Floor heave crushing machine in coal mine tunnel

A coal mine roadway and crusher technology, which is applied in tunnels, mining equipment, grain processing, etc., can solve the problems of manpower consumption, slow bottom drum speed, and large vehicle body, and achieve flexible and convenient use, easy relative rotation, and wide range of activities Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

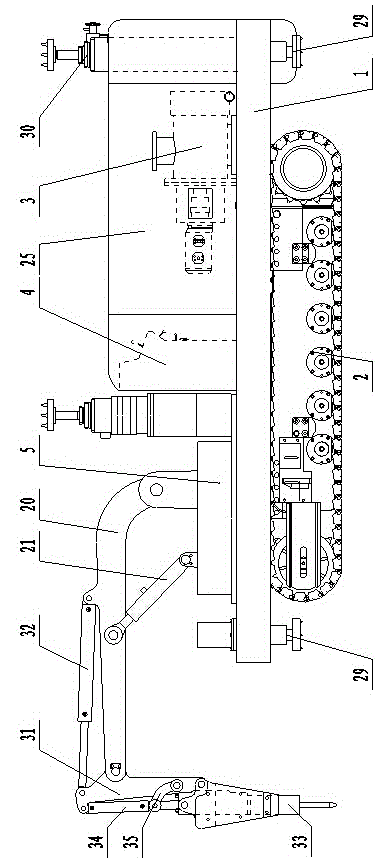

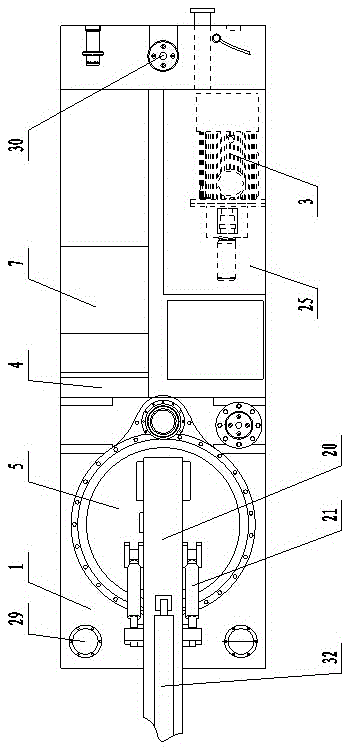

[0027] like Figure 1-3 As shown, the bottom drum crusher in the coal mine roadway of the present invention includes a frame 1, a traveling mechanism 2, an explosion-proof diesel engine 3, a hydraulic system, a console 4, a turntable 5 and a hydraulic crushing device. Mechanism 2, the rear end of the hydraulic breaking device is fixedly installed on the front part of the frame 1 through the turntable 5, and the rear part of the frame 1 is installed with an explosion-proof diesel engine 3 and a hydraulic system to provide power, and a console 4 is also installed on the frame 1 and driver's seat 7;

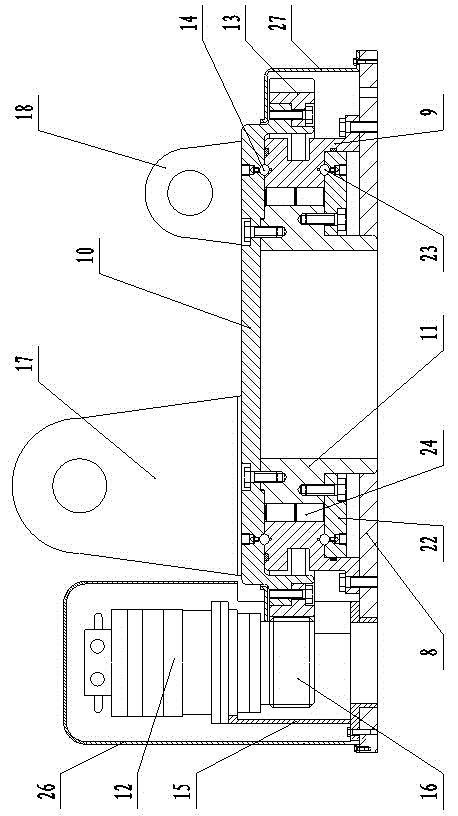

[0028] The structure of the turntable 5 includes a base 8, a turntable bracket 9, an upper turntable 10, an intermediate movable frame 11, a hydraulic motor 12 and a ring gear 13, the turntable support 9 is fixed on the base 8 by bolts, and the upper turntable 10 is an undercut The disc shape is movably buckled on the turntable support 9, and the horizontal contact surface of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com