Simultaneous derusting process of inner surface and outer surface of steel pipe

An inner surface and outer surface technology, used in manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve the problems of large floor space, low rust removal efficiency, and high equipment cost, and achieves a small footprint and The effect of high rust efficiency and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

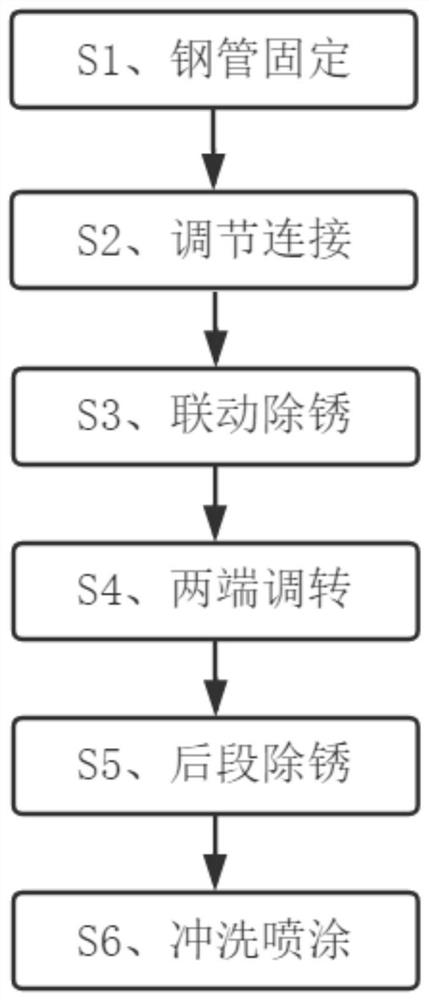

[0047] see figure 1 , a process for simultaneously removing rust on the inner surface and the outer surface of a steel pipe, comprising the following steps:

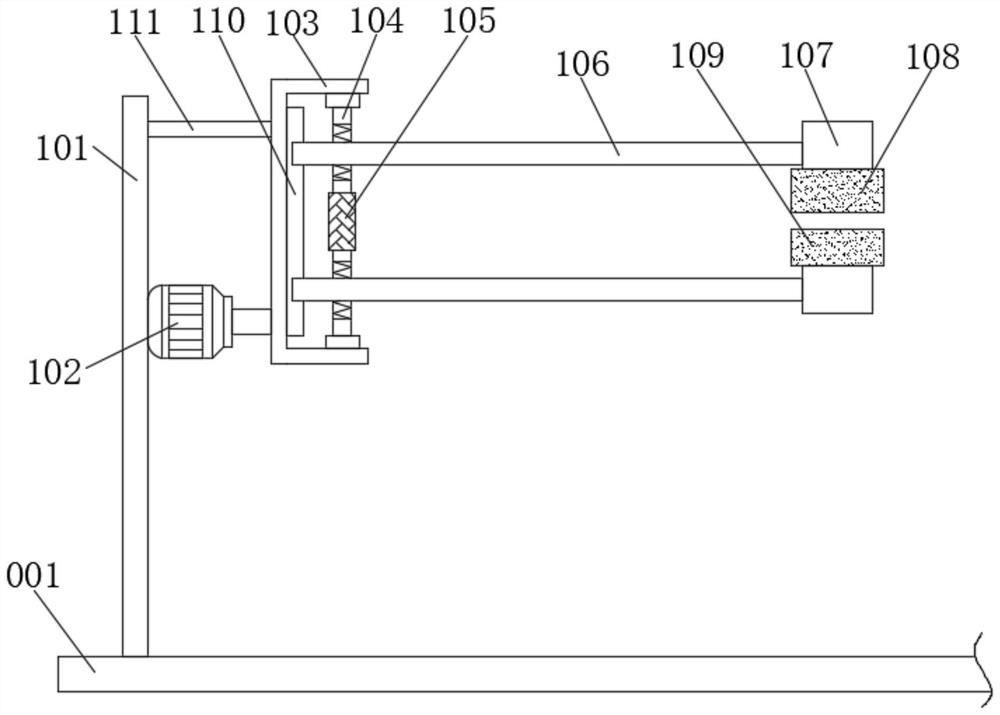

[0048] S1, steel pipe fixing: pass one end of the steel pipe through the support ring 204 and clamp it to the steel pipe clamp 203, so as to fix the steel pipe to the manual travel assembly of the double-sided simultaneous removal device;

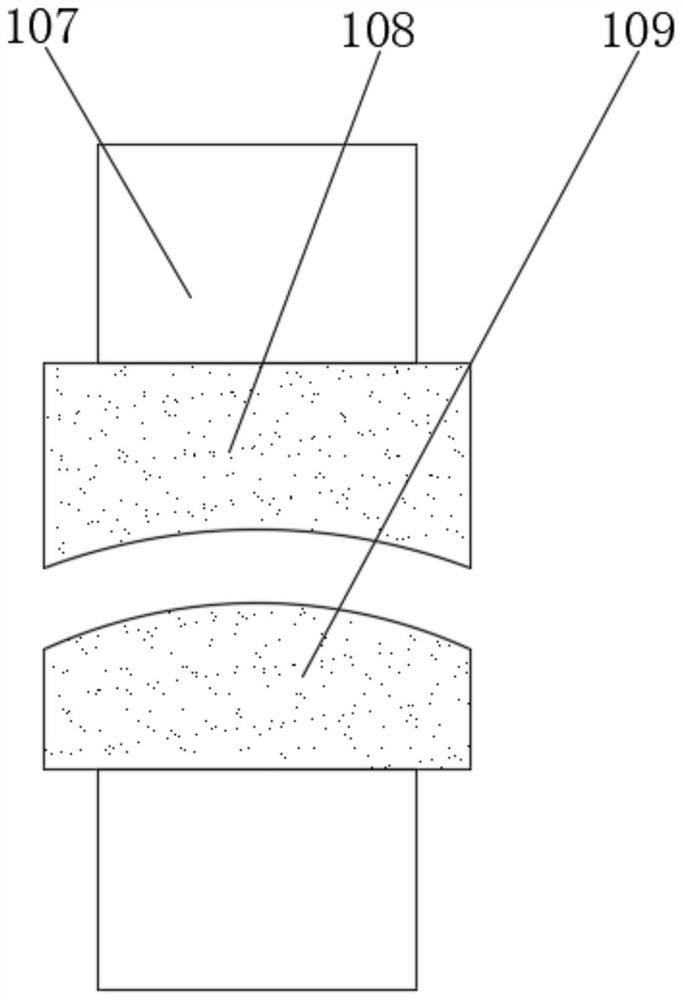

[0049] S2. Adjust the connection: turn the handle 208 to drive the steel pipe through the circular through hole 210 and approach the electric grinding assembly until the pipe wall at the top of the steel pipe is between the outer surface grinding block 108 and the inner surface grinding block 109, then turn the adjustment lever 104 make the outer surface grinding block 108 and the inner surface grinding block 109 move toward each other until the outer surface grinding block 108 and the inner surface grinding block 109 are respectively close to the outer surface and the inner surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com