Electrode elevation control method and system of submerged arc furnace based on neural network decoupling

A technology of electrode lifting and neural network, applied in general control system, control/regulation system, control using feedback, etc., can solve problems such as increased power consumption, unstable electrode control, random interference of coupling effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

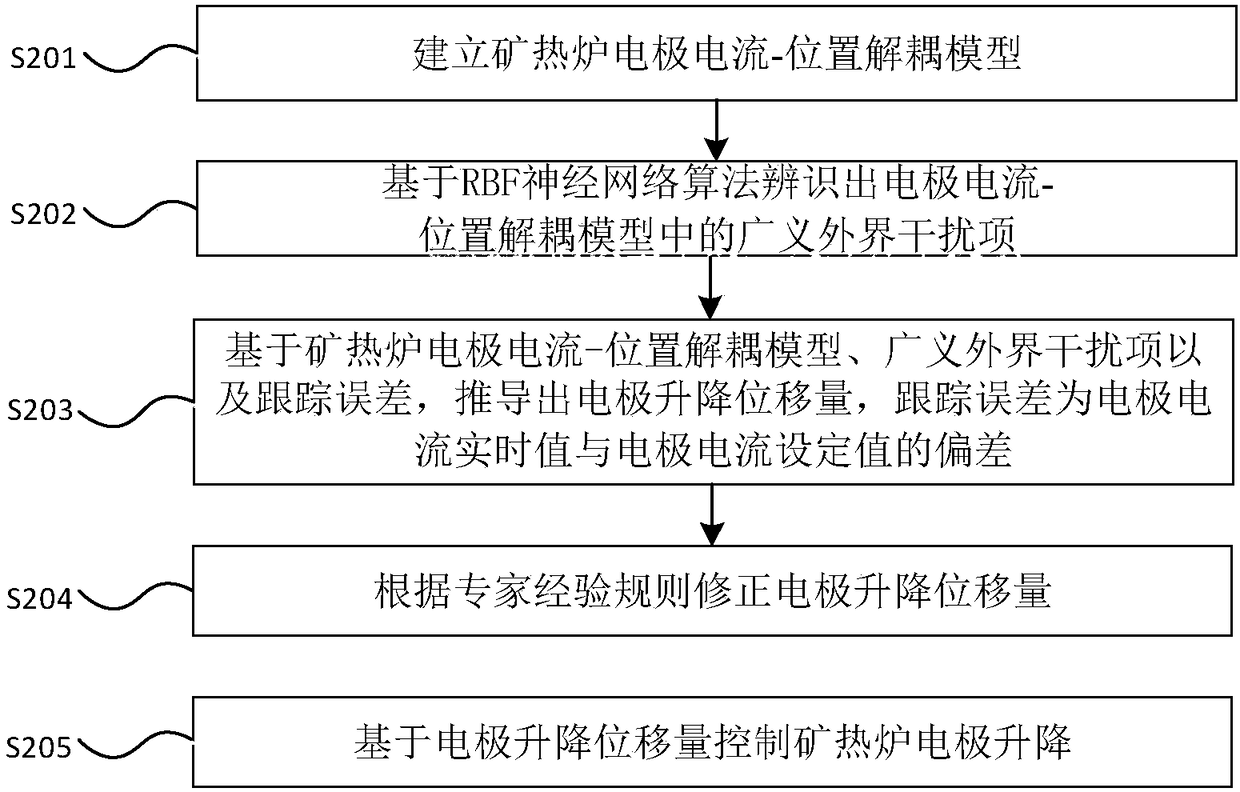

[0062] refer to figure 1 The first embodiment of the present invention provides a decoupling-based neural network electrode lifting control method for submerged arc furnaces, including:

[0063] Step S101, establishing an electrode current-position decoupling model of the submerged arc furnace;

[0064] Step S102, identifying the generalized external disturbance term in the electrode current-position decoupling model based on the RBF neural network algorithm;

[0065] Step S103, based on the electrode current-position decoupling model of the submerged arc furnace, the generalized external disturbance term and the tracking error, deduce the lifting displacement of the electrode, and the tracking error is the deviation between the real-time value of the electrode current and the set value of the electrode current;

[0066] Step S104, controlling the lifting and lowering of the electrode of the submerged arc furnace based on the lifting and lowering displacement of the electrode...

Embodiment 2

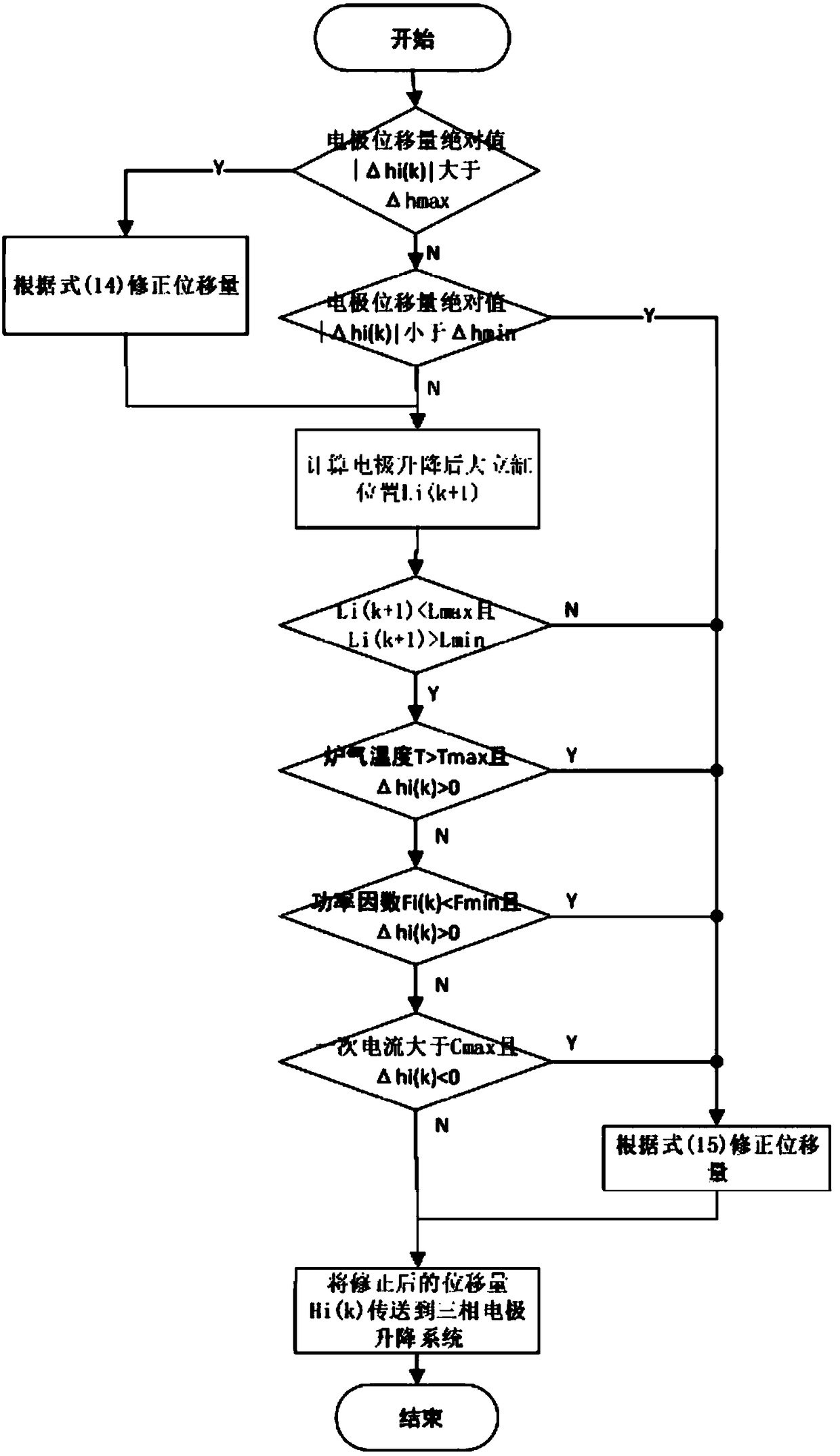

[0072] refer to figure 2 The second embodiment of the present invention provides a decoupling-based neural network electrode lifting control method for submerged arc furnaces, including

[0073] Step S201, establishing an electrode current-position decoupling model of the submerged arc furnace.

[0074] Specifically, the establishment of the electrode current-position decoupling model of the submerged arc furnace in the embodiment of the present invention includes:

[0075] Based on the electrode displacement and electrode current variation, the electrode current-position model of the submerged arc furnace is established as:

[0076] △I(k+1)=Φ(k)△h(k) (1)

[0077] Where △I(k+1)=I(k+1)-I(k) is the electrode current variation, △h(k)=h(k)-h(k-1) is the electrode displacement, I(k ) = [I 1 (k),I 2 (k),I 3 (k)] T is the three-phase electrode current, h(k)=[h 1 (k), h 2 (k), h 3 (k)] T is the three-phase electrode position, is the current displacement response coefficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com