Lifting mechanism of frame splitting machine for industrial aquaculture

A lifting mechanism and dismantling machine technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of large left and right swing of the lifting body, large instability of the breeding frame stack, increase of the lifting body colliding with surrounding workpieces, etc., to achieve overall The structural design is compact and reasonable, reducing the intensity of manual operation and ensuring the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

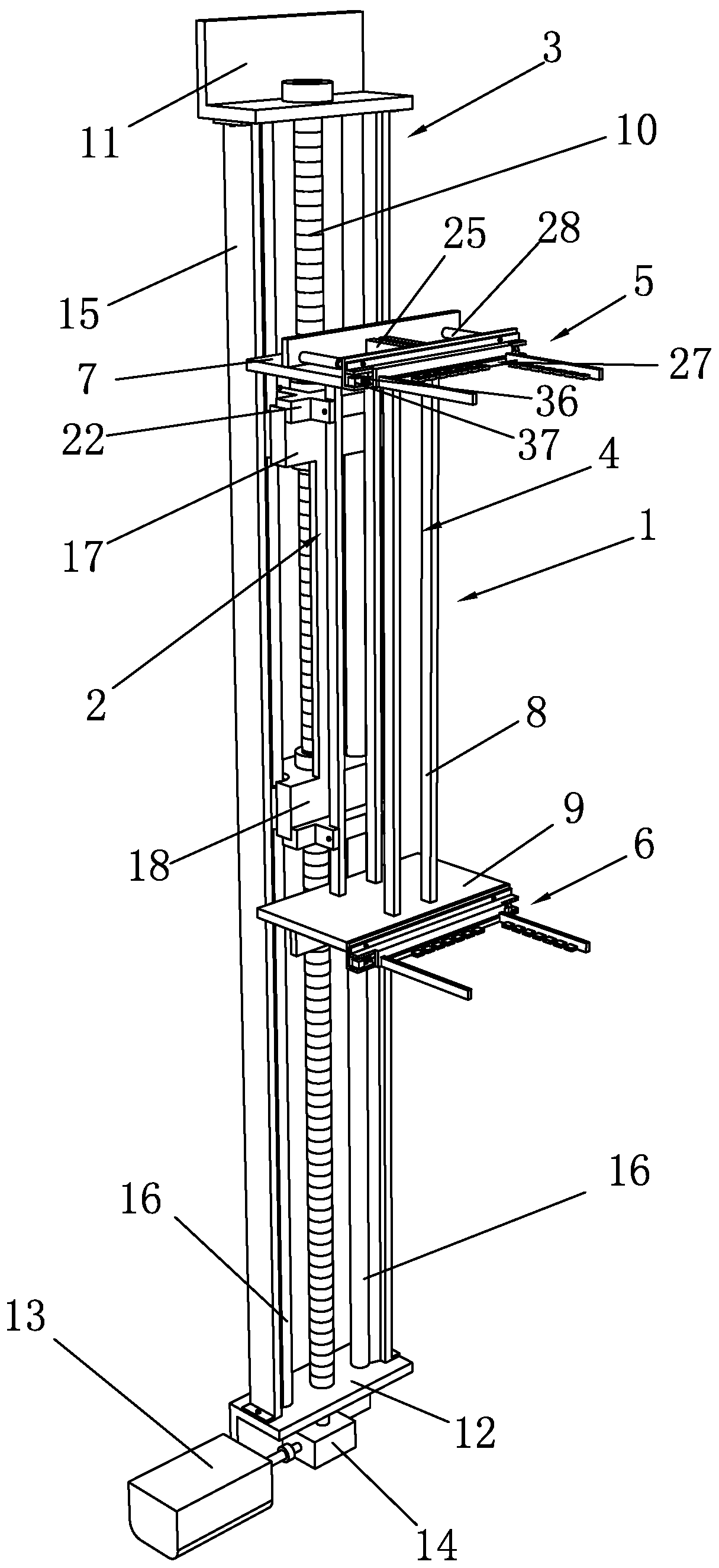

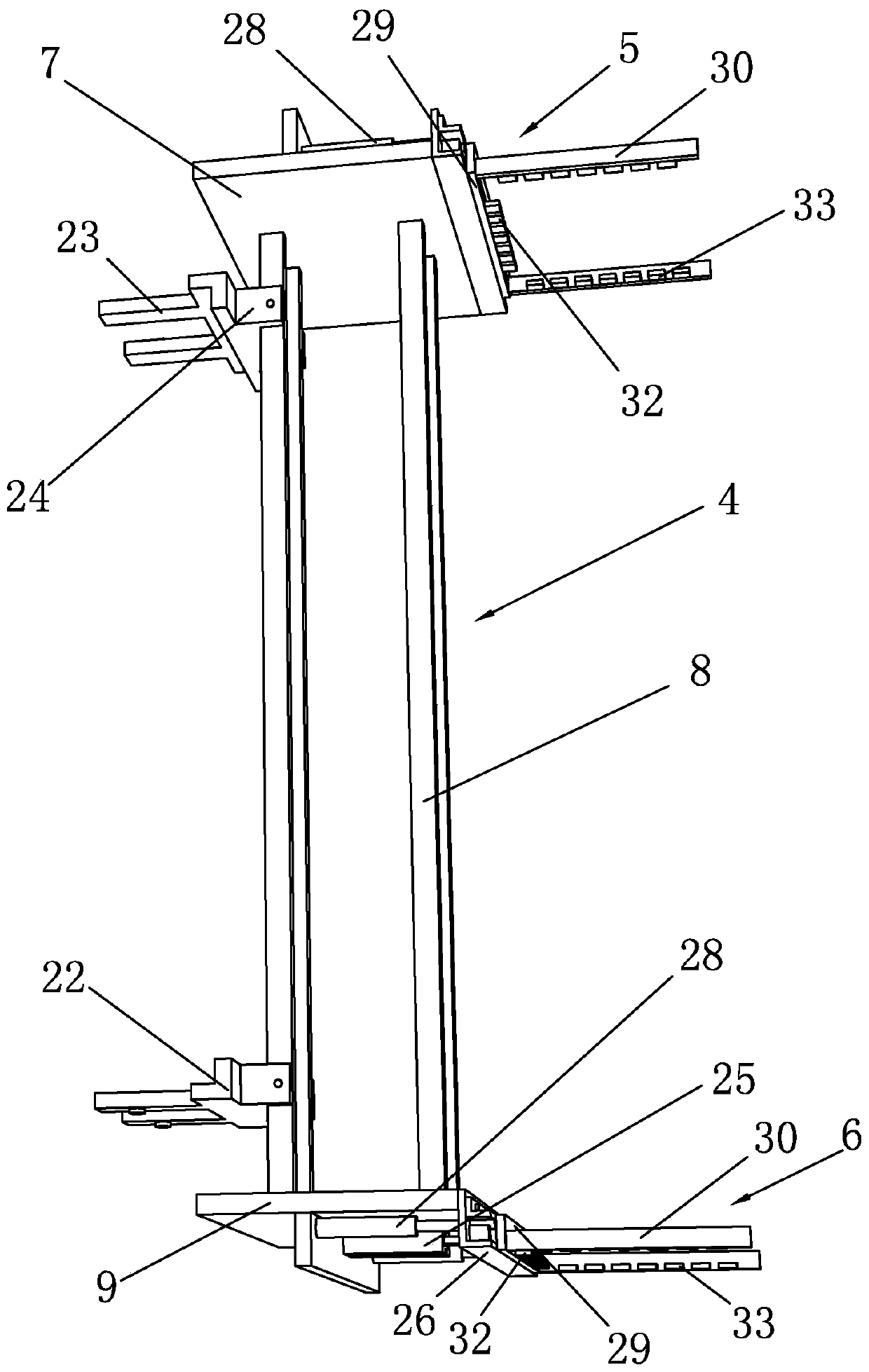

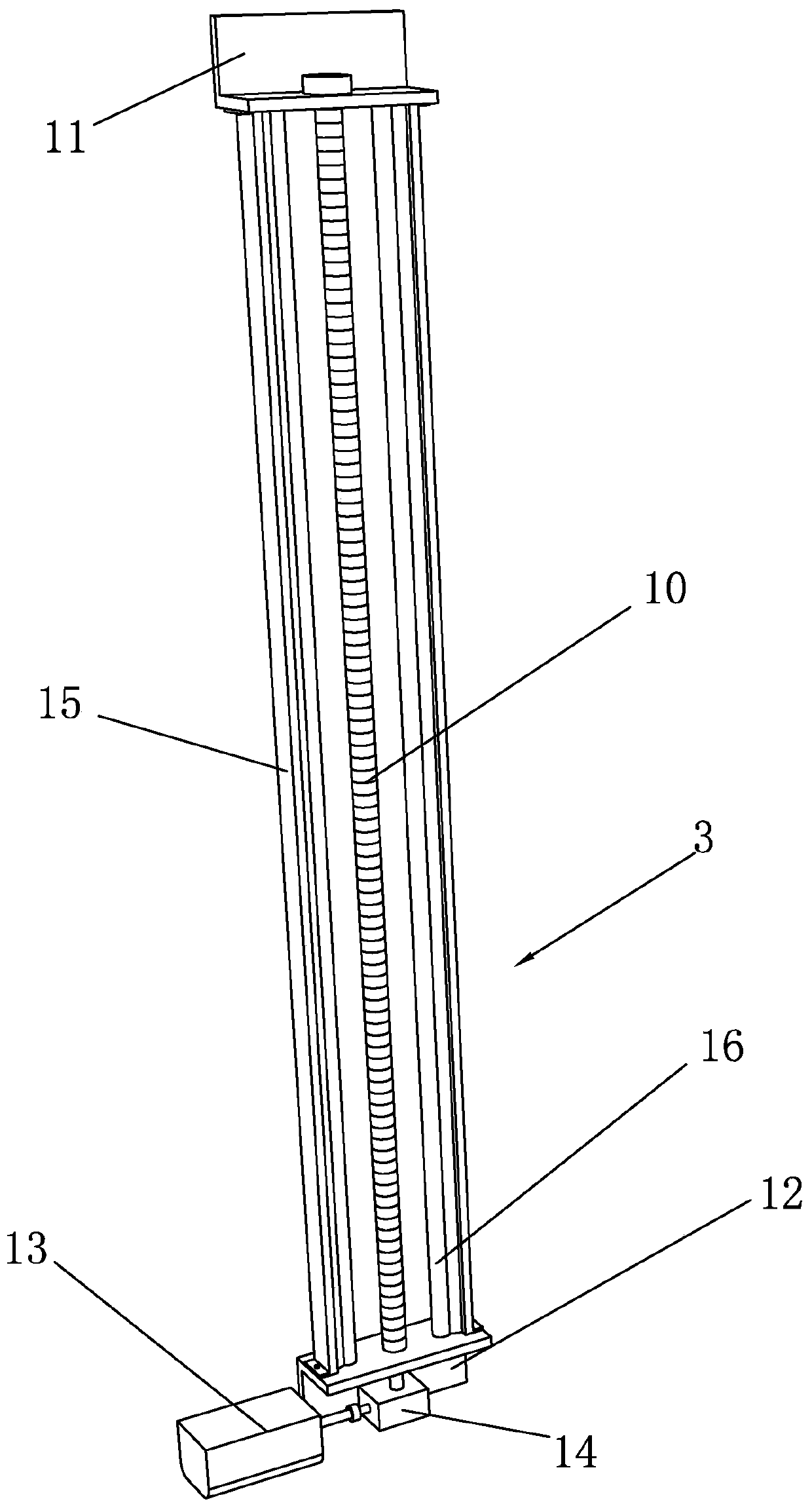

[0032] like Figure 1 to Figure 9 As shown, it is a lifting mechanism of a frame splitting machine for industrial farming of the present invention, including a lifting body 1, a slider body 2 and a lifting screw assembly 3, the lifting body 1 is connected with the slider body 2, and the slider body 2 is located on the lifting screw assembly 3, and the lifting screw assembly 3 drives the lifting body 1 to slide up and down through the slider body 2.

[0033] The lifting body 1 includes a frame body 4, an upper claw mechanism 5 and a lower claw mechanism 6, the upper claw mechanism 5 is located at the upper part of the frame body 4, the lower claw mechanism 6 is located at the lower part of the frame body 4, and the frame body 4 includes a top plate 7 , vertical rod 8 and bottom plate 9, four vertical rods 8 are provided, and the four vertical rods 8 are evenly arranged between the top plate 7 and the bottom plate 9. The frame body 4 ensures the overall structural strength and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com