as figure 1 , 2 As shown in and 6, the present embodiment is basically the same as Embodiment 1. Preferably, the traction mechanism 14 includes two installation bars 141, and the upper and lower ends of the four installation bars two 141 sides are rotatably connected with installation rods 142, and the two installation bars 141 The outer walls are all fixedly connected with transmission rollers 143 by screws, the front sides of the two transmission rollers 143 at the upper and lower ends pass through the installation strip 141 and are rotatably connected by the conveyor belt 144, and the rear sides of the two transmission rollers 143 on the same side also pass through the installation strip two. 141 and is connected through the rotation of gear set 145, and one side of the rear end of the installation bar two 141 is also provided with a support seat 146, and the top surface of the support seat 146 is fixedly connected with a servo motor 147 by screws, and the outpu...

Embodiment 3

[0039] Such as figure 1 , 2 As shown in and 5, this embodiment is basically the same as Embodiment 1. Preferably, both sides of the top surface of the cutting hole 132 are fixed with electric telescopic rods 136 by screws, and the output ends of the electric telescopic rods 136 are all connected with U by screws. Shaped frame 137, U-shaped frame 137 front and back side inner walls are rotatably connected with pressure roller 138.

[0040] In this embodiment, when cutting, the electric telescopic rod 136 drives the electric telescopic rod 136 to move down so that the pressure roller 138 and the bristles are lifted together, thereby realizing the limit and fixing of both sides of the cut bristles, and then providing a certain amount for the stable cutting of the bristles. protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com