A jacking device for a crane

A technology of jacking devices and cranes, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of long construction period, increased construction difficulty and risk, stop construction on site, etc., and achieve easy on-site adjustment, time saving and economic cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

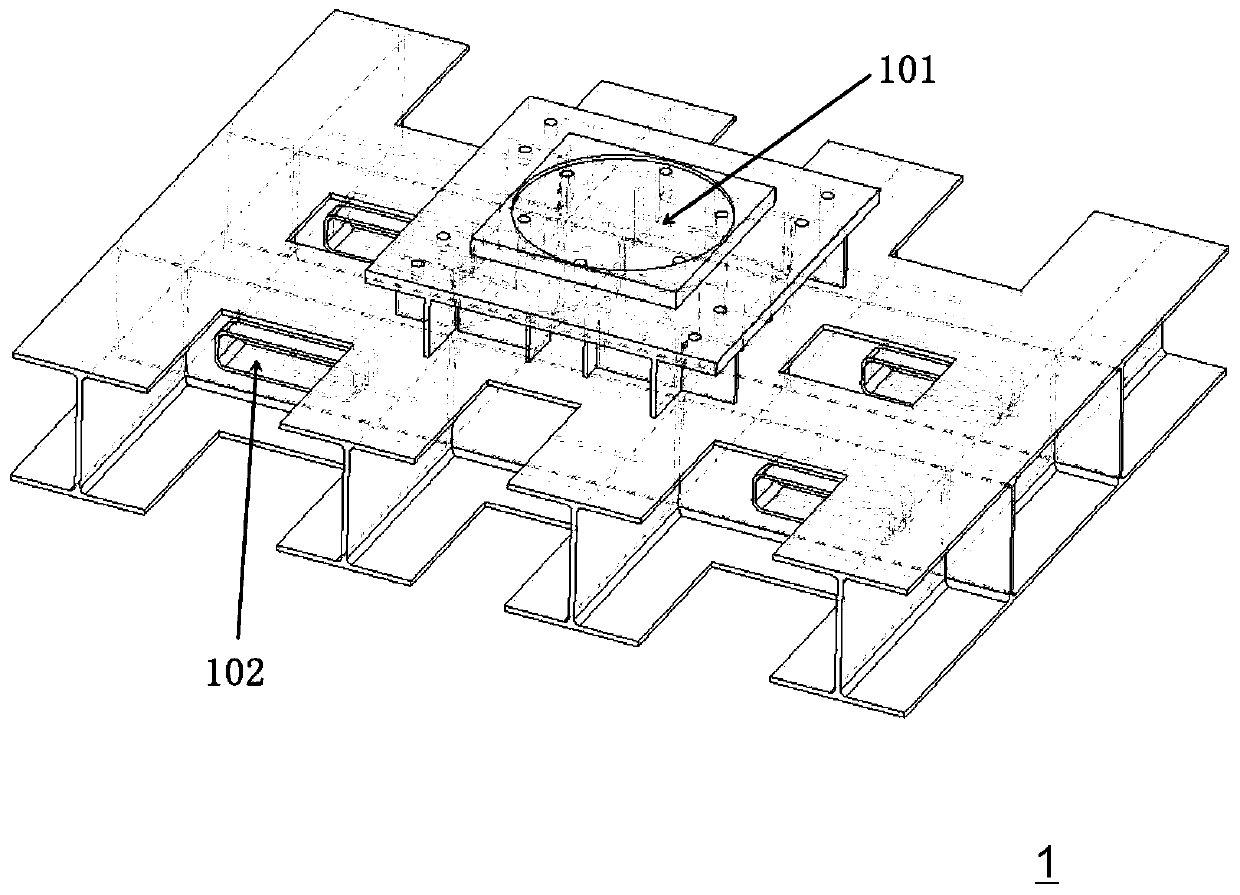

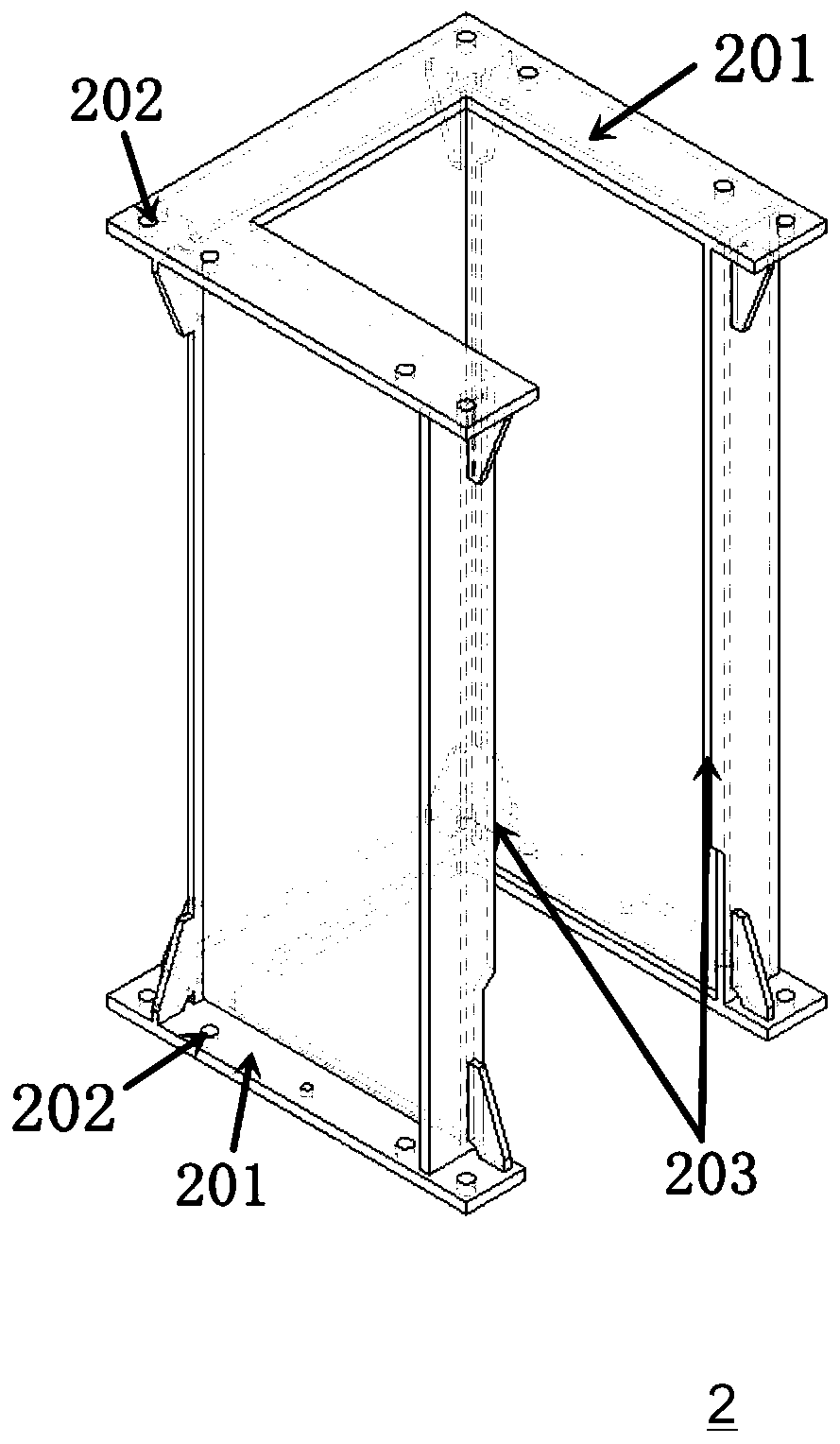

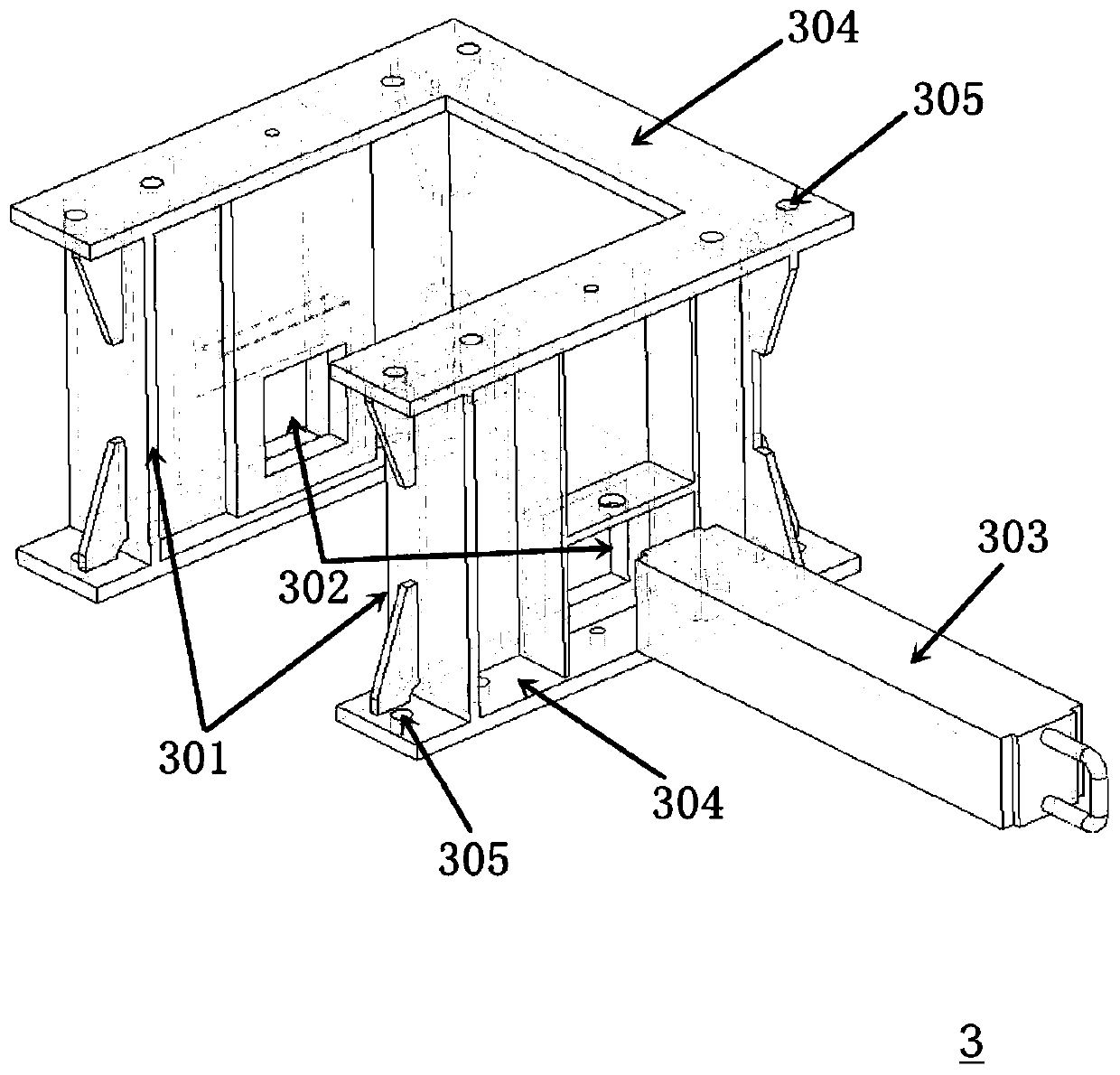

[0033] Please combine Figure 1 to Figure 6 As shown, a jacking device for a crane provided by the present invention includes: a jacking assembly 4, the jacking assembly 4 is arranged in a rectangular frame structure, and the four right-angled positions of the rectangular frame structure are connected successively below There are heightening short column 3, fixed column 2 and base 1, and heightening short column 3 can be connected several.

[0034] Preferably, the jacking assembly 4 includes: jacking beams 402, jacking columns 401, long connecting rods 405 and short connecting rods 406 connected with each other by high-strength bolts, and there are four jacking beams 402, located at Four right-angle positions of the rectangular frame structure, each jacking beam 402 is connected longitudinally by a long connecting rod 405 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com