Sleeve-type safety clip and high-voltage switch cabinet

A safety clip and sleeve-type technology, which is applied in the field of electrical equipment, can solve the safety and hidden dangers that the insulation baffle is easily opened by mistake, so as to avoid electric shock and improve operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

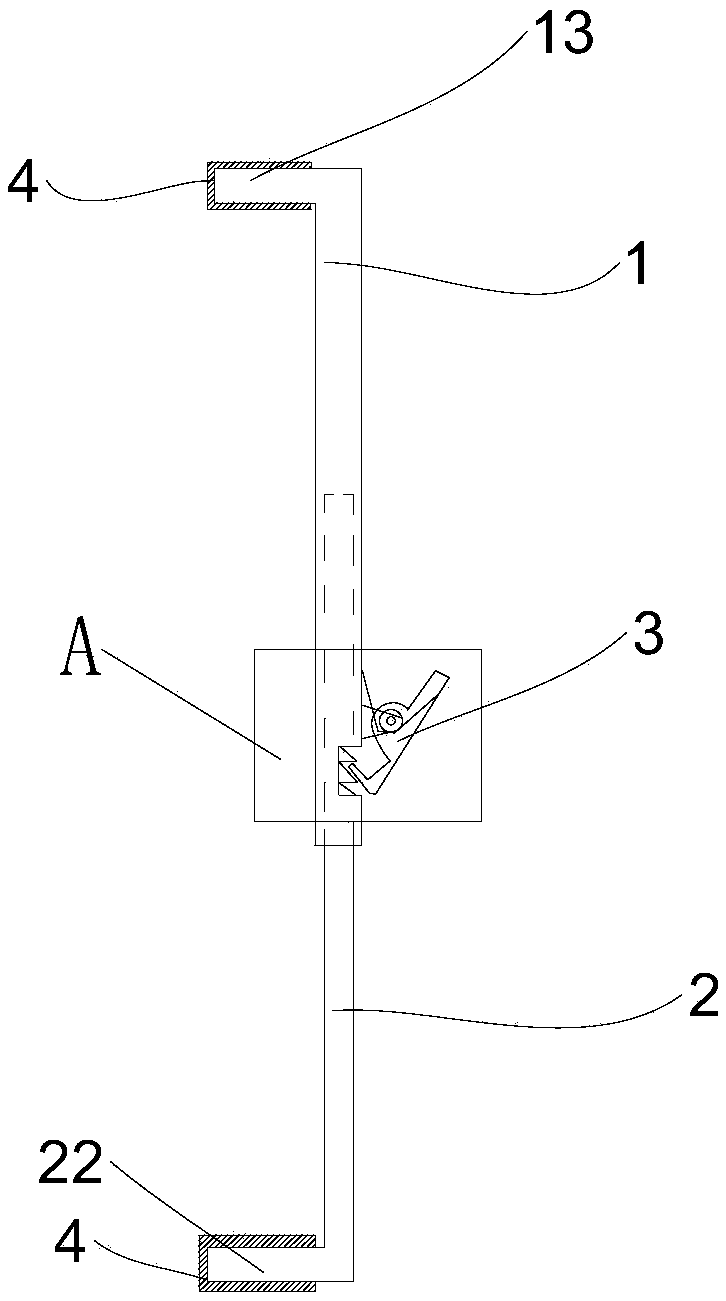

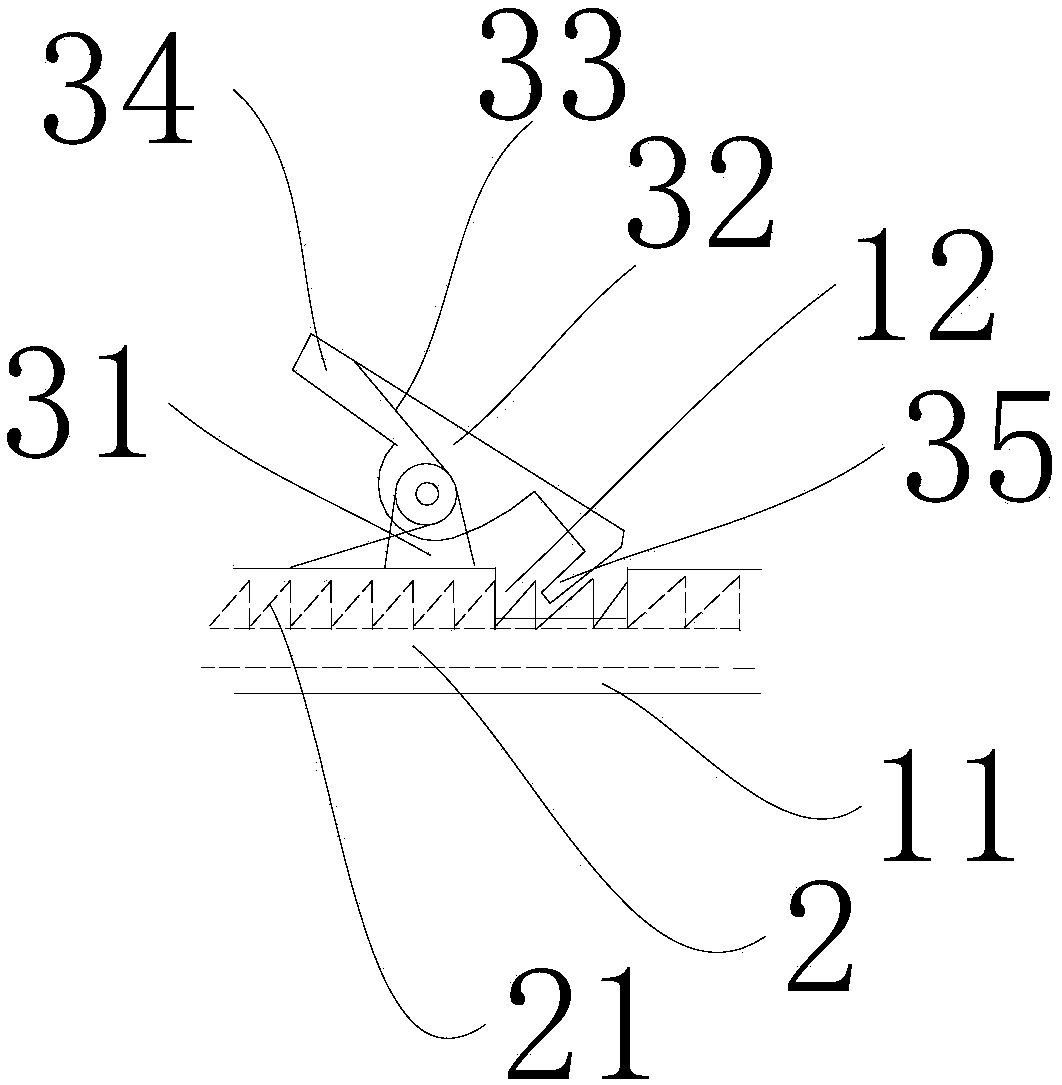

[0044] see Figure 1 to Figure 4 As shown, this embodiment provides a sleeve-type safety clip including a first clamping rod 1 , a second clamping rod 2 and a fixing assembly.

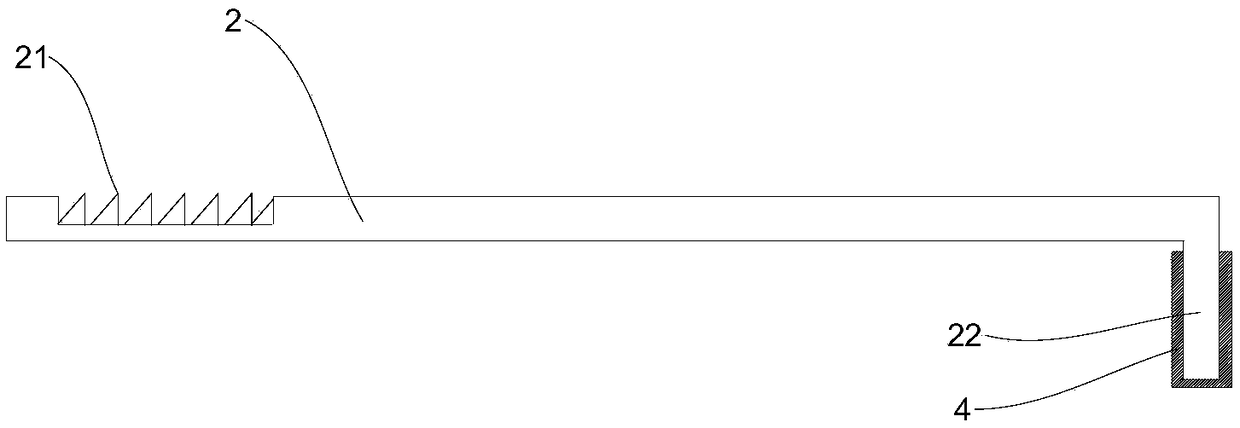

[0045] One end of the first clamping rod 1 is provided with a sleeve 11, the axial direction of the sleeve 11 is consistent with the extension direction of the first clamping rod 1, and one end of the second clamping rod 2 is inserted into the sleeve 11 and the second clamping rod 2 can slide along the axial direction of the sleeve 11, and the ends of the first clamping rod 1 and the second clamping rod 2 away from the sleeve 11 are respectively provided with pressing The clamping assembly of the insulating baffle. The fixing assembly is used to limit the relative movement between the second clamping rod 2 and the sleeve 11 .

[0046] It can be understood that the sleeve 11 is preferably formed by a hollow structure at the end of the first clamping rod 1 close to the second clamping rod 2, that is, t...

Embodiment 2

[0073] This embodiment provides a high-voltage switchgear, including a switchgear body and the sleeve-type safety clip described in Embodiment 1.

[0074] The switchgear body includes an upper contact box and a lower contact box, an upper insulating baffle is arranged above the upper contact box, and a lower insulating baffle is arranged below the lower contact box.

[0075] The clamping assembly of the first clamping rod 1 presses on the upper edge of the upper insulating baffle, and the clamping assembly of the second clamping rod 2 presses on the lower edge of the lower insulating baffle. Or, the clamping assembly of the first clamping rod 1 presses on the lower edge of the lower insulating baffle, and the clamping assembly of the second clamping rod 2 presses on the upper edge of the upper insulating baffle.

[0076]Preferably, the clamping assembly of the first clamping rod 1 is pressed in the middle of the lengthwise direction of the upper insulating baffle, and the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com