Mold capable of being intelligently controlled

An intelligent control and mold technology, applied in the field of mold manufacturing, can solve problems such as the influence of thread fit, the influence of precision degree on equipment operation accuracy and transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

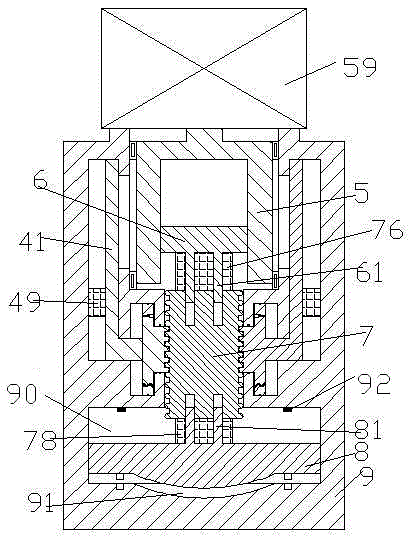

[0011] Combine below Figure 1-3 Embodiments of the present invention will be described.

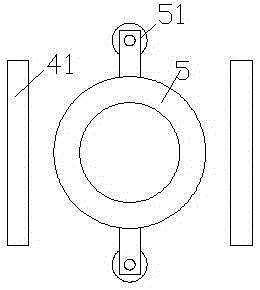

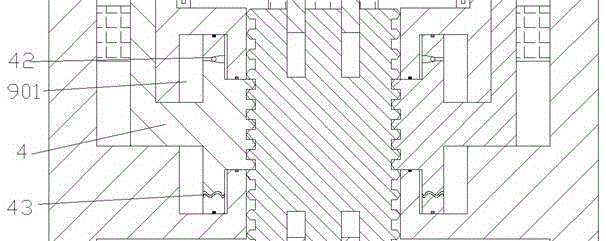

[0012] refer to Figure 1-3 , the intelligently controlled mold according to the embodiment includes a frame 9, which is opposite to a die 91 arranged at the bottom of the frame 9 and is fixed circumferentially and axially in the bottom cavity 90 of the frame 9 The upper movable punch 8 and the connecting bearing column 7, the lower end of the connecting bearing column 7 is connected with the movable punch 8 through the lower elastic connector 78, and the movable punch 8 is connected to the The upper surface is fixedly arranged and slidably extends into a plurality of punch extensions 81 in the connecting bearing column 7 to be fixed with the connecting bearing column 7 in the circumferential direction; the upper end of the connecting bearing column 7 is connected by the upper elastic 76 and is connected with the threaded block 6 that is threadedly fitted in the threaded sleeve 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com