Lightweight concrete mixing device and mixing method for subway vibration-reducing vibration-isolation ballast bed

A light-weight concrete, vibration reduction and vibration isolation technology, applied in the direction of mixing operation control device, clay preparation device, cement mixing device, etc., can solve the problems of high price, limited service life, and difficulty in achieving vibration reduction and vibration isolation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

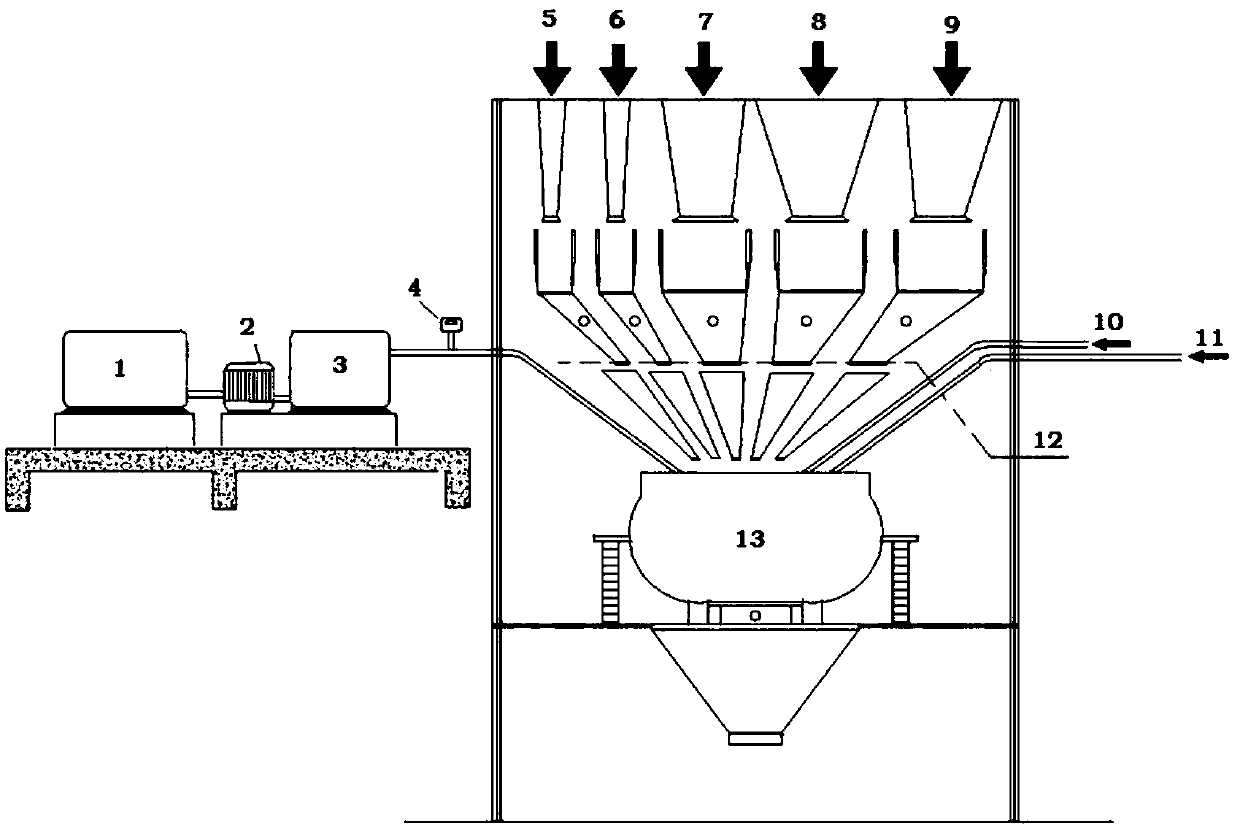

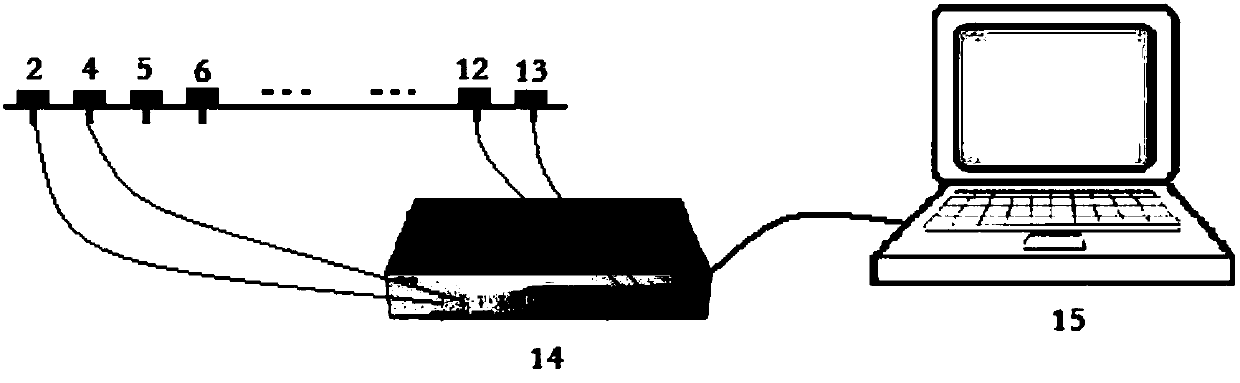

[0021] In the lightweight concrete mixing device for subway vibration-reducing vibration-isolation ballast bed of the present invention, the EPS storage warehouse 1 is communicated with the EPS storage bin 3 through the centrifuge 2, and the EPS storage bin 3 is connected to the upper port of the mixing bin 13 through the flow meter 4, The water feed port 5, the water reducing agent feed port 6, the cement feed port 7, the stone feed port 8, and the sand feed port 9 are respectively connected to the upper port of the mixing bin 13 through the weighing scale 12, and the viscous agent The feed port 10 and the polymer feed port 11 are respectively connected to the upper port of the mixing chamber 13; the control instruction unit 14 is connected to the computer 15 to control the flow meter 4, the water feed port 5 and the water reducer feed port 6 respectively , cement feed port 7, stone feed port 8, sand feed port 9, viscous agent feed port 10, polymerization agent feed port 11, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com