Production method of durable lightweight concrete for vibration reduction and isolation track bed

A technology of lightweight concrete and its production method, which is applied in the fields of lightweight concrete and durable lightweight concrete, can solve the problems of limited service life, high price, and difficulty in achieving vibration reduction and vibration isolation effects, so as to reduce additional vibration or The effect of causing secondary vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The manufacturing method of durable lightweight concrete for a vibration-damping and vibration-isolated ballast bed described in this embodiment, the specific manufacturing method is as follows:

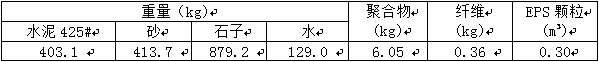

[0019] 1) The volume ratio of concrete and EPS particles is 7:3 (see Table 1 for the ratio of related materials), the strength grade of lightweight concrete reaches C35, the particle size of EPS particles is 2mm, and the bulk density of EPS particles is 14kg / m 3 ;

[0020] 2) Mix the concrete and EPS particles according to the ratio determined in step 1). In order to prevent the light concrete from cracking under the long-term vibration of the subway train, a certain amount of polyacrylonitrile fiber is added during the production process. The mixing ratio is 0.09% of the cement weight;

[0021] 3) Since EPS particles and acrylonitrile fibers are hydrophobic materials, in order to ensure that EPS particles and acrylonitrile fibers can be evenly mixed with concrete, it is nece...

Embodiment 2

[0026] The manufacturing method of durable lightweight concrete for a vibration-damping and vibration-isolated ballast bed described in this embodiment, the specific manufacturing method is as follows:

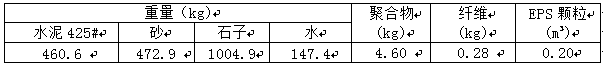

[0027] 1), the volume ratio of lightweight concrete and EPS particles is 3:1 (see Table 2 for the relevant material ratio), the strength grade of lightweight concrete reaches C40, the particle size of EPS particles is 1mm, and the bulk density of EPS particles is 12kg / m 3 ;

[0028] 2) Mix the concrete and EPS particles according to the ratio determined in step 1). In order to prevent the light concrete from cracking under the long-term vibration of the subway train, a certain amount of polyacrylonitrile fiber is added during the production process. The mixing ratio is 0.07% of the cement weight;

[0029] 3) Since EPS particles and acrylonitrile fibers are hydrophobic materials, in order to ensure that EPS particles and acrylonitrile fibers can be evenly mixed with concrete, ...

Embodiment 3

[0034] The manufacturing method of durable lightweight concrete for a vibration-damping and vibration-isolated ballast bed described in this embodiment, the specific manufacturing method is as follows:

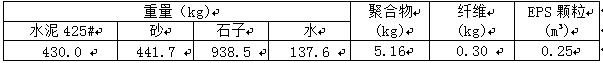

[0035] 1), the volume ratio of concrete and EPS particles is 4:1 (see Table 3 for the ratio of related materials), the strength grade of lightweight concrete reaches C35, the particle size of EPS particles is 2mm, and the bulk density of EPS particles is 12kg / m 3 .

[0036] 2) Mix the concrete and EPS particles according to the ratio determined in step 1). In order to prevent the light concrete from cracking under the long-term vibration of the subway train, a certain amount of polyacrylonitrile fiber is added during the production process. The mixing ratio is 0.06% of the cement weight.

[0037] 3) Since EPS particles and acrylonitrile fibers are hydrophobic materials, in order to ensure that EPS particles and acrylonitrile fibers can be evenly mixed with concrete, it is nec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com