Composite ballast bed with adjustable vibration damping and vibration isolation bandwidth and manufacturing method thereof

A technology of vibration reduction and vibration isolation and compound road, which is applied in the direction of roads, tracks, ballast layers, etc., can solve the problems of limited service life, difficulty in achieving vibration reduction and vibration isolation effects, and high price, and achieve the effect of reducing additional vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

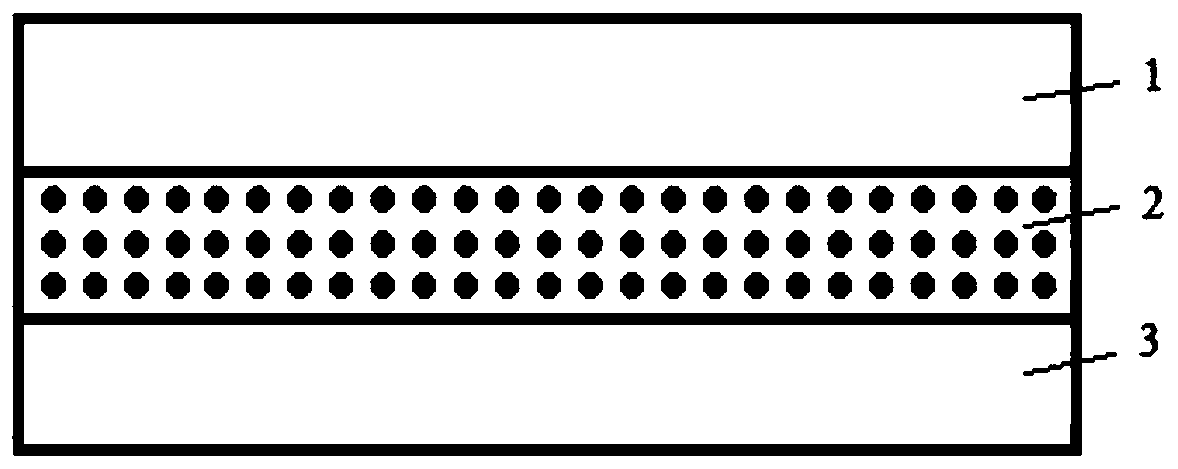

[0018] refer to figure 1 As shown, the composite ballast bed with adjustable vibration damping and vibration isolation bandwidth has a three-layer structure, in which the first layer is an ordinary concrete layer with a strength of C35-40MPa and a thickness of h1;

[0019] The second layer (middle layer) is a lightweight concrete layer with a strength of C35-40MPa and a thickness of h2;

[0020] The third layer (lower layer) is an ordinary concrete layer with a strength of C35-40MPa and a thickness of h3; the total thickness of the three layers is fixed at 30cm, namely h1+h2+h3=30cm.

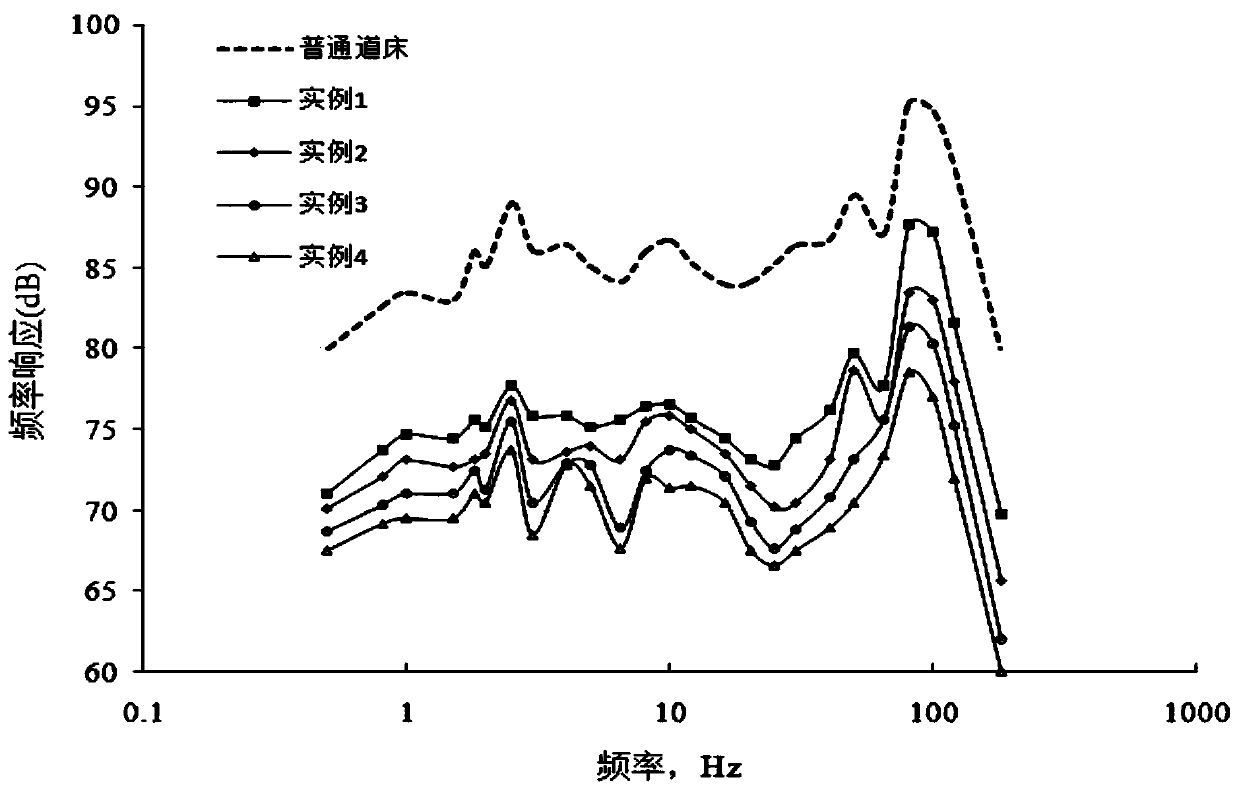

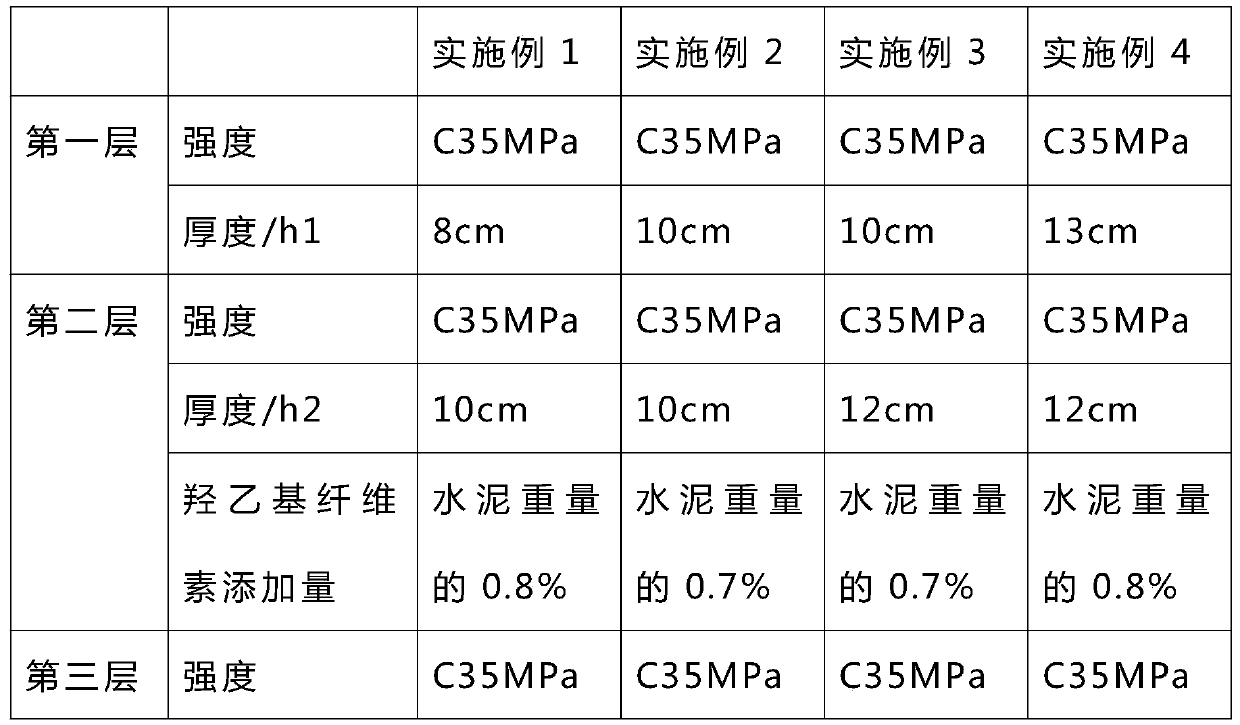

[0021] The structural arrangement of the compound ballast bed for the regulation and control of the vibration damping and vibration isolation bandwidth of Examples 1-4 is shown in Table 1:

[0022] Table 1

[0023]

[0024]

[0025] The second layer of embodiment 1-4 is a lightweight concrete layer, selects particle diameter as uniform stone (fresh basalt) of 1-2cm as aggregate, adds EPS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com