Communication equipment maintenance device

A technology for communication equipment and fixed boxes, applied to workpiece clamping devices, workbenches, manufacturing tools, etc., can solve problems such as poor mobility, weak scalability, and failures, and achieve the effect of reducing support pressure and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

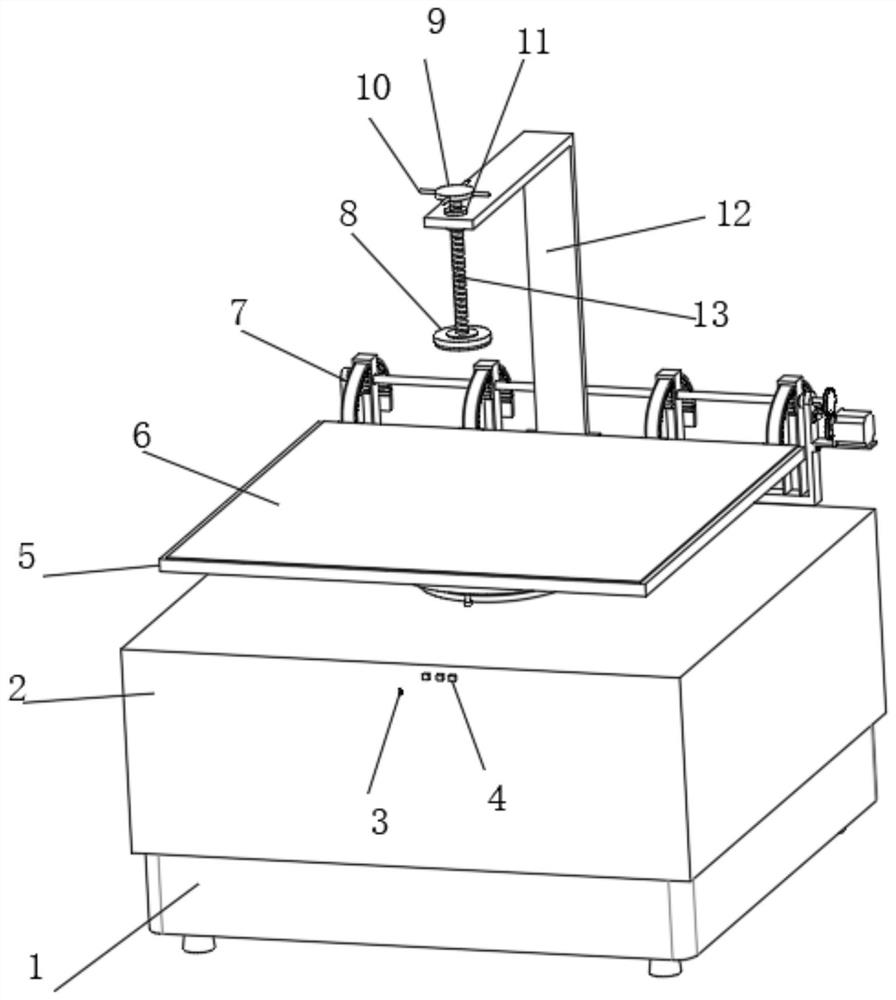

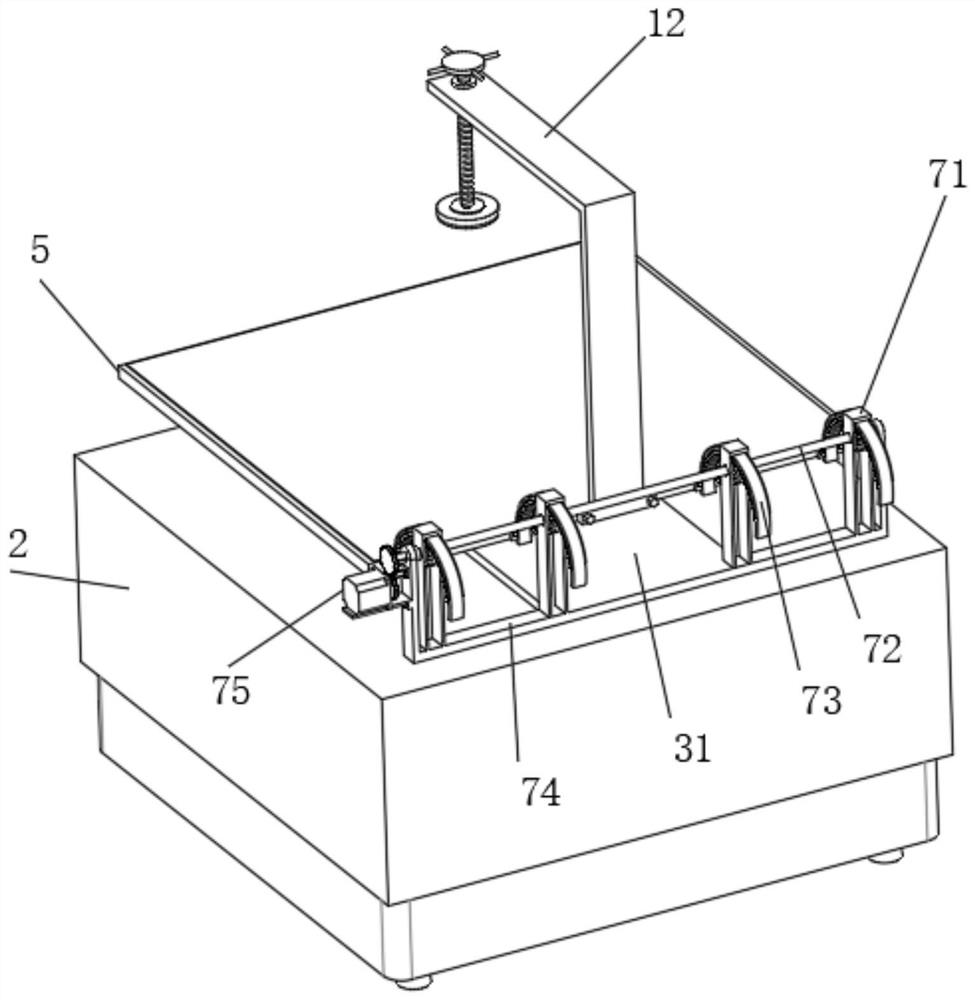

[0035] Such as Figure 1-8A maintenance device for communication equipment is shown, which includes a fixed box body 1. The inner bottom of the fixed box body 1 is connected with a height adjustment mechanism 14 for adjusting the height of the communication equipment. The top of the height adjustment mechanism 14 is connected with the fixed box body. 1. The outer wall of the casing 2 is fitted with a sliding connection. The outer wall of the casing 2 is fixedly connected with a switch 4. The casing 2 is connected with a horizontal rotation structure 3 for adjusting the horizontal rotation of the communication equipment. The rear side wall of the casing 2 Connected with a vertical rotation structure 7 for adjusting the vertical rotation of the communication equipment, the vertical rotation structure 7 includes an n-shaped plate 71, a first rotation rod 72, an arc-shaped tooth plate 73, a U-shaped plate 74, and a first drive motor 75 , the first mounting plate 76, the first ring...

Embodiment 2

[0037] Embodiment 2 is a further improvement to Embodiment 1.

[0038] Such as Figure 1-8 The communication equipment maintenance device shown includes a fixed box body 1, the inner bottom of the fixed box body 1 is connected with a height adjustment mechanism 14 for adjusting the height of the communication equipment, and the top of the height adjustment mechanism 14 is connected with the fixed box body. The outer wall of the body 1 is attached to the casing 2 which is slidingly connected. The outer wall of the casing 2 is fixedly connected with a switch 4. The casing 2 is connected with a horizontal rotation structure 3 for adjusting the horizontal rotation of the communication equipment. The horizontal rotation structure 3 includes a rotation Plate 31, pull ring 32, rotating rod 33, guide ring 34, T-shaped plate 35, steel rope 36, spring 37, first sleeve 38, universal ball 39 and straight sleeve 310, guide ring 34 and straight sleeve 310 and The top of cover box 2 is fixe...

Embodiment 3

[0040] Embodiment 3 is a further improvement to Embodiment 1.

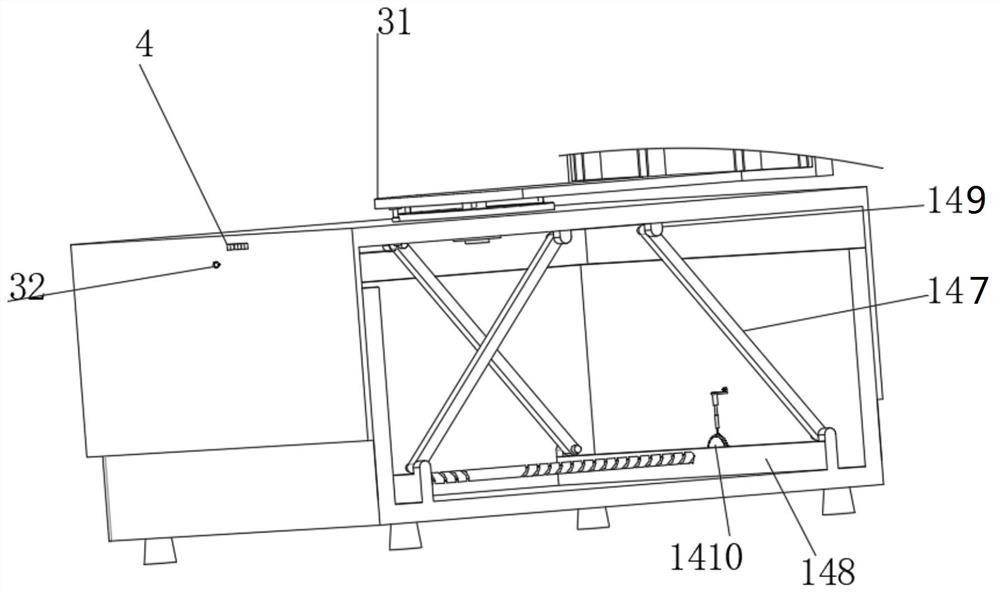

[0041] Such as Figure 1-8The communication equipment maintenance device shown includes a fixed box body 1. The inner bottom of the fixed box body 1 is connected with a height adjustment mechanism 14 for adjusting the height of the communication equipment. The height adjustment mechanism 14 includes a second drive motor 141, The fourth ring gear 142, the second ring gear 143, the second mounting plate 144, the thread groove 145, the second rotating rod 146, the rotating support plate 147, the U-shaped plate 148, the bump 149, the rotating disc 1410, the first right-angle tooth Block 1411, horizontal plate 1412, the second electric push rod 1413, the second spring 1414, the second spring 1415, the square slide bar 1416 and the second right-angle tooth block 1417, the fixed casing 1 inner wall is fixedly connected with the second mounting plate 144 and The horizontal plate 1412, the second mounting plate 144 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com