Numerical control equipment cascade system and method based on virtual and actual combination

A technology of numerical control equipment and cascading system, applied in the field of numerical control, can solve the problems of inability to connect the control panel, unable to connect the numerical control equipment, and unable to connect the knowledge of students with the real factory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

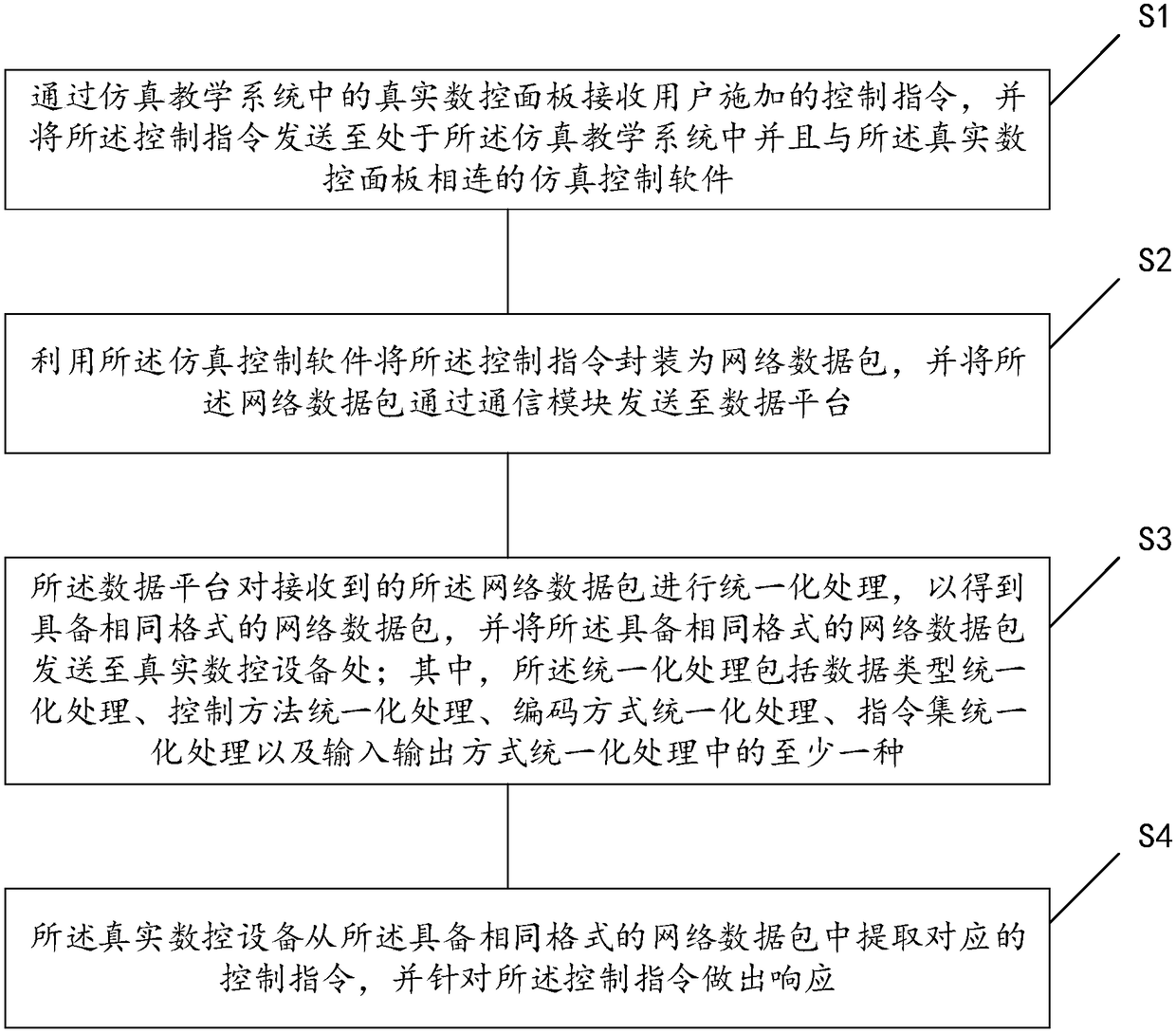

[0047] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

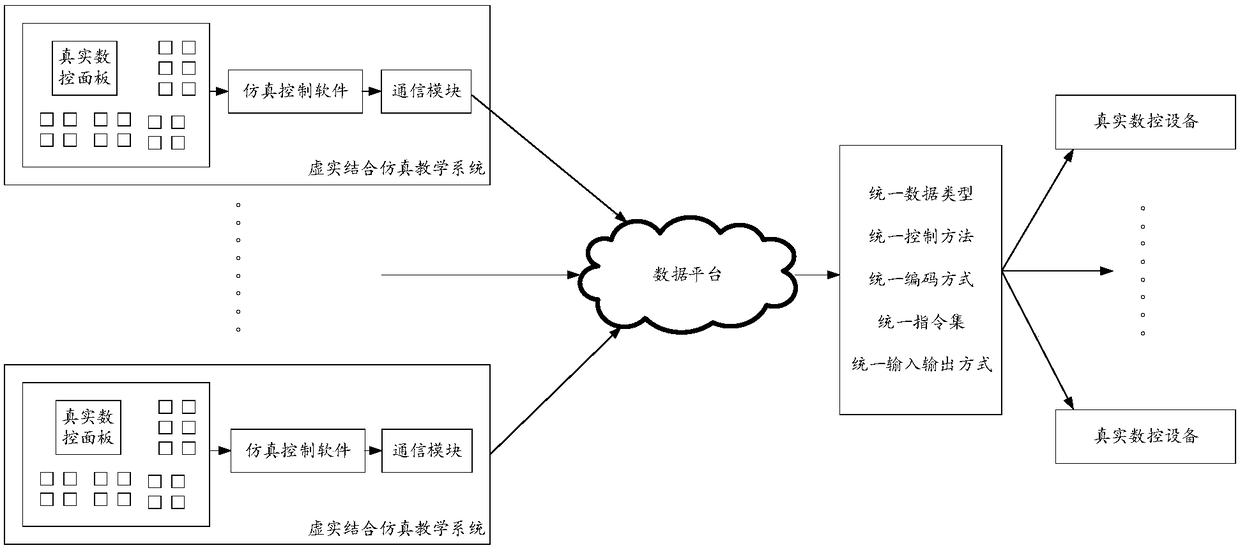

[0048] see figure 1 , the present application provides a virtual-real combined numerical control equipment cascading system, said cascading system includes a simulation teaching system, a data platform and real numerical control equipment, wherein:

[0049] The simulation teaching system includes a real numerical control panel, simulation control software and a communication module, the real numerical control panel is used to receive control instructions imposed by users, and send the control instructions to the simulation control software; the simulation control software It is used to encapsulate the control instruction into a network data packet, and send the networ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com