Leading deep hole pre-splitting roof gob-side entry retaining method

A technology of gob-side entry retaining and roof, which is applied in earth-moving drilling, surface mining, underground mining, etc., can solve the problems of difficult maintenance of gob-side entry retaining, damage of roadside support, and increased roof pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

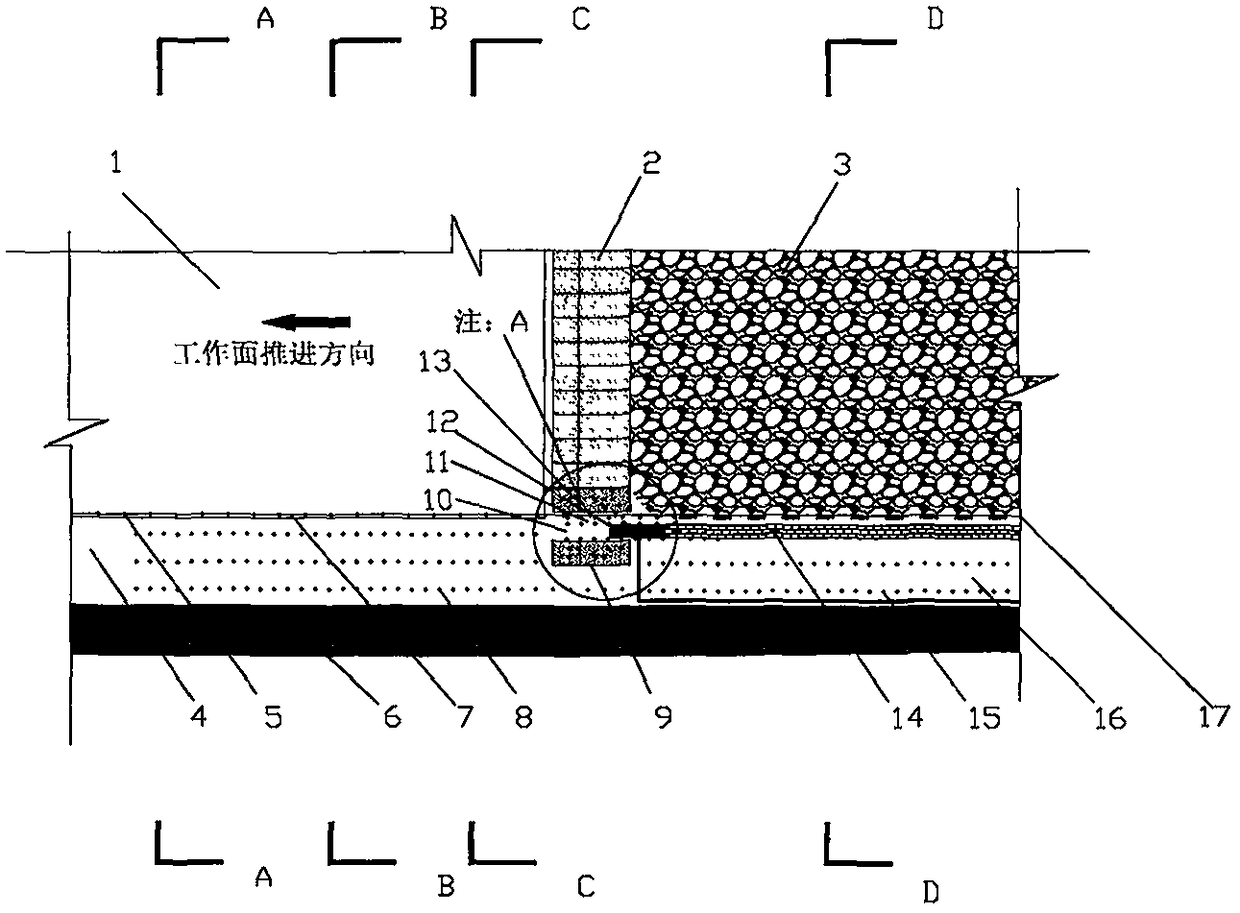

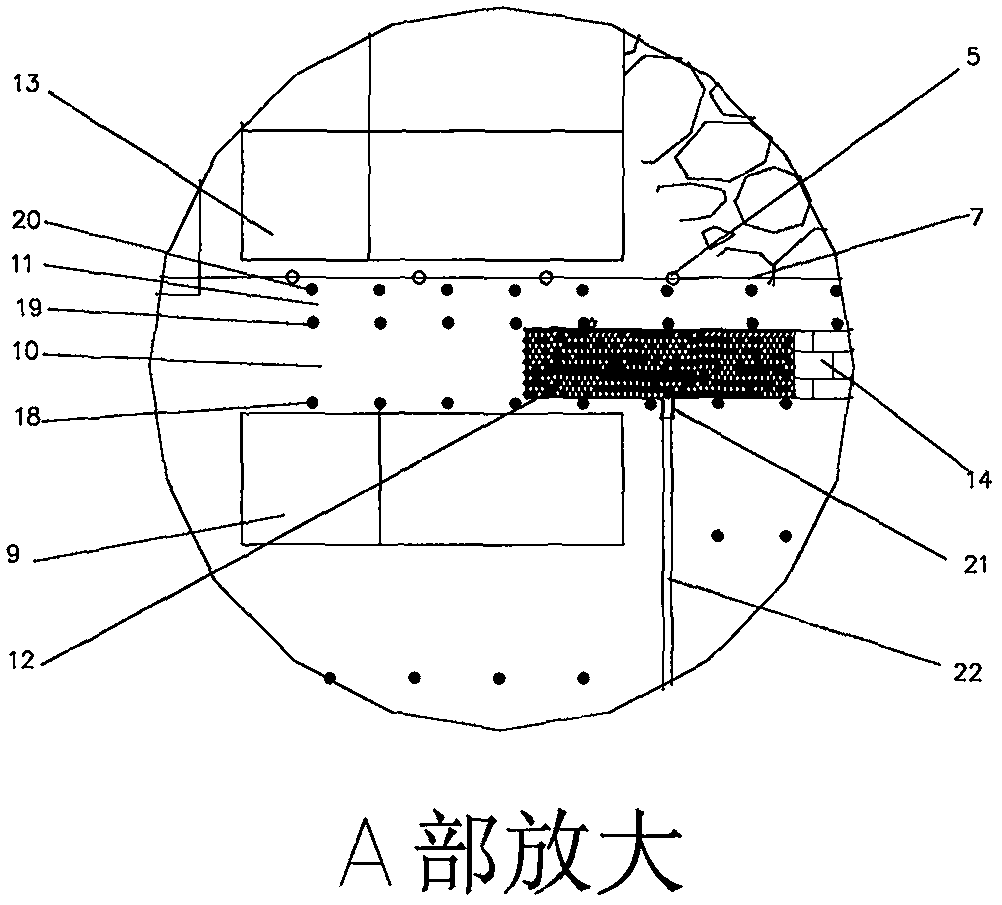

[0047] The position of the roof pre-crack line is determined according to the width of the gob-side entry and the width of the retaining wall beside the entry.

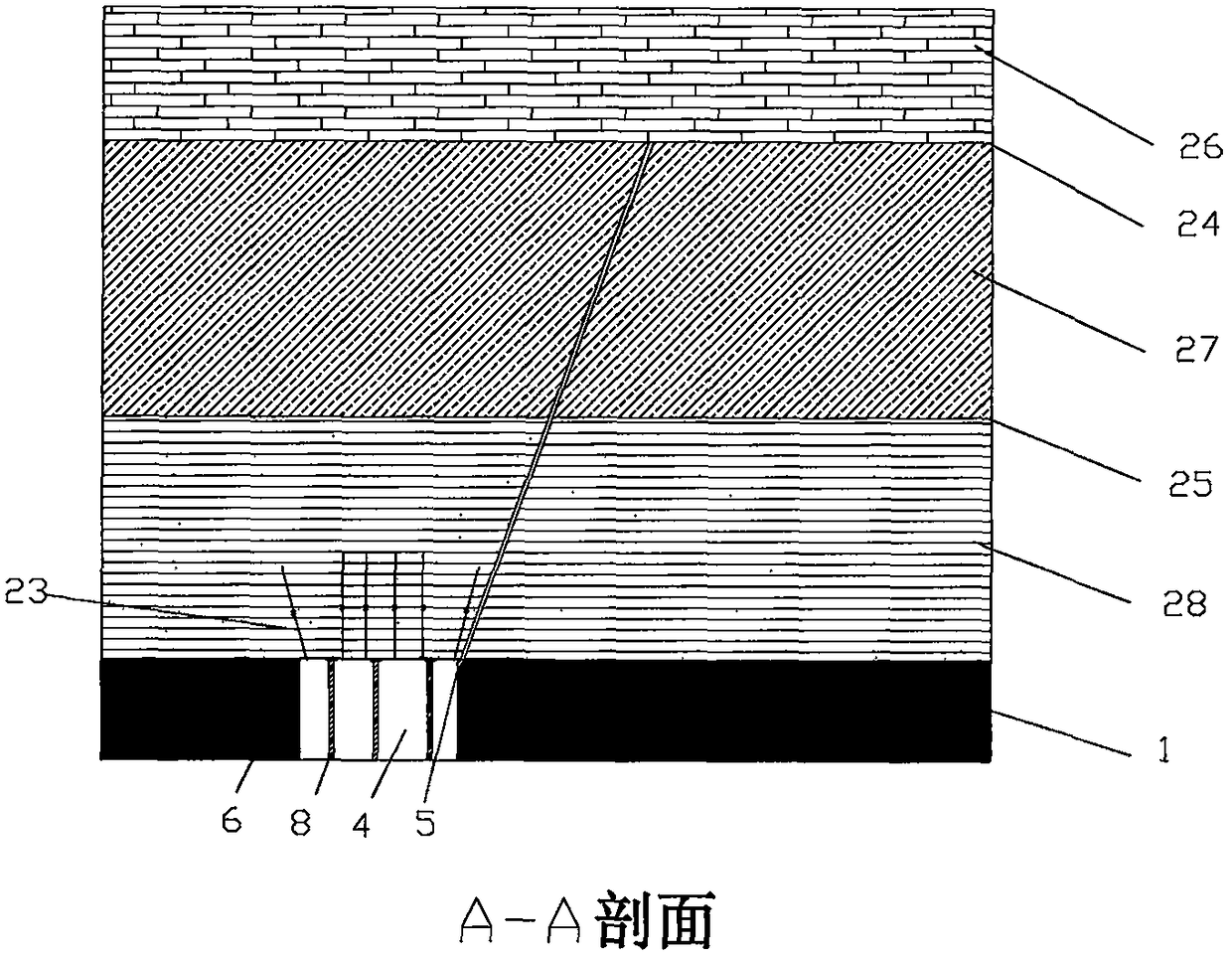

[0048] 30-50m in front of the coal mining face 1, along the roof pre-splitting line 7, construct the roof pre-splitting drilling 5. The pre-splitting drilling 5 has a diameter of ¢40mm-¢80mm, a distance of 1-3m, an inclination of 70°-80°, and a hole depth. 15-25m.

[0049] Before the stress concentration area in front of the working face, put the explosive 29 and the detonator 36 into the blasting tube 37, install the blasting tube 37 section by section from the bottom of the pre-split hole 5 on the top plate until it reaches the lower limit of the pre-split hole, and charge the blasting tube. Length 5-12m.

[0050] The remaining part of the pre-splitting hole 5 is packed with clay 30 .

[0051] Immediately after the charge is completed, blasting is performed, and the kerf 32 is formed along the direction of the roof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com