Vacuum pumping system with glass cover

A technology of vacuum system and glass bell jar, which is applied in the field of vacuum system, can solve the problems of poor observation, achieve the effect of low cost, reduce the number of interface requirements, and reduce the volume requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

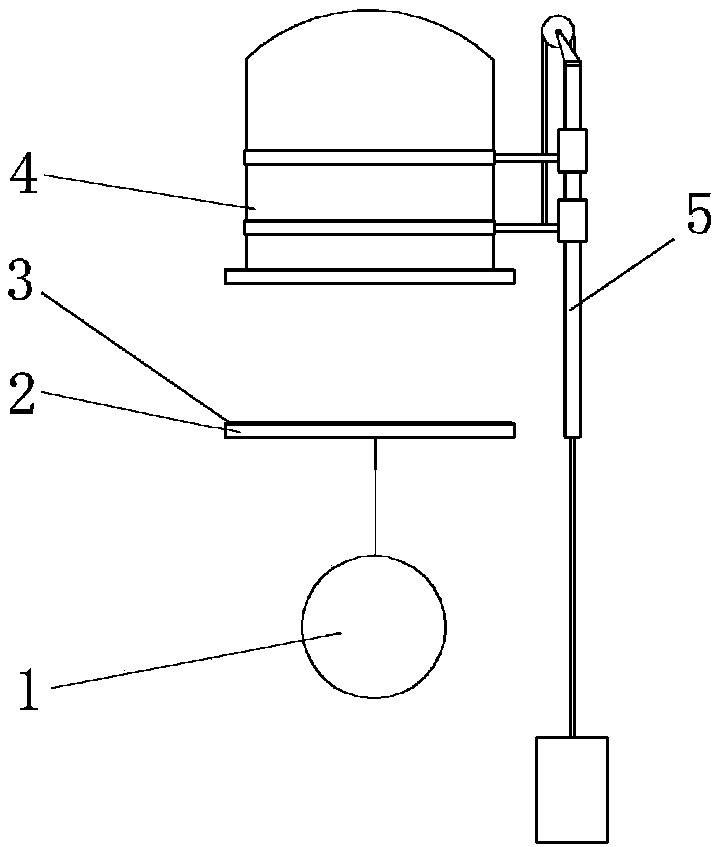

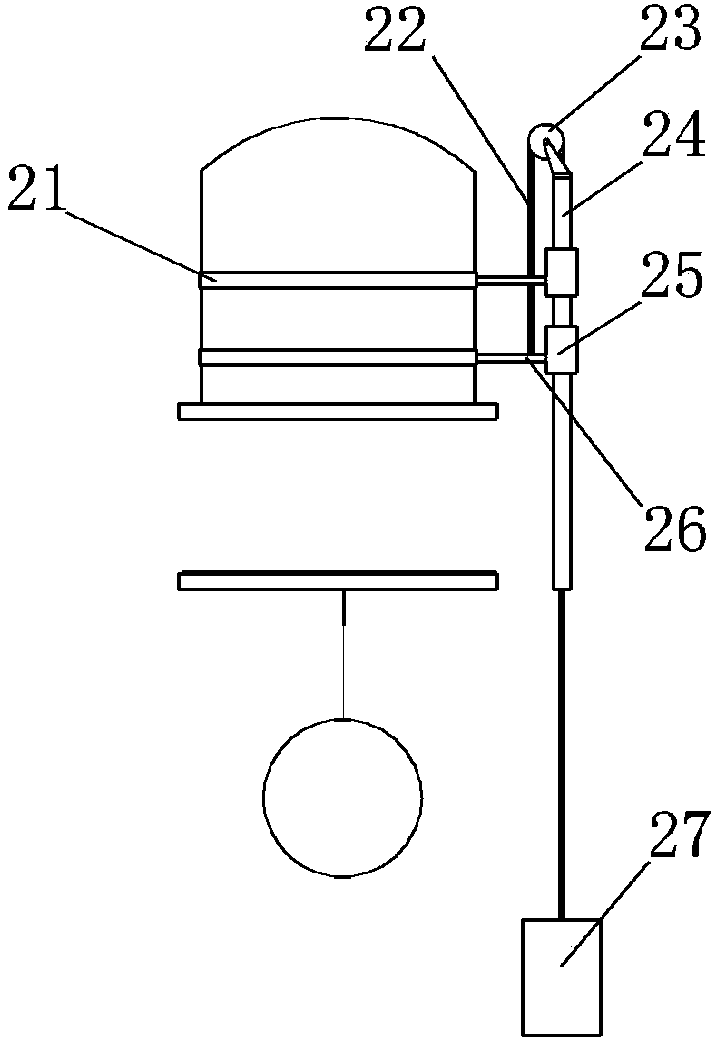

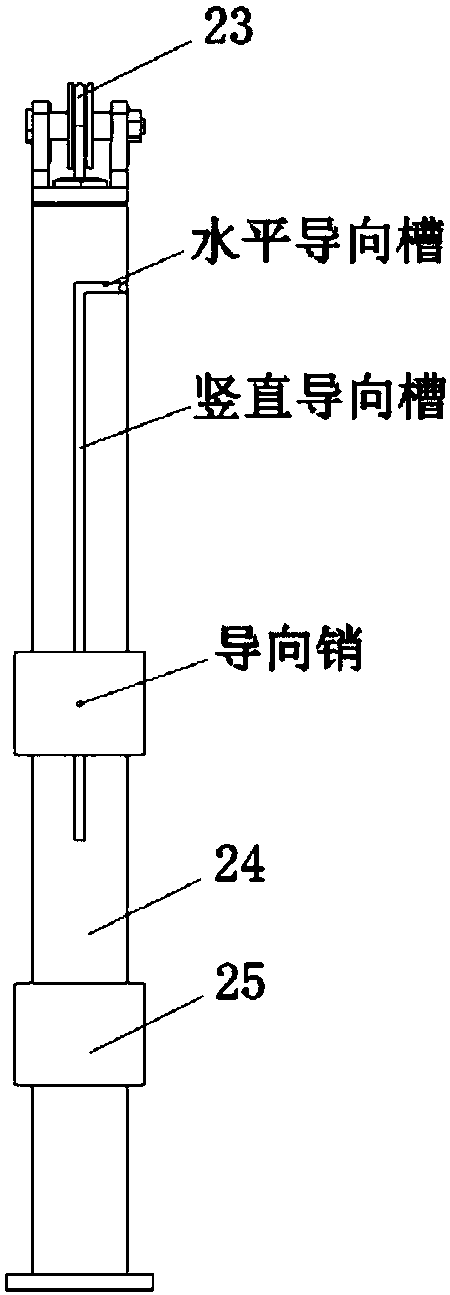

[0032] The vacuum pumping system consists of an air-cooled molecular pump, a vortex dry pump, a manual flapper valve, a solenoid valve, a hot cathode ionization gauge, a resistance gauge and a pumping pipeline. The pumping speed of the molecular pump is 300L / s, the pumping speed of the scroll dry pump is 3L / s, the diameter of the manual slide valve is DN100mm, and the diameter of the solenoid valve is DN25mm. The no-load limit pressure of the vacuum pumping system can reach 10 -5 Pa.

[0033] The connecting flange is made of stainless steel, and the size is: Φ445mm×20mm. The upper surface of the flange is used to seal with the glass bell jar and install the test piece, and the sealing groove and threaded hole are processed on the upper surface. The lower surface of the flange is provided with a CF100mm vacuum pumping interface, a CF35mm ionization gauge interface, and a KF16mm resistance gauge interface.

[0034] O-ring, made of fluorine rubber, size: Φ400mm×8mm, installed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap