Laminated slab transportation protection structure

A technology for protecting structures and laminated panels, which is applied in the direction of transportation and packaging, types of packaged items, and special packaged items, etc. It can solve problems such as uneven force, inability to synchronize stability, poor protection effect, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

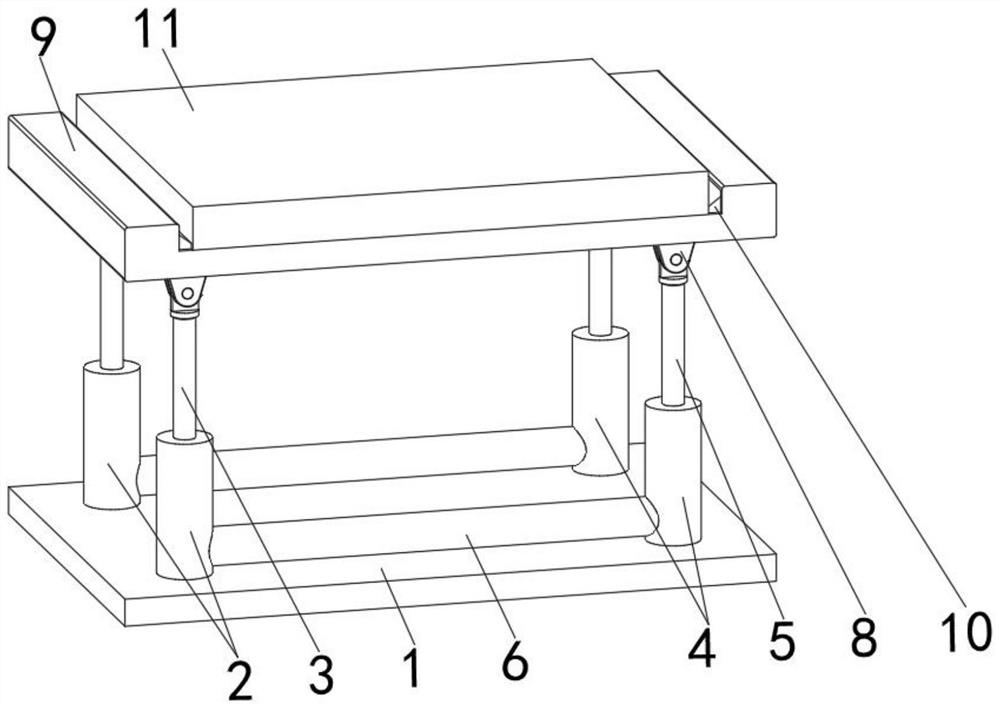

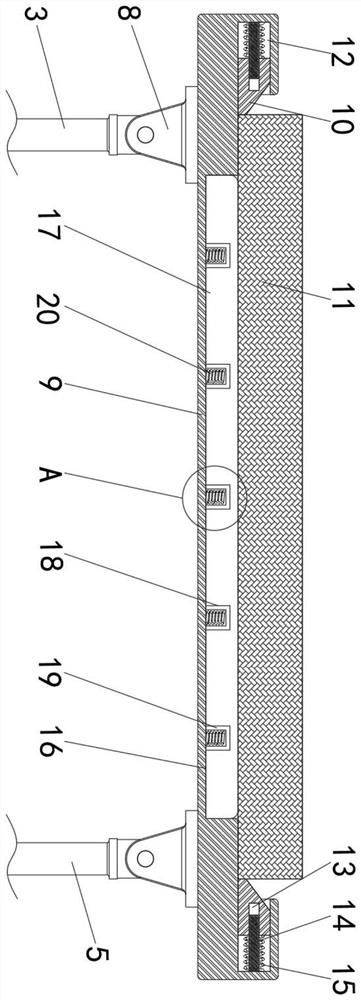

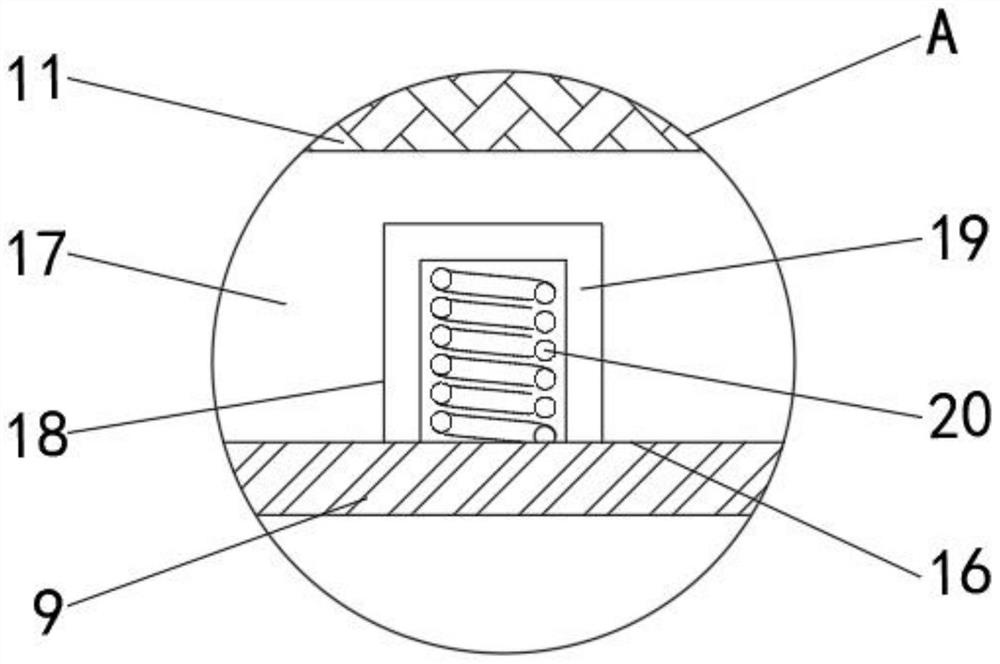

[0046] see Figure 1-10 , the present invention provides a technical solution: a laminated plate transport protection structure, including a fixed seat 1, a hinge block 8 and a laminated plate 11, and the left and right adjustment cylinders are fixedly installed on the left and right sides of the top of the fixed seat 1, respectively. 4. The inner sealing sleeve of the left adjustment cylinder 2 is connected with the left support column 3, the inner sealing sleeve of the right adjustment cylinder 4 is connected with the right support column 5, and the connecting column 6 is fixedly installed between the left adjustment cylinder 2 and the right adjustment cylinder 4, The inside of the communication column 6 is provided with a slow flow mechanism 7, the inner chambers of the left adjustment cylinder 2, the right adjustment cylinder 4 and the communication column 6 are all filled with hydraulic oil 22, and the left support column 3 and the right support column 5 are moved through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com