Positioning press fitting mechanism of compressor shell bearing automatic press fitting machine

A compressor shell and press-fitting machine technology, which is applied in the field of appliances, can solve the problems of affecting the service life of the compressor, insufficient cooperation between bearings and bearing sleeves, and achieve the effects of ensuring service life, improving production efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

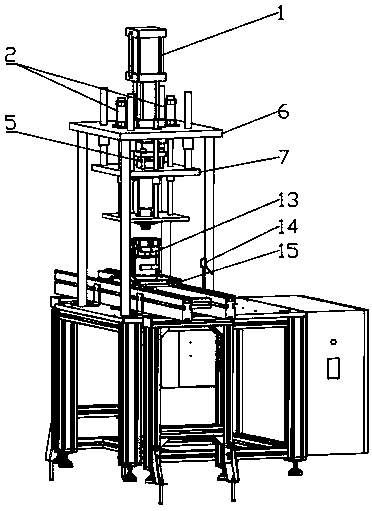

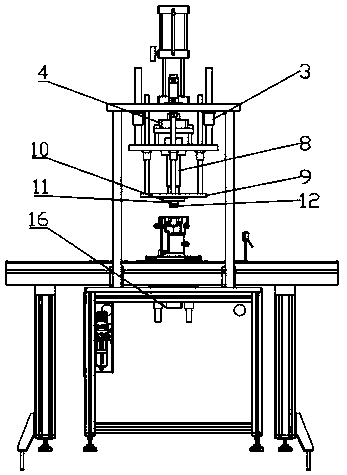

[0011] Combine below figure 1 and figure 2 Specifically describe the embodiment:

[0012] The automatic press-fitting point-printing equipment for the shell bearing of an air conditioner compressor includes a bracket, characterized in that the bracket is provided with a working position slide rail and a fixed seat, the working position slide rail is slidably provided with a tray, and the fixed seat is provided with a tray. The lower part is provided with a photoelectric sensor. When the air conditioner compressor casing is placed on the tray and slid to the station, the photoelectric sensor detects that the bottom of the tray is provided with a lifting cylinder; the top of the fixed seat is provided with There are a positioning cylinder and an oil booster cylinder, the output end of the positioning cylinder is connected with a limit plate, and a guide sleeve for positioning the upper surface of the cylinder port of the air conditioner compressor shell is arranged at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com