Patents

Literature

51results about How to "Reduce support pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seat

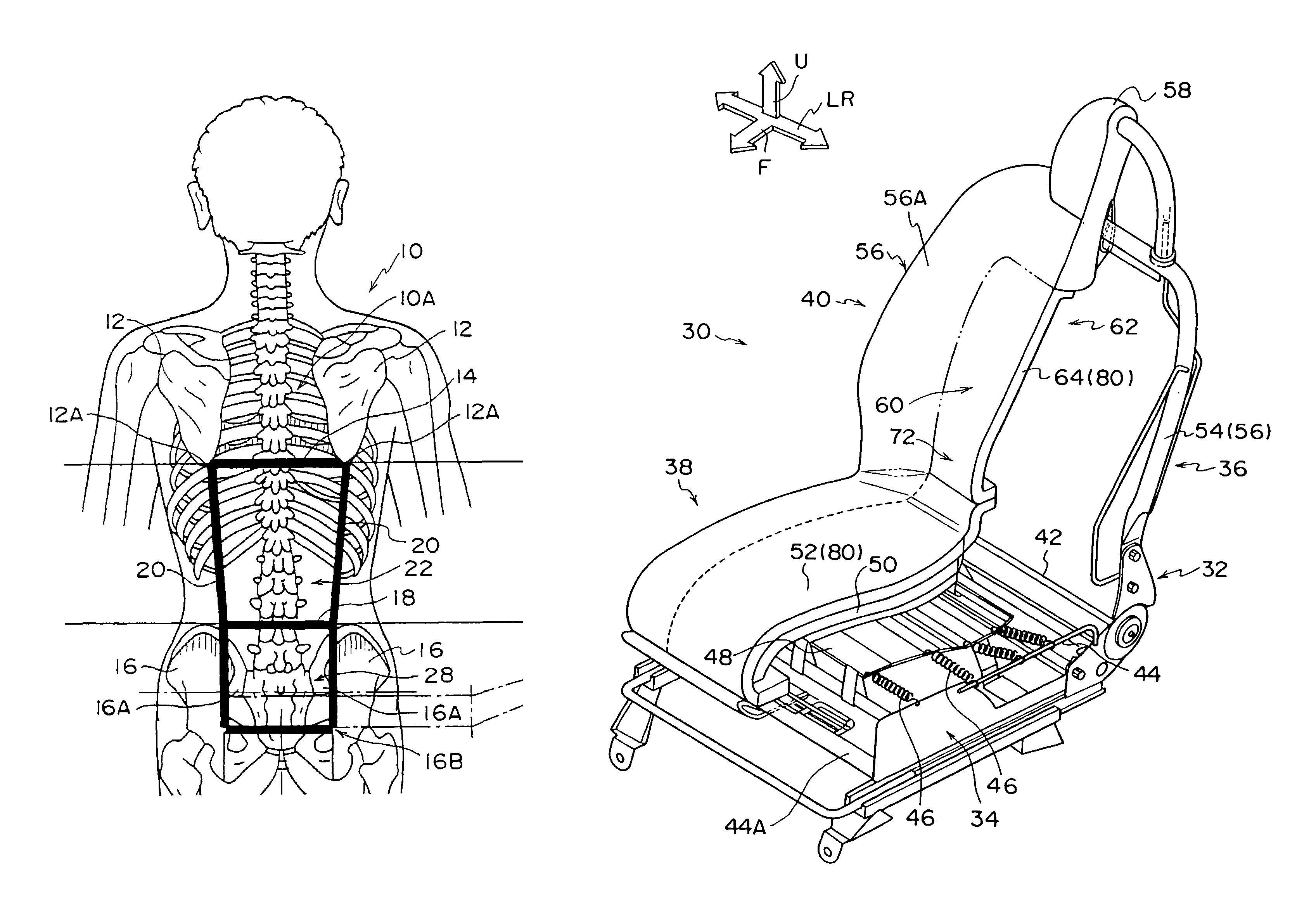

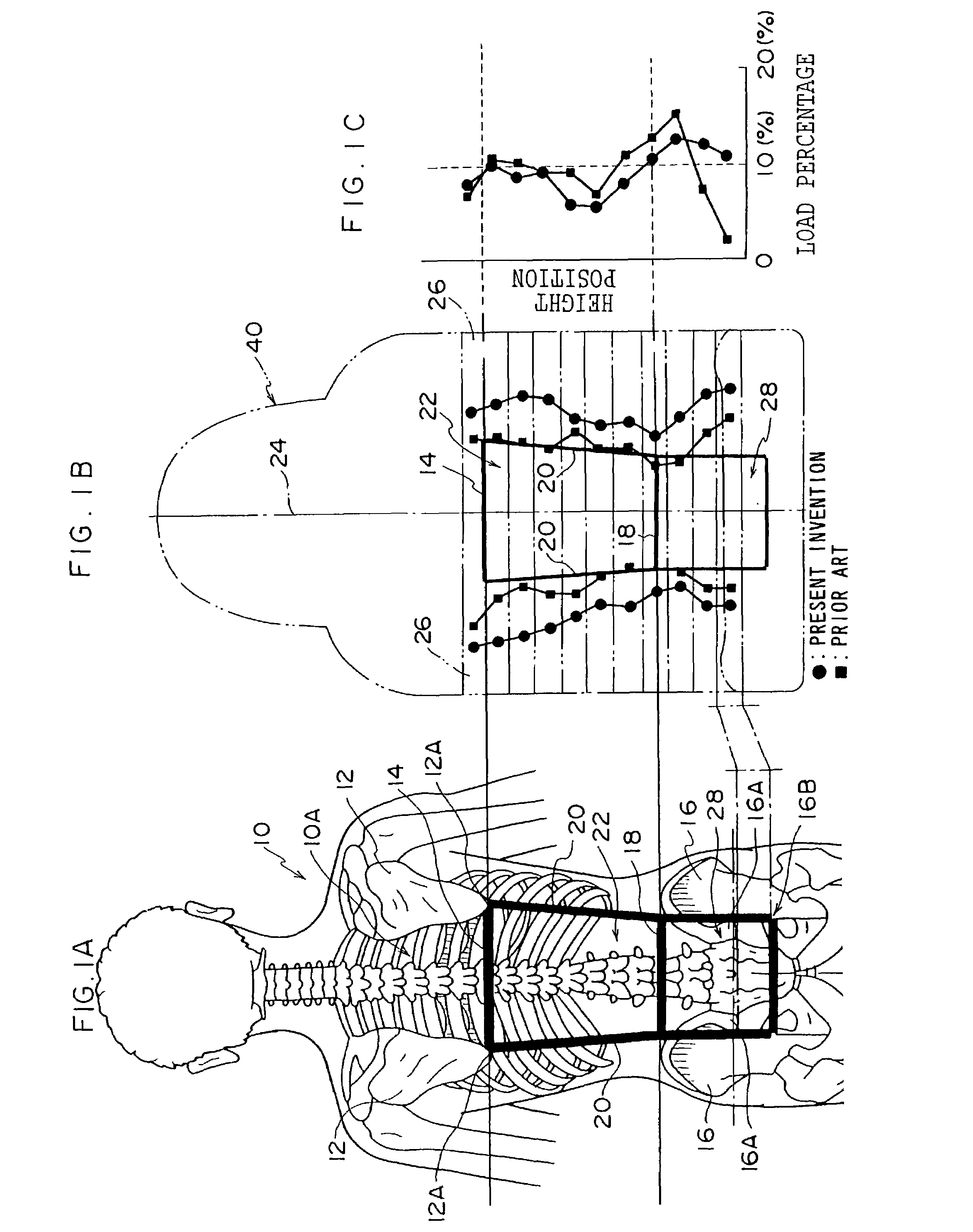

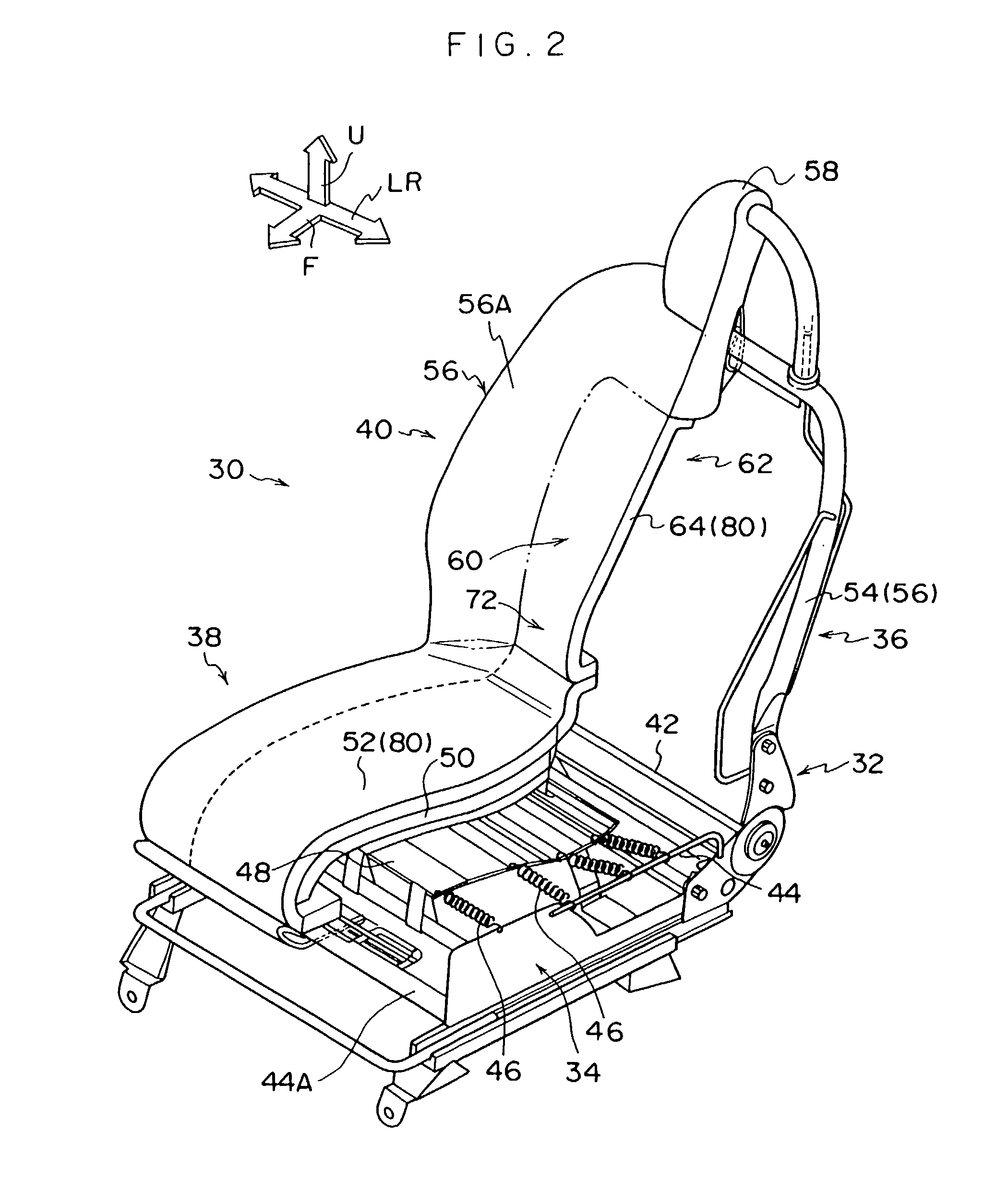

ActiveUS7600821B2Reduce muscle fatigueInhibitionSeat coveringsWeft knittingPosterior regionInferior angle of the scapula

A seat provides a band-like support for the body sides of a user so as to reduce the supporting pressure on the user's lumbar and to hold the user's upper body stably. In this seat, the center of a load to be received in regions symmetrically divided to a vertical central line of the seat are positioned outside of a back region defined by left and right angulus inferior scapulae and by the upper ends of iliac bones. Moreover, the load ratios in the individual regions are not more than 25% in the region corresponding to a region extended downward from the back region.

Owner:DELTA TOOLING CO LTD

Leading deep hole pre-splitting roof gob-side entry retaining method

ActiveCN108457653AAccurate control of breakagePrevent rotation and sinkingUnderground miningSurface miningHigh strength concreteShaped charge

The invention relates to the field of underground mining of coal mines and particularly relates to a leading deep hole pre-splitting roof gob-side entry retaining method. The method disclosed by the invention comprises the following steps: drilling on an upper roof along a roof pre-splitting line in a roadway in front of a coal face, filling shaped charge at the upper part of the drill hole in a certain range, not filling the charge at the lower part of the drill hole in a certain range, tamping with stemming, detonating before a leading pressure of the face, blasting and pre-splitting rock stratum at a charged part at the upper part of the drill hole, wherein the lower rock stratum is kept complete, and construction space safety is ensured. Quick-hardening and high-strength concrete roadway supporting walls are built after face pushing by adopting a technology for filling pump concrete in a mold bag, non-split lower roadway roof is cut off by the roadway supporting walls under the action of a roof pressure, and the roof breakage position and falling height can be manually controlled. According to the method disclosed by the invention, gangue falling in a goaf can be promoted, thegoaf can be filled in time, and the overlying roof pressure can be borne by the gangue in the goaf; the suspended length of the roof in the goaf is reduced, so that the aim of reducing the deformationand pressure of the gob-side entry retaining roadway is achieved.

Owner:中矿科创(北京)煤炭技术有限公司

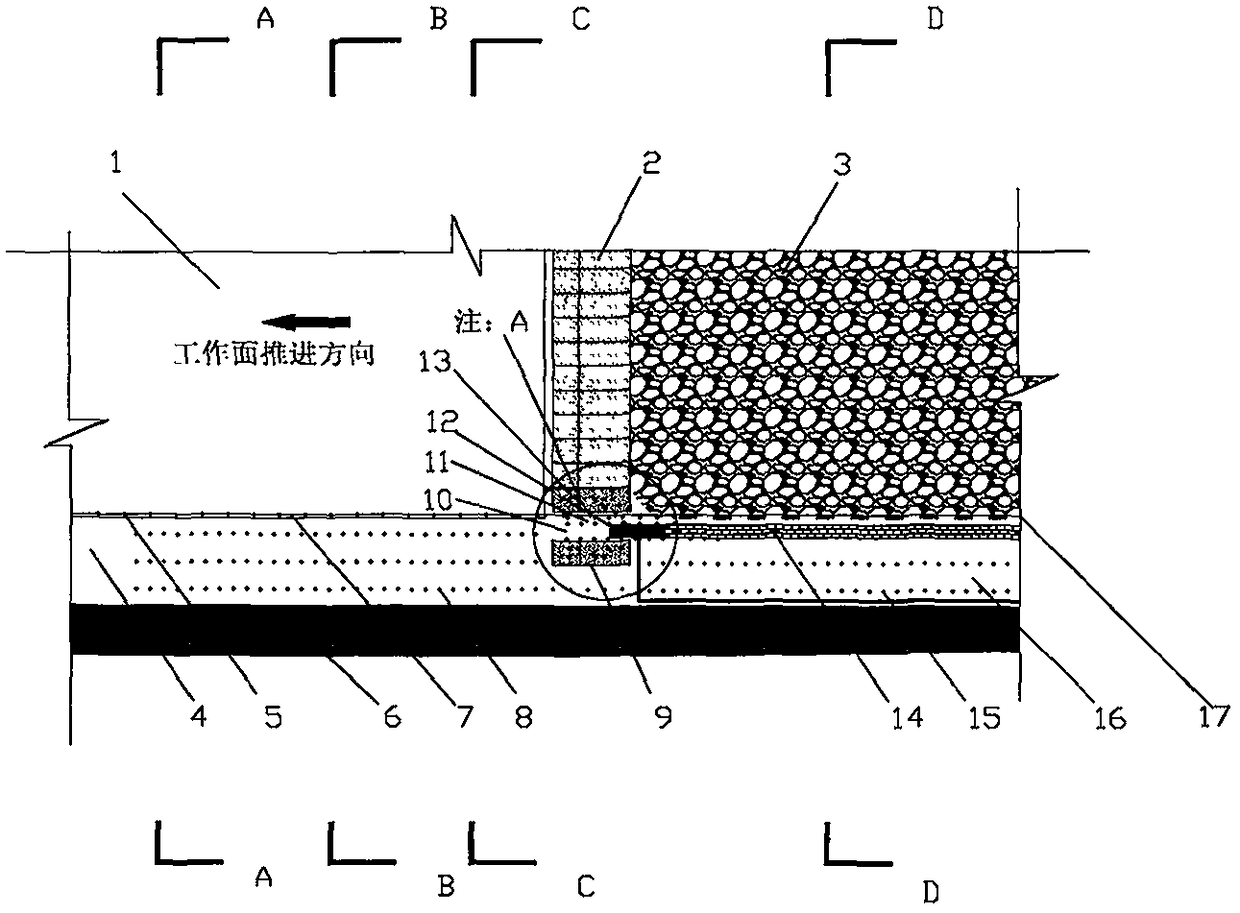

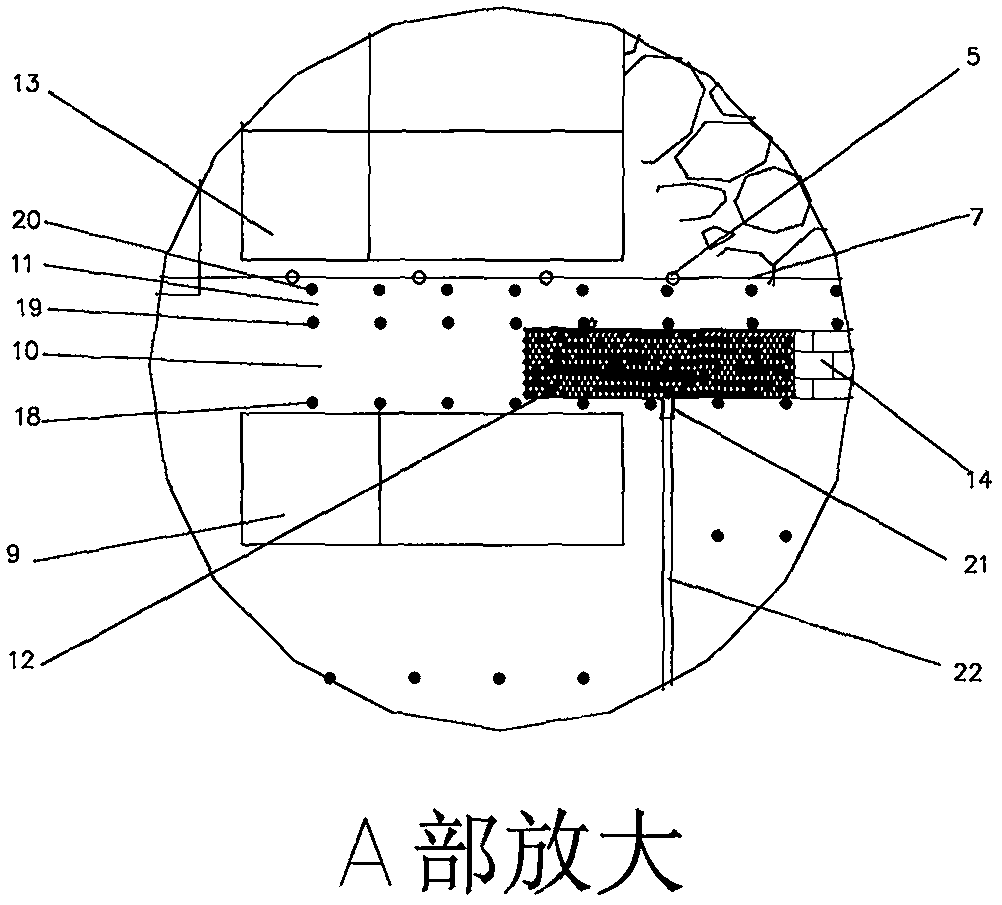

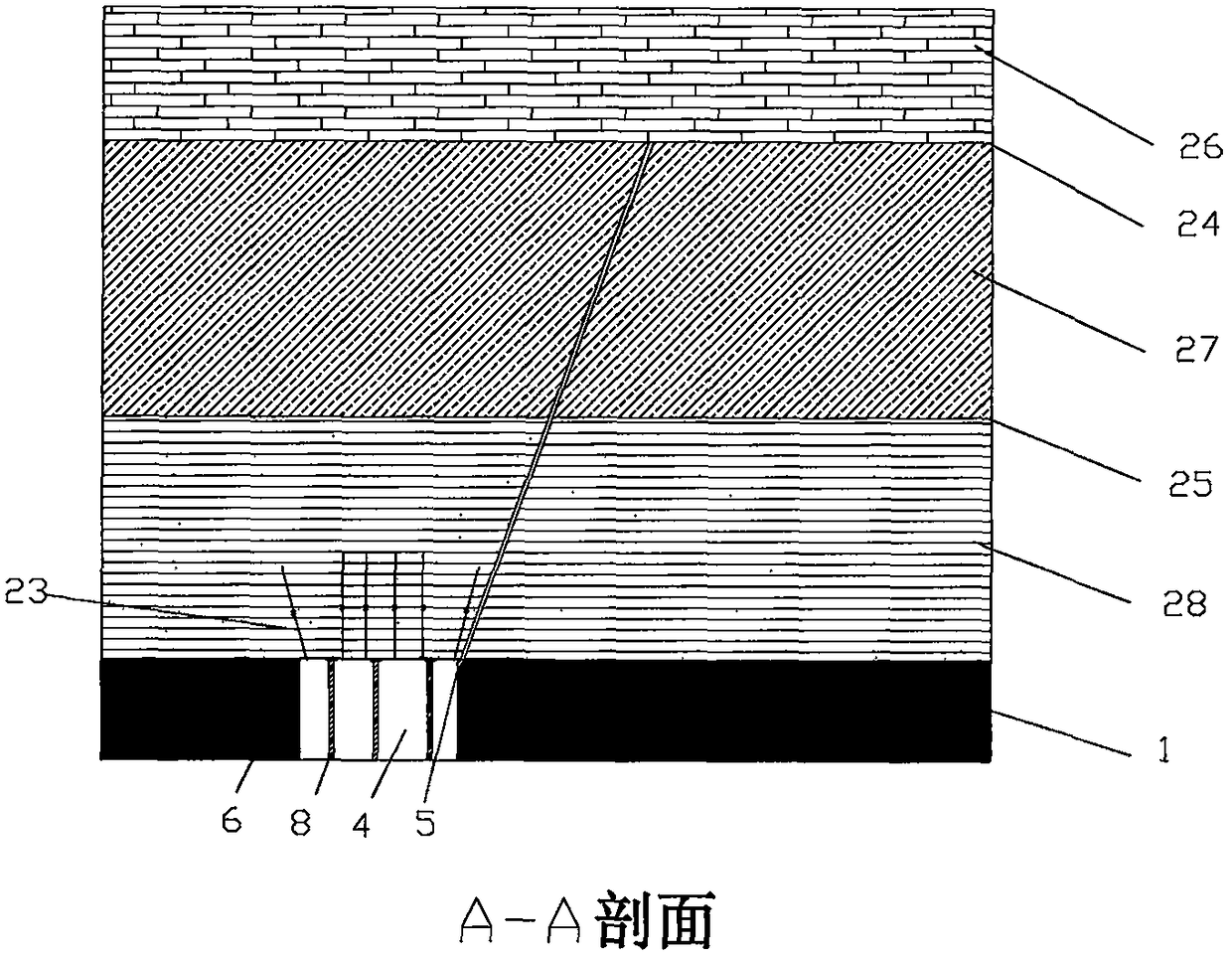

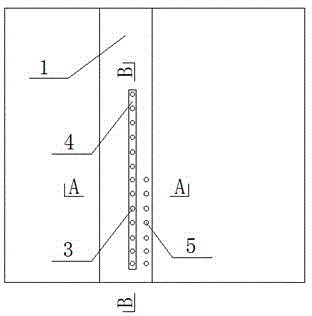

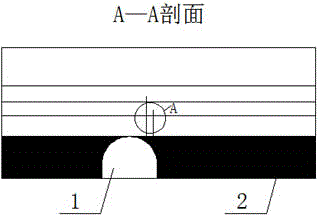

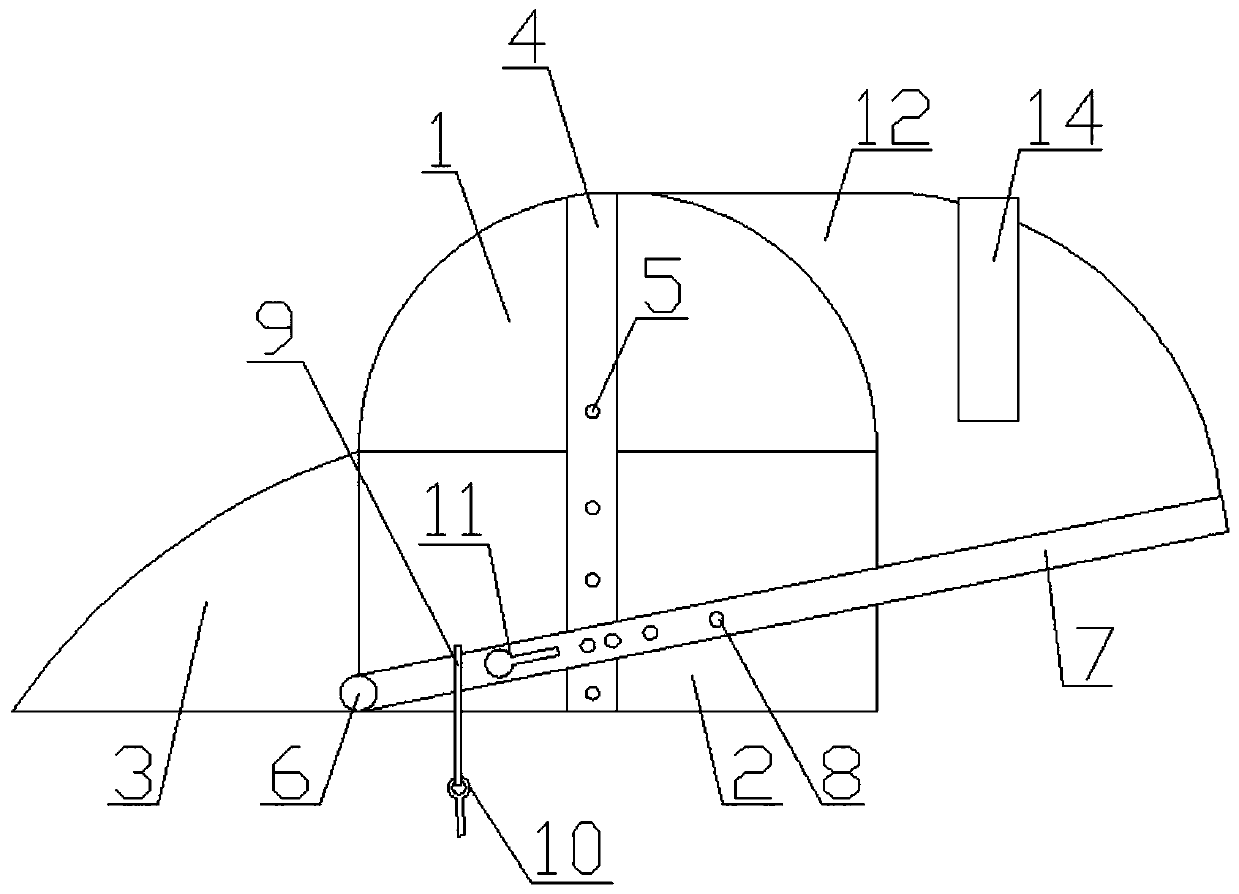

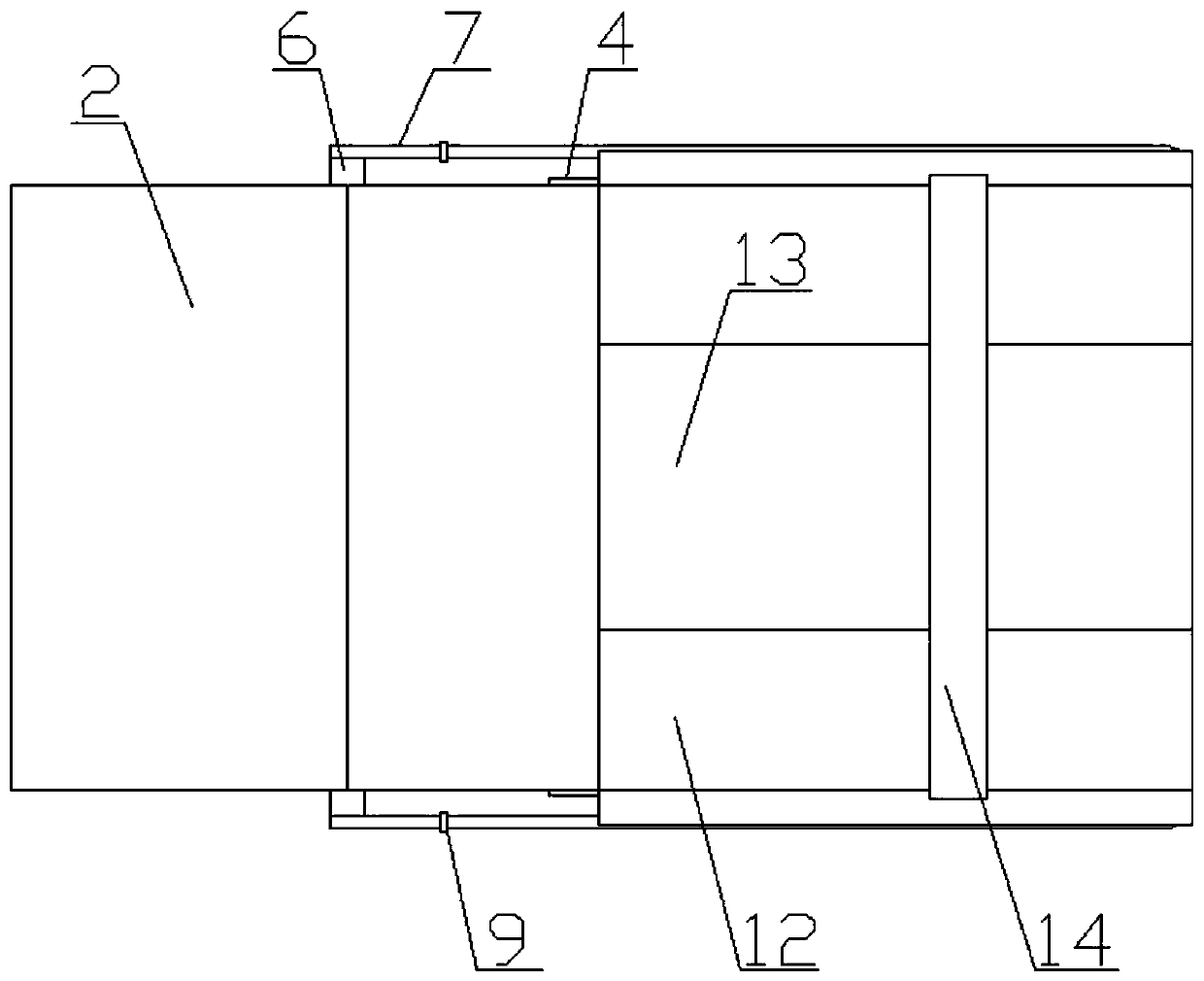

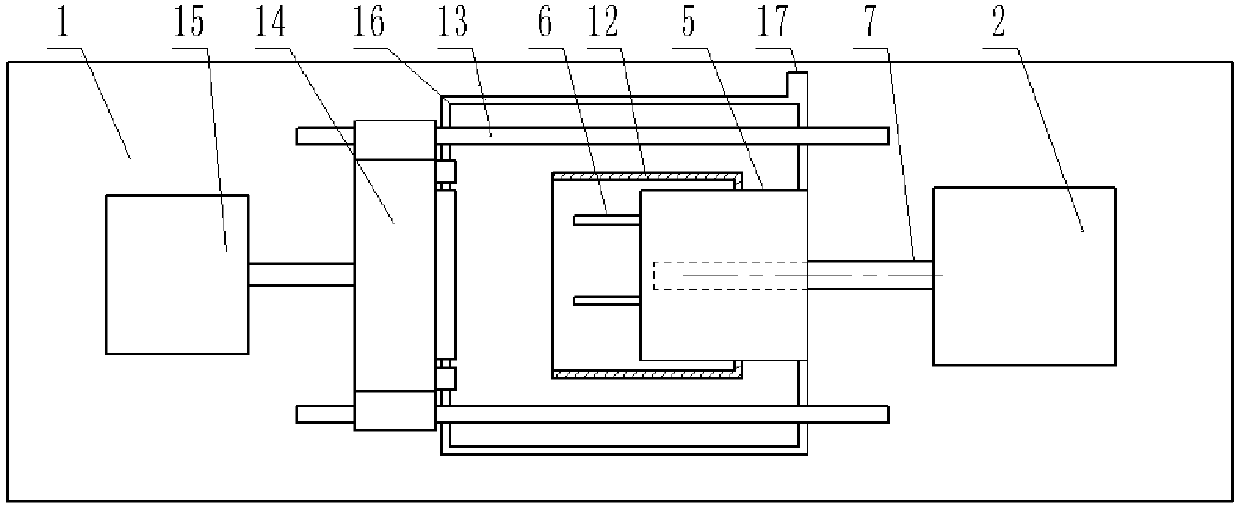

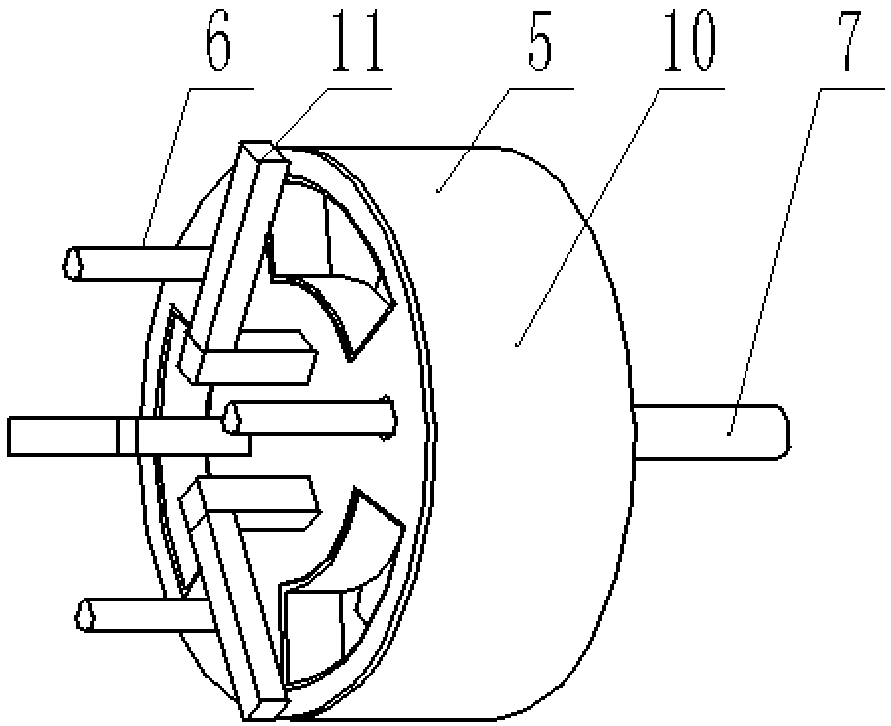

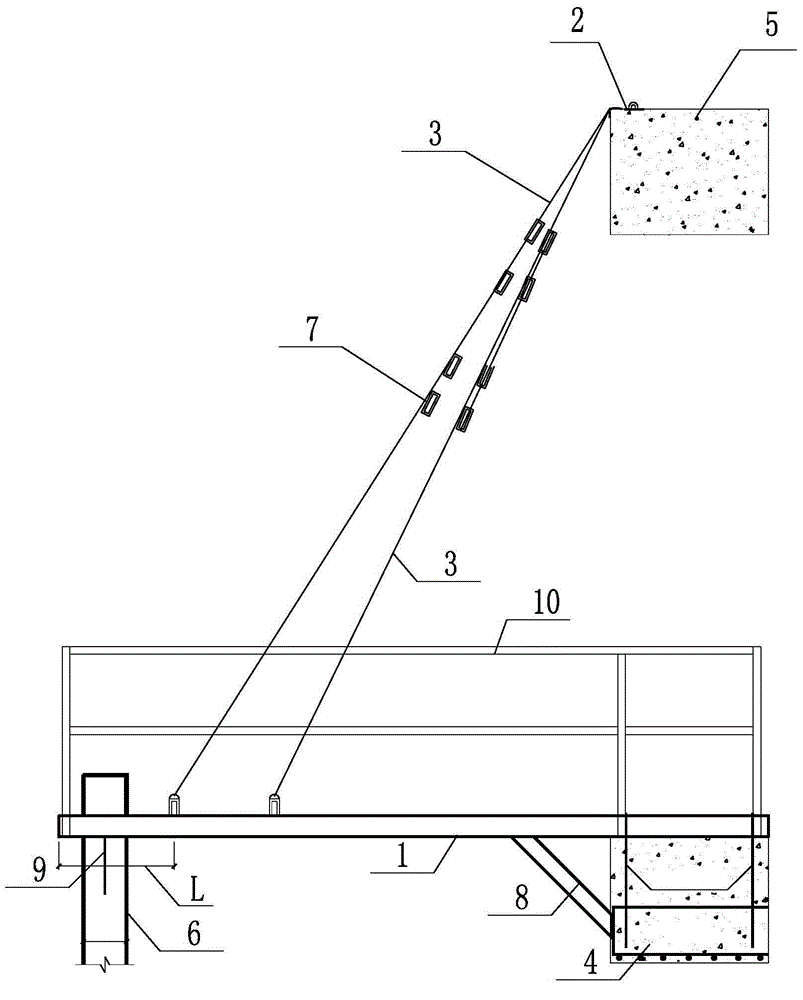

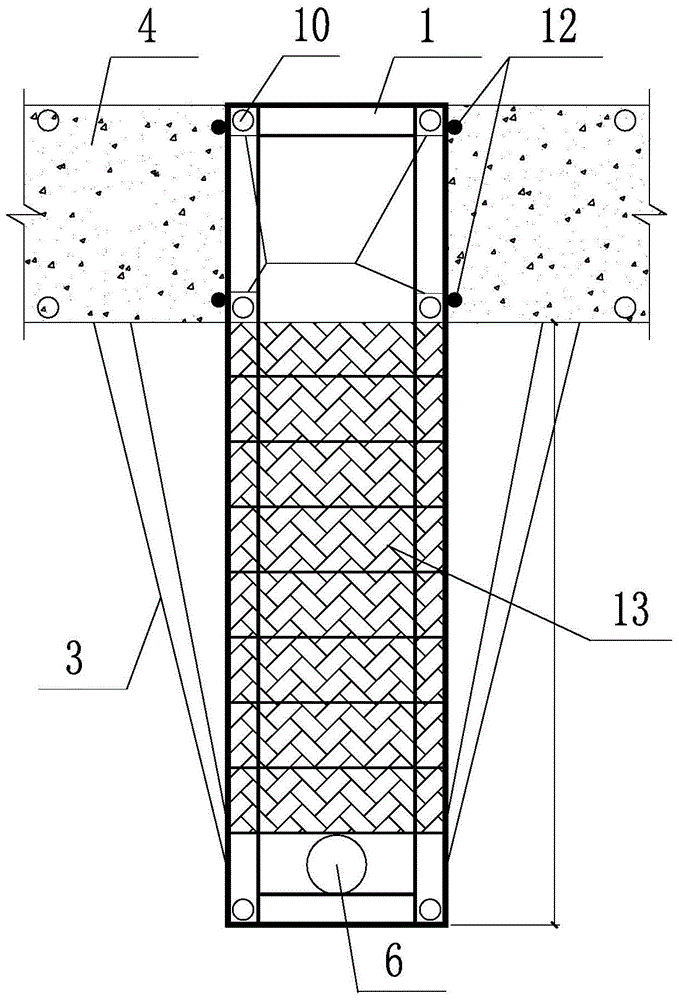

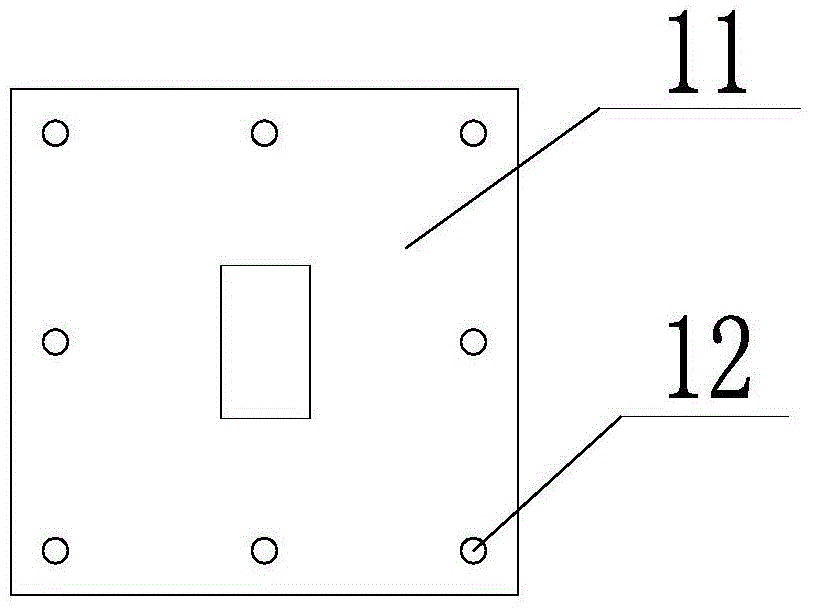

Gob-side entry retaining method for coal mine gateway by directional-predetermined crack blasting and truncating crest and pressure relief mode

ActiveCN104806246AReduce support pressureWill not affect the integrityUnderground miningSurface miningCoalEngineering

The invention discloses a gob-side entry retaining method for a coal mine gateway by a directional-predetermined crack blasting and truncating crest and pressure relief mode. The gob-side entry retaining method comprises the following steps of firstly, equidistantly constructing anchor cables (3) at one side of a preserved gateway (1) along the trend; secondly, constructing a W-shaped steel strip (4) for connecting the anchor ropes (3) to form a whole, and performing lock gate support; thirdly, equidistantly constructing pre-split blasting holes (5) between the constructed positions of the anchor ropes (3) and a mining working face (2) along the trend; fourthly, placing directional round tubes (6) in the pre-split blasting holes (5); fifthly, laying a metal net (7) at the gobbing area of the preserved gateway (1); sixthly, erecting wooden pillars (8) in the preserved gateway (1) for reinforcing support. According to the gob-side entry retaining method disclosed by the invention, the defects that when an existing underground gateway of a coal mine generally adopts methods of roadside filling or entry-in support reinforcing and the like to realize gob-side entry retaining, and the gob-side entry retaining is realized by adopting a roadside filling technology, the construction technology is complex, the filling cost is high and the management difficulty is high are overcome, and when the entry-in support reinforcing method is adopted, the labor intensity is improved, the entry retaining effect is poor and the like are solved.

Owner:PANJIANG COAL & ELECTRICITY GROUP INSITUTE OF COAL MINING DESIGN

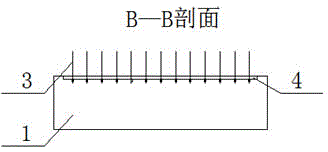

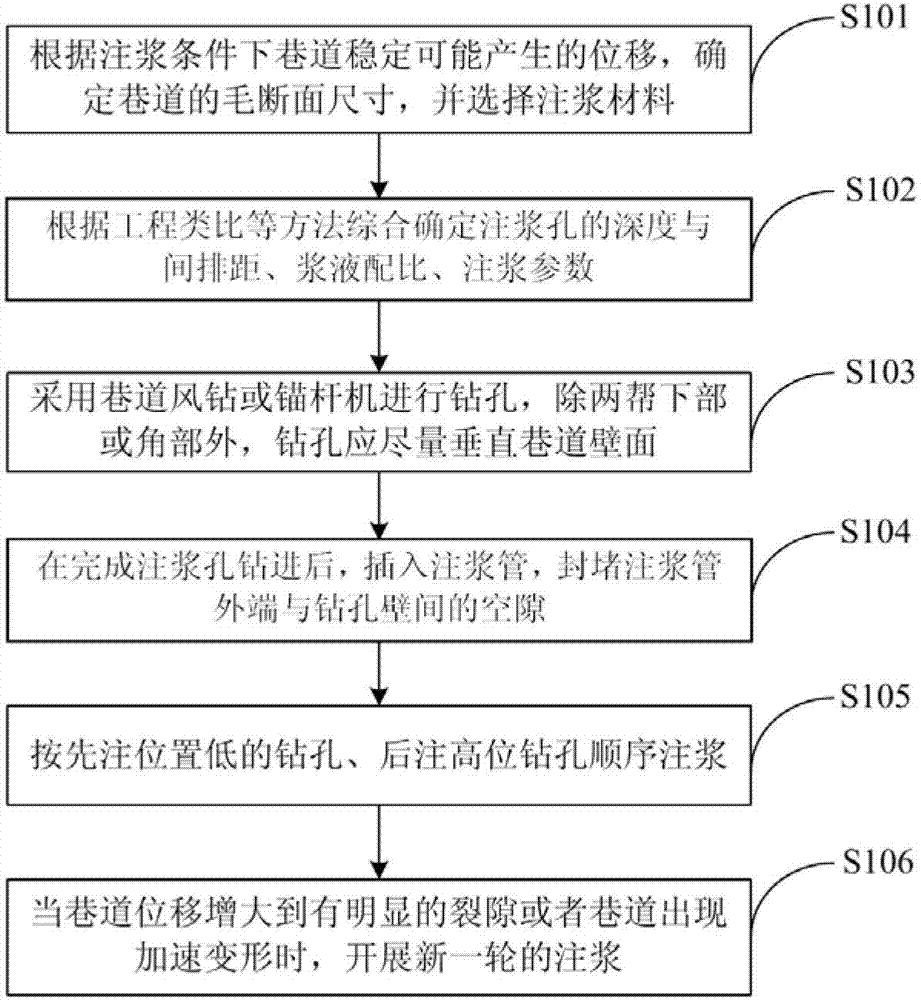

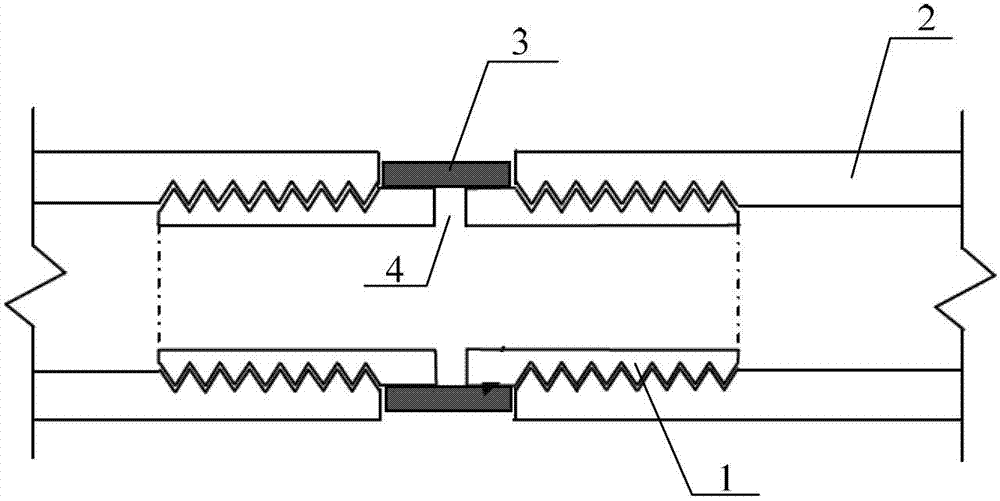

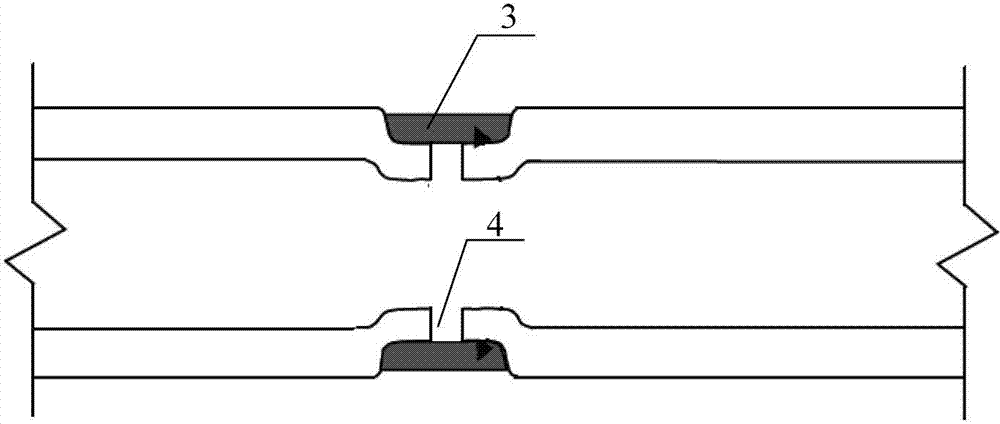

Method capable of repeated grouting and reinforcing surrounding rocks of roadway

The invention discloses a method capable of repeated grouting and reinforcing surrounding rocks of roadway. The method includes the following steps: 1, confirming gross section size and selecting grouting materials according to displacement probably generated when a roadway reaches to stabilization on the condition of grouting, 2, confirming the depth and the array pitch of a grouting hole, seriflux ratio and grouting parameters, 3, adopting an air drill or a jumbolter to drill grouting holes on the periphery of the roadway, inserting a grouting pipe, and blocking gaps between an outer end of a blocking pipe and hole walls, 4, grouting in a sequence from a low-position hole to a high-position hole, 5, grouting in a separated-row and jumping mode to raise grouting effect, 6, when the displacement of the roadway increases to the fact that an obvious gap occurs, or acceleration or unstable deformation occur to thee roadway, conducting a new round of grouting. The method has the advantages that the roadway releasing energy through orderly deformation, thus needed supporting pressure is reduced gradually. Besides, broken surrounding rocks caused by constriction of the roadway are glued together timely though repeated grouting, thus a supporting structural body with good integrity and high strength always exists around the periphery of the roadway, and ultimately, the needed supporting force for maintaining stabilization of the roadway is reached or exceeded.

Owner:HENAN POLYTECHNIC UNIV

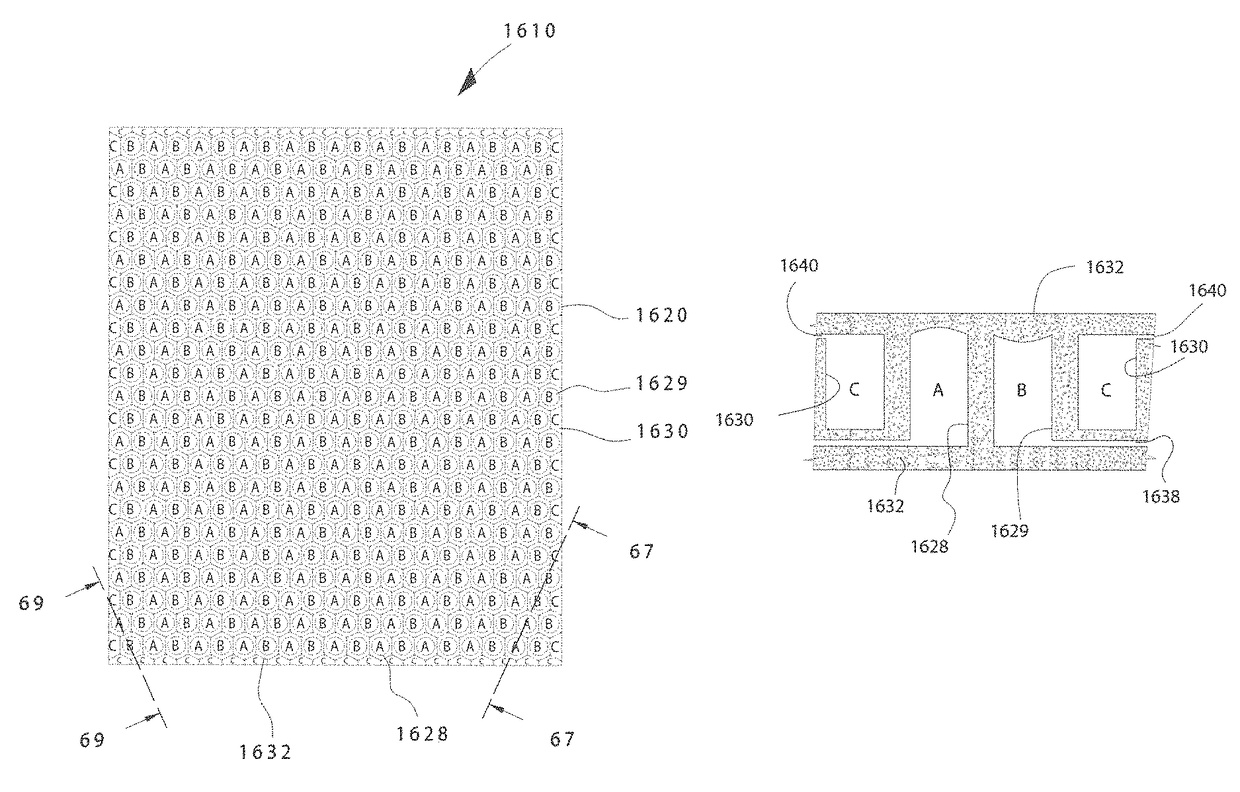

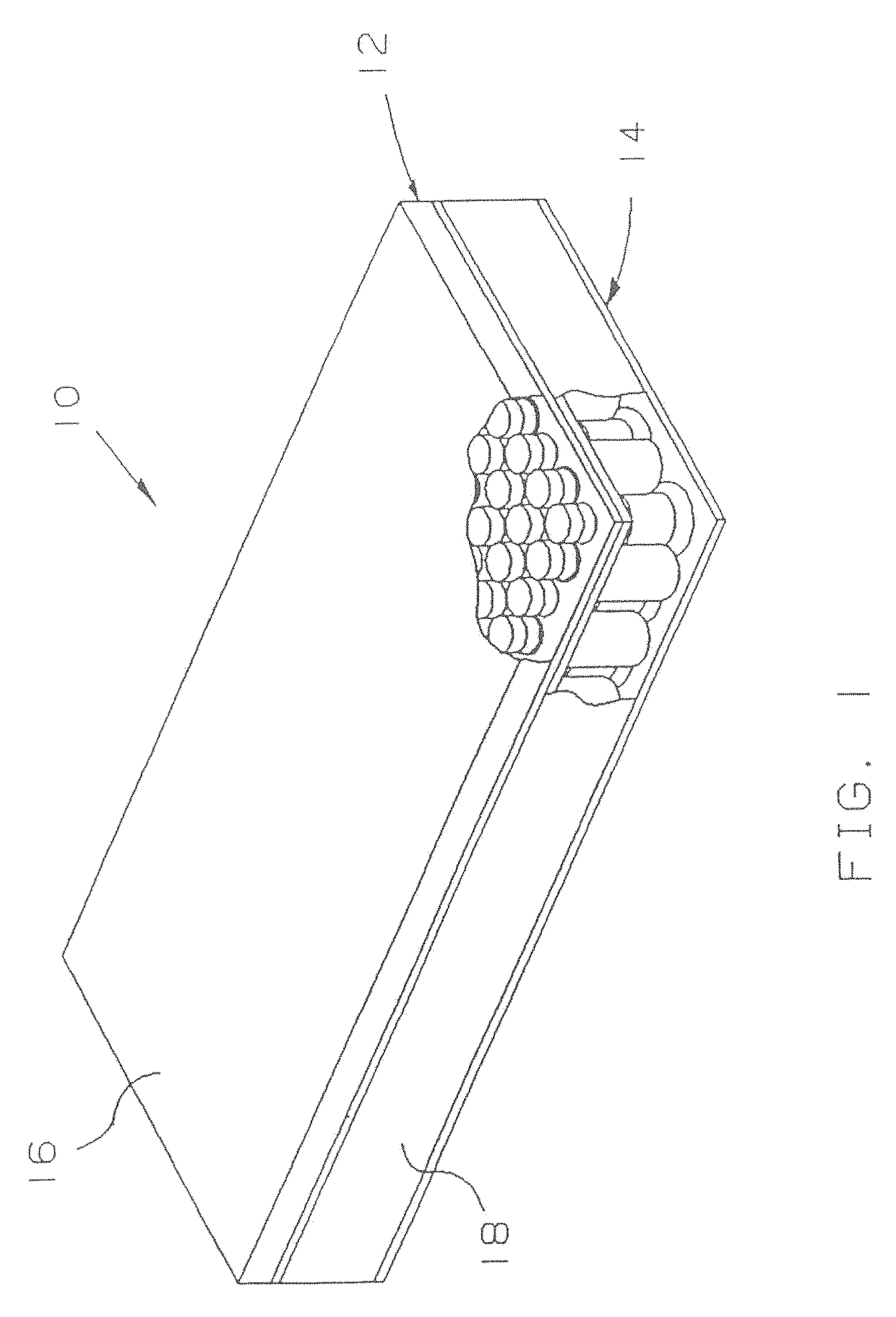

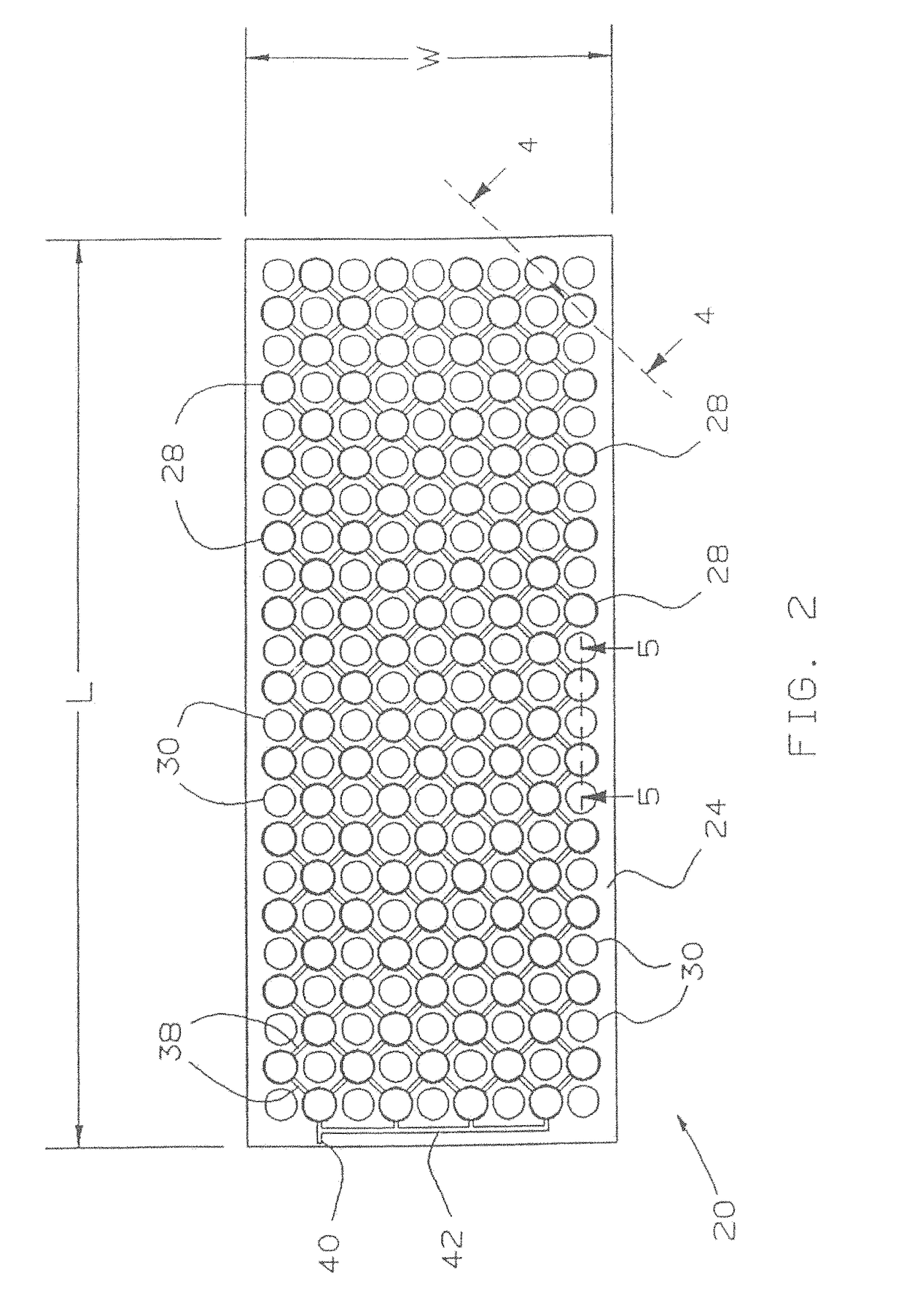

Air support apparatus

InactiveUS9056037B1High magnitudeIncrease deflectionDiagnosticsDismountable chairsNODALRadio frequency

A two layer air support apparatus having at least two preformed air node circuits, where a top layer is radio frequency welded to a bottom layer for providing cyclic support to periodically shift pressure between different parts of a user's anatomy. The periodic shifting of the area supported by a user's anatomy over a period of time improves comfort and blood circulation. It is well known that periodic redistribution of skin pressure can help prevent some of the negative effects experienced through extended usage of beds and chairs. Additionally, enhancement of health and cosmetic improvement to vigorous individuals is suggested by the periodic shifting of supported anatomy due to improved rest from the benefits of a cyclic air support apparatus that has reduced complexity and cost.

Owner:LEVENTHAL ROBERT D +1

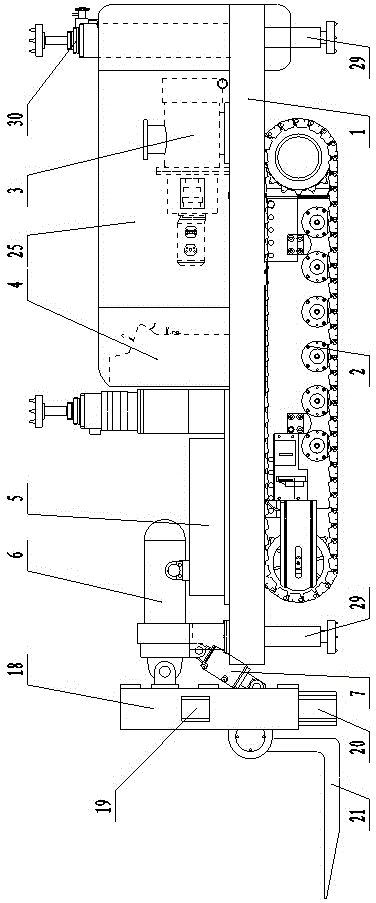

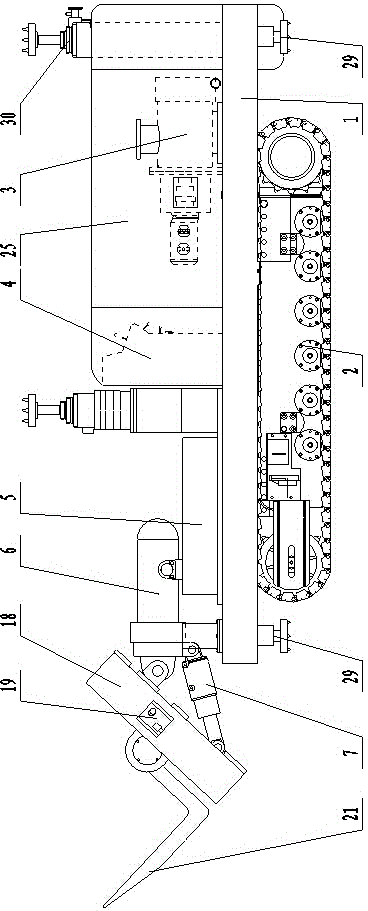

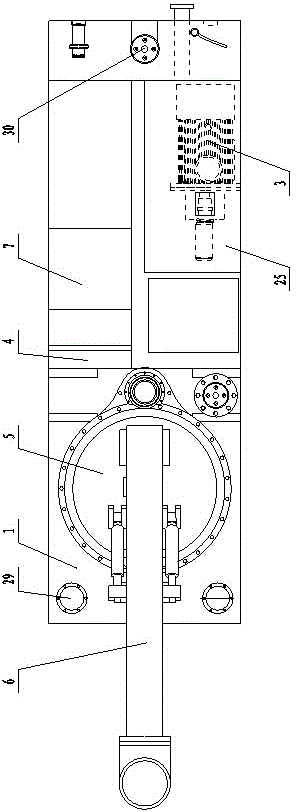

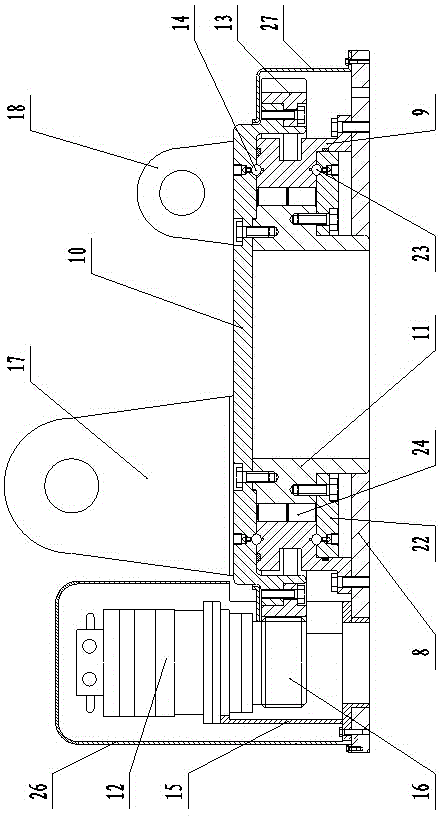

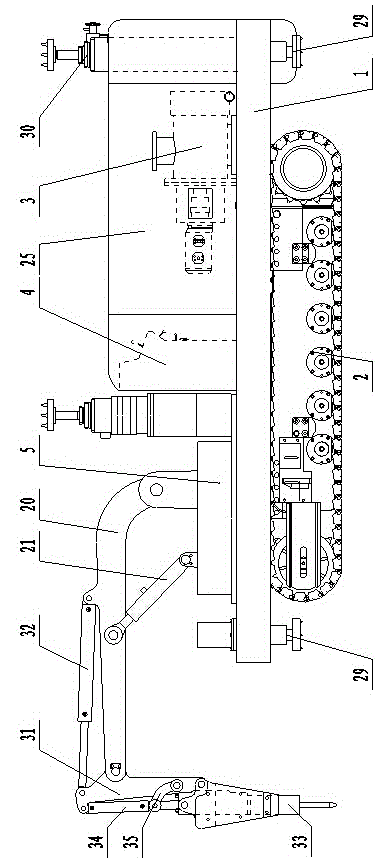

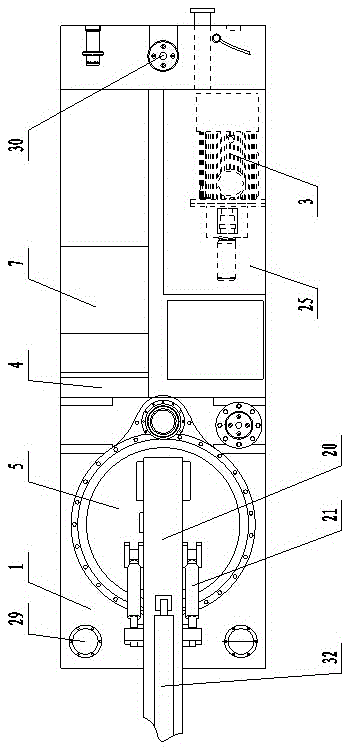

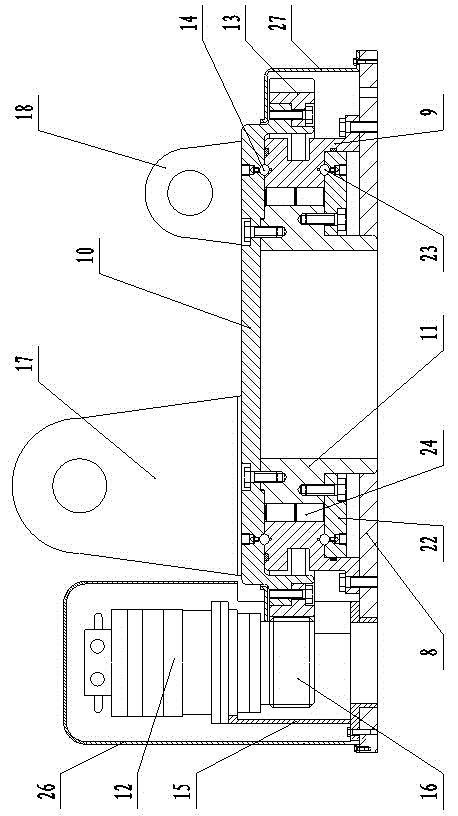

Fork truck transport machine in coal mine tunnel

PendingCN104803322AAdjustable orientationFlexible useLifting devicesHydraulic motorTransportation technology

The invention discloses a fork truck transport machine in a coal mine tunnel, and belongs to the technical field of material transportation in the coal mine tunnel. In order to solve the technical problems, a transport cart which is special for coal mine tunnel and has flexibly rotary fork truck parts is provided. The fork truck transport machine is convenient and flexible to use without enabling the whole vehicle body to rotate, barriers can be avoided efficiently, working safety is guaranteed, and work efficiency is increased. The adopted technical scheme is that multiple groups of traveling mechanisms are arranged on the lower part of a rack, the back end of a fork truck part is fixedly arranged on the front part of the rack through a turntable, the back part of the rack is provided with an explosion-proof diesel engine and a hydraulic system both of which provide motive power, the rack is also provided with a console and a driver's seat. The hydraulic crushing device of the floor heave crushing machine is arranged on the front part of the rack through the turntable, a hydraulic motor controls a gear transmission device to realize rotation of the turntable, the direction of the fork truck part is adjustable, the whole rack is unnecessary to rotate, and the floor heave crushing machine is more flexible to use.

Owner:SHANXI DONGHUA MACHINERY

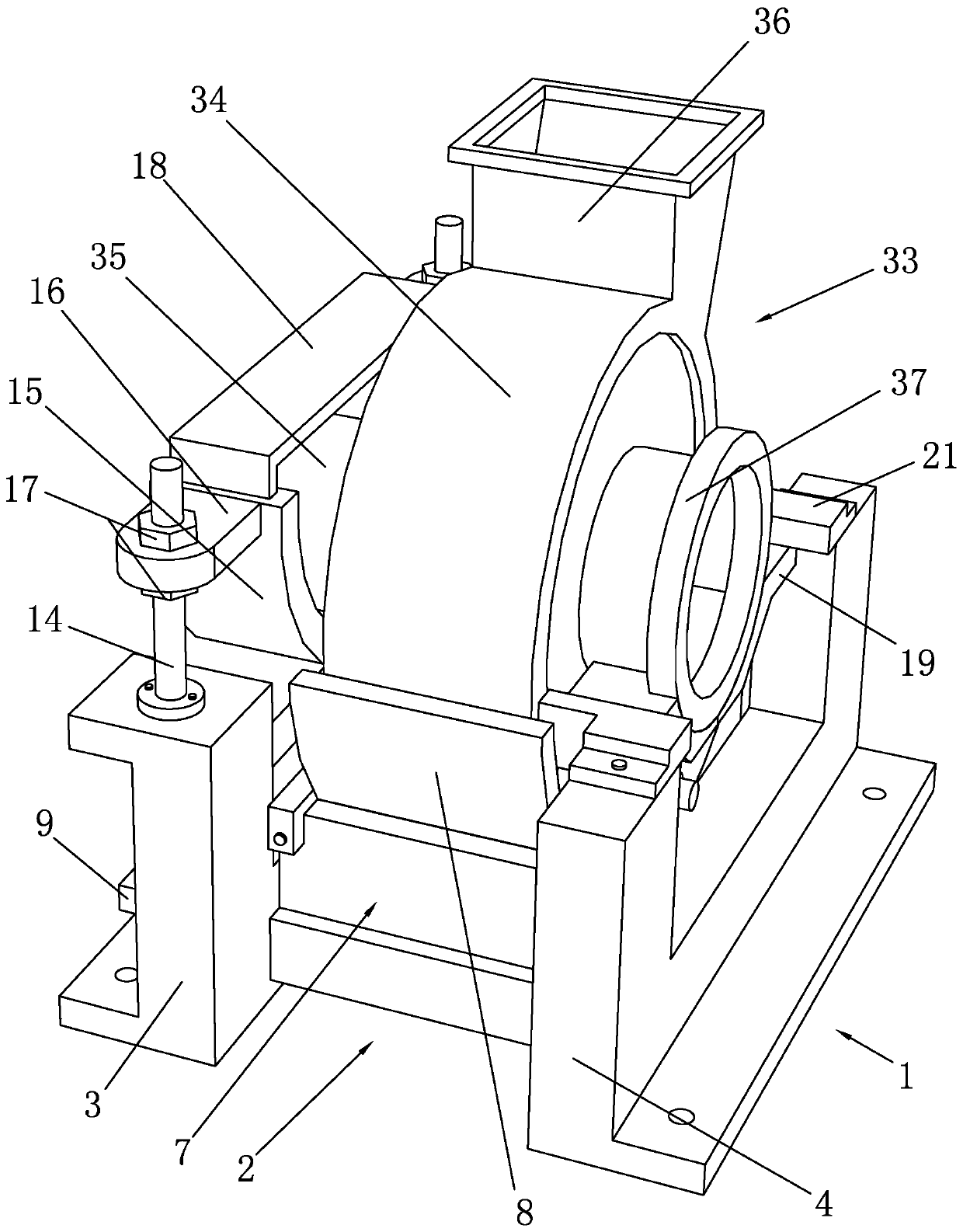

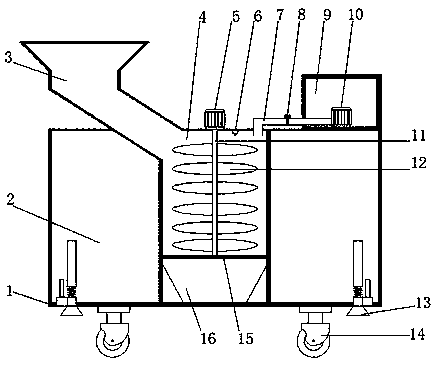

Chemotherapy nursing device used in oncology departments

InactiveCN109894032ASpeed up the mixingImprove work efficiencyRotating receptacle mixersMixer accessoriesEngineeringMedicine.oncology

The invention discloses a chemotherapy nursing device used in oncology departments. The chemotherapy nursing device used in oncology departments comprises a pedestal; the middle part of the upper surface of the pedestal is fixedly provided with a rotary motor; the bottom sides of the pedestal are fixedly provided with supporting legs; an output shaft of the rotary motor is fixedly provided with arotating column; the top end of the rotating column is fixedly provided with a rotating disc; the upper part of the rotating disc is provided with a medicine preparation mixing box; the two sides of the medicine preparation mixing box are provided with bracing frames which are fixedly arranged on the top of the rotating disc. The chemotherapy nursing device used in oncology departments is capableof reducing medical staff labor intensity, avoiding troubles caused by hand-operated mixing of chemotherapy nursing medicines, saving both labor and time, accelerating medicine mixing speed, and increasing working efficiency, is convenient for subsequent chemotherapy nursing on patients, is stable in operation, and is convenient to use.

Owner:田晓晓

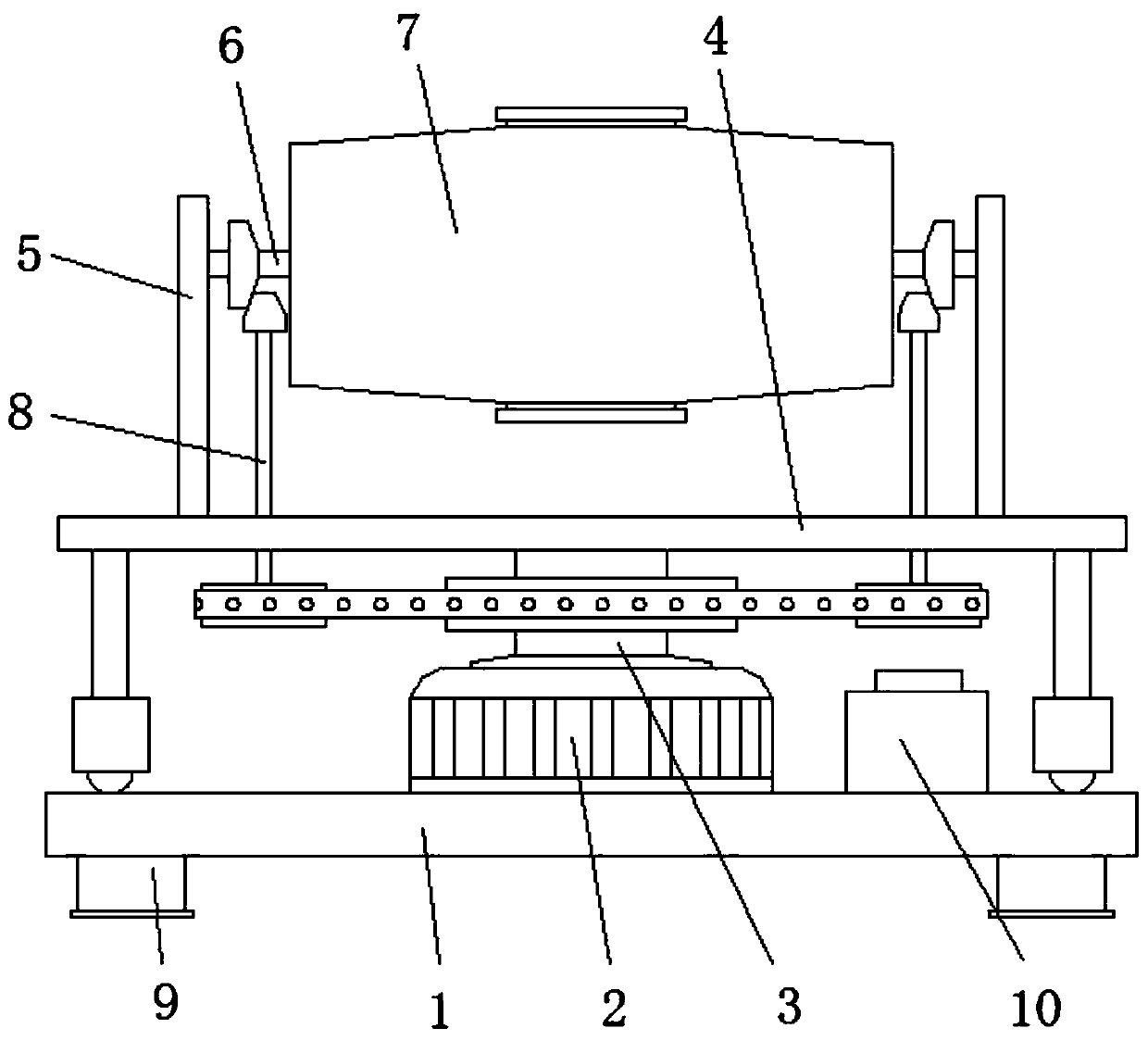

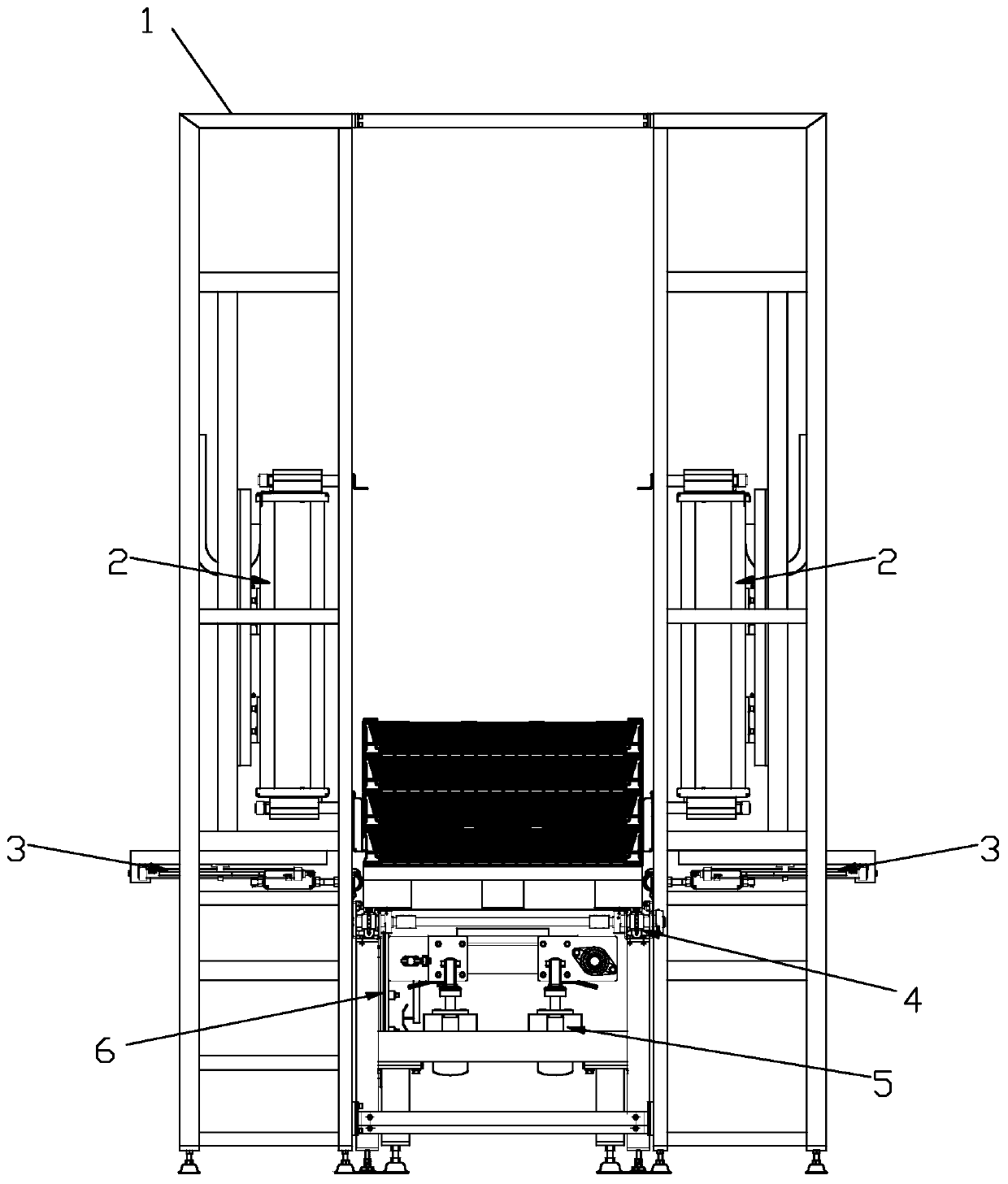

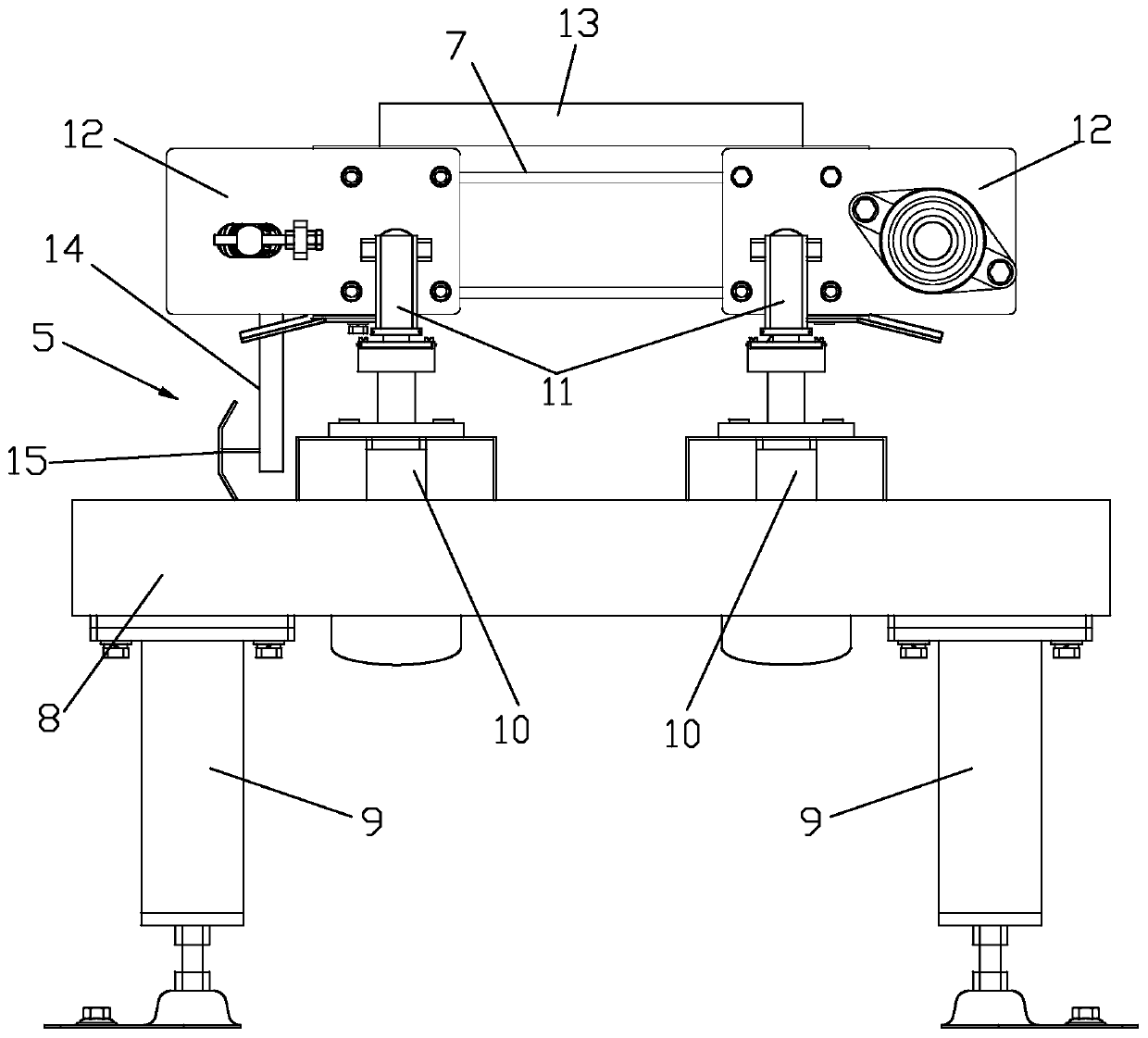

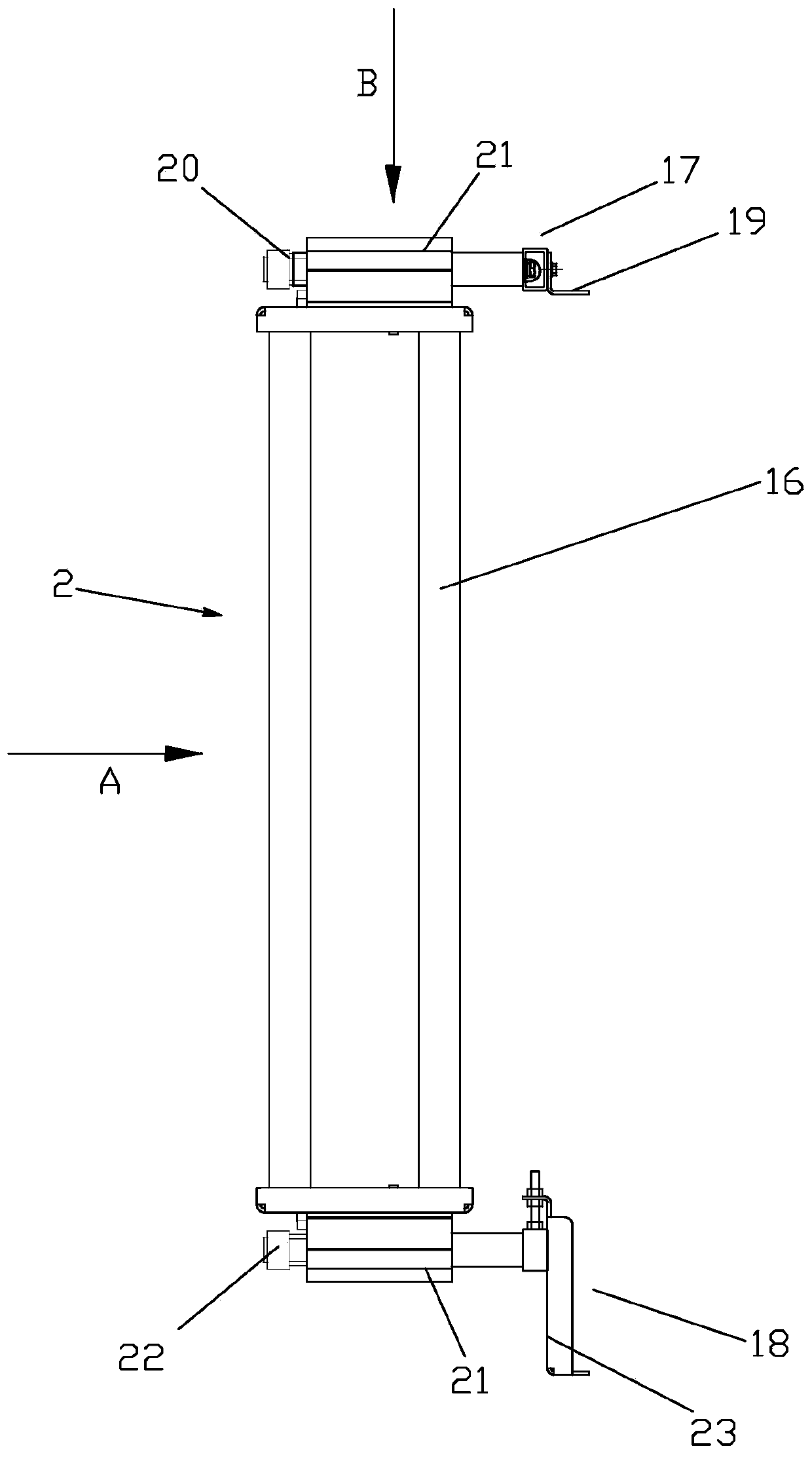

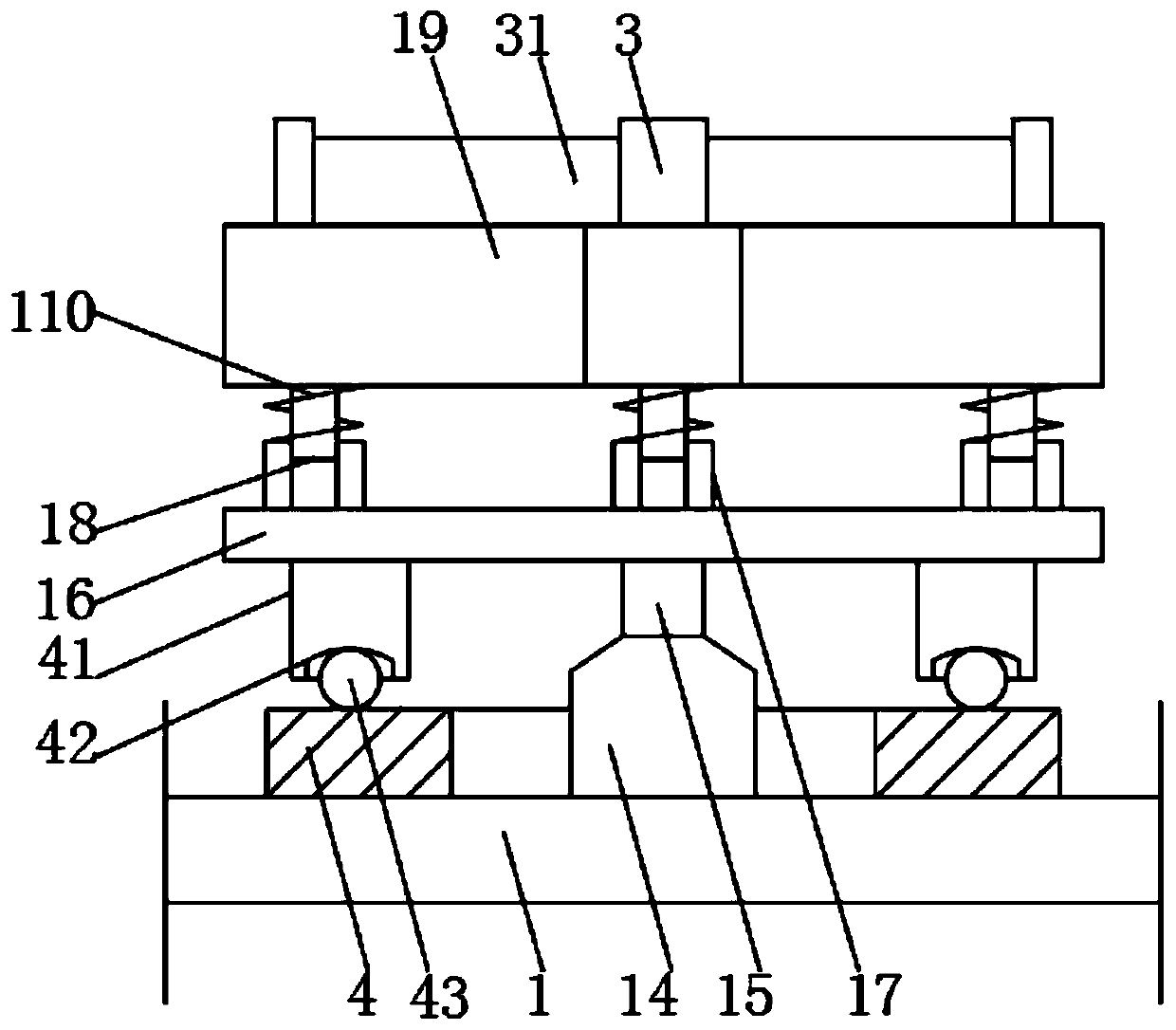

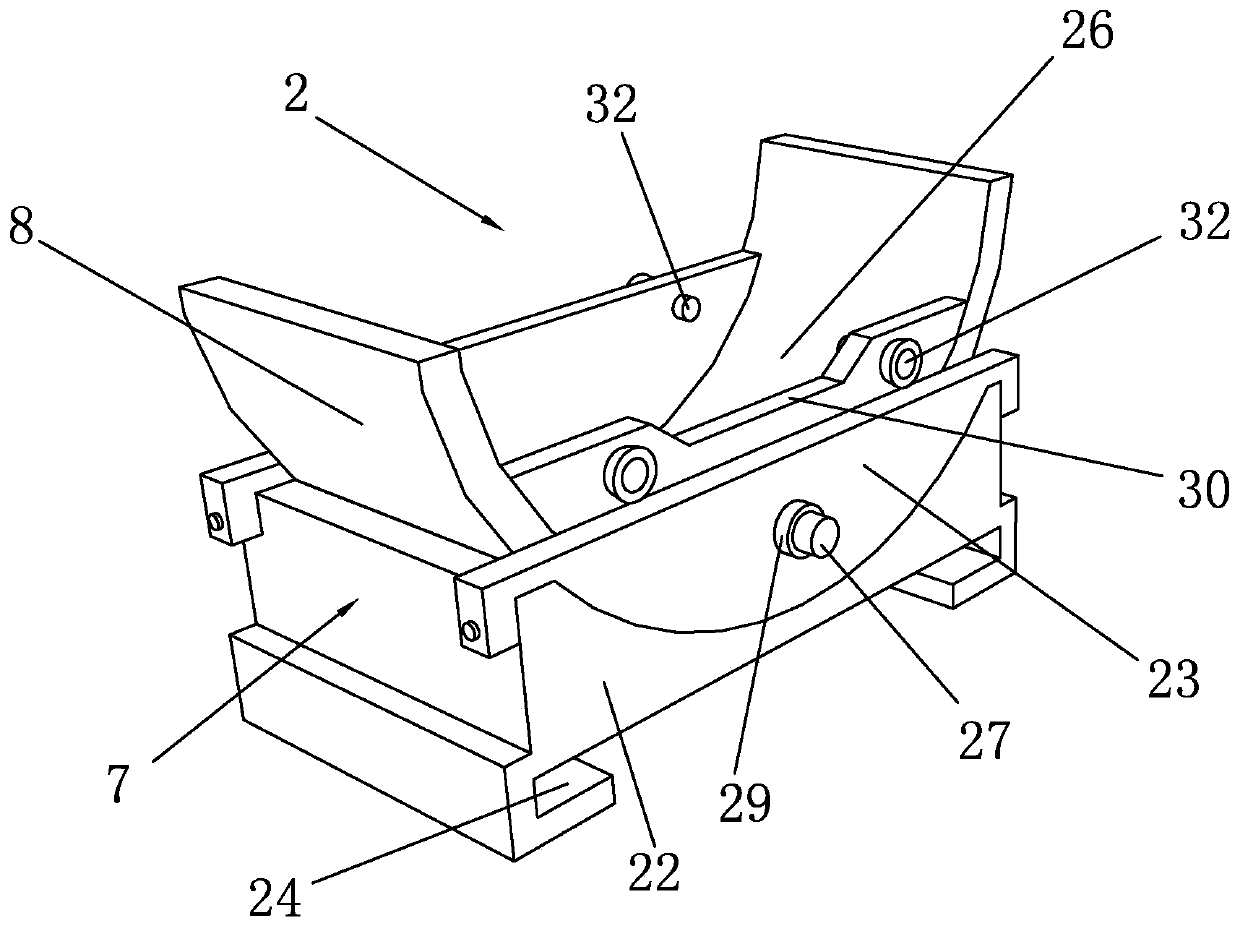

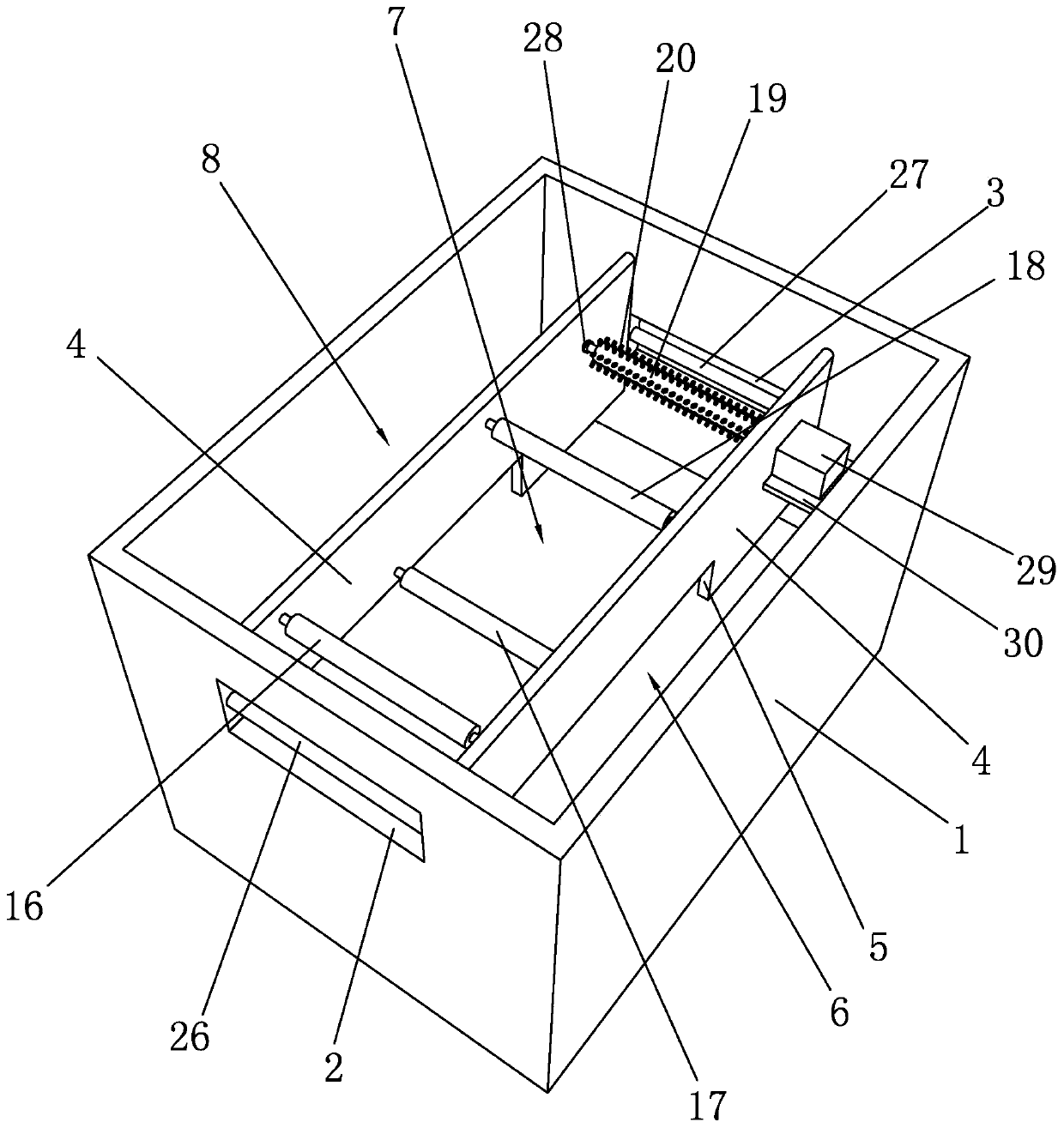

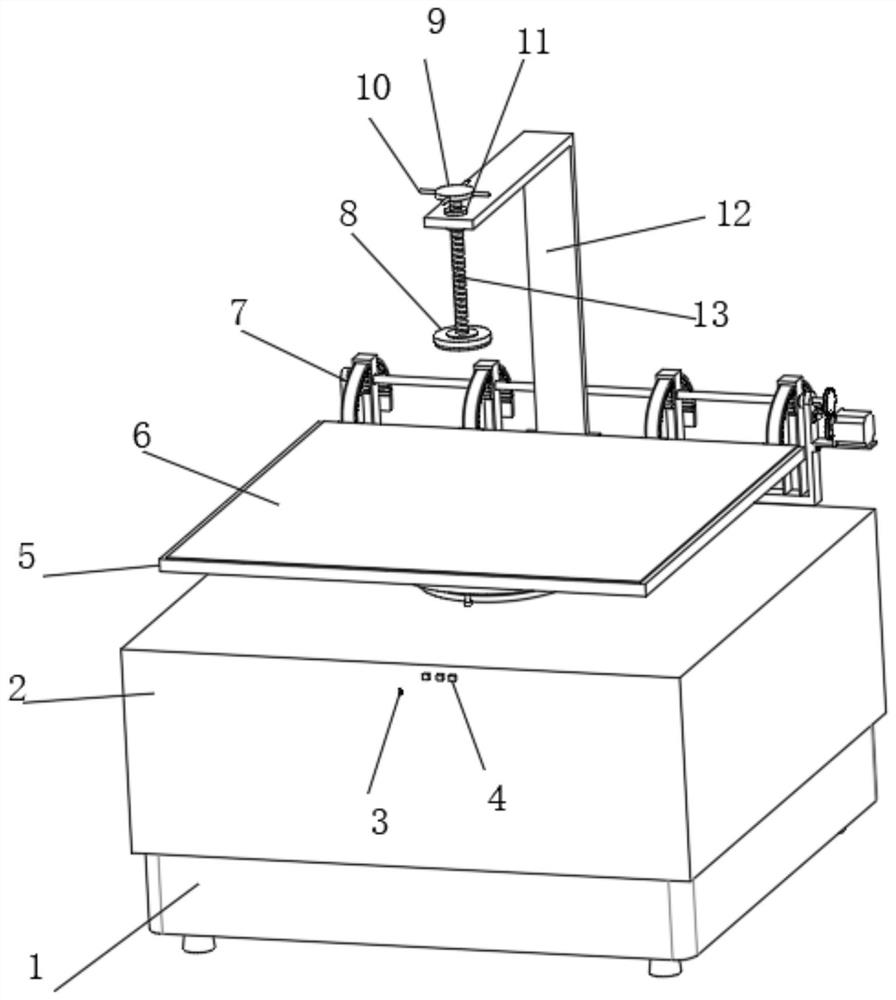

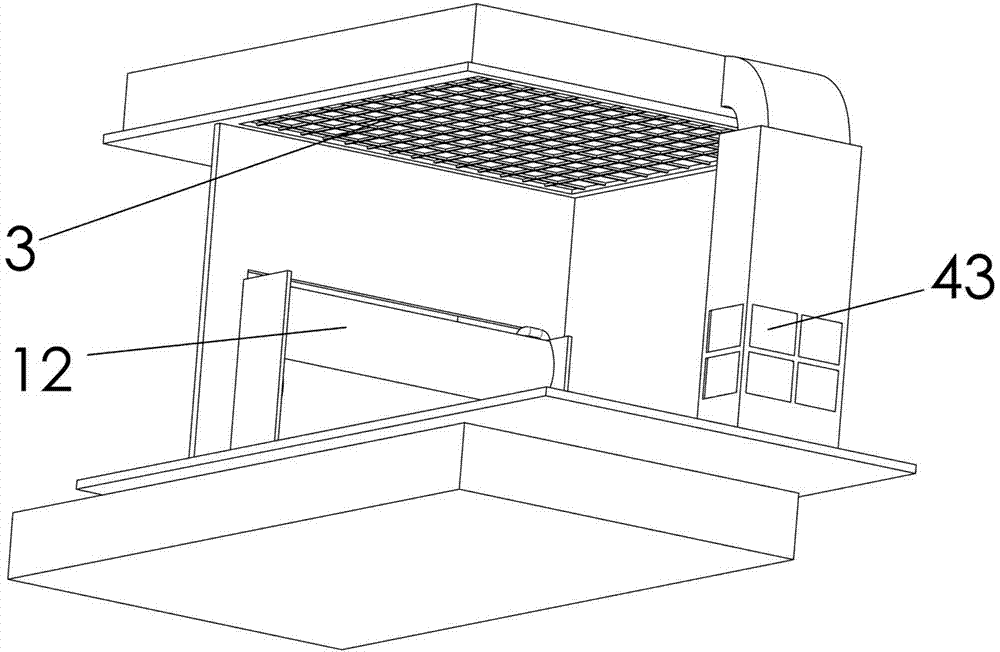

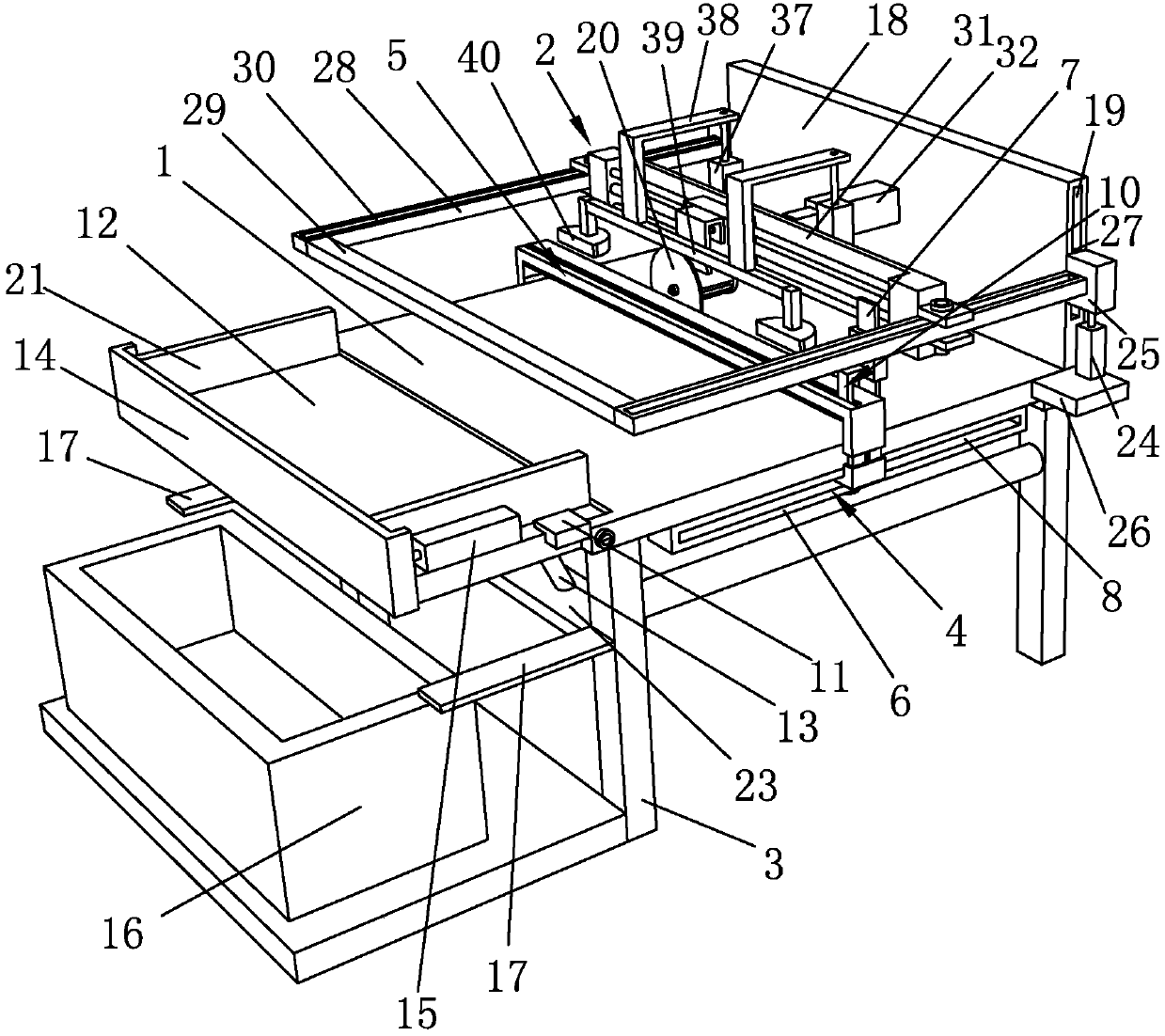

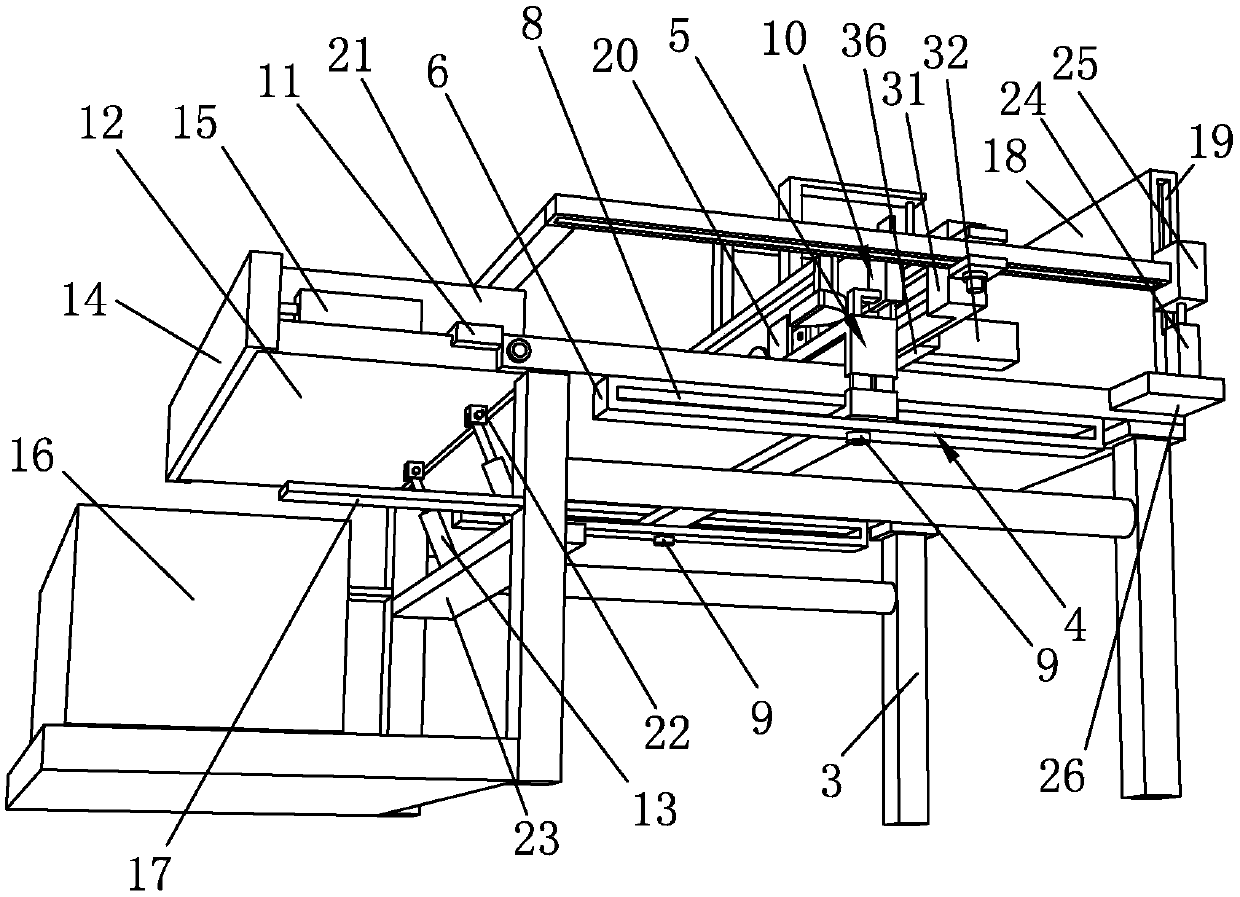

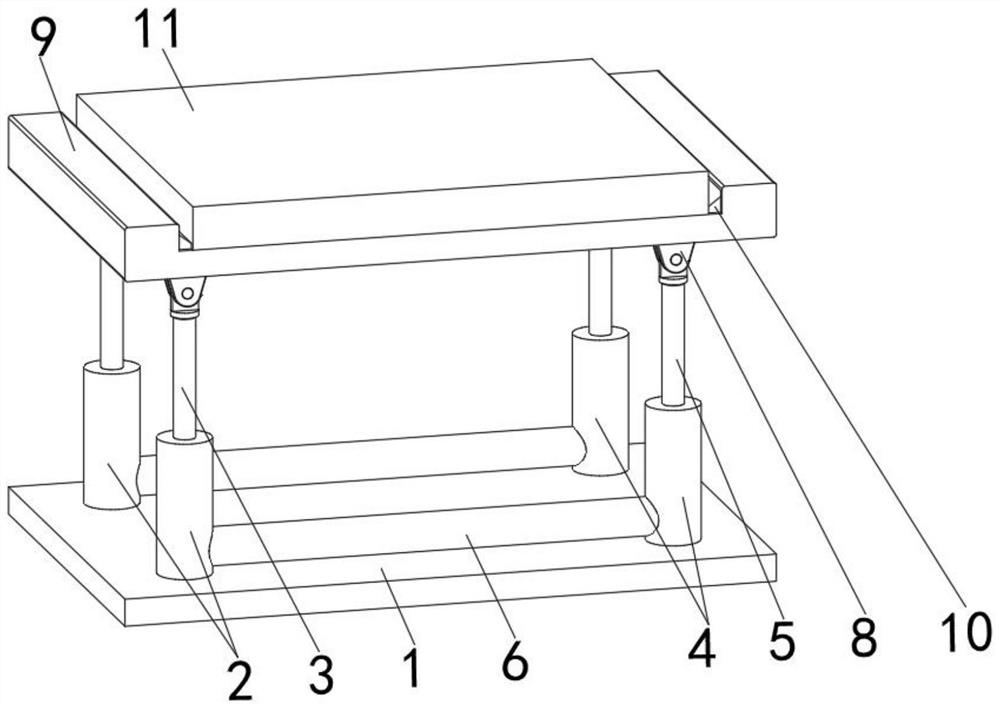

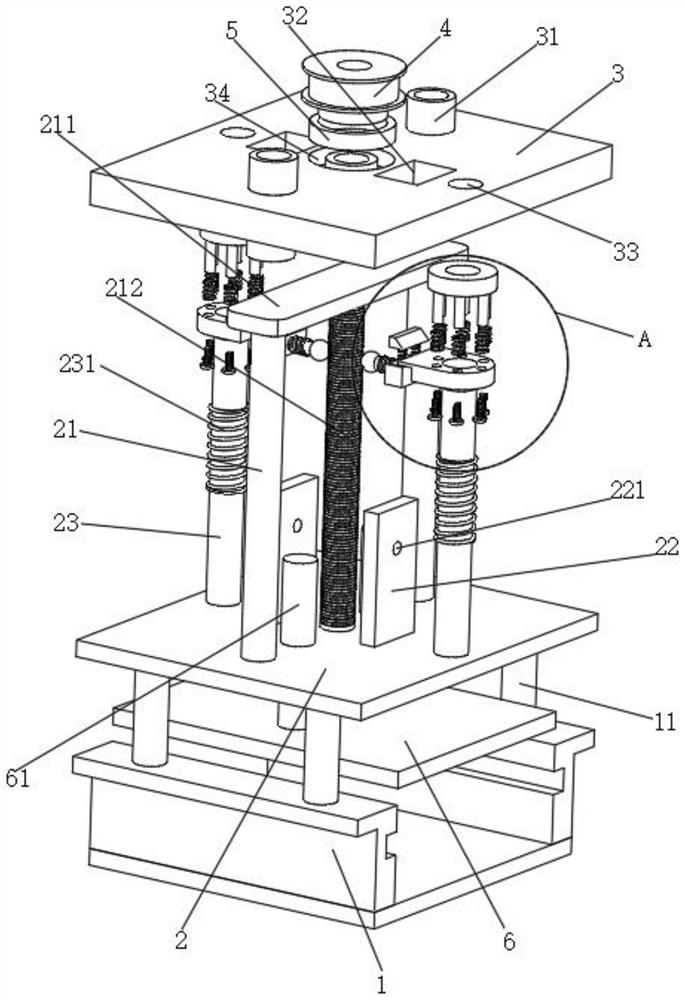

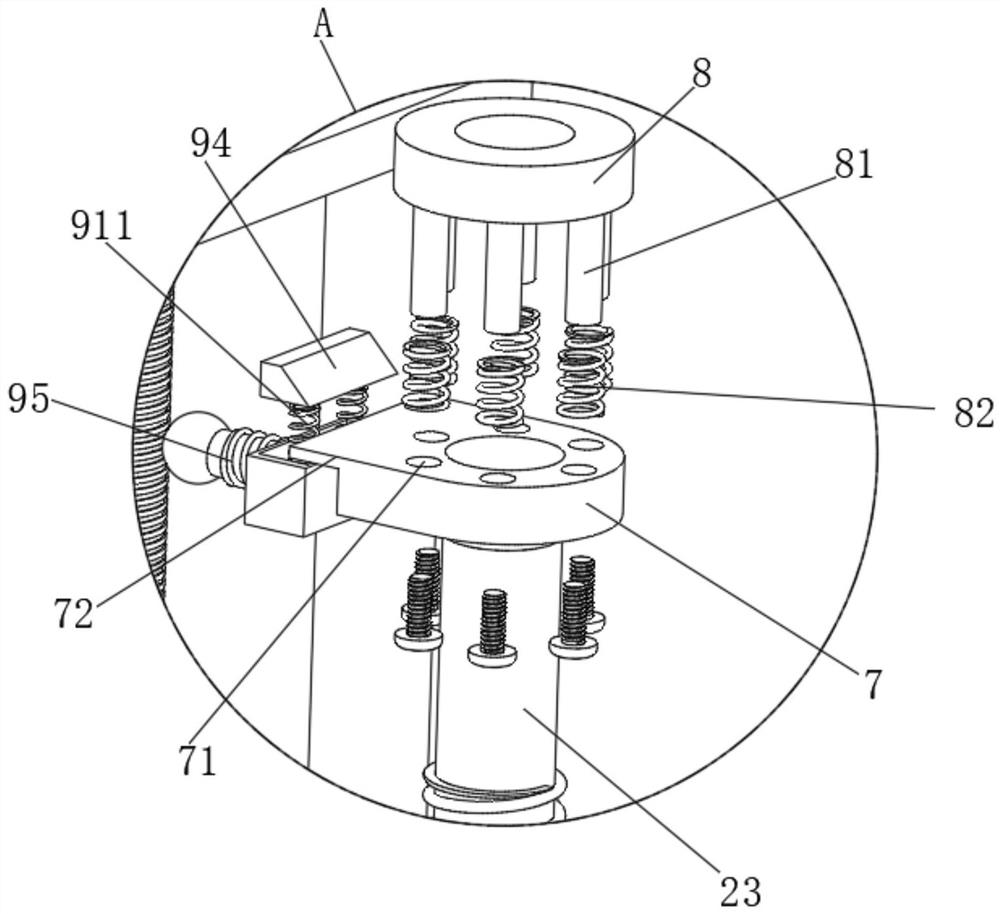

Lifting mechanism of frame splitting machine for industrial aquaculture

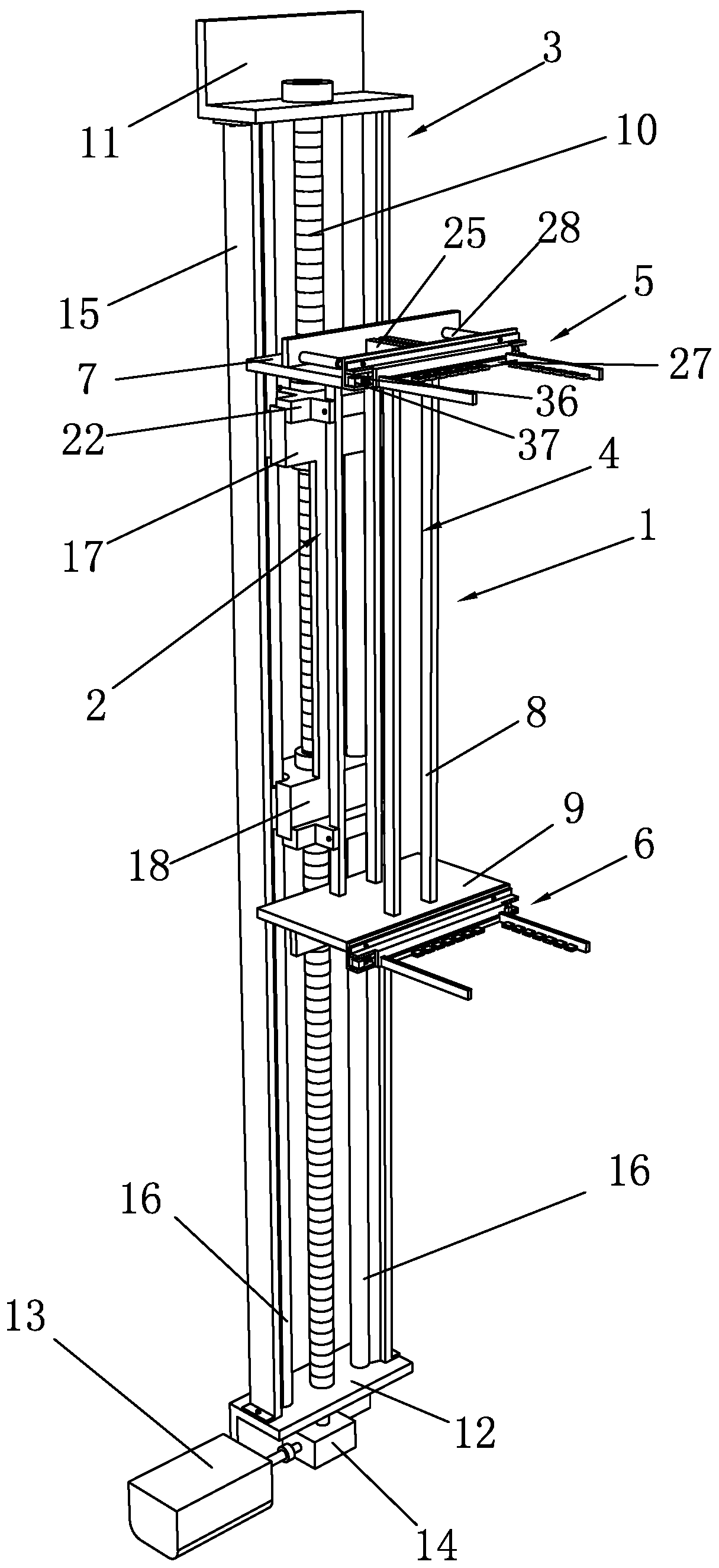

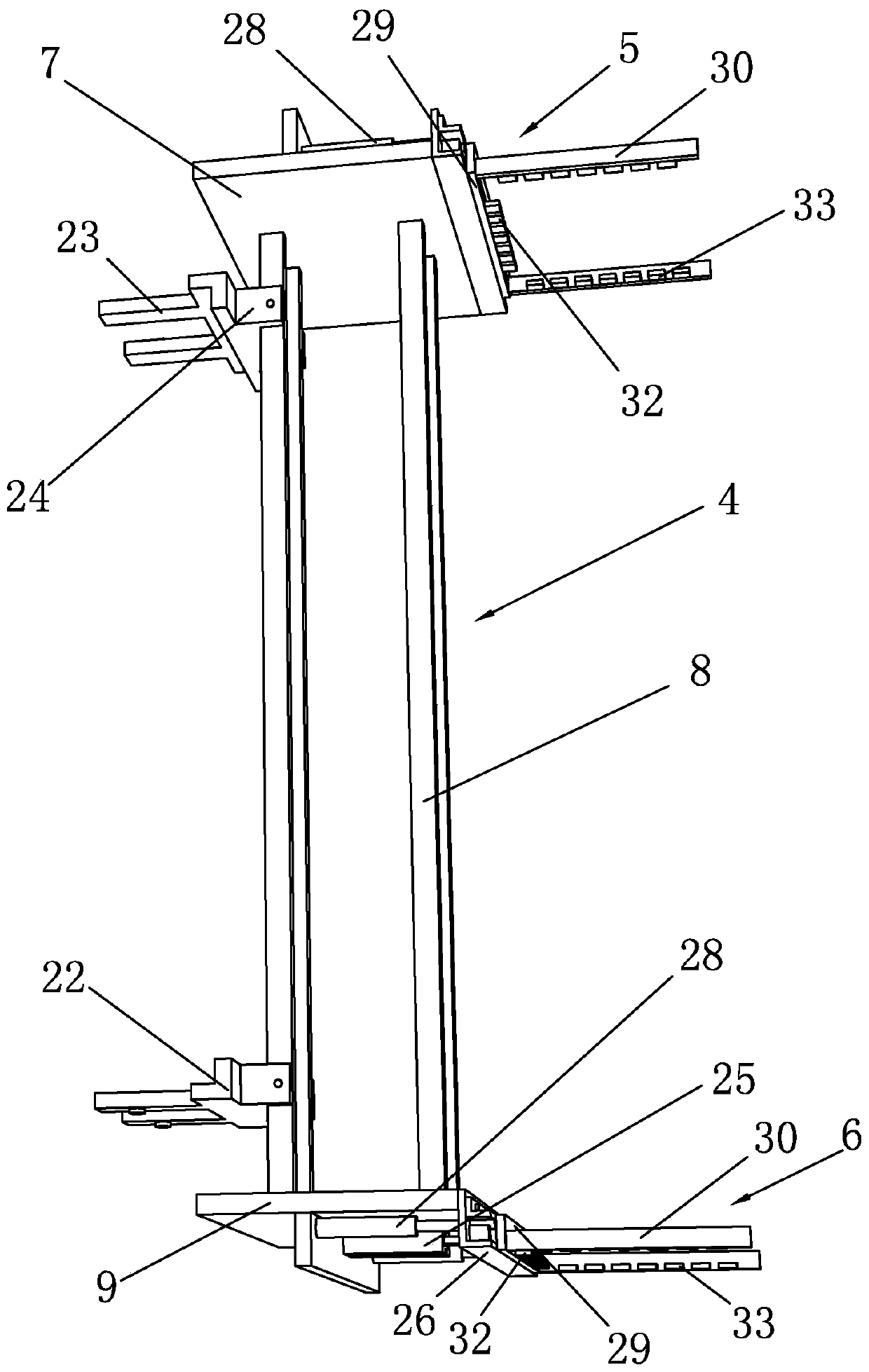

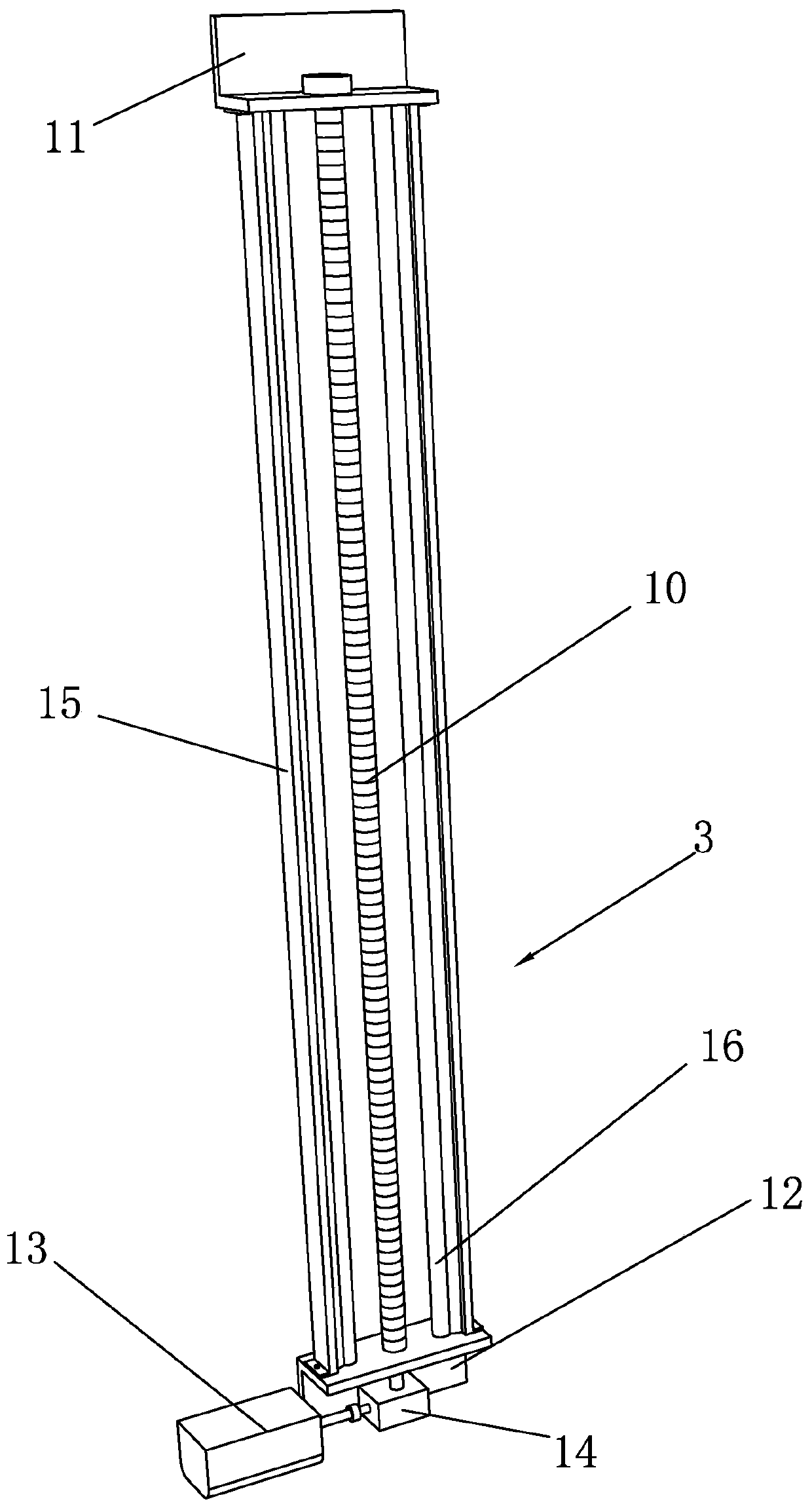

ActiveCN111232866AThe overall structure design is compact and reasonableEnsure structural stabilityLifting framesElectric machineryDrive motor

The invention discloses a lifting mechanism of a frame splitting machine for industrial aquaculture. The lifting mechanism comprises a lifting body, a sliding block body and a lifting screw rod assembly, wherein the lifting body is connected with the sliding block body, the sliding block body is positioned on the lifting screw rod assembly, and the lifting screw rod assembly drives the lifting body to slide up and down through the sliding block body. According to the lifting mechanism, the overall structural design is ingenious and reasonable, a driving motor drives a lifting screw rod to rotate through a gear conversion box, so that the lifting of the sliding block body is achieved to drive the lifting of the lifting body, the step-by-step separation between a lower culture frame and an upper culture frame stack is achieved, the assembly and disassembly of the culture frame stack is more convenient, the assembly line operation of cocoon collection in the culture frame is achieved, thewhole operation is more automated, and the labor intensity of workers is effectively reduced; and the lifting screw type lifting is adopted, the stability in the lifting process of the lifting body can be effectively guaranteed, the lifting process of the lifting body is more smooth and stable, collision caused by swinging of the lifting body in the lifting process is avoided, and the operation safety performance is improved.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

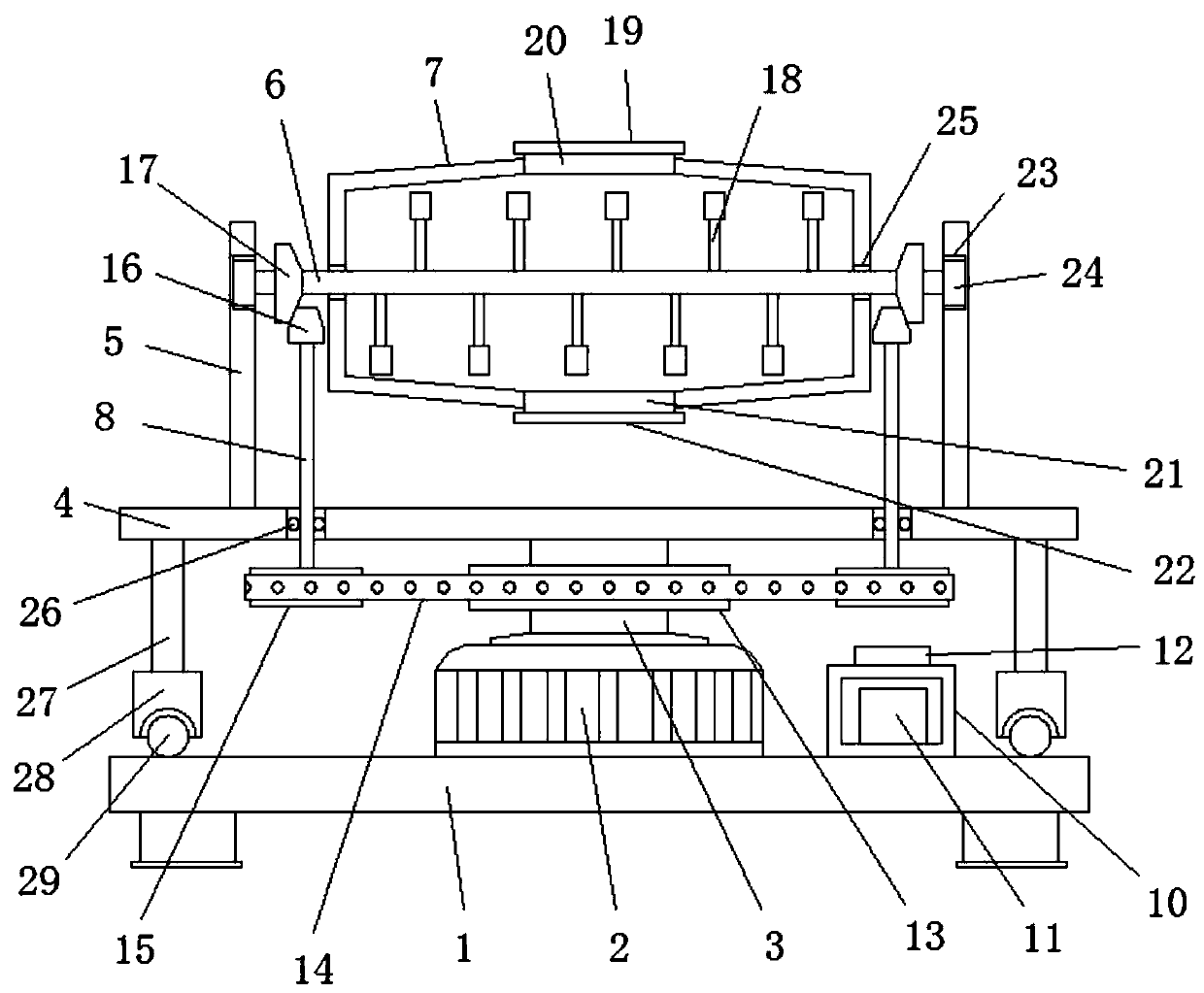

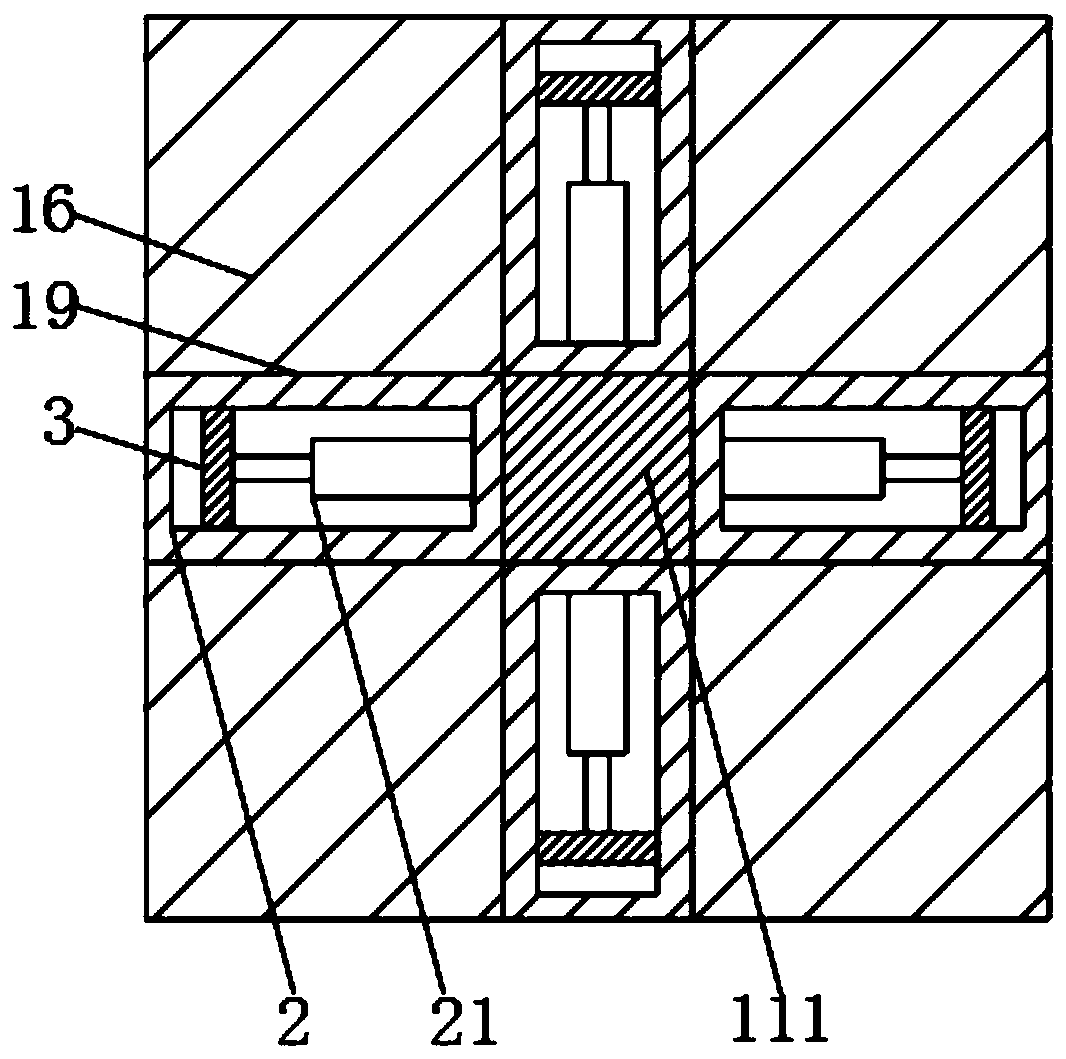

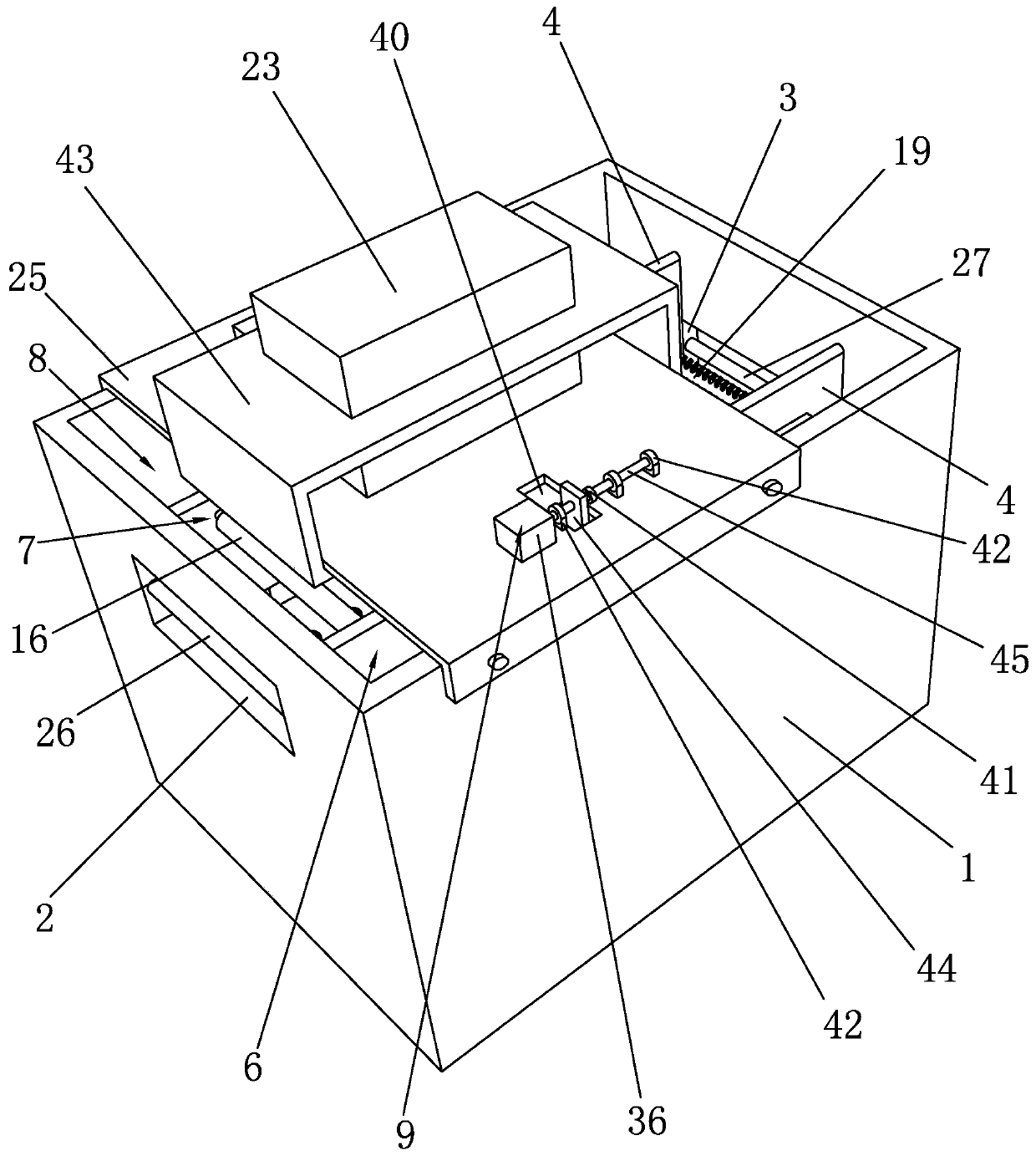

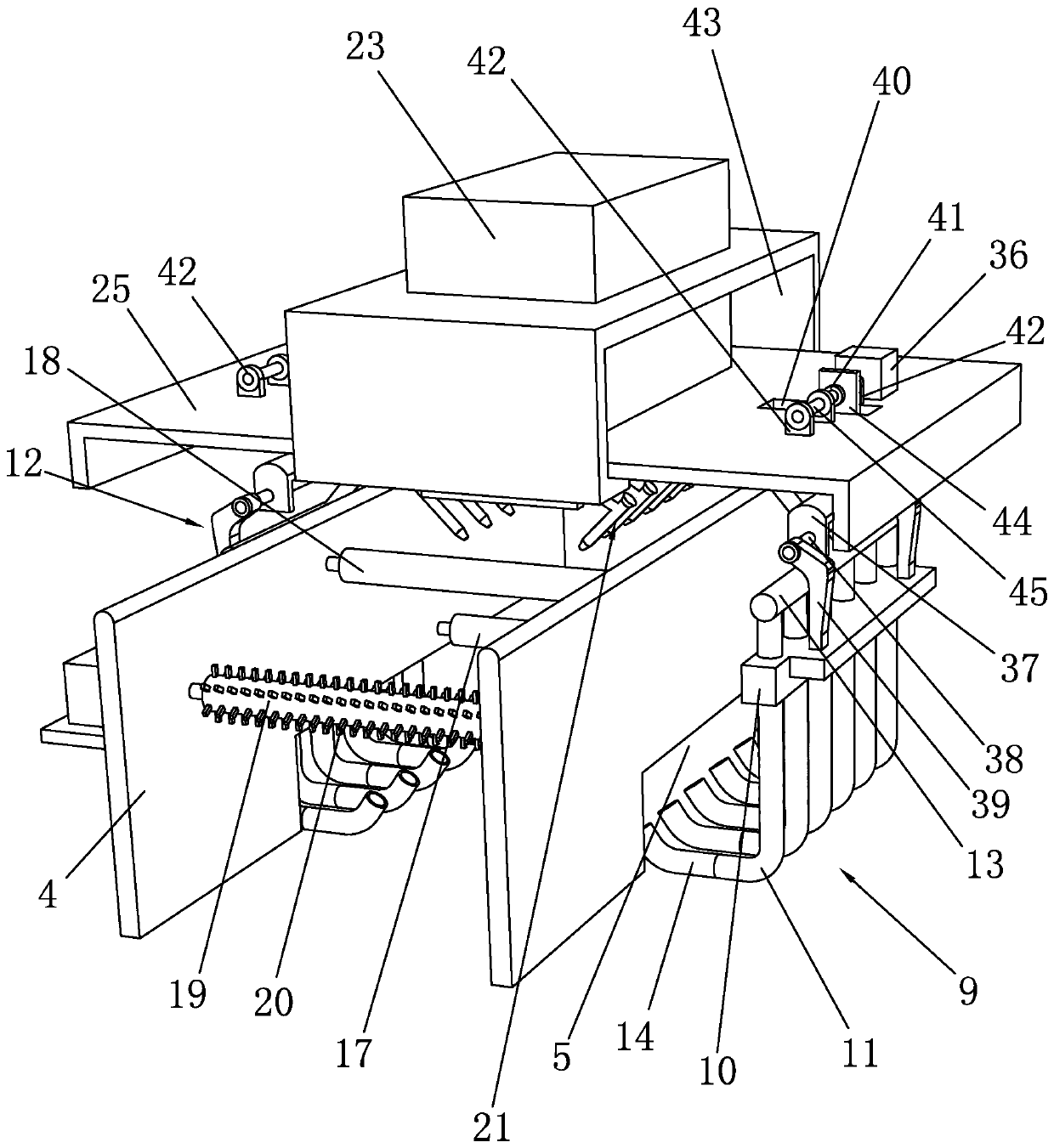

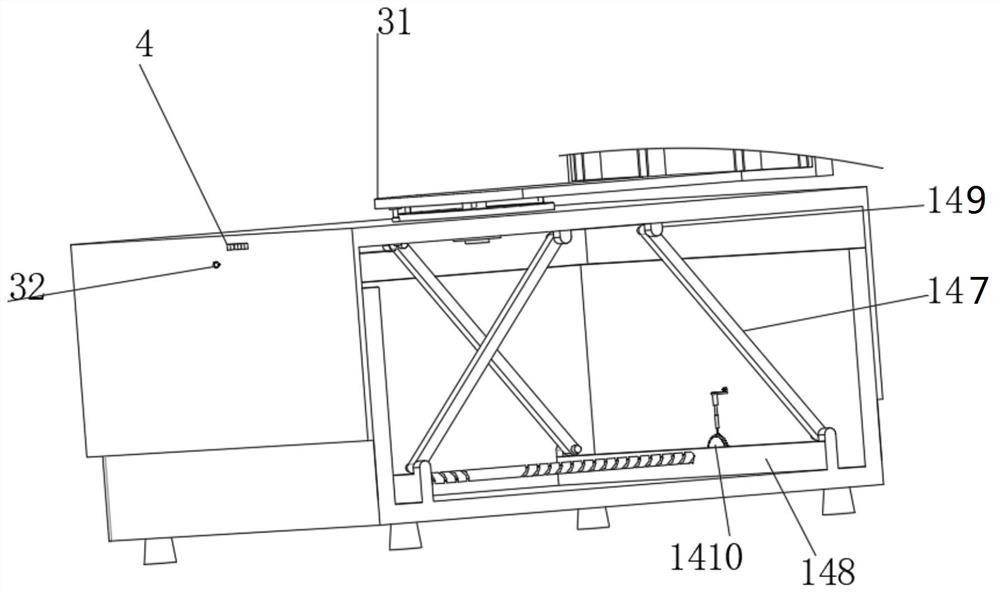

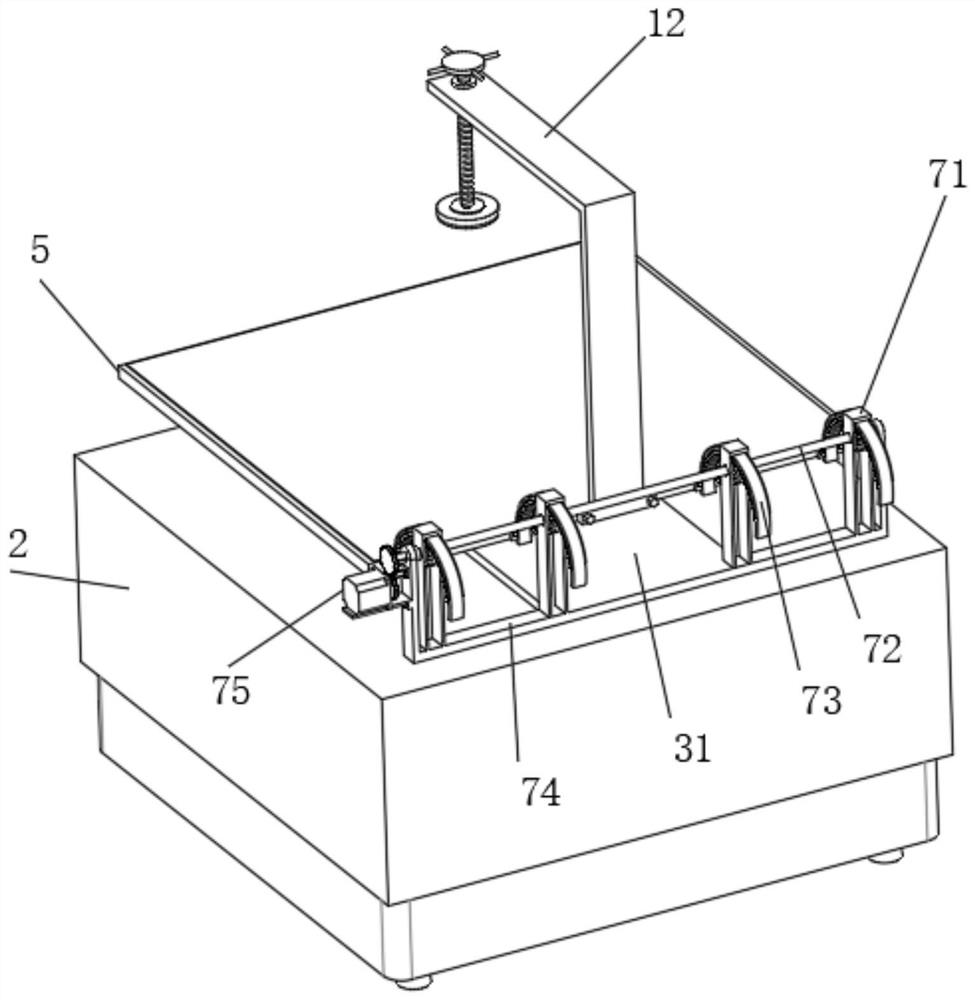

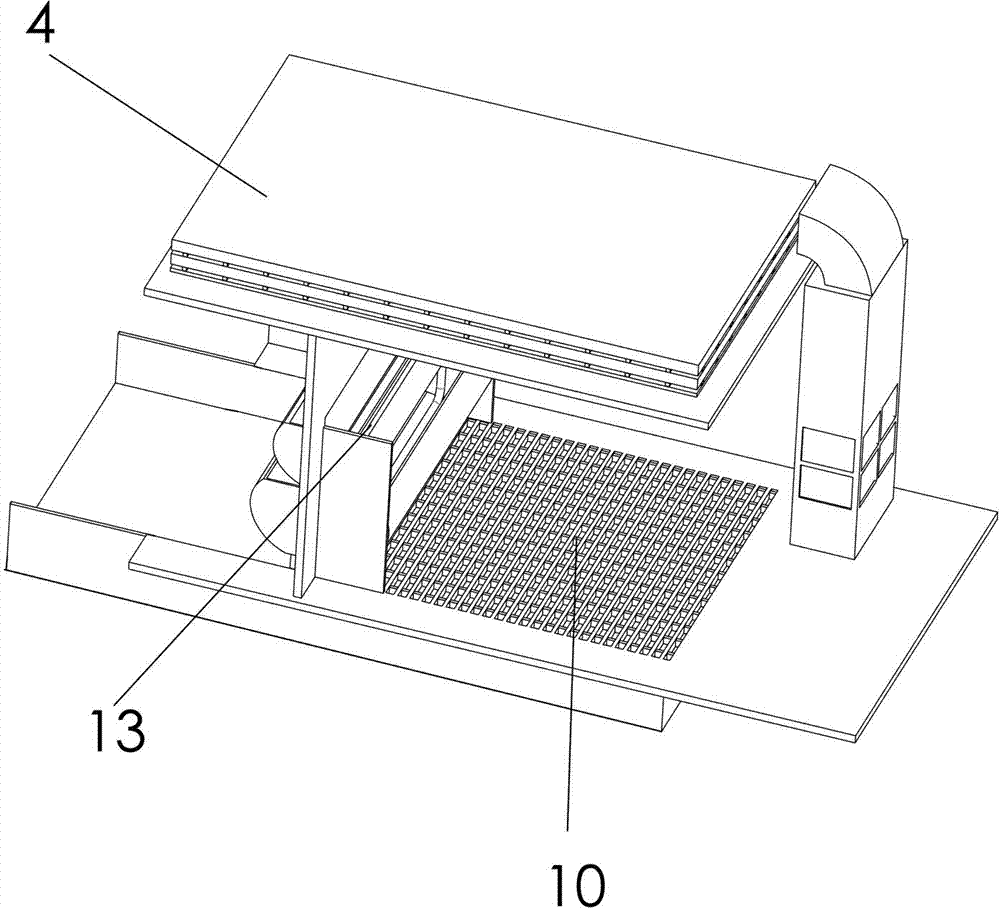

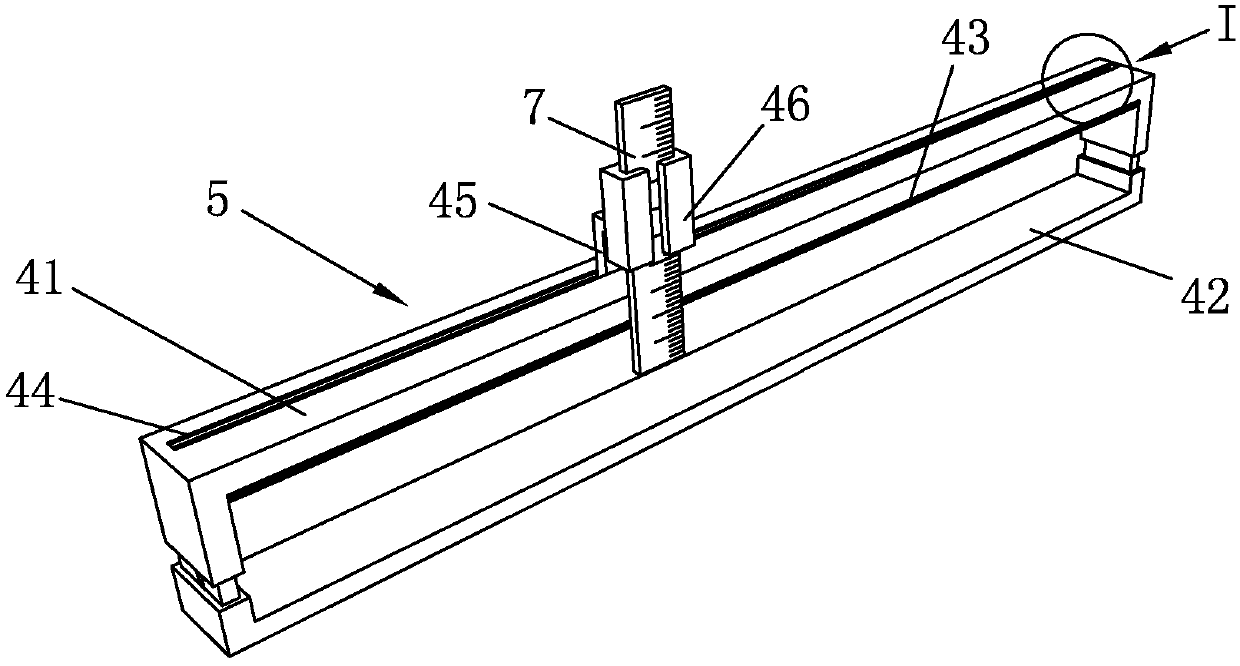

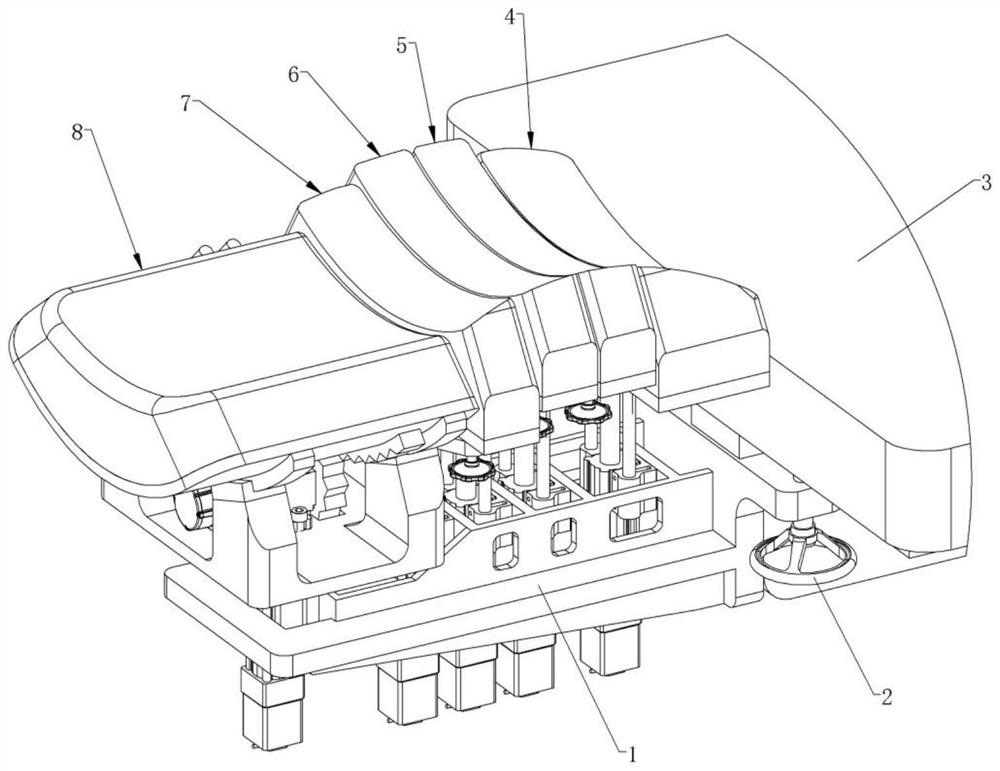

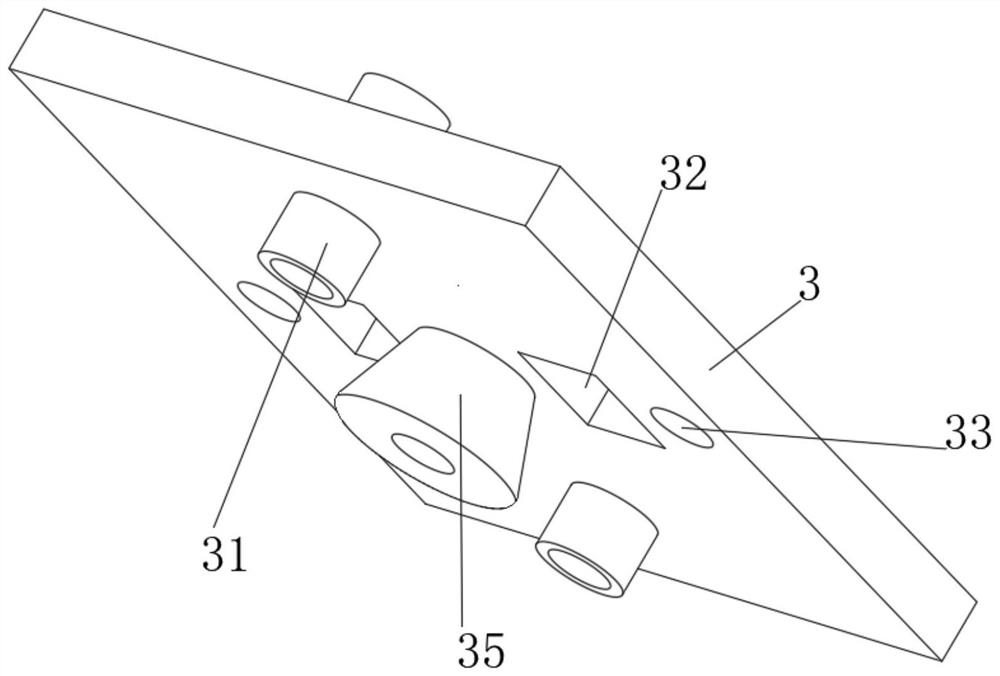

Lifting cocoon cage disc splitting machine for industrial aquaculture and splitting method for lifting cocoon cage disc splitting machine for industrial aquaculture

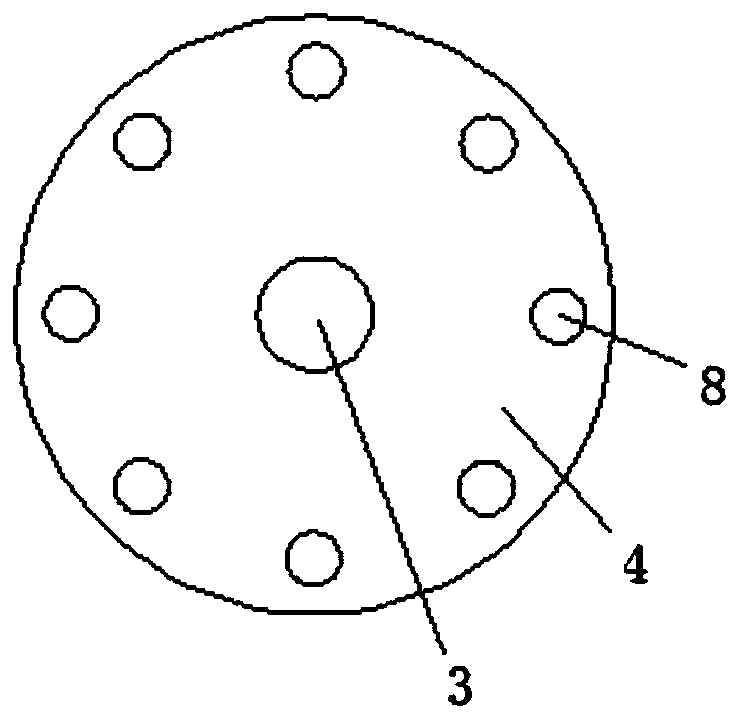

ActiveCN111066747AReduce support pressureAvoid prone to shaking and dumping problemsAnimal husbandryAnimal scienceEngineering

The invention discloses a lifting cocoon cage disc splitting machine for industrial aquaculture. The lifting cocoon cage disc splitting machine for industrial aquaculture comprises a rack and is characterized in that flat supporting mechanisms are installed on the two sides of the rack respectively and are provided with supporting claws respectively to support a culture frame group through the supporting claws; a lifting mechanism and chain conveyors are installed among the rack; the lifting mechanism is installed between the chain conveyors; the culture frame group is lifted through the lifting mechanism; and the chain conveyor carries the culture frame group. By adopting the lifting cocoon cage disc splitting machine for industrial aquaculture, culture frames and cocoon cages are subjected to centralized treatment, transfer and the like by adopting a stacking manner in industrial sericulture, so that the culture scale is greatly increased, the culture efficiency is improved, and theculture yield is increased; and in order to split the stacked culture frame groups to enable the culture frame groups to be thrown into a production line one by one, the lifting cocoon cage disc splitting machine is designed specifically, so that the stacked culture frame groups can be split in a lifting manner, and realization of industrialized and large-scale culture operation is greatly promoted.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

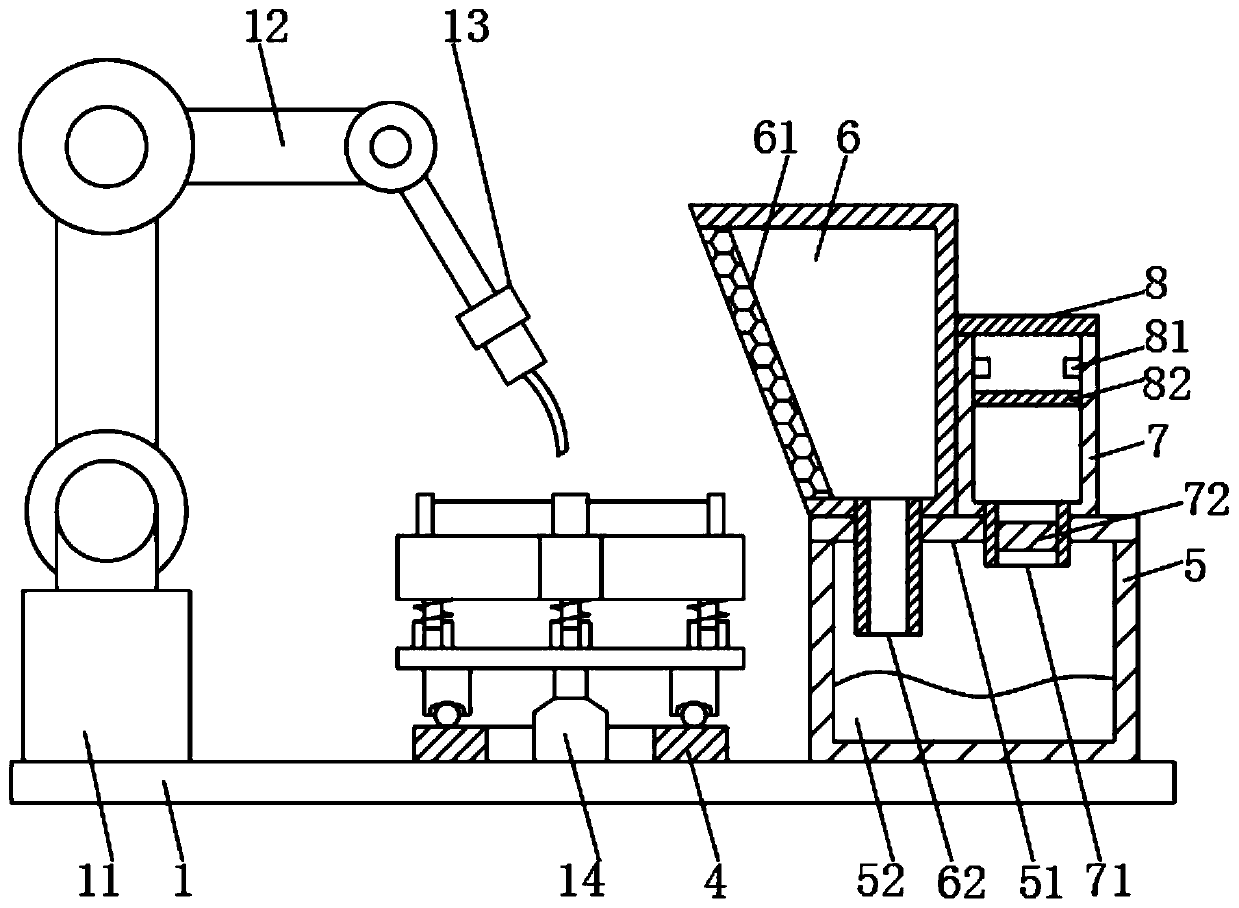

Intelligent welding robot

InactiveCN110524110APlay the effect of auxiliary rotationReduce support pressureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSupport pressure

The invention discloses an intelligent welding robot. Including a base, a supporting table is arranged on the base. A mechanical arm is arranged on the supporting table; a laser welding head is arranged at the end part of the mechanical arm; a motor is further arranged on the base, a rotating shaft is arranged on the motor, a supporting plate is fixedly installed on the rotating shaft, a buffer sleeve is arranged on the supporting plate, a buffer rod is slidably arranged in the buffer sleeve, a clamping base is arranged on the buffer rod, a spring is arranged on the buffer rod, the two ends ofthe spring are connected with the clamping base and the buffer sleeve respectively, and a connecting block is fixedly installed at one end of the clamping base. According to the intelligent welding robot, through cooperation of clamping plates on four clamping bases and the moving effect of an air cylinder, a plate body can be erected and clamped, through rotation of a motor, the plate body can rotate to be matched with a laser welding head for welding work, balls can achieve the auxiliary rotating effect, and the supporting pressure on a rotating shaft is reduced.

Owner:LUOYANG NORMAL UNIV

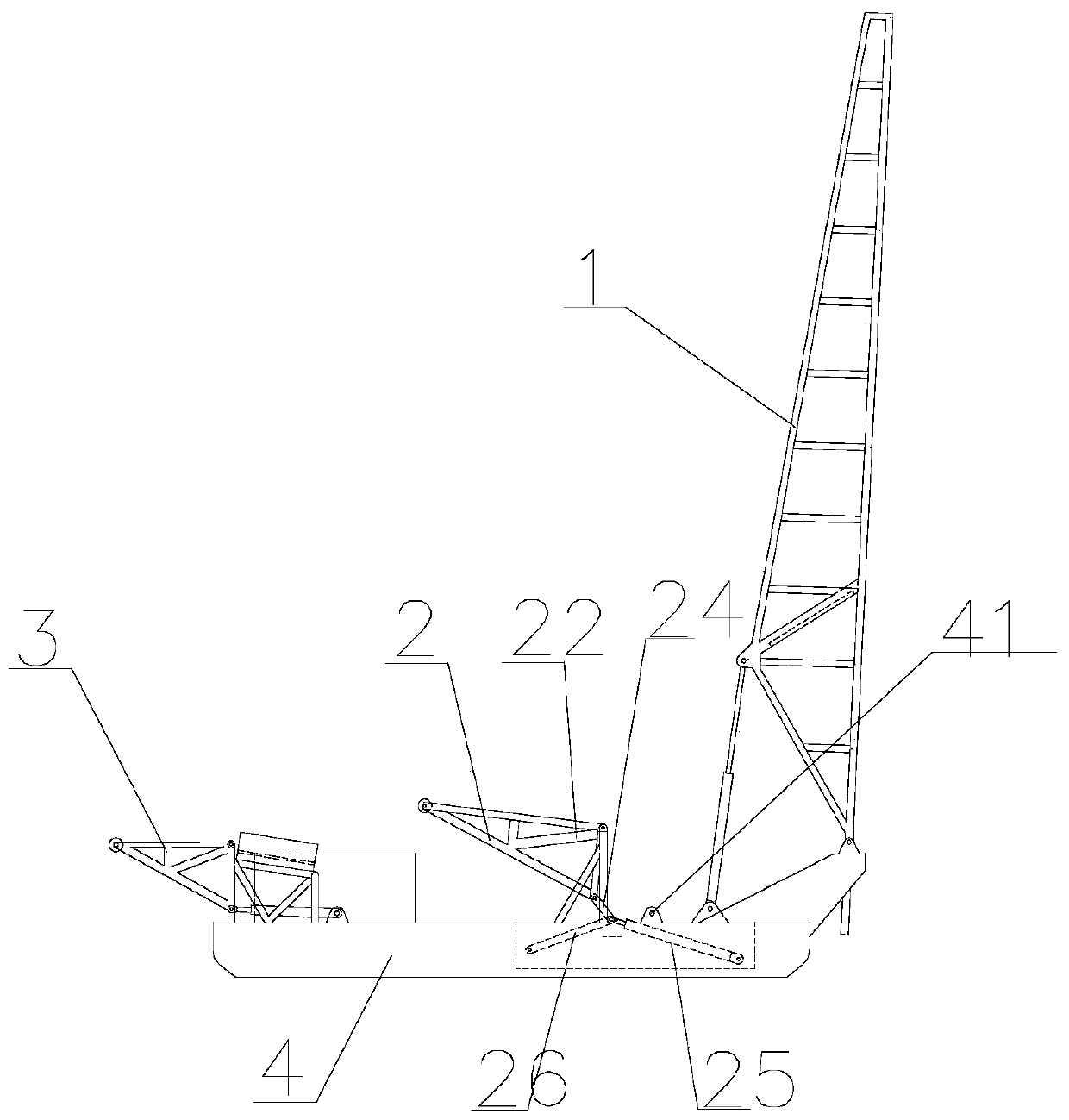

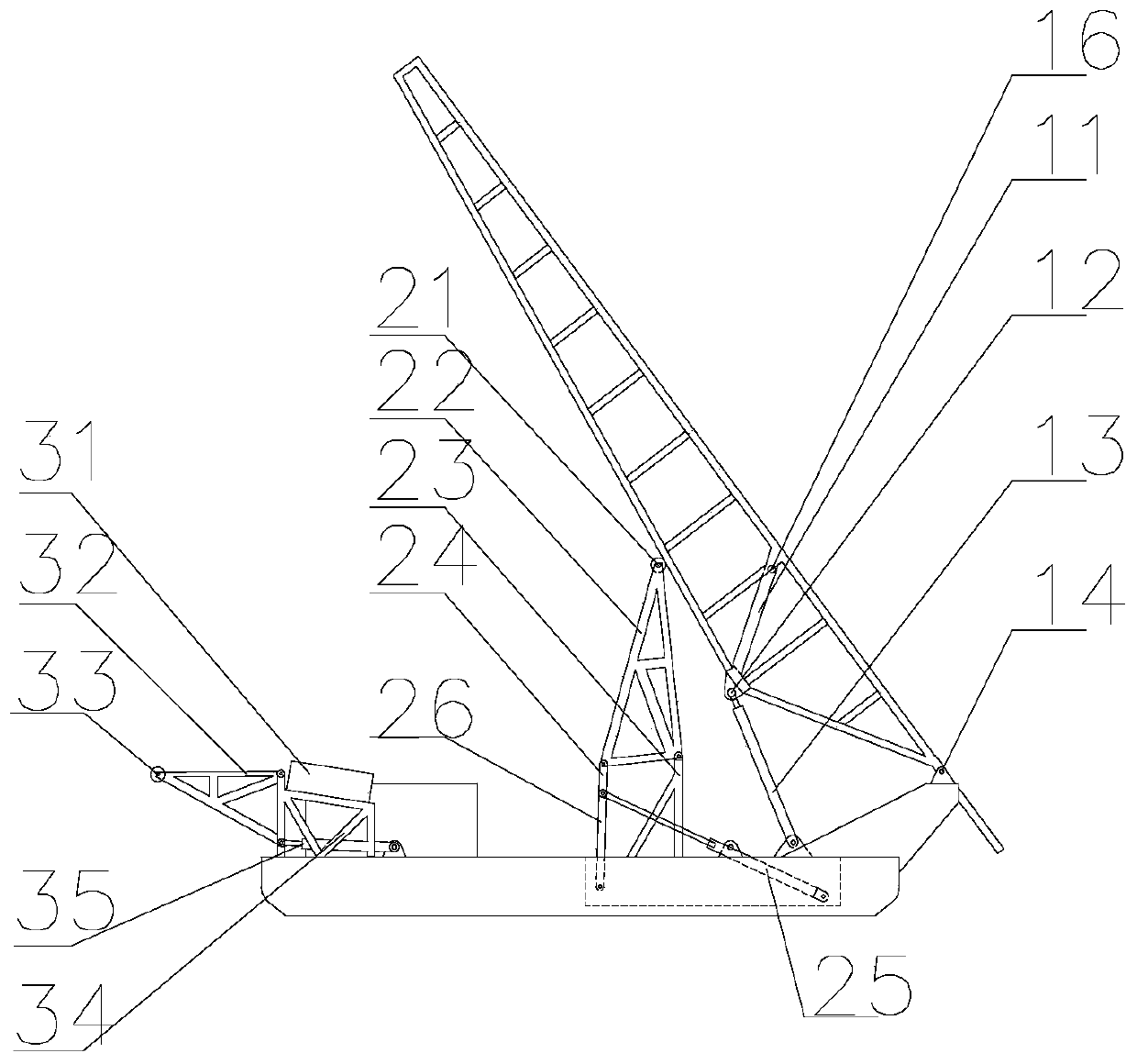

Automatic horizontal-arranging device of pile driving barge pile frame

ActiveCN110042837AImprove securityReduce support pressureWaterborne vesselsSpecial purpose vesselsStructural engineeringBARGE

The invention discloses an automatic horizontal-arranging device of a pile driving barge pile frame. The automatic horizontal-arranging device comprises a middle supporting mechanism, a tail supporting mechanism and a slide way, wherein the middle supporting mechanism and the tail supporting mechanism are hinged to a hull, and the slide way is obliquely formed in the pile frame, a movable block isarranged in the slide way, a main oil cylinder is hinged to the hull, the end of a piston rod of the main oil cylinder is hinged to the movable block, an upper fixing point and a lower fixing point which are used for fixing the movable block are arranged at the two ends of the slide way correspondingly, a pile frame front hinging point and a pile frame rear hinging point are arranged on the hull,and when the pile frame is hinged to the front hinging point and the movable block is fixed to the lower fixing point, the piston rod of the main oil cylinder extends out to enable the pile frame tobe in an erecting state. According to the automatic horizontal-arranging device, through supporting of the middle supporting device and the tail supporting device, the positions of the hinging pointsof the pile frame and the hull are transformed, the pile frame is put down gradually, and using is convenient and safe.

Owner:SHANGHAI SSOEC MARINE ENG CO LTD

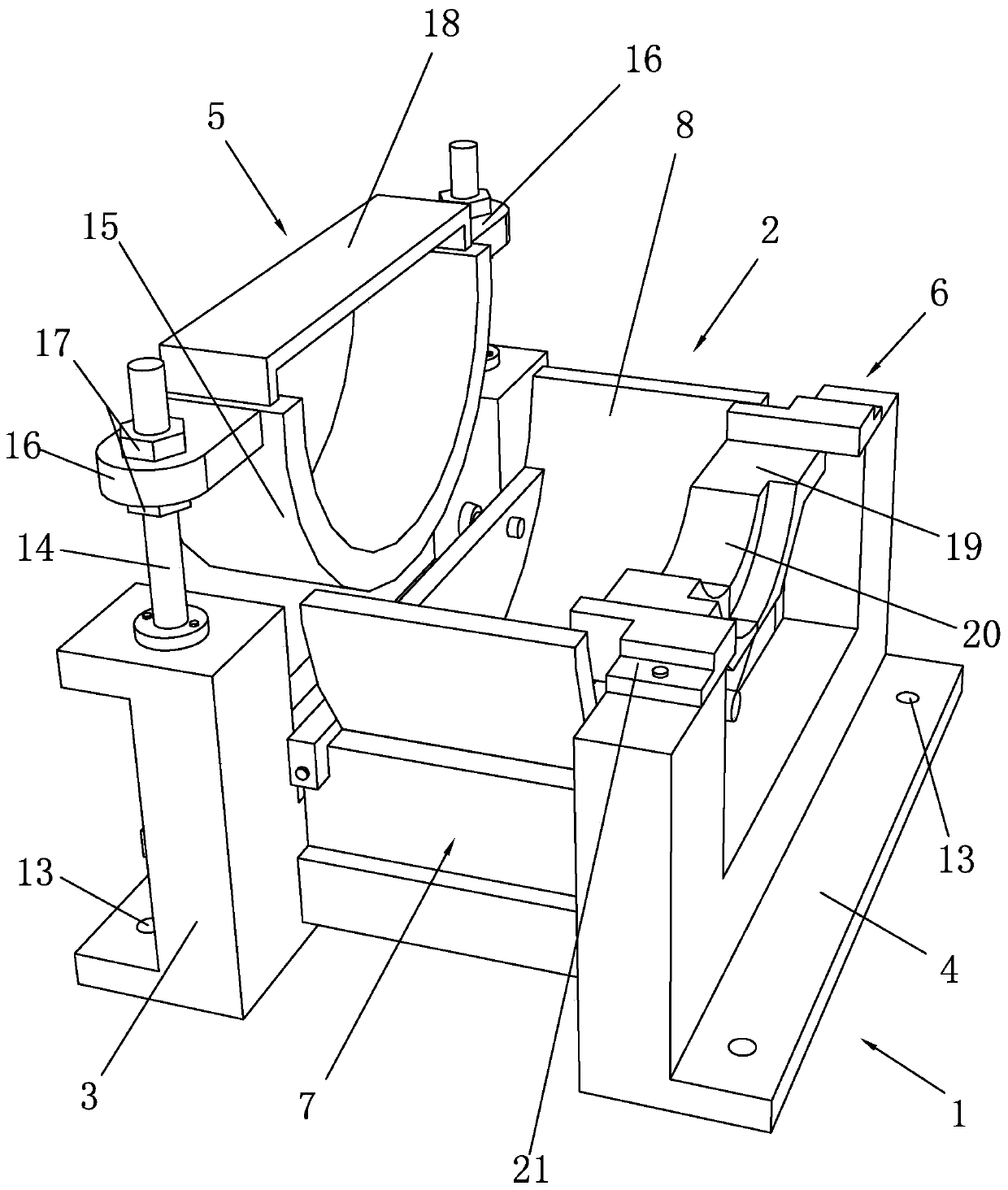

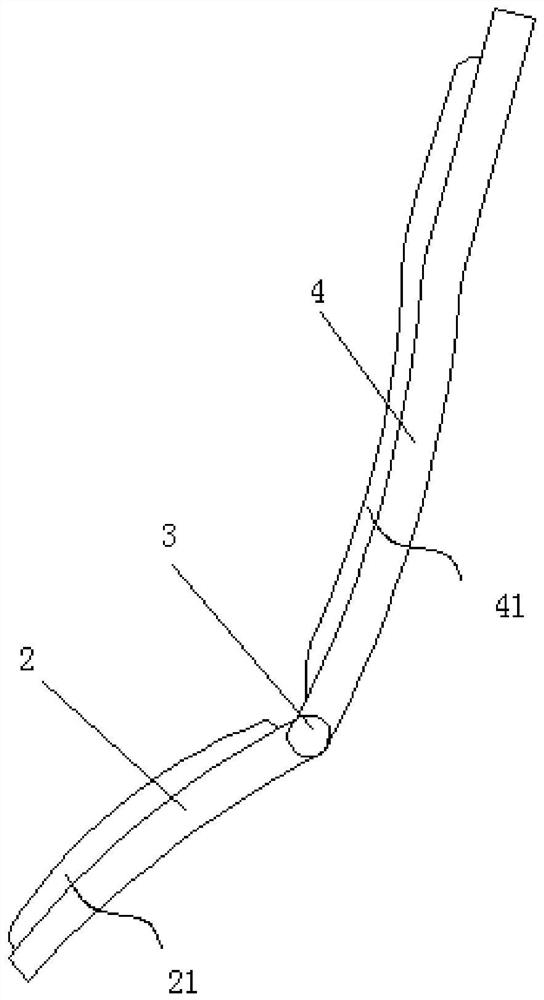

Mounting rack for integrated cooker fan and mounting method of mounting rack

ActiveCN110374933ARealize preliminary clamping limitEasy to install and disassembleDomestic stoves or rangesPump componentsPipe supportTurbine

The invention discloses a mounting rack for an integrated cooker fan. The mounting rack comprises a base and an arc-shaped clamping seat, the arc-shaped clamping seat is arranged on the base, the arc-shaped clamping seat comprises a bottom support and an arc-shaped frame, and the arc-shaped frame is located in the bottom support. A mounting method comprises the following steps that 1) the arc-shaped clamping seat is mounted; 2) the arc-shaped clamping seat and the base are mounted; 3) a motor supporting part and an air inlet pipe supporting part are mounted; and 4) the fan and the mounting rack are mounted. According to the mounting rack for the integrated cooker fan, mounting and fixing between the mounting rack and the inner wall of an integrated cooker are realized through the base, thearc-shaped clamping seat can be used for clamping and fixing a turbine casing on the fan, meanwhile, a motor on the fan is supported through the motor supporting part, and then an air inlet pipe on the fan is supported by using the air inlet pipe supporting part, so that the mounting firmness and reliability between the whole fan and the mounting rack are effectively guaranteed, the structural stability of the integrated cooker is improved, moreover, the angle of an air outlet pipe can be adjusted according to the actual position of an air duct pipe in the integrated cooker after the fan is mounted on the arc-shaped clamping seat.

Owner:钱松良

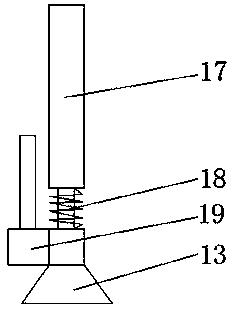

Concrete stirring device used for buildings and having automatic cleaning function

InactiveCN111195985AStir wellQuality improvementCement mixing apparatusArchitectural engineeringElectric machinery

The invention discloses a concrete stirring device used for buildings and having an automatic cleaning function. The concrete stirring device comprises a base; a box body is welded at the upper end ofthe base; a stirring box is welded in the middle of the box body; a feeding opening is formed in the upper end of the left side of the stirring box; a motor is fixed to the outer wall of the top of the stirring box through bolts; a first through hole is formed under an output shaft of the motor and in the top end of the stirring box; a rotating shaft is fixed to the bottom end of the output shaftof the motor through bolts; the rotating shaft penetrates through the first through hole to be erected in the stirring box; a water tank is welded on one side, far away from the feeding opening, of the outer wall of the top end of the box body; a water pump is fixed in the water tank through bolts; and hydraulic ejection rods are fixed to four corners of the inside bottom surface of the box bodythrough bolts. The concrete stirring device can be placed stably in various building site environments and can buffer the supporting pressure, and the uniform concrete having the relatively high quality can be stirred under the condition that the service life of the machine is not damaged.

Owner:贺建新

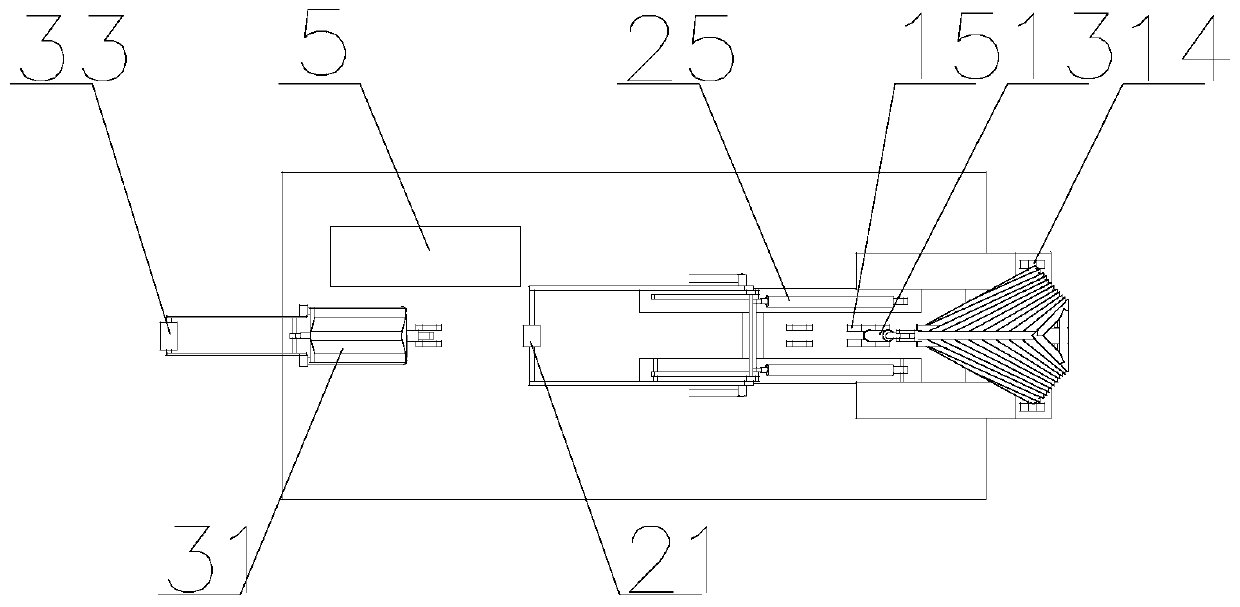

Transport vehicle provided with boom with multidirectional flexible steering function

The invention discloses a transport vehicle provided with a boom with a multidirectional flexible steering function, belongs to the technical field of article transportation in a coal mine tunnel, and provides a special transport vehicle which is used for the coal mine tunnel, is provided with the boom with the multidirectional flexible rotating function, does not require overall rotation of an operation rack, is flexible to use, guarantees the working safety and improves the working efficiency. According to the technical scheme, multiple groups of walking mechanisms are mounted at the lower part of a rack; the rear end of a boom assembly is fixedly mounted at the front part of the rack through a rotary table; an explosion-proof diesel engine for supplying power and a hydraulic system are mounted at the rear part of the rack; a control console and a driver's seat are mounted on the rack; the boom assembly comprises a boom body, a chained lifting hook and a boom oil cylinder, the rear end of the boom body is hinged to a boom support lug, the chained lifting hook is fixedly mounted at the rear end of the boom body, a cylinder body of the boom oil cylinder is hinged on an oil cylinder support lug, and an end part of a piston rod of the boom oil cylinder is hinged with the middle of the boom body. The transport vehicle is mainly used for lifting and transporting equipment such as a middle trough and the like in the coal mine tunnel.

Owner:SHANXI DONGHUA MACHINERY

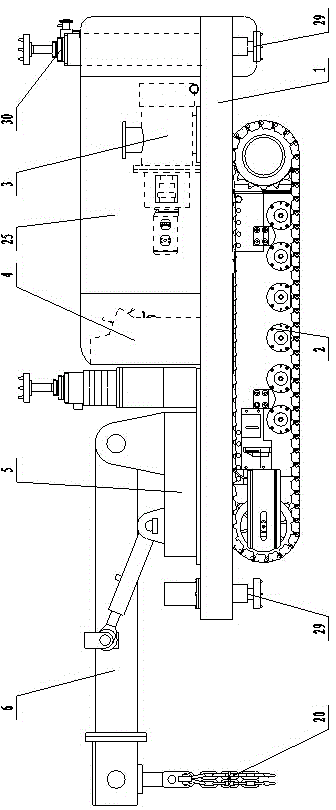

Floor heave crushing machine in coal mine tunnel

InactiveCN104806263AAdjustable orientationFlexible useGrain treatmentsTunnelsHydraulic motorEngineering

The invention discloses a floor heave crushing machine in a coal mine tunnel and belongs to the technical field of floor heave crushing and cleaning in the coal mine tunnel. In order to solve the technical problems, a transport cart special for the coal mine tunnel and having a hydraulic crushing hammer which can rotate flexibly in multiple directions is provided. A large area of the floor heave can be crushed without enabling the whole rack to rotate, so that working safety is ensured and work efficiency is increased. The adopted technical scheme is that multiple groups of traveling mechanisms are arranged on the lower part of the rack, the back end of the hydraulic crushing device is fixedly arranged on the front part of the rack through a turntable, the back part of the rack is provided with an explosion-proof diesel engine and a hydraulic system both of which provides motive power, the rack is also provided with a console and a driver's seat. The hydraulic crushing device of the floor heave crushing machine is arranged on the front part of the rack through the turntable, a hydraulic motor controls a gear transmission device to realize rotation of the turntable, the direction of the hydraulic crushing device is adjustable, the whole rack is unnecessary to rotate, and the floor heave crushing machine is more flexible to use.

Owner:SHANXI DONGHUA MACHINERY

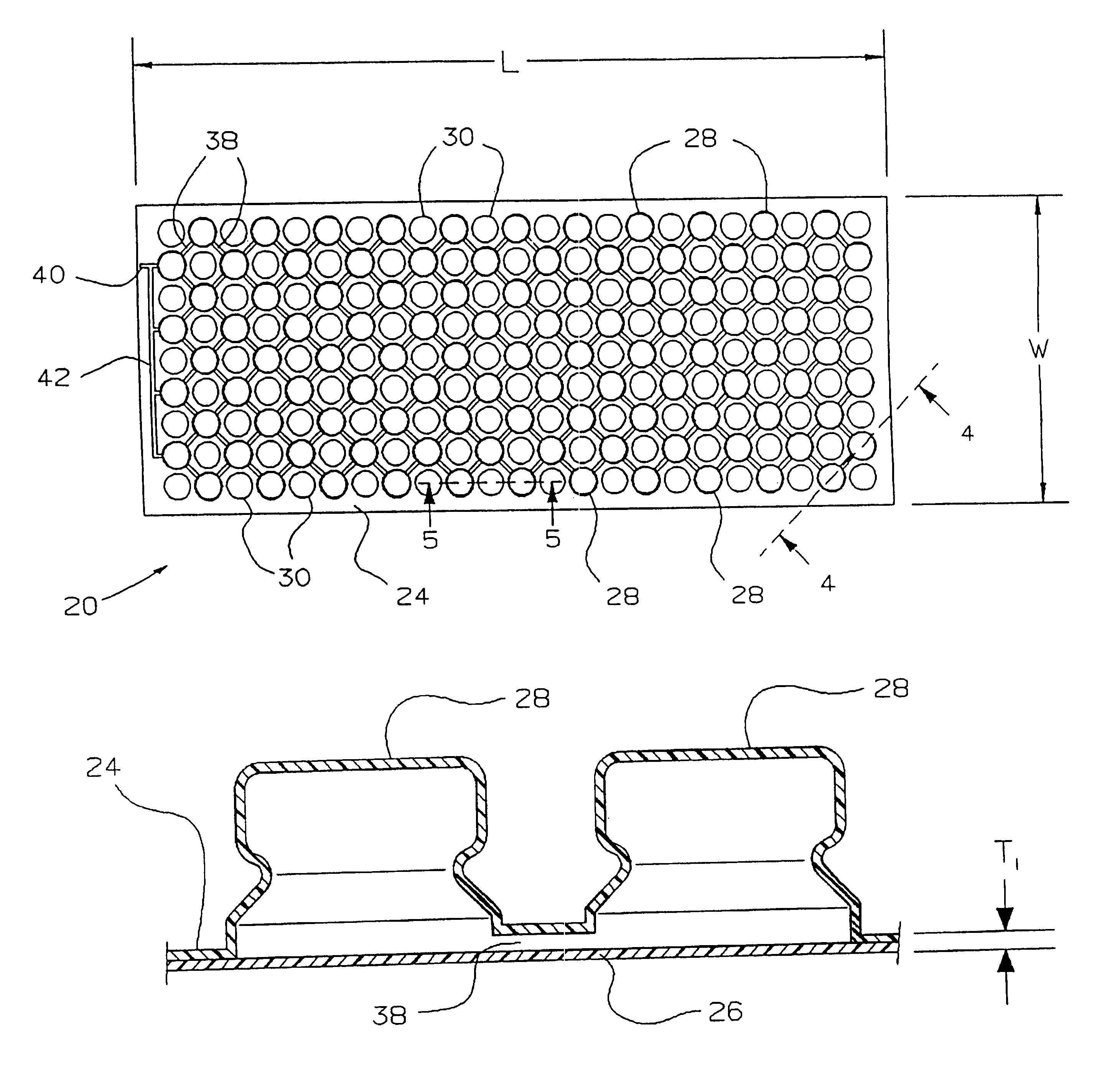

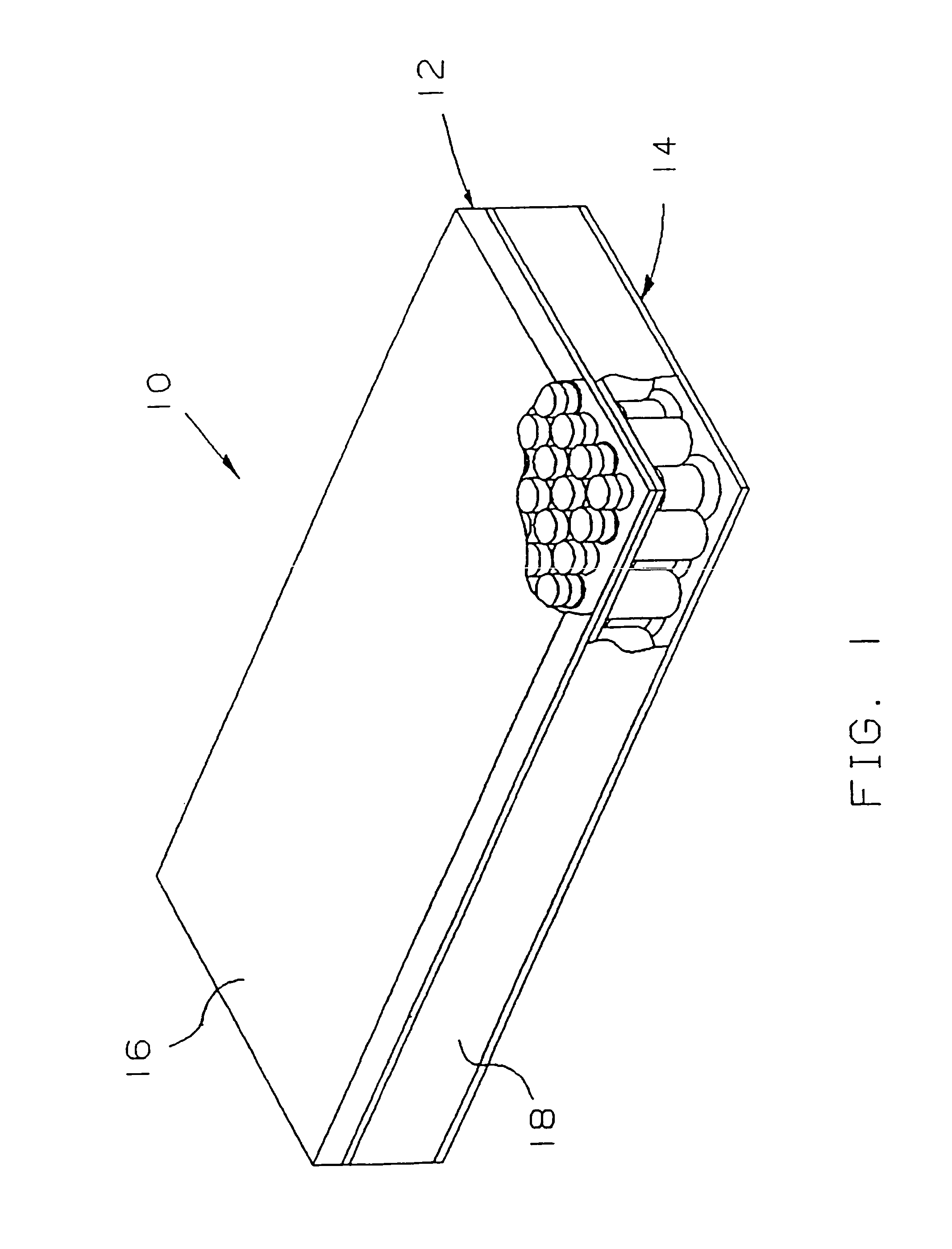

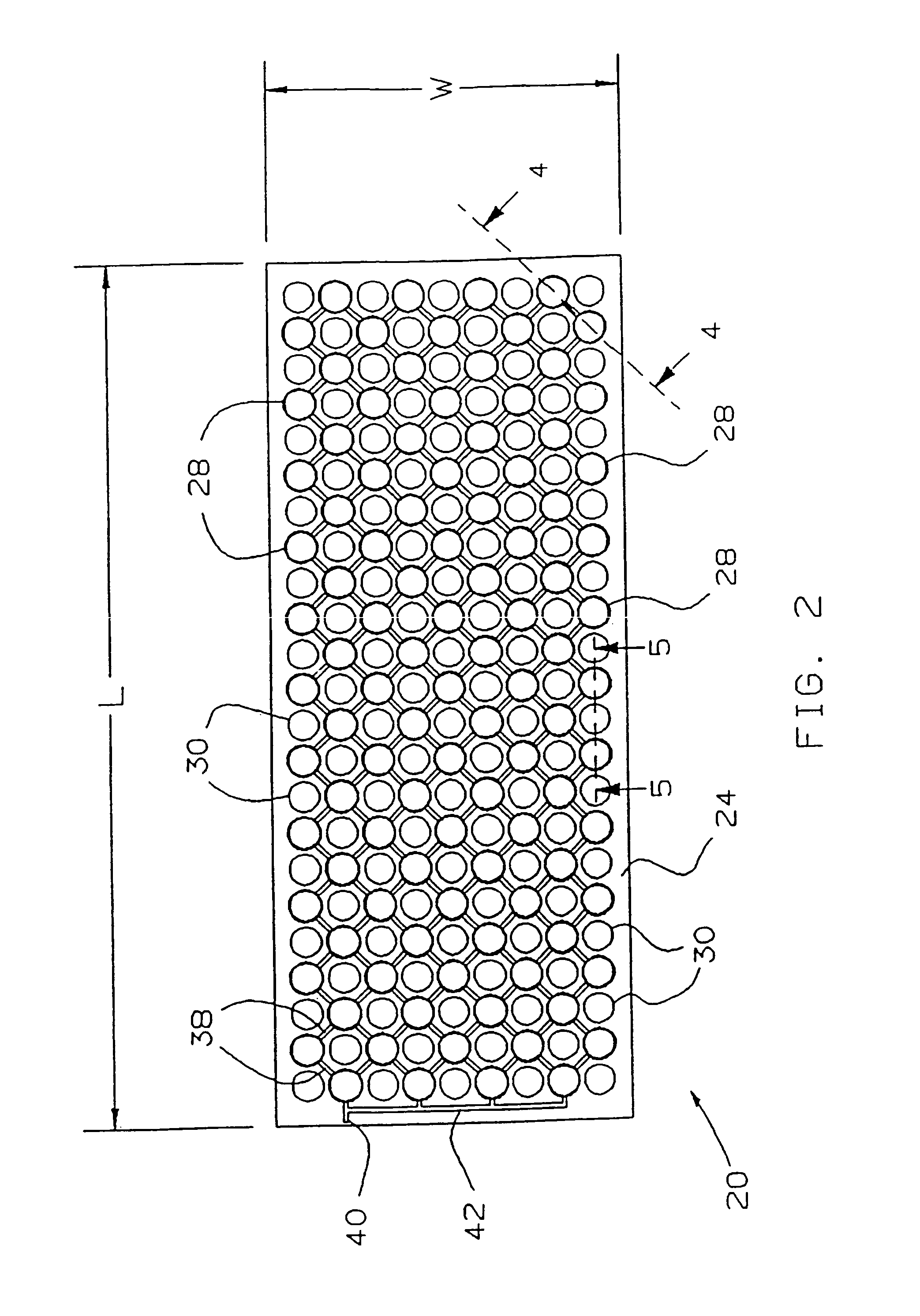

Encapsulated zonal dual air and foam spring bed system with noise suppression

InactiveUS9867476B1Supportive and pliableMinimum surface tensionStuffed mattressesDiagnosticsBand shapeEngineering

An encapsulated zonal dual air and foam spring bed system with noise suppression wherein air zones are created for individual or multiple sleepers that permit costs saving by providing manifold controls to enable a single pump to serve multiple circuits simultaneously (both pressure level increase and pressure level decrease) that is contained within a complete noise deadening structure whose body is easily formed to reduce cost and provide sanitation. Through the reduction of stress by cycling air support between two areas that in unison and each at half pressure support subject fully.

Owner:THOMAS PAUL BRUCE

Fabric humidifier for spinning machinery

ActiveCN109706660AReduce mechanical noiseEasy to installTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationEngineeringLower face

The invention discloses a fabric humidifier for spinning machinery. The fabric humidifier comprises a box, two space plates are symmetrically and horizontally arranged in the box, and the interior ofthe box is divided into a front cavity, a middle cavity and a rear cavity through the two space plates; bottom spray rod assemblies are arranged in the front cavity and the rear cavity, the middle cavity corresponds to a fabric inlet groove and a fabric outlet groove, and a first fabric guide roller, a tension roller, a second fabric guide roller and a vibration roller are arranged in the middle cavity from left to right in sequence; a top spray rod assembly is arranged over the tension roller. According to the fabric humidifier for spinning machinery, through the top spray rod assembly and the bottom spray rod assemblies, the upper and lower faces of the fabric are humidified at the same time, compared with humidification only on one face of the fabric in the prior art, the whole fabric is more evenly humidified, more convenience is provided for following ironing operation on the fabric, based on the actual conveying angle and speed of the fabric, the angle is adjusted through the bottom spray rod assemblies, the humidification condition of the bottom face of the fabric is guaranteed, and the processing quality of the fabric in the later period is improved.

Owner:朱泽鹏

Communication equipment maintenance device

InactiveCN113427449AEnsure stabilityGuaranteed stabilityWork holdersWork benchesElectric machineryStructural engineering

Owner:六安保识信息技术有限公司

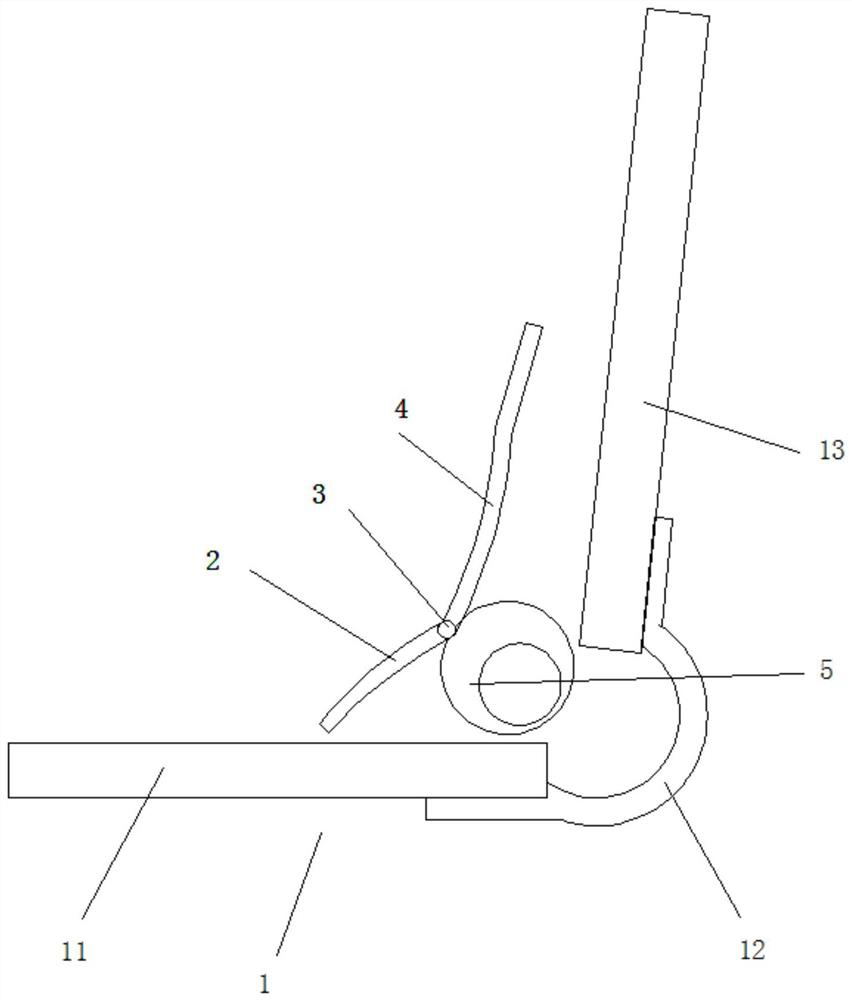

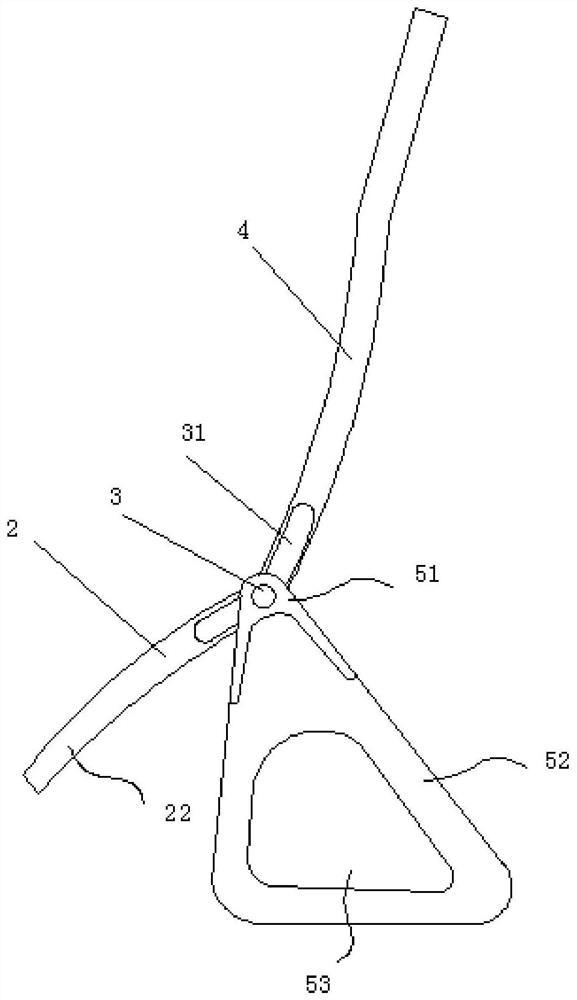

Self-adaptive waist-hip back cushion structure

PendingCN112773120AReduce support pressureImprove comfortStoolsChairsHuman bodyPhysical medicine and rehabilitation

The invention belongs to the technical field of waist rests or waist cushions, and particularly relates to a self-adaptive waist-hip back cushion structure, which comprises a hip supporting plate, a waist backup plate, a rotating pivot and a rear supporting piece, the rotating pivot is connected to the intersection of the hip supporting plate and the waist backup plate, and the rotating pivot is as high as the hip joint of a human body in a sitting posture. The hip supporting plate and the waist backup plate form a lever by taking the rotating pivot as a fulcrum; the rotating pivot is rotatably connected with the rear supporting piece, and the rear supporting piece is used for supporting the rotating pivot to be arranged at a set height position; according to the scheme, the hip and the waist of a human body can be synchronously supported, and the supporting pressure borne by hip joints is effectively reduced; due to the lever type linkage relation between the hip supporting plate and the waist backup plate, the comfort of the human body in the pitching process is guaranteed; the rotating pivot not only can provide rotating support, but also ensures comfort and self-adaptability of waist and hip support in the scheme by means of the supporting main body in an air bag type design or a spring type design according to the height of the rotating pivot.

Owner:赵斌

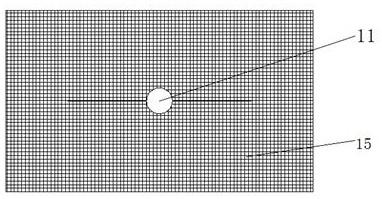

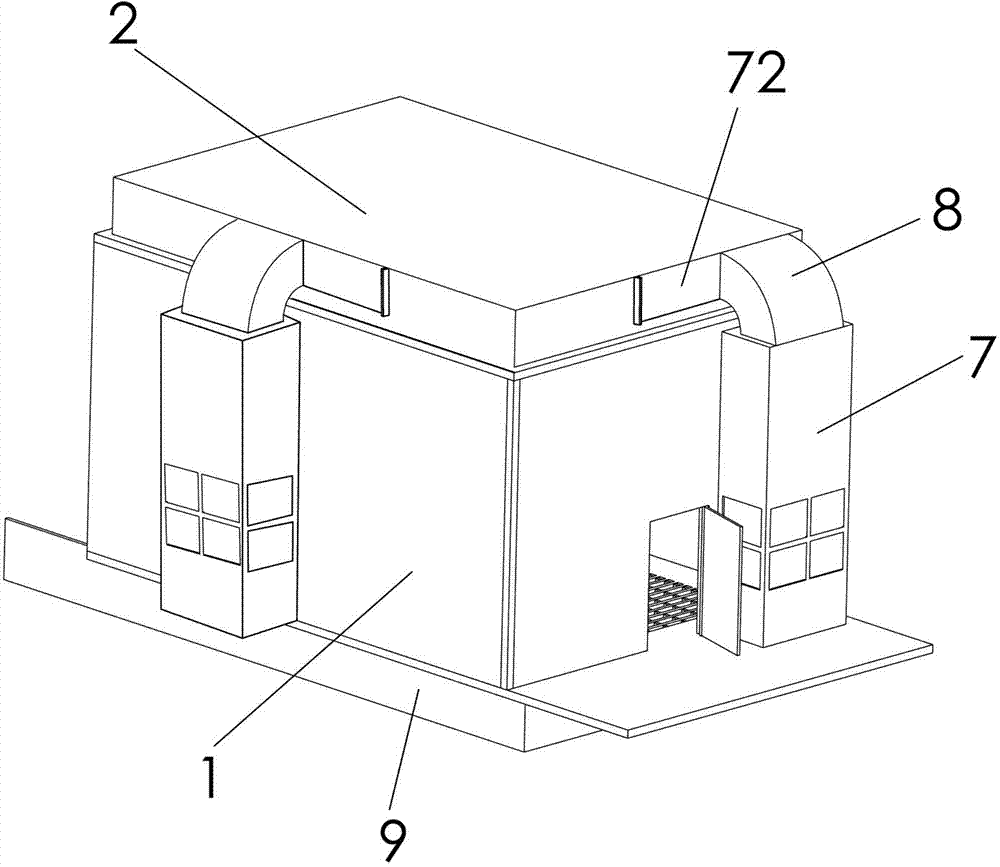

Oil paint house structure

InactiveCN104259039ASmooth circulationLight lacquer smellLiquid surface applicatorsSpraying apparatusFiltrationSewage

The invention belongs to the furniture processing field, and particularly relates to a novel tasteless oil paint house. An oil paint house structure of the novel tasteless oil paint house comprises a house body formed by a wall and a roof in surrounding mode, an indoor floor located in the house body, an air feed device located on the exterior of the house body and an odor removal and sewage draining device arranged in the house body, wherein a top net rack is arranged below the roof, filtration cotton is laid on the top net rack, an air feed cavity is formed between the filtration cotton and the roof, the air feed device comprises a plurality of air draft cases, and air draft mouths and air feed pipes, which are arranged on the air draft cases, the odor removal and sewage draining device comprises a water draining pond and an exposed undercoat net rack erected on the water draining pond, and a sewage outlet is formed in the wall body. According to the oil paint house structure, natural wind which blows downwards from the roof blows oil paint which is sprayed and floats and air with a paint smell downwards to the water draining pond, the oil paint which is sprayed and floats and the air with the paint smell are absorbed by water, and then are discharged out of the tasteless oil paint house through the sewage outlet, a water tank is further arranged on the sewage outlet, water which overflows from the water tank forms a water curtain, air which passes through the sewage outlet is filtered by the water curtain, and therefore the oil paint and the paint smell in the air which is exhausted from the sewage outlet are removed.

Owner:ZHEJIANG ANJI ANFENG FURNITURE

Cutting machine for hardware fitting production

ActiveCN109623022AGuaranteed structural strengthAvoid collection impactShearing machinesShearing machine accessoriesEngineeringUltimate tensile strength

The invention discloses a cutting machine for hardware fitting production. The cutting machine comprises a cutting table and a cutting head set; the cutting table is provided with a positioning module; the positioning module comprises a positioning clamping plate, a slide frame and a positioning staff; a placing table is arranged at the front end of the cutting table, and is hinged with the cutting table; a collecting box is arranged under the placing table; and the cutting head set comprises a vertical adjusting module, a transverse adjusting module, a longitudinal adjusting module and a cutting head. Through a positioning module, the precise positioning between the cutting head and a workpiece cutting position is realized, so that the cutting precision is effectively improved, and the cutting error rate is reduced; the positioning module also can be used for realizing pressing and positioning of workpieces, so that the cutting precision is further improved, and the workpieces are prevented from moving in the cutting process; meanwhile, the cut workpieces can be temporarily placed through the placing table; a rotating cylinder is matched to realize automatic collection of the workpieces; and the workpieces accumulated on the placing table are automatically put in the collecting box for collection, so that the manual operation intensity is effectively relieved.

Owner:南通旭之初新材料科技有限公司

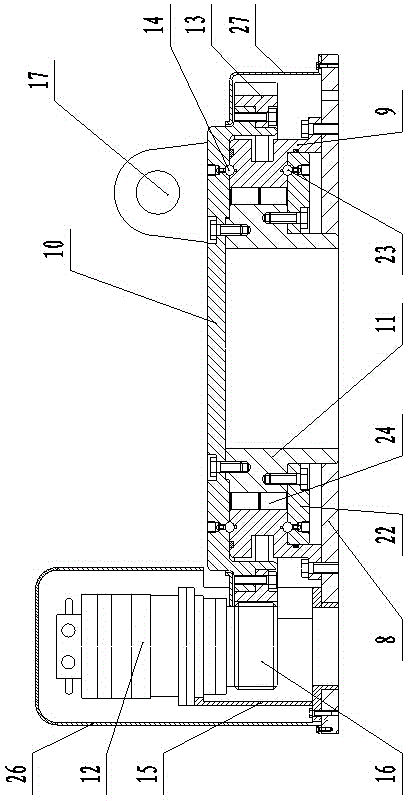

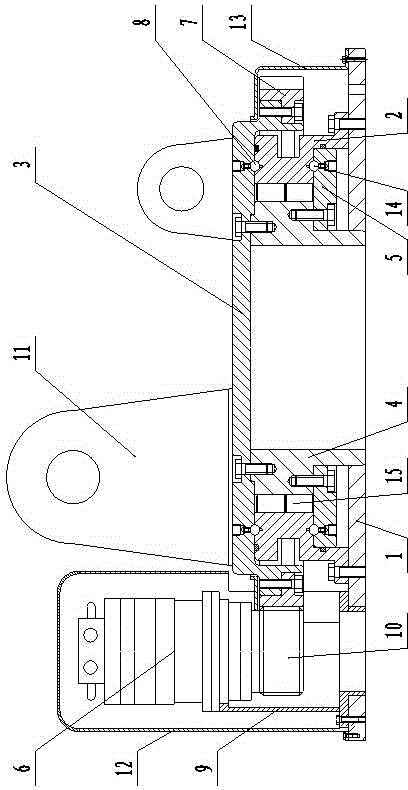

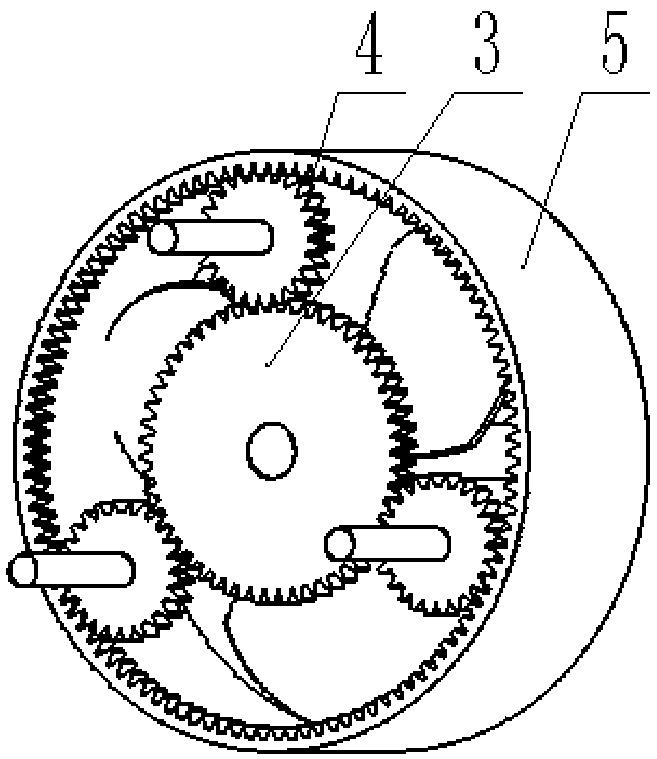

Suspension arm rotary table on carrier vehicle

The invention provides a suspension arm rotary table on a carrier vehicle and belongs to the technical field of coal mining equipment transportation. The suspension arm rotary table on the carrier vehicle aims to provide a rotary table for connecting a suspension arm with a vehicle body, wherein the rotary table can drive the suspension arm to rotate to a certain position under the condition that the vehicle body does not move, the operation difficulty is reduced, and the work safety is guaranteed. According to the technical scheme, a rotary plate support is fixedly mounted on a base through a bolt, an upper rotary plate is in an upturned disk-like shape and movably buckled on the rotary plate, matched grooves are formed in horizontal contact surfaces of the upper rotary plate and the rotary plate support, multiple first steel balls are arranged in the grooves, a middle movable rack is fixedly mounted in the middle of the bottom surface of the upper rotary plate and located in the rotary plate support, a gear ring is fixedly mounted on a circumferential side surface of the upper rotary plate, a hydraulic motor is fixedly mounted on one side of the rotary plate support through a motor support, and a gear meshed with the gear ring is fixedly mounted on an output shaft of the hydraulic motor. With the adoption of the suspension arm rotary table, work parts are more flexible relative to the vehicle body.

Owner:SHANXI DONGHUA MACHINERY

Medical pillow

PendingCN111407580AReduce labor intensityAvoid conditions that interfere with intubationPillowsTracheal tubesTube intubationEngineering

The invention discloses a medical pillow and in particular relates to the technical field of medical auxiliary instruments. The medical pillow comprises a semi-columnar neck rest, wherein fixing plates are symmetrically arranged on both sides of the neck rest; first bolt holes are formed at intervals in the fixing plates; rotating shafts are in rotational connection with the neck rest; lifting rods are arranged on the rotating shafts; second bolt holes corresponding to the first bolt holes are formed in the lifting rods; bolts for connecting and fixing the lifting rods in an insertion manner are detachably connected with the lifting rods; the bolts are matched with first insertion holes and second insertion holes; a headrest is arranged on the lifting rods; and rubber belts are arranged onboth sides of the headrest. By adopting the technical scheme of the invention, the problem that the respiratory track of a patient cannot be easily opened for tube intubation by a medical operator can be overcome, and the respiratory track can be also kept smooth in painless anesthesia.

Owner:张林

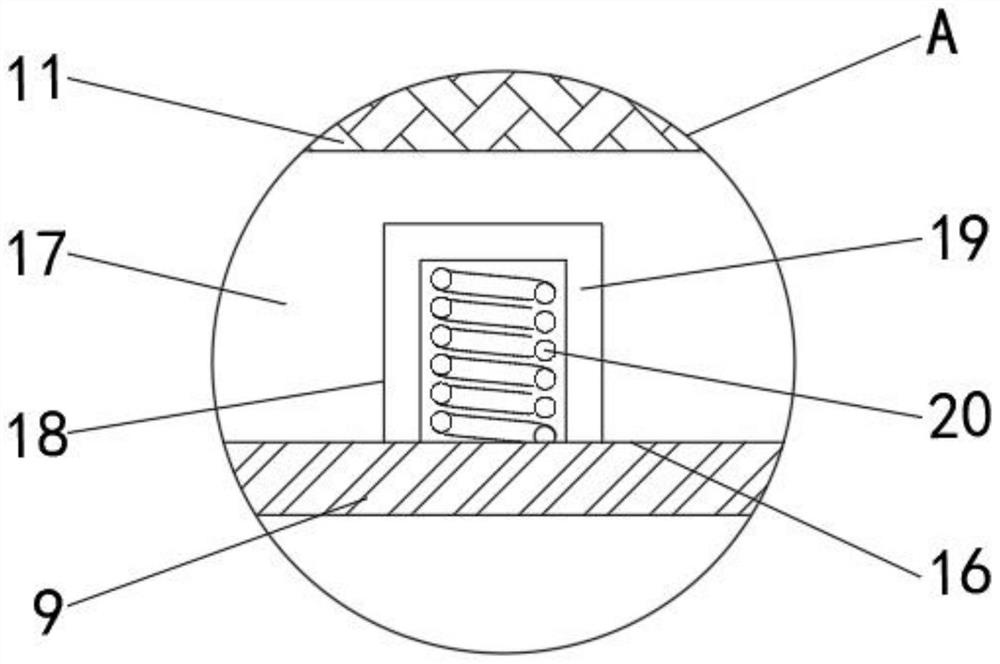

Fine-tuning drilling device

InactiveCN108015324AImprove machining accuracySave cleanup timePositioning apparatusBoring/drilling componentsFastenerDrill bit

The invention discloses a fine-tuning drilling device, and relates to the field of machine tool drilling. The fine-tuning drilling device comprises a support, a drilling mechanism and a clamping mechanism; the drilling mechanism comprises a planetary gear train, a drilling motor for driving the planetary gear train to rotate and fan blades, wherein the drilling motor is fixed on the support, and an output shaft of the drilling motor is coaxially fixed to a sun gear; drill rods and drill bits which are used for drilling are installed on planetary gears; a gear ring is divided into an engaging part and a smooth part, wherein the end part of the smooth part is closed, and the fan blades are installed on the inner side of the smooth part; a planet carrier wraps teeth of the sun gear and the planetary gears, and ventilation holes are formed in the planet carrier; an outer cylinder is connected to the outer side of the gear ring in a sliding mode, air inlet holes are formed in the outer cylinder, and the outer cylinder is in sliding connection with the planet carrier; a fastener for limiting rotation of the outer cylinder is installed on the support; the clamping mechanism comprises sliding rails, a positioning frame and an air cylinder, wherein a clamping part for clamping a workpiece is installed on the positioning frame, and the clamping part comprises a clamping jaw and an air bag for pushing the clamping jaw to slide; and the air bag communicates with the inside of the gear ring through a pipeline. According to the scheme, the drill bits can be finely tuned before drilling.

Owner:宁波江北珂达汽车技术有限公司

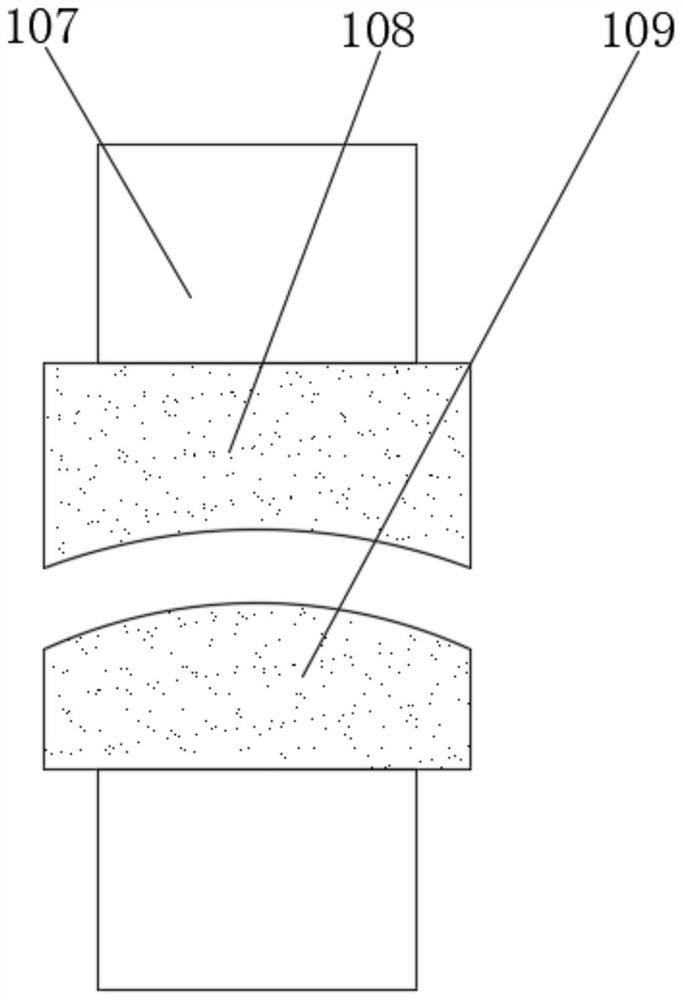

Laminated slab transportation protection structure

ActiveCN114313587AReduce harmImprove protectionContainers to prevent mechanical damageDamagable goods packagingArchitectural engineeringStructural engineering

The invention discloses a laminated slab transportation protection structure in the technical field of laminated slab transportation protection, the laminated slab transportation protection structure comprises a fixed seat, a hinge block and a laminated slab, a left adjusting cylinder and a right adjusting cylinder are fixedly mounted on the left side and the right side of the top of the fixed seat respectively, and a left supporting column is hermetically sleeved with the left adjusting cylinder; a right supporting column is sleeved with the right adjusting cylinder in a sealed mode, a communicating column is fixedly installed between the left adjusting cylinder and the right adjusting cylinder, and a flow slowing mechanism is arranged in the communicating column. According to the device, extrusion damage generated in the relative movement process of the laminated plate and the supporting plate is avoided, and meanwhile, the guide columns are arranged to drive the clamping blocks and the guide columns to move relative to each other in the inertial movement process of the laminated plate; and then the guide columns are in limiting contact with the inner walls of the guide holes, so that buffering is provided for the laminated plate, the situation that the movement degree of the laminated plate is too large, and the limiting pressure is too large is avoided, damage to the laminated plate is reduced, and the protection effect of the laminated plate is multiplied.

Owner:江苏宇辉新材料集团有限公司

Large-span cable-stayed locking dewatering operating platform and construction method thereof

InactiveCN105003069AImprove stabilityImprove securityFoundation engineeringBuilding support scaffoldsCable stayedPressure reduction

The invention provides a large-span cable-stayed locking dewatering operating platform and a construction method thereof. The large-span cable-stayed locking dewatering operating platform and the construction method aim to solve difficult problems of excessively long distances from pressure reduction well pipes to braces and excessively large span of existing platforms in foundation pit dewatering procedures in the prior art. The large-span cable-stayed locking dewatering operating platform is used for bracing a dewatering well and comprises a steel platform, a detaching clip and steel wire ropes. One end of the steel platform is arranged on a second brace and is used as a fixed end, the other end of the steel platform outwardly extends in a cantilever manner to be used as a cantilever end, the dewatering well is arranged at the cantilever end of the steel platform, the detaching clip is arranged on a first brace, one end of each steel wire rope is pulled by the detaching clip, and the other end of each steel wire rope is connected onto a position, which is close to the dewatering well, of the steel platform. The large-span cable-stayed locking dewatering operating platform and the construction method have the advantages that the steel platform is arranged on the second brace, the detaching clip can be arranged on the first brace, the positions, which are close to the dewatering well, of the steel platform can be pulled by the detaching clip, the steel platform can be turned into a 'simply supported beam' form from a 'cantilever beam' form, accordingly, brace pressures on the fixed end of the steel platform and bending moment which is generated by upper loads on the fixed end can be relieved, and the stability and the safety of the integral operating platform can be improved.

Owner:SHANGHAI NO 4 CONSTR

Supporting frame for thyroid surgery

A bottom plate can be connected with an operating bed, five supporting mechanisms are all installed on the bottom plate, a first pad, a second pad and a headrest pad are all made of silica gel materials, inner cavities of the first pad, the second pad and the headrest pad are all filled with low-melting-point alloy and are provided with heat exchange pipes, a first actuator controls lifting and positioning of the first pad, and a second actuator controls lifting and positioning of the second pad. The second actuator controls lifting and positioning of the second cushion, the second supporting mechanism, the third supporting mechanism and the fourth supporting mechanism are the same in structure and installation mode and can move along with rotation of the head and the neck of the patient, the headrest cushion and the arc plate support form a rotation pair through an arc plate, and the motor can drive the headrest cushion to rotate. A third actuator can control lifting and positioning of a headrest cushion, a temperature control system can achieve phase state change of low-melting-point alloy in the five cushions, the five cushions can be attached and supported according to the curved surface shape of the lower side of the head and neck of the patient, and the head and neck of the patient can be effectively fixed.

Owner:杜雪生

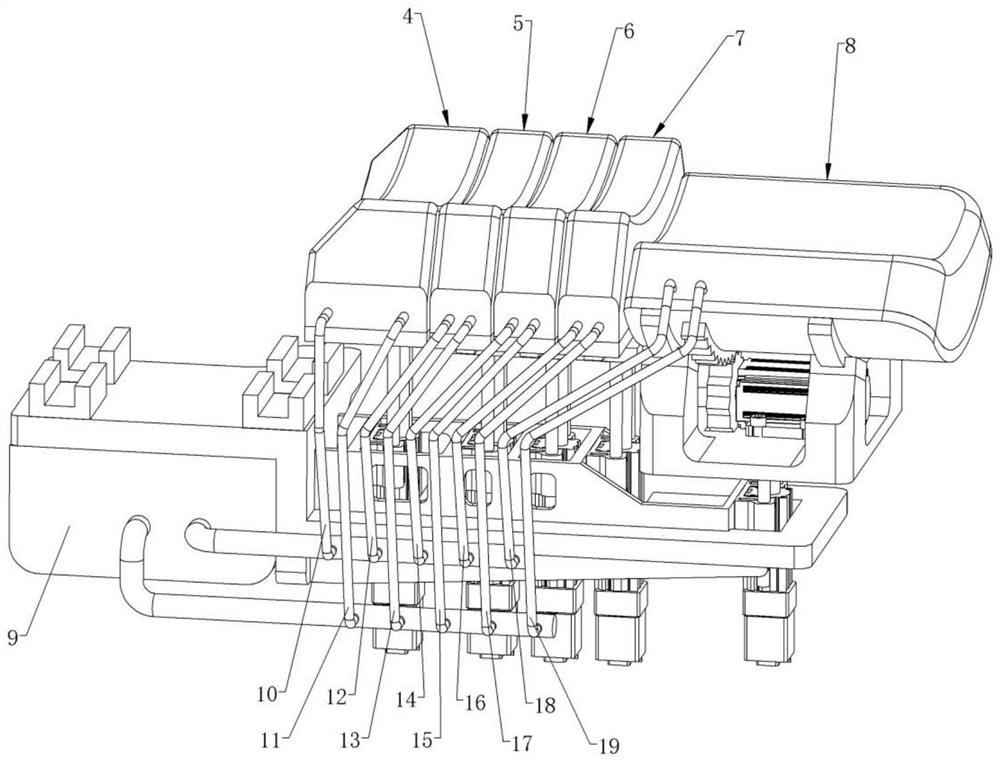

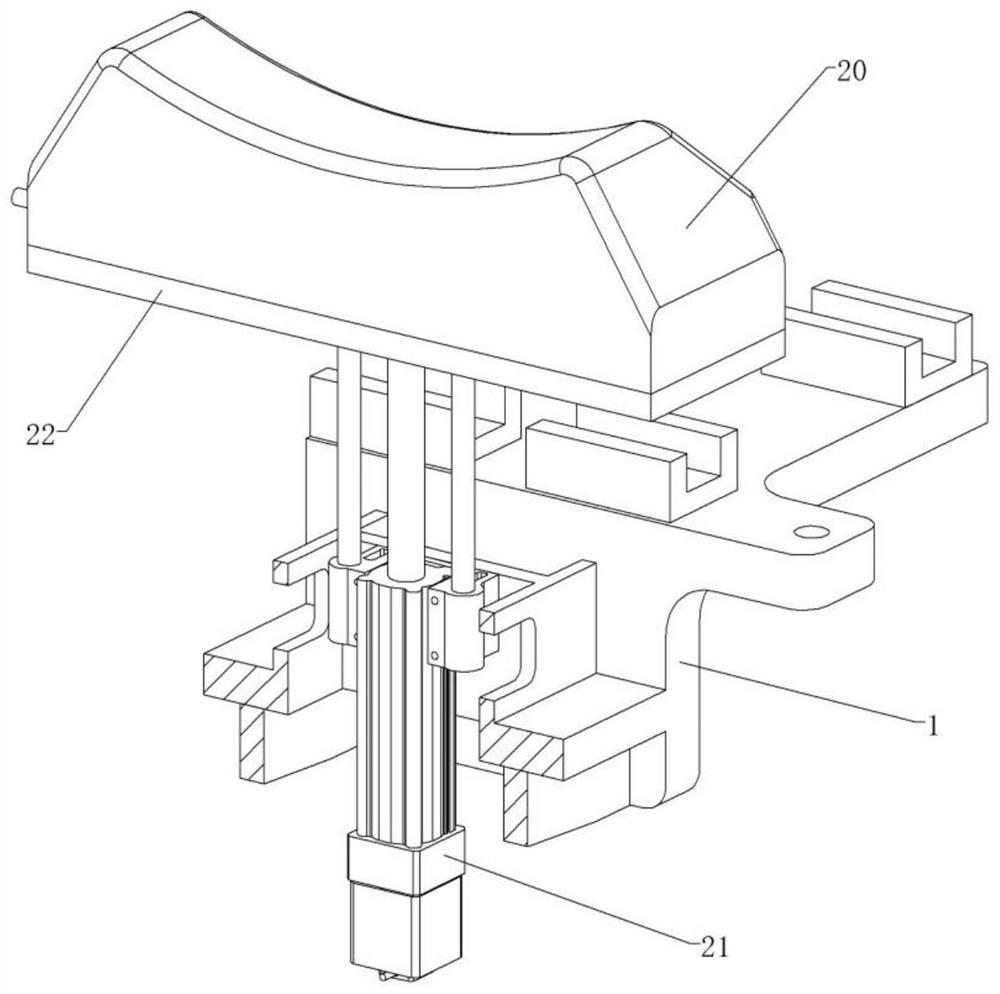

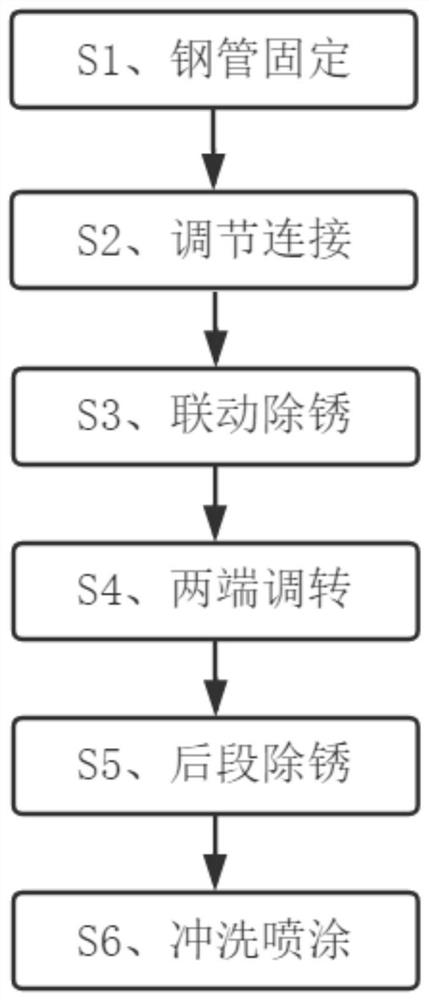

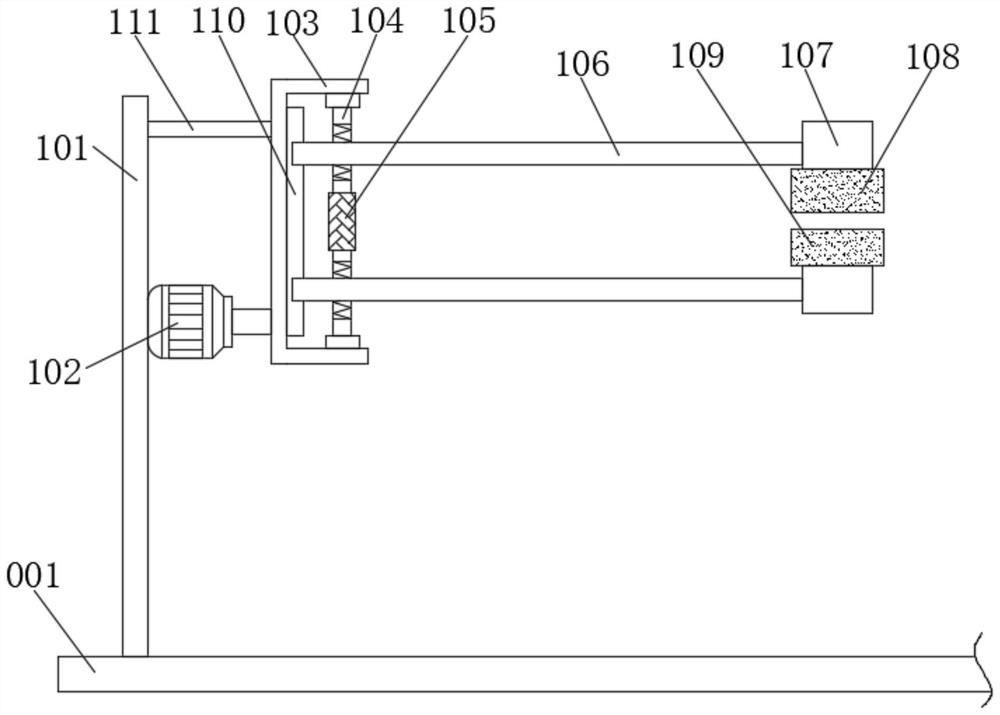

Simultaneous derusting process of inner surface and outer surface of steel pipe

ActiveCN112059734BTravel controlSimple processGrinding carriagesGrinding drivesElectric machinerySmall footprint

The invention discloses a simultaneous derusting process for the inner surface and the outer surface of a steel pipe, which belongs to the technical field of steel pipe derusting. A simultaneous derusting process for the inner surface and the outer surface of a steel pipe comprises the following steps: S1, fixing the steel pipe; ; S3, linkage derusting; S4, turning both ends; S5, rear end derusting, S6 flushing and spraying. It can be combined with the rust removal process and is equipped with a double-sided simultaneous removal device, which can grind and remove rust on the inner and outer surfaces of the steel pipe at the same time. The process is simple, the rust removal efficiency is high, the equipment cost is low, and the floor area is small. The driving method, the more labor-intensive grinding, is handed over to the electric grinding component to be driven by the motor, and the manual travel component is used to manually control the travel of the steel pipe during the rust removal process, so that it can be controlled more accurately according to the site conditions. The travel of the steel pipe avoids incomplete rust removal, improves the work quality, and is easy to operate and consumes little physical strength.

Owner:山东绿钢环保科技有限公司

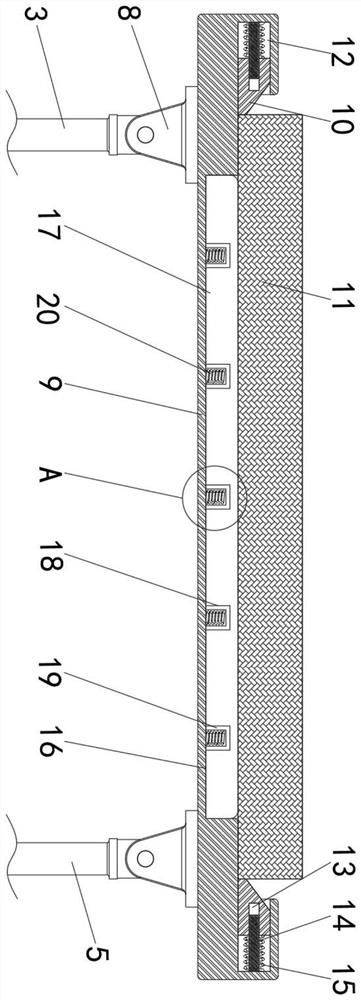

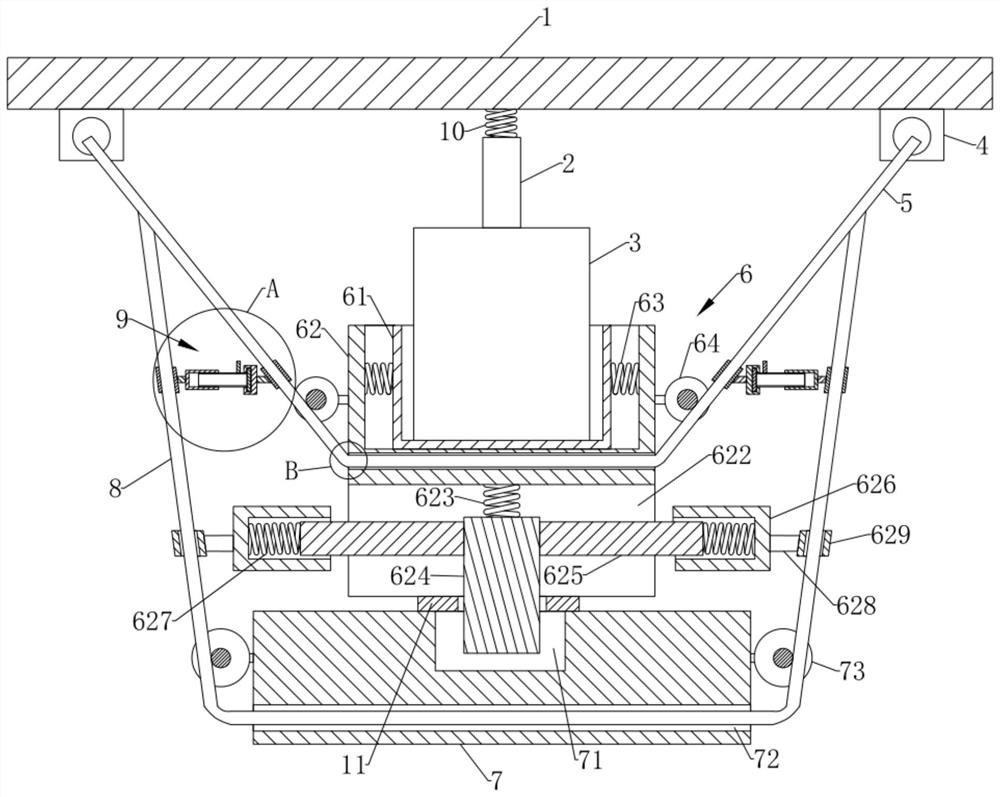

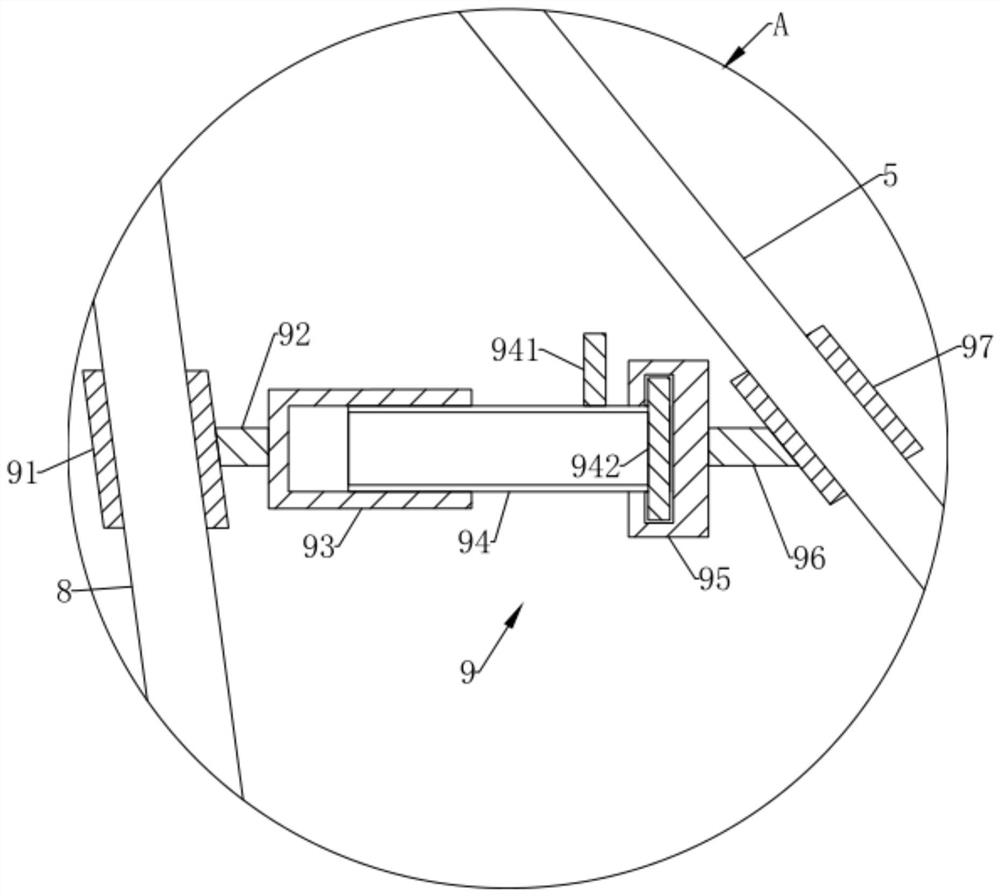

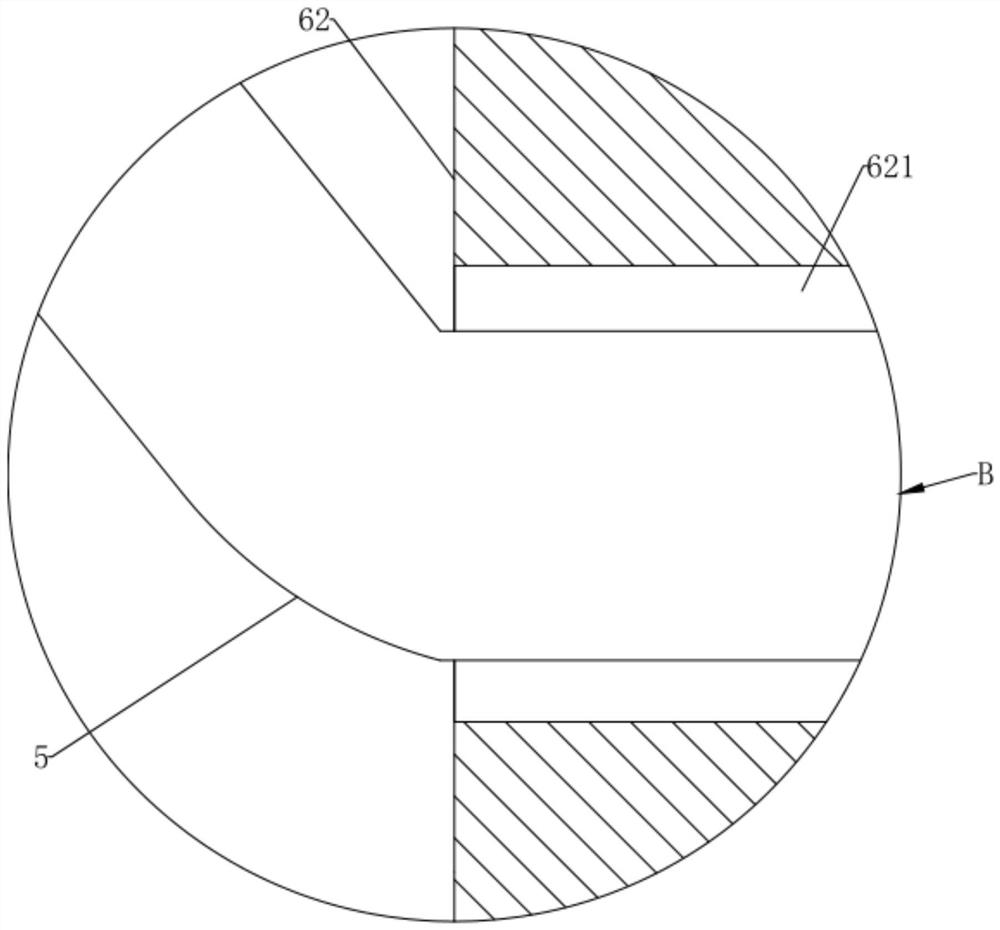

A wire rope anti-seismic support system for suspension equipment

ActiveCN111853439BReduce support pressureEven by forcePipe supportsNon-rotating vibration suppressionShock absorberWire rope

The invention discloses a steel wire rope anti-seismic support system for suspension equipment, which includes a main support, a suspension rod, a suspension equipment, a steel wire rope connecting column and a steel wire rope. A shock absorbing device is movable below the suspension equipment. The device includes an inner box body and an outer box body, and a number of damping springs are connected between the inner box body and the outer box body. Horizontal damping rod, a fixed base is arranged below the outer box, and a steel wire rope 2 is fixedly connected to the steel wire rope 1, and several fixing devices are arranged between the steel wire rope 2 and the steel wire rope. Suspension equipment provides good lateral and longitudinal shock resistance, while reducing the support pressure of the wire rope, improving the service life and safety of the overall device, easy to use, and very worthy of promotion.

Owner:HEFEI YUANKANG ENVIRONMENT SCI & TECH

An ict pressure detection module with a stable guide support device

ActiveCN113985249BGuaranteed accuracyStable supportPrinted circuit testingMeasurement instrument housingEngineeringMechanical engineering

Owner:SHENZHEN DONGYINGXUNDA ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com