Automatic horizontal-arranging device of pile driving barge pile frame

A technology for a pile frame and a hull is applied in the field of automatic laying devices, which can solve the problems of time-consuming, low operation efficiency, and danger, and achieve the effects of reducing support pressure, improving safety, and high operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

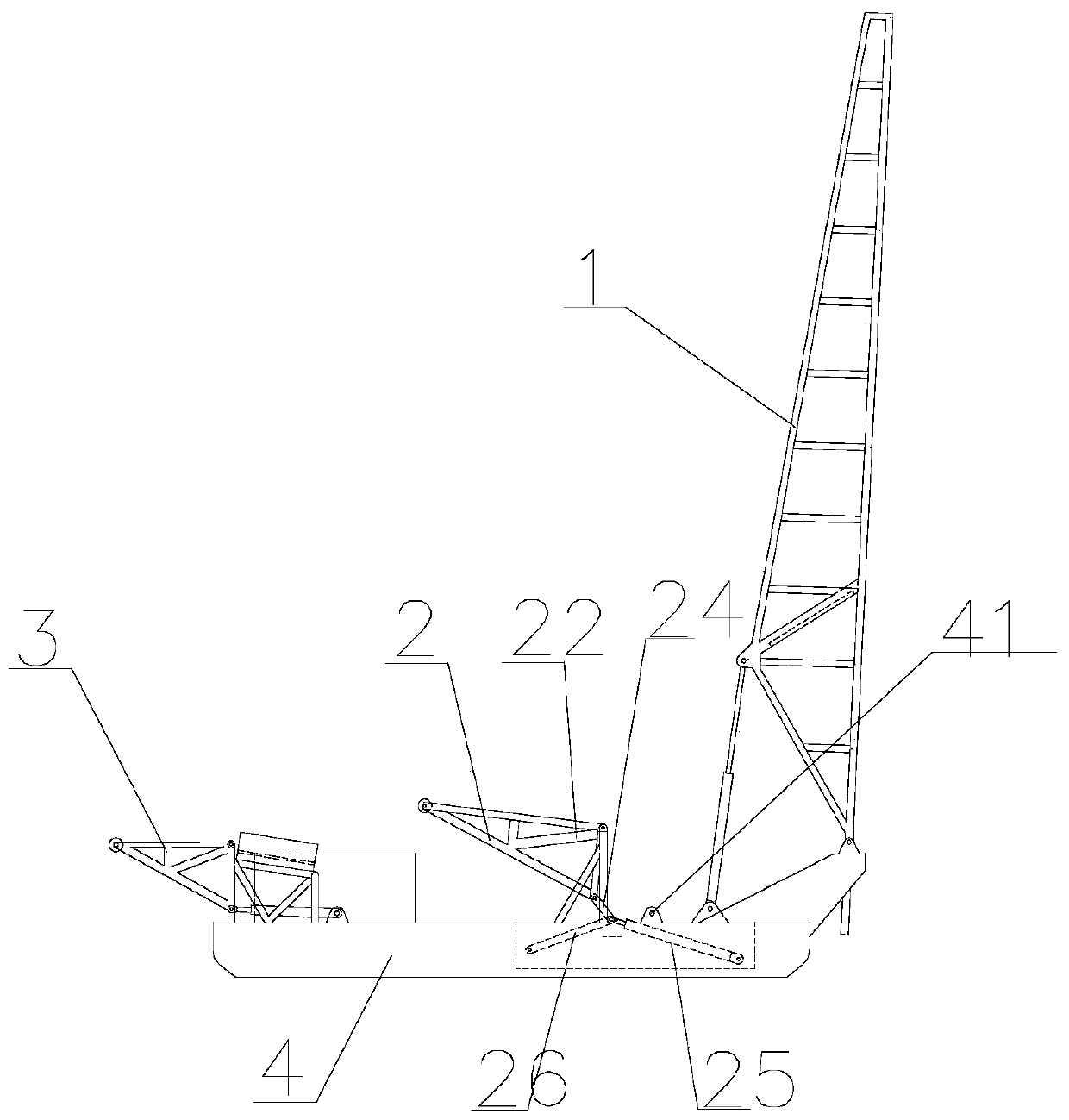

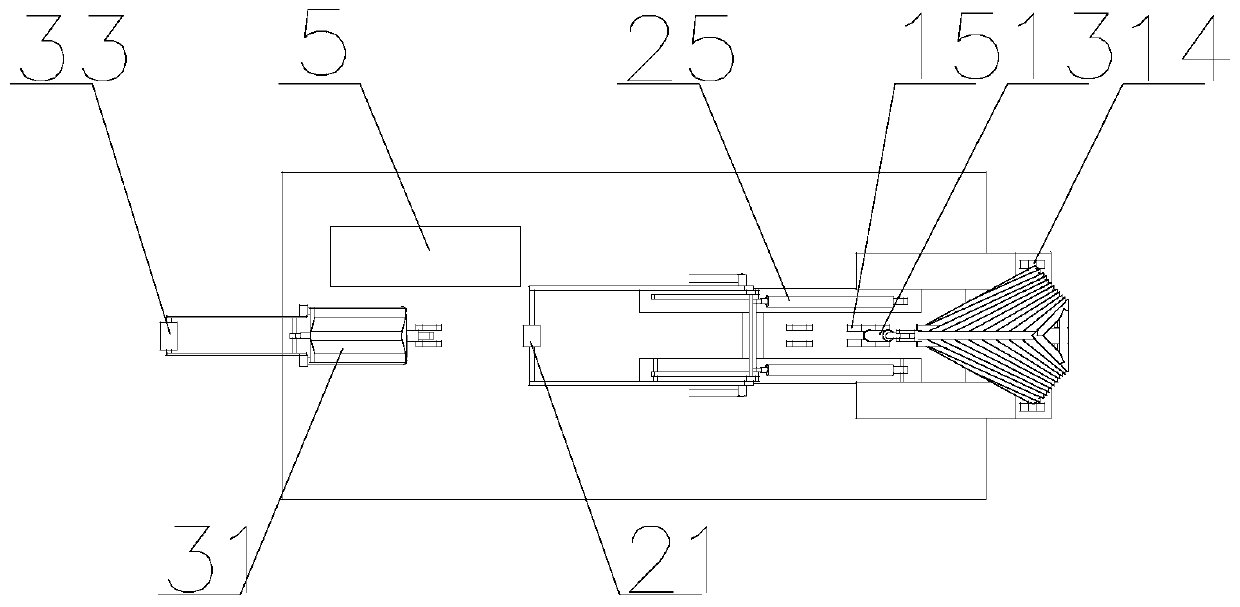

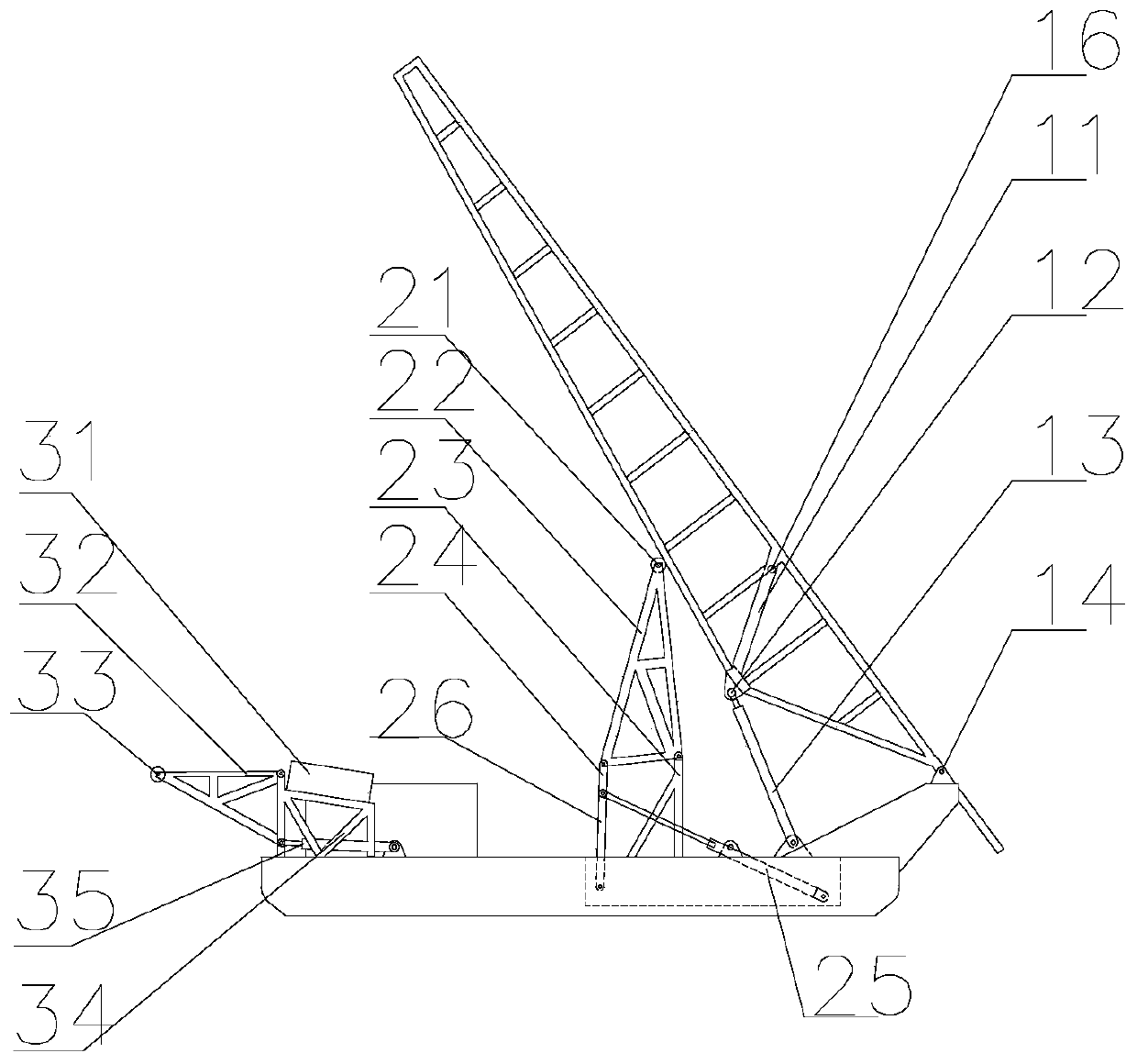

[0018] Such as Figure 1-6 As shown, the automatic lying device of the pile frame of the piling ship includes the intermediate support mechanism 2 and the tail support mechanism 3 hinged on the hull 4 and the inclined slide 11 on the pile frame 1, and the slide 11 is provided with movable block, the hull 4 is hinged with a main oil cylinder 13, the piston rod end of the main oil cylinder 13 is hinged with the movable block, and the two ends of the slideway 11 are respectively provided with an upper fixed point 16 and a lower fixed point 12 of the fixed movable block. There is a front hinge point 14 and a rear hinge point 15 of the pile frame. When the pile frame 1 is hinged at the front hinge point 14 and the movable block is fixed at the lower fixed point 12, the piston rod of the main oil cylinder 13 is stretched out so that the pile frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com