Suspension arm rotary table on carrier vehicle

A technology for transporting vehicles and booms, applied in the field of boom turntables, can solve the problems of increasing the labor intensity of workers, affecting the work safety of workers, and difficulty in operation, and achieves the effects of avoiding heavy load, shortening service life, and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

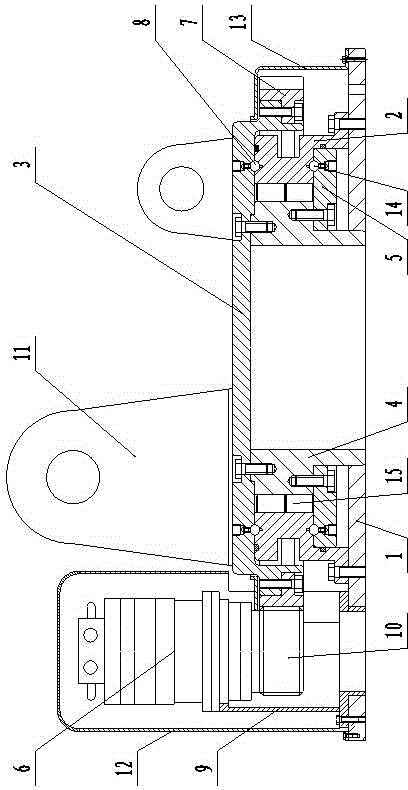

[0014] like figure 1 As shown, the boom turntable on the transport vehicle of the present invention includes a base 1, a turntable support 2, an upper turntable 3, an intermediate movable frame 4, a hydraulic motor 6 and a ring gear 7, and the turntable support 2 is fixedly installed on the base 1 by bolts. The upper turntable 3 is an upside-down disc shape and is movably buckled on the turntable support 2. The horizontal contact surface of the upper turntable 3 and the turntable support 2 is provided with matching grooves and a plurality of first steel balls 8 are placed in the grooves. The middle of the bottom surface of the upper turntable 3 is fixedly equipped with an intermediate movable frame 4 and the intermediate movable frame 4 is located in the turntable bracket 2. The circumferential side of the upper turntable 3 is fixedly equipped with a ring gear 7, and the hydraulic motor 6 is fixedly installed on the On one side of the turntable bracket 2 and on the output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com