Wave-compensating marine A-type gate crane foundation

A wave compensation, marine technology, applied in the direction of hoisting equipment braking devices, cranes, hoisting devices, etc., can solve the problems of inability to meet production work requirements, increase system load, and obvious hysteresis, and achieve functional integration and device structure Reliable, simple-in-principle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

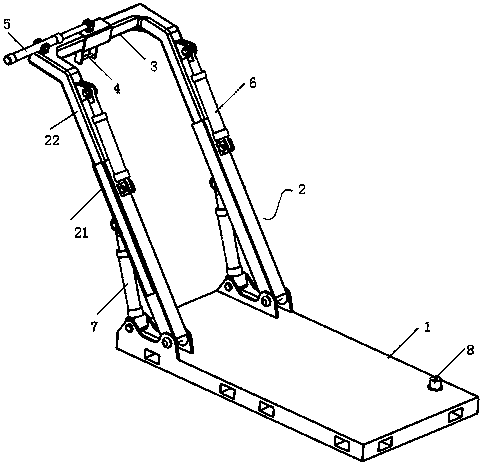

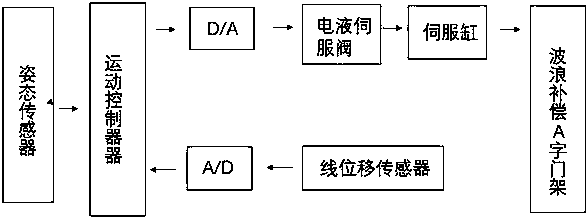

[0028] In this embodiment, the A-type gantry base for wave compensation ships is a four-degree-of-freedom A-shaped gantry for wave compensation ships. 3.

[0029] A telescopic frame 2 is arranged on the upper surface of one end of the base 1 , and an attitude sensor 8 is also arranged on the upper surface of the base 1 .

[0030] The telescopic frame 2 includes a swing frame 21 that is hinged with the base 1 and symmetrically arranged on both sides of the base 1, and the swing frame 21 can rotate around a plane, and the inner cavity of the other end of the swing frame 21 is sleeved with a movable frame 22; 3 is fixedly connected with the movable frame 22 at the end far away from the swing frame 21, and the crossbeam 3 is slidably sleeved with a connector hanger 4, and the connector hanger 4 is fixedly connected with a driving connector hanger 4 for lateral movement along the beam 3 Beam servo hydraulic cylinder 5 with linear displacement sensor.

[0031] The A-type gantry ba...

Embodiment 2

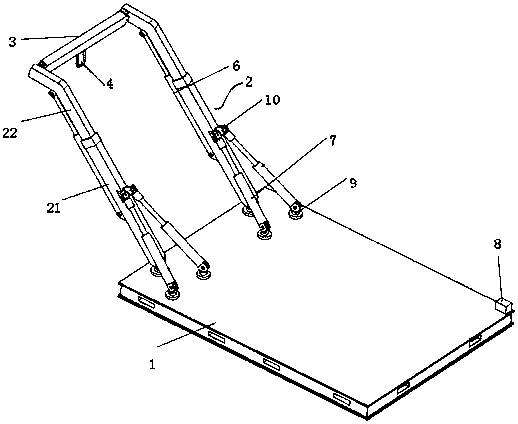

[0037] In this embodiment, the base of the A-type gantry for a wave compensation ship is an A-shaped gantry for a five-degree-of-freedom wave compensation ship, and the base of the A-type gantry for a wave compensation ship is arranged on the side of the hull; image 3 As shown, it includes a base 1, a telescopic frame 2 and a beam 3.

[0038] On both sides of the upper surface of one end of the base 1 are symmetrically distributed rotary pin groups, each rotary pin group includes three triangularly distributed rotary pins 9 , and the upper surface of the base 1 is also provided with an attitude sensor 8 .

[0039] The telescopic frame 2 includes a swing frame 21 symmetrically arranged on both sides of the base 1, and the swing pin 9 at the top angle in the swing pin group of the swing frame 21 is hinged, and the inner cavity of the other end of the swing frame 21 is sleeved with a movable frame 22; The two ends of 3 are connected to the movable frame 22 at the end far away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com